Aerated concrete prepared from copper smelting water quenching slag and titanium white slag and preparation method thereof

A technology of air-entrained concrete and water-quenched slag, which is applied in applications, household appliances, ceramic products, etc., can solve problems such as environmental pollution and waste of resources, and achieve the effects of avoiding two major drying shrinkage, reducing water demand, and increasing viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

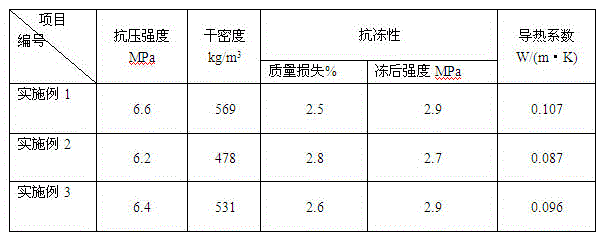

Embodiment 1

[0048] Air-entrained concrete is composed of the following raw material components and their weight percentages: copper smelting water quenching slag 20%, quicklime powder 14%, quartz sand 45%, cement clinker 15%, titanium white slag 6%, and the total amount of the above substances 0.06 % aluminum powder, 0.05% polyoxyethylene alkanolamide foam stabilizer, 0.3% water reducer, 1% modifier and 0.5 times the above total amount of water, titanium white slag needs to be treated as follows before use: natural ventilation and wind exposure for 24 hours , Calcined at 150~250℃ for 1 hour, homogenized and crushed until the specific surface area>350 m 2 / kg.

[0049] Wherein, the ratio of water glass, bone glue, sodium carboxymethyl cellulose, and caustic soda in the modifier is 1:2:2:3, and the ratio of triethanolamine and triisopropanolamine is 1:1. After mixing, the former accounts for 95% of the total modifier, the latter accounts for 5% of the total modifier.

[0050] The steps of p...

Embodiment 2

[0059] Aerated concrete is composed of the following raw material components and their weight percentages: copper smelting water quenching slag 50%, quicklime powder 15%, quartz sand 15%, cement clinker 15%, titanium white slag 5%, and the total amount of the above substances 0.1 % aluminum powder, 0.1% polyoxyethylene alkanolamide foam stabilizer, 1% water reducing agent, 2% modifier and 0.3 times the above total amount of water, titanium white slag needs to be treated as follows before use: natural ventilation and wind exposure for 24 hours , Calcined at 150~250℃ for 1 hour, homogenized and crushed until the specific surface area>350 m 2 / kg.

[0060] Wherein, the ratio of water glass, bone glue, sodium carboxymethyl cellulose, and caustic soda in the modifier is 2:1:2:3, and the ratio of triethanolamine and triisopropanolamine is 1:2. After mixing, the former accounts for 90% of the total modifier, the latter accounts for 10% of the total modifier.

[0061] The steps of p...

Embodiment 3

[0070] Air-entrained concrete is composed of the following raw material components and their weight percentages: copper smelting water quenching slag 30%, quicklime powder 17%, quartz sand 40%, cement clinker 10%, titanium white slag 3%, and the total amount of the above substances 0.08 % aluminum powder, 0.09% polyoxyethylene alkanolamide foam stabilizer, 0.6% water reducer, 2% modifier and 0.4 times the above total amount of water, titanium white slag needs to be treated as follows before use: natural ventilation and wind exposure for 24 hours , Calcined at 150~250℃ for 1 hour, homogenized and crushed until the specific surface area>350 m 2 / kg.

[0071] Wherein, the ratio of water glass, bone glue, sodium carboxymethyl cellulose, and caustic soda in the modifier is 1:1:1:1, and the ratio of triethanolamine and triisopropanolamine is 1:2. After mixing, the former accounts for 90% of the total modifier, the latter accounts for 10% of the total modifier.

[0072] The steps o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com