Underground diaphragm wall steel bar cage structure and construction method thereof

A technology for underground diaphragm walls and steel cages, which is applied in basic structure engineering, sheet pile walls, buildings, etc., can solve the problems of long laying down of steel cages, difficult to guarantee construction quality, and unfavorable verticality of groove walls, and reduce the difficulty of hoisting. , The effect of easy vertical deviation and easy construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in conjunction with accompanying drawings.

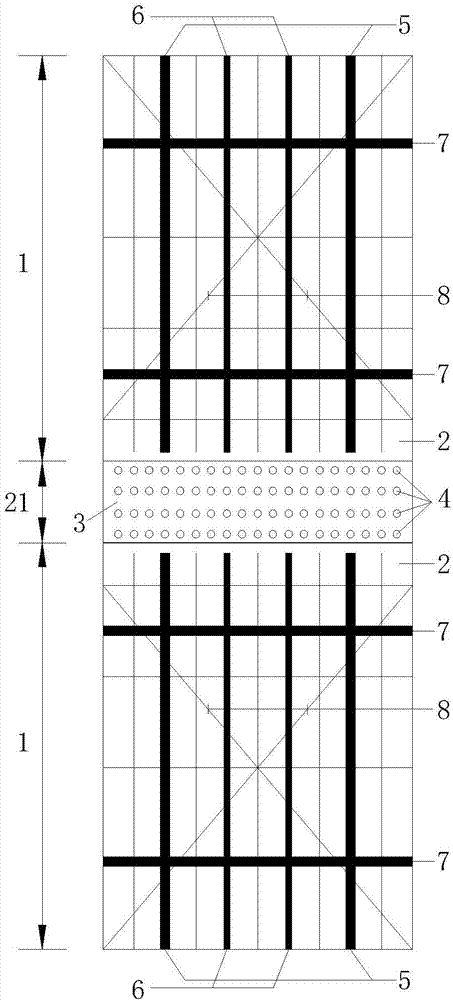

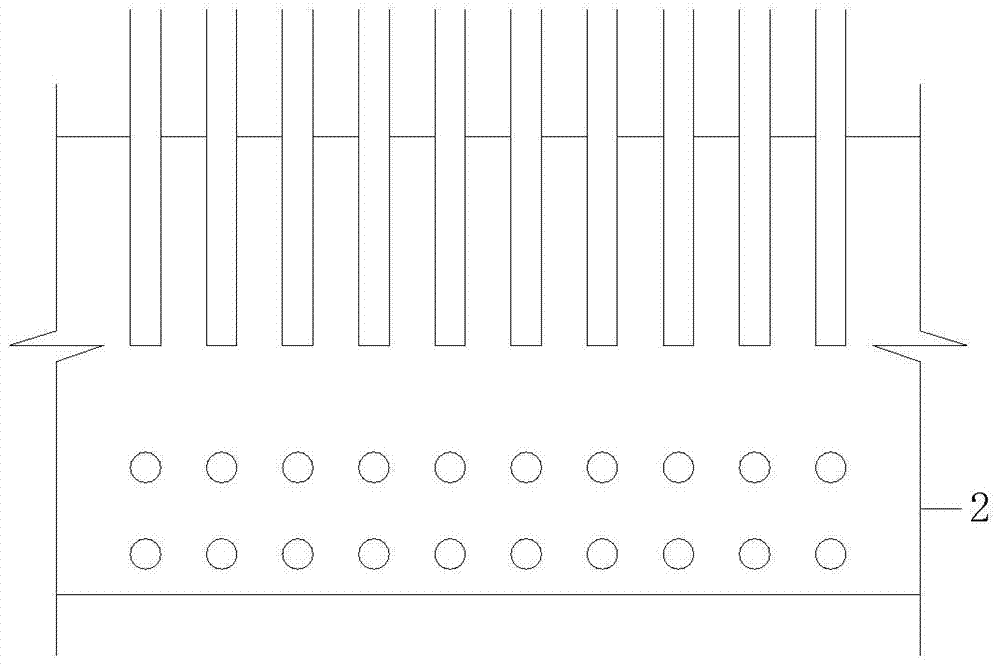

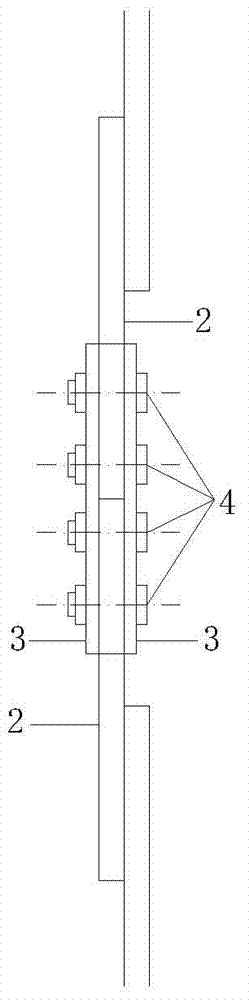

[0041] like Figure 1-8 As shown, the reinforced cage structure of the underground diaphragm wall of the present invention includes several reinforced cage units 1 and several connecting structures 21 from top to bottom, and the described reinforced cage units 1 are connected through the described connecting structures 21, and the reinforced cages The unit 1 is provided with a longitudinal reinforcing truss 5, a longitudinal structural truss 6, and a transverse reinforcing truss 7; the connecting structure 21 includes two connecting steel plates 2 and two connecting splints 3; the connecting steel plates 2 are provided with bolts on the plane Holes, the two connecting steel plates 2 are respectively welded to the connecting ends between the steel cage units 1, and can be symmetrically arranged; the two connecting splints 3 are located on both sides of the plane of the two connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com