Construction method for putting tunnel shield into hole in special stratum

A construction method and shield tunneling technology, applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve problems such as subsidence, ground subsidence, influx, etc., and achieve the effect of reducing soil loss and controlling ground subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

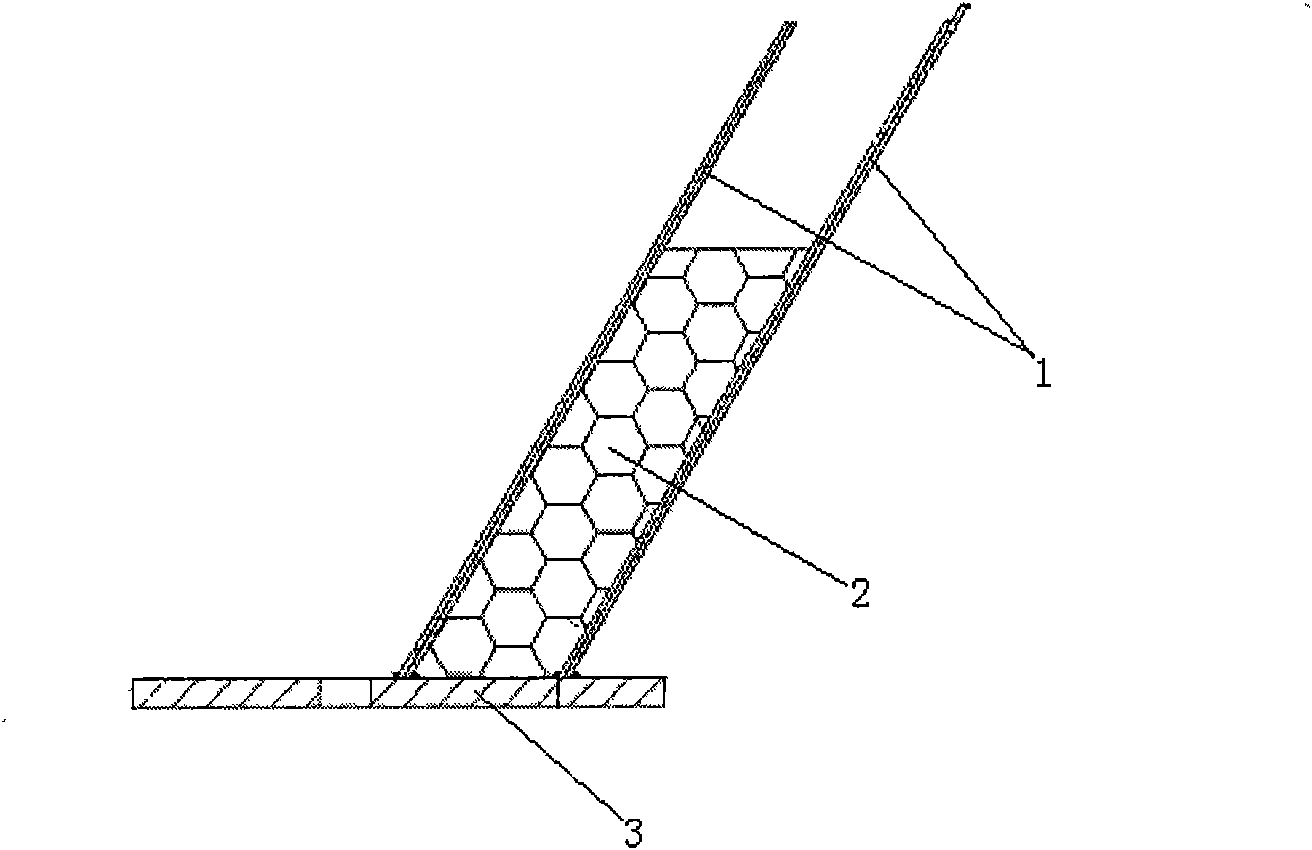

[0024] The present invention is suitable for tunnel excavation construction in areas where the geology is relatively poor, such as sandy silt, sandy soil, etc.

