Roller type cutter rectangular pipe jacking machine

A drum type, pipe jacking machine technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of inability to continue cutting, construction difficulties, tool tip collapse, etc., to overcome construction problems, reduce construction risks, The effect of enhancing adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

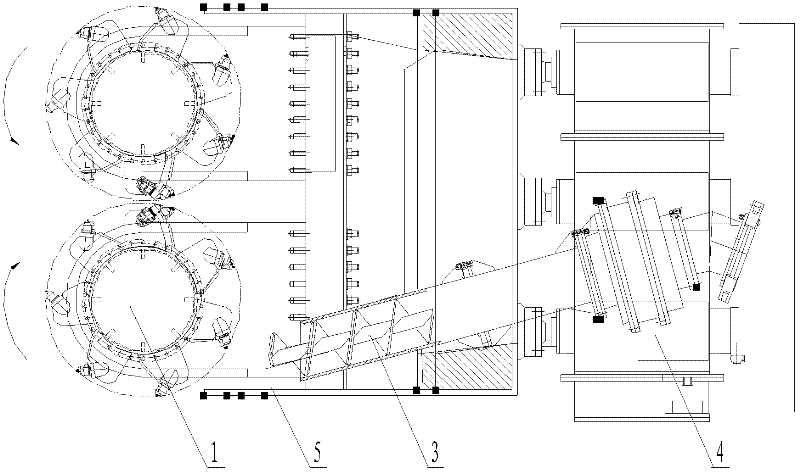

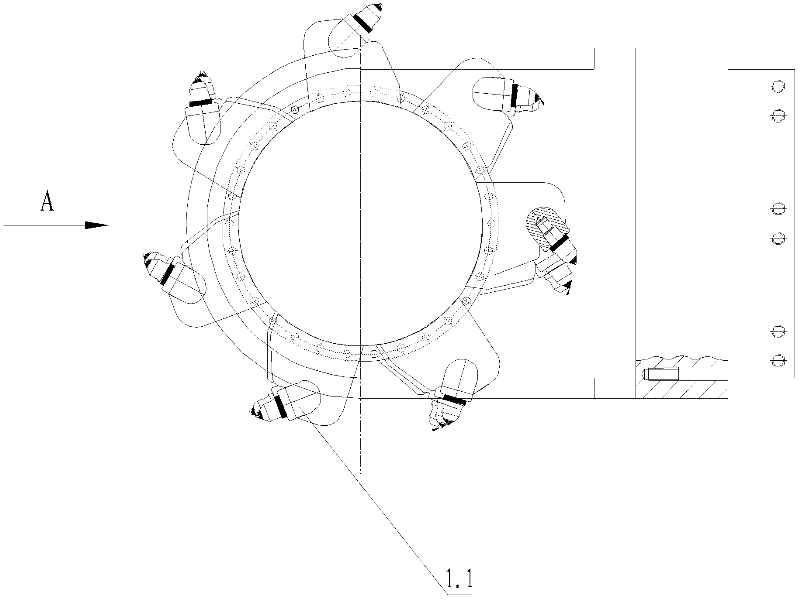

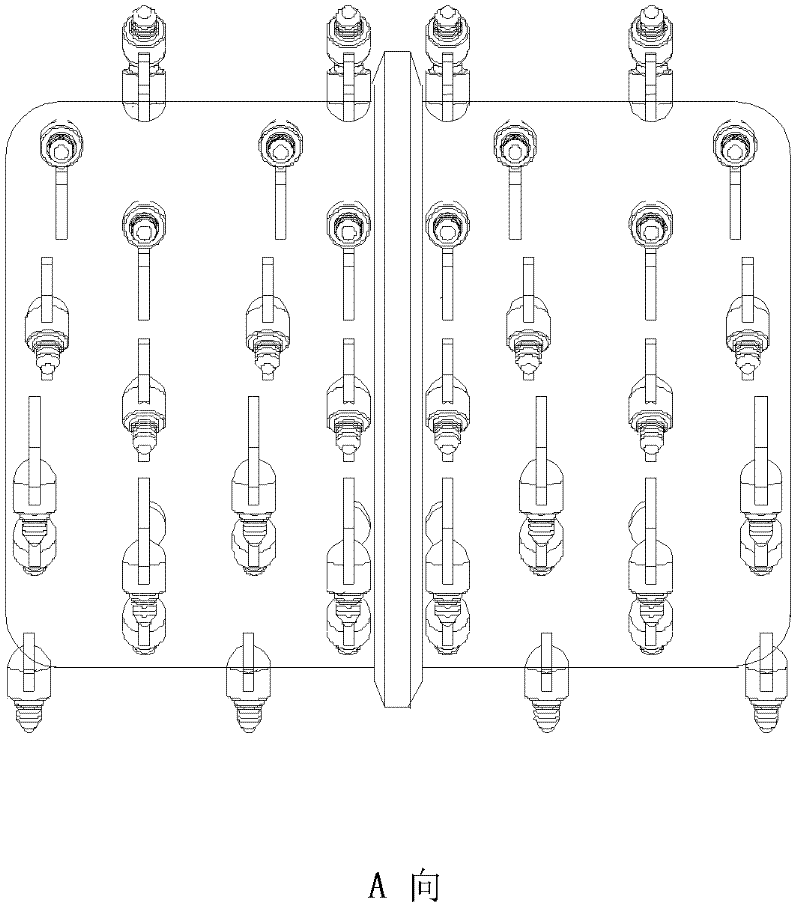

[0015] See first figure 1 The structure diagram of the present invention shows that the overall structure of the drum-type cutter head rectangular pipe jacking machine is similar to that of the ordinary pipe jacking machine, mainly including the cutter head, the cutter head drive system 2, the screw excavation system 3, the hydraulic propulsion system 4 and the rectangular shell Body 5. When faced with various complicated working conditions, the present invention has better adaptability than existing pipe jacking machines, and can complete the excavation tasks that common rectangular pipe jacking machines cannot. The main reason is that the present invention improves the form of the cutter head, innovatively adopts the composite formation drum type cutter head, and is equipped with a special oscillating cutter on the cutter head. Under the combination of the two, it ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com