Secant pile of sand-gravel red sandstone composite stratum and construction method of secant pile

A technology of composite strata and construction method, applied in excavation, sheet pile wall, foundation structure engineering and other directions, can solve the problems of good water-stop effect, high construction cost, poor pile forming effect in red sandstone stratum, etc. Simple, improved enclosure strength, and fast hole formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A construction method of an occlusal pile in a sandy pebble-red sandstone composite stratum, comprising the steps of:

[0035] A. Construction of occlusal piles

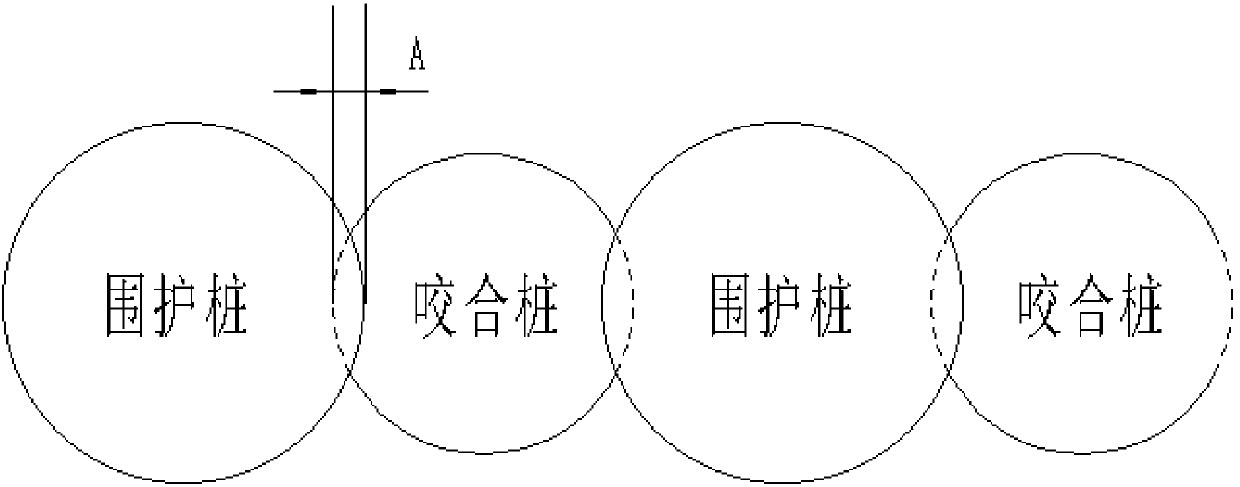

[0036] The pile diameter 800mm of described occlusal pile and enclosure pile, adopts full rotary drilling construction to offer occlusal pile hole, pours concrete in pile hole and makes occlusal pile;

[0037] B. Construction of retaining pile holes

[0038] Full rotary drilling is used to create surrounding pile holes on both sides of the occlusal pile, and the full rotary drilling drill cuts the side of the occlusal pile to form an occlusal intersecting gap; the occlusal pile is dried until the concrete strength reaches 50% and the hole is drilled. The thickness A of the occlusal intersecting gap 150mm;

[0039] C. Construction of retaining piles

[0040] The surrounding protection piles are built with steel bars in the holes of the surrounding protection piles and the intersecting gaps.

Embodiment 2

[0042] A construction method of an occlusal pile in a sandy pebble-red sandstone composite stratum, comprising the steps of:

[0043] A. Construction of occlusal piles

[0044] The occlusal pile pile diameter is 800mm, and the pile diameter of the surrounding protection pile is 900mm. The enclosing pile adopts full rotary drilling construction to set up the occlusal pile hole, and pouring concrete in the pile hole makes the occlusal pile;

[0045] B. Construction of retaining pile holes

[0046] Full rotary drilling is used to create surrounding pile holes on both sides of the occlusal pile, and the full rotary drilling drill cuts the side of the occlusal pile to form an occlusal intersecting gap; the occlusal pile is dried until the concrete strength reaches 50% and the hole is drilled. The thickness A of the occlusal intersecting gap 200mm; the verticality between the occlusal pile hole and the retaining pile hole is above 3‰;

[0047] C. Construction of retaining piles

...

Embodiment 3

[0050] A construction method of an occlusal pile in a sandy pebble-red sandstone composite stratum, comprising the steps of:

[0051] A. Construction of occlusal piles

[0052] The occlusal pile pile diameter is 800mm, and the pile diameter of the surrounding protection pile is 900mm. The enclosing pile adopts full rotary drilling construction to set up the occlusal pile hole, and pouring concrete in the pile hole makes the occlusal pile;

[0053] B. Construction of retaining pile holes

[0054] Use full rotary drilling to set up surrounding protection pile holes on both sides of the occlusal pile, and the full rotary drilling drill cuts the side of the occlusal pile to form an occlusal intersecting gap; the thickness A of the occlusal intersecting gap is 200mm; the occlusal pile hole and the surrounding protection pile hole The verticality is above 3‰;

[0055] C. Construction of retaining piles

[0056] The surrounding protection piles are built with steel bars in the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com