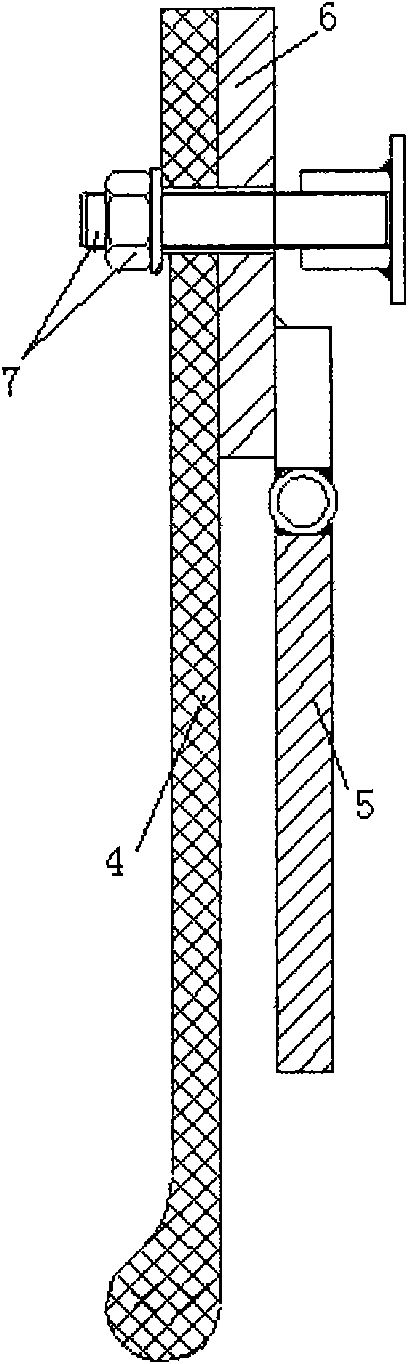

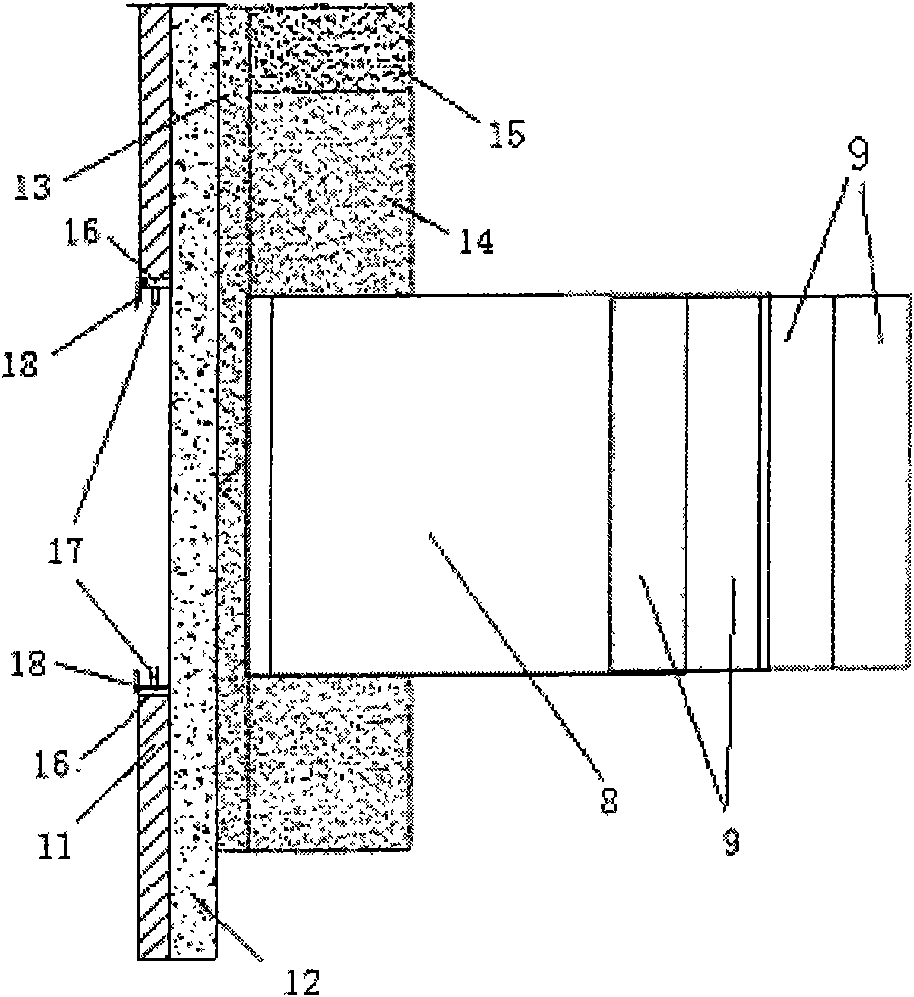

[0025] First, before the shield enters the hole, retest the axis of the shield several times to make it conform to the design axis, and recheck the opening, and then make the shield gradually approach the opening. According to experience, the tip of the shield basically touches the ground continuously. The head of the shield machine has stopped on the reinforced soil, and the double liquid grout is injected into the outer soil layer from the grouting holes of the first to second ring segments behind the shield tail, in order to cut off the special soil layer. The water rushes to the front door, commonly known as the first hoop water retaining ring, which also plays a role in controlling the settlement of the tunnel. The underground continuous wall concrete with a thickness of 650mm to 700mm inside the steel ring of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com