Patents

Literature

54results about How to "Reduced lifting capacity requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

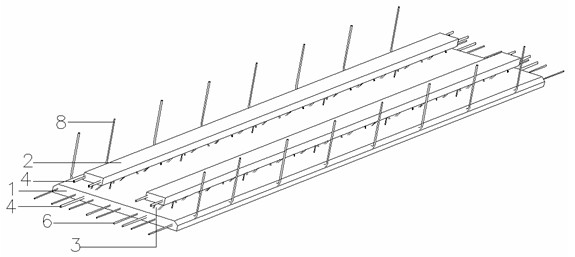

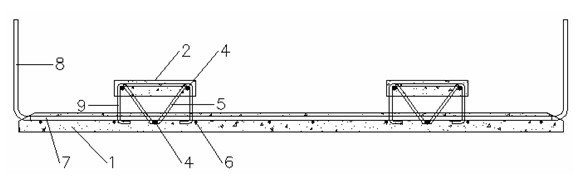

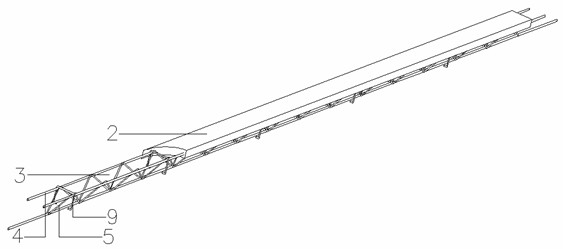

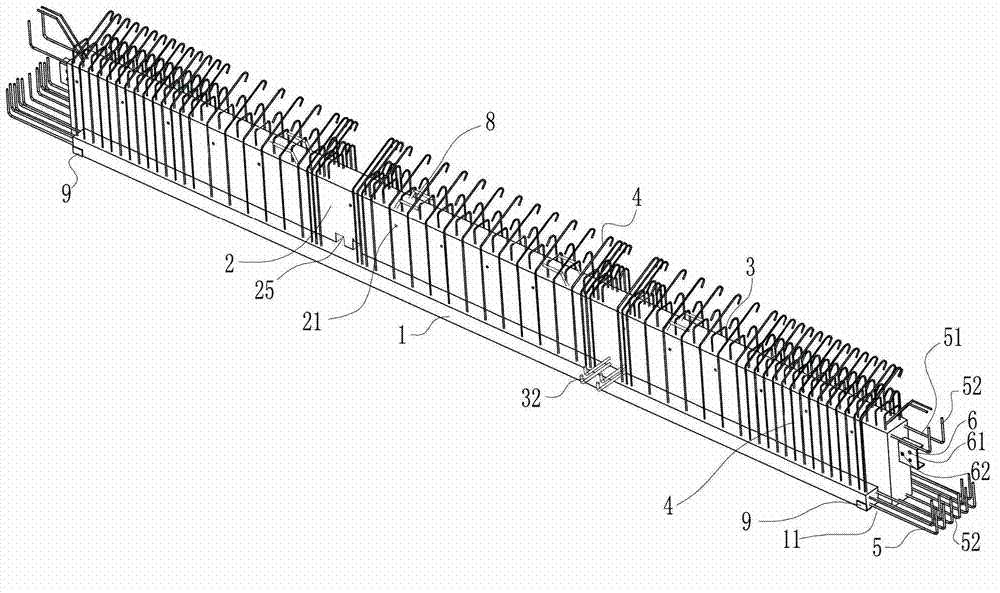

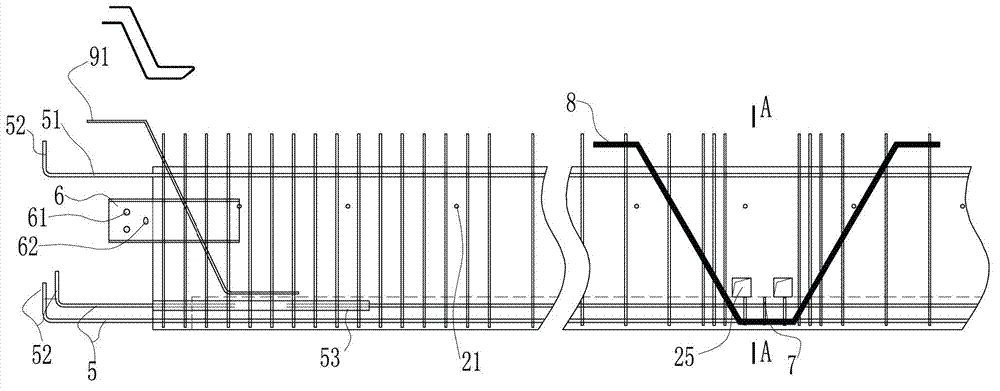

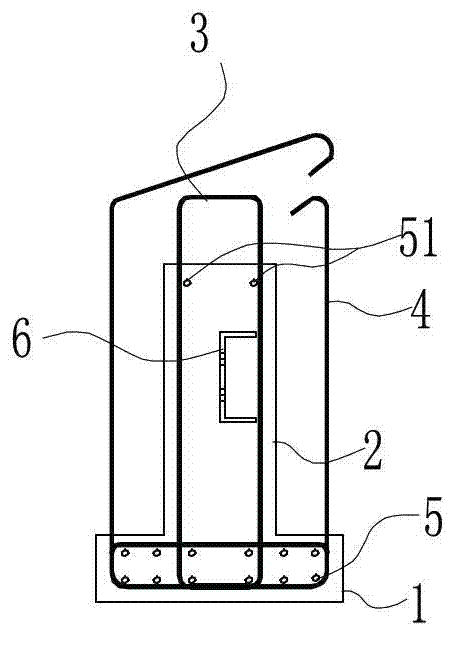

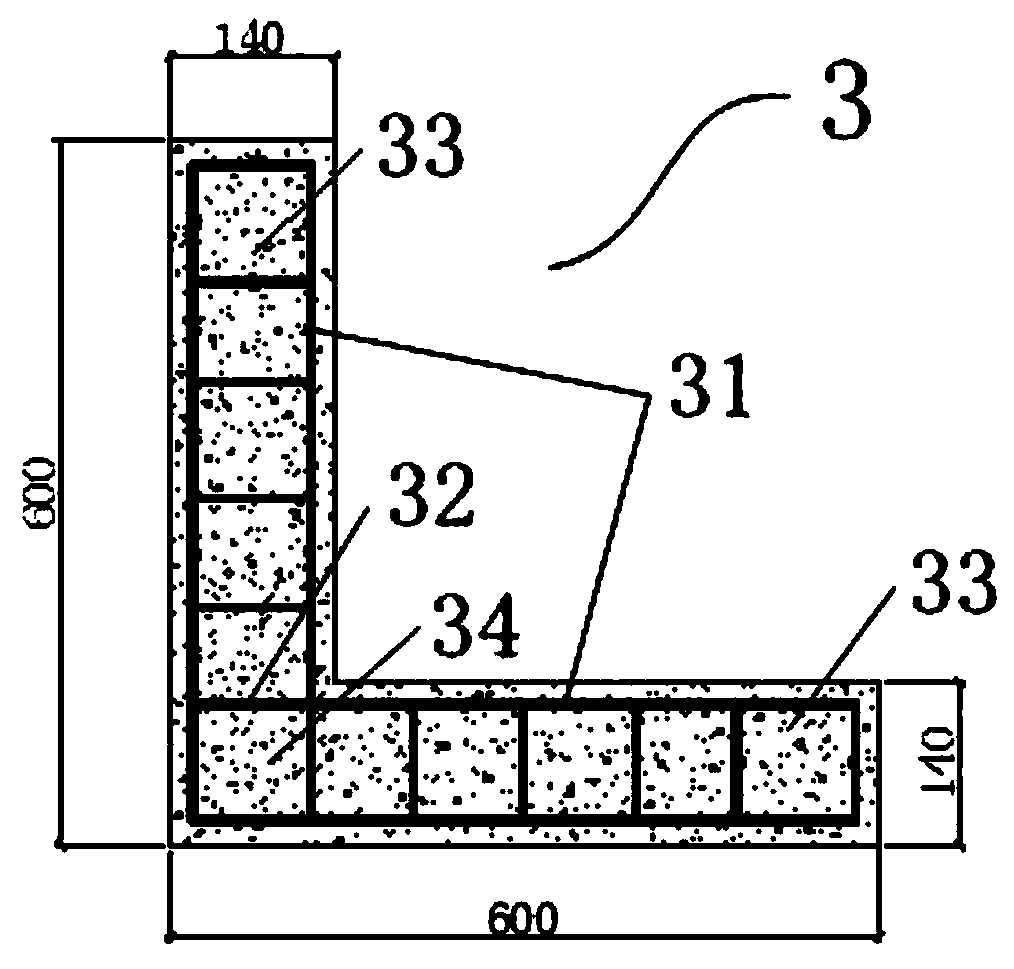

