Pretreatment method of phosphogypsum and paper gypsum board and preparation method thereof

A technology of plasterboard and phosphogypsum, which is applied in the direction of manufacturing tools, surface layering devices, ceramic molding machines, etc., can solve the problems of large primary investment, waste water generation, secondary pollution, etc., achieve small water demand, and avoid secondary pollution. Secondary pollution and reduction of treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

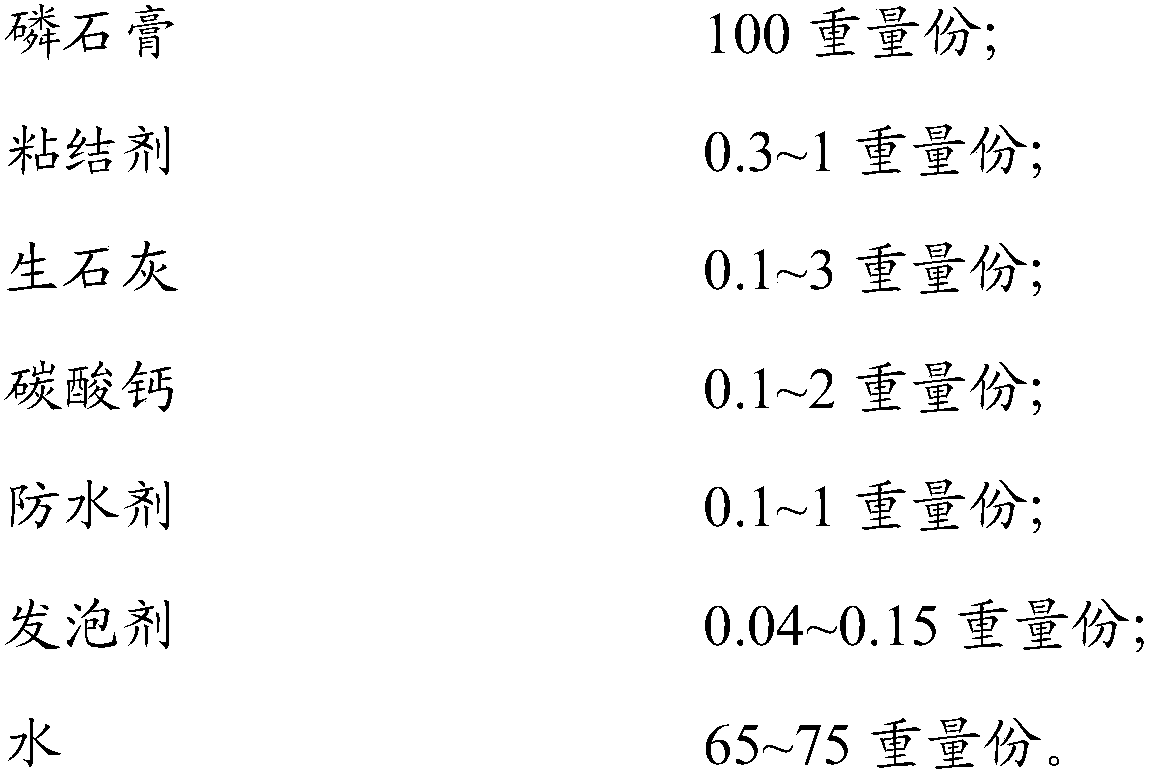

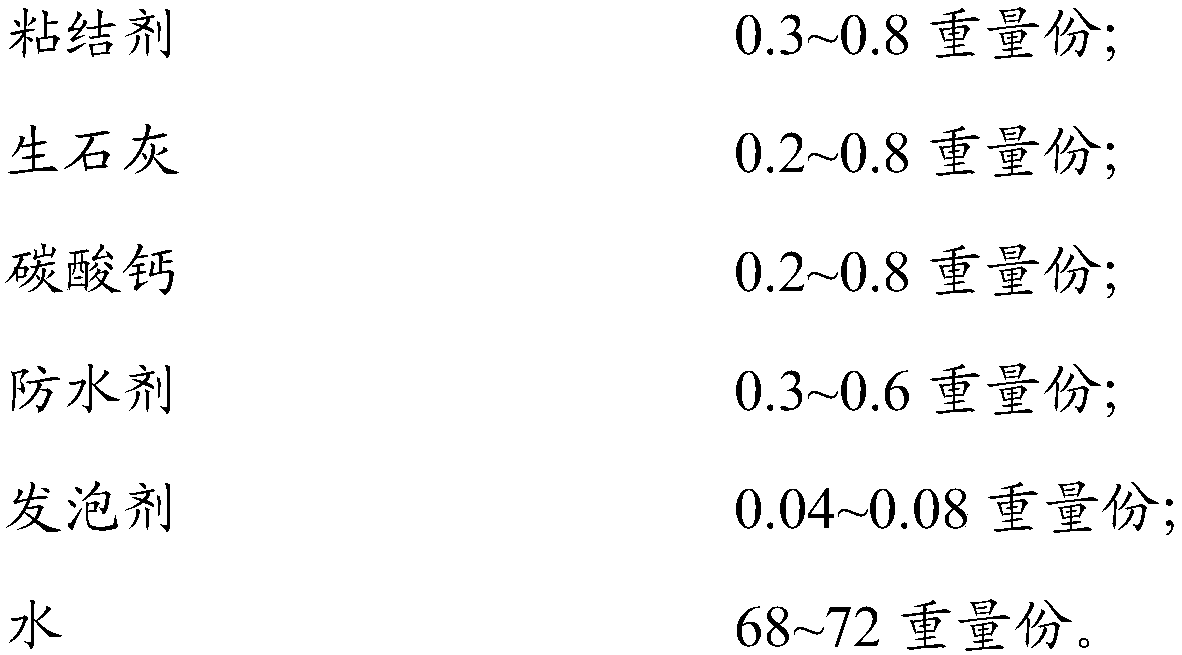

Method used

Image

Examples

Embodiment 1

[0031] After drying 100kg phosphogypsum, mix with 0.1kg quicklime, ball mill, calcinate at 140℃, and age; add 1kg modified corn starch, 2kg CaCO 3 , 1kg of organic silicon oil, 0.15kg of sodium alkyl sulfonate, 75kg of water, stir evenly to make a slurry; the slurry is combined with the upper and lower protective paper to form, cut, and finally dried to make a plasterboard.

[0032] Compared with the gypsum board prepared by using untreated phosphogypsum (other preparation processes are the same as in Example 1), the bonding performance of the gypsum board prepared in Example 1 has been improved from level V to level II, 2h The water absorption rate reached 6.83%, the transverse breaking load increased by 24%, and the longitudinal breaking load increased by 31%.

Embodiment 2

[0034] After drying 100kg phosphogypsum, mix with 3kg quicklime, ball mill, calcinate at 180℃, and age; add 0.3kg modified corn starch, 0.1kg CaCO 3 , 0.1kg organosilicon oil, 0.04kg polyethylene glycol, 65kg water, stir evenly to make a slurry; the slurry is combined with the upper and lower protective paper to form, cut, and finally dried to make a plasterboard.

[0035] Compared with the gypsum board prepared by using untreated phosphogypsum (other preparation processes are the same as in Example 2), the bonding performance of the gypsum board prepared in Example 2 has been improved from level V to level II, 2h The water absorption rate reached 8.9%, the transverse breaking load increased by 22%, and the longitudinal breaking load increased by 29%.

Embodiment 3

[0037] After drying 100kg phosphogypsum, mix with 0.8kg quicklime, ball mill, calcinate at 180℃, and age; add 0.6kg modified corn starch, 0.8kg CaCO 3 , 0.6kg organosilicon oil, 0.08kg saponin rosin acid, 72kg water, stir evenly to make a slurry; the slurry is combined with the upper and lower masking paper to form, cut, and finally dried to make a paper gypsum board.

[0038] Compared with the gypsum board prepared using untreated phosphogypsum (other preparation processes are the same as in Example 3), the bonding performance of the gypsum board prepared in Example 3 has been improved from level V to level I, 2h The water absorption rate reached 6.9%, the transverse breaking load increased by 40%, and the longitudinal breaking load increased by 53%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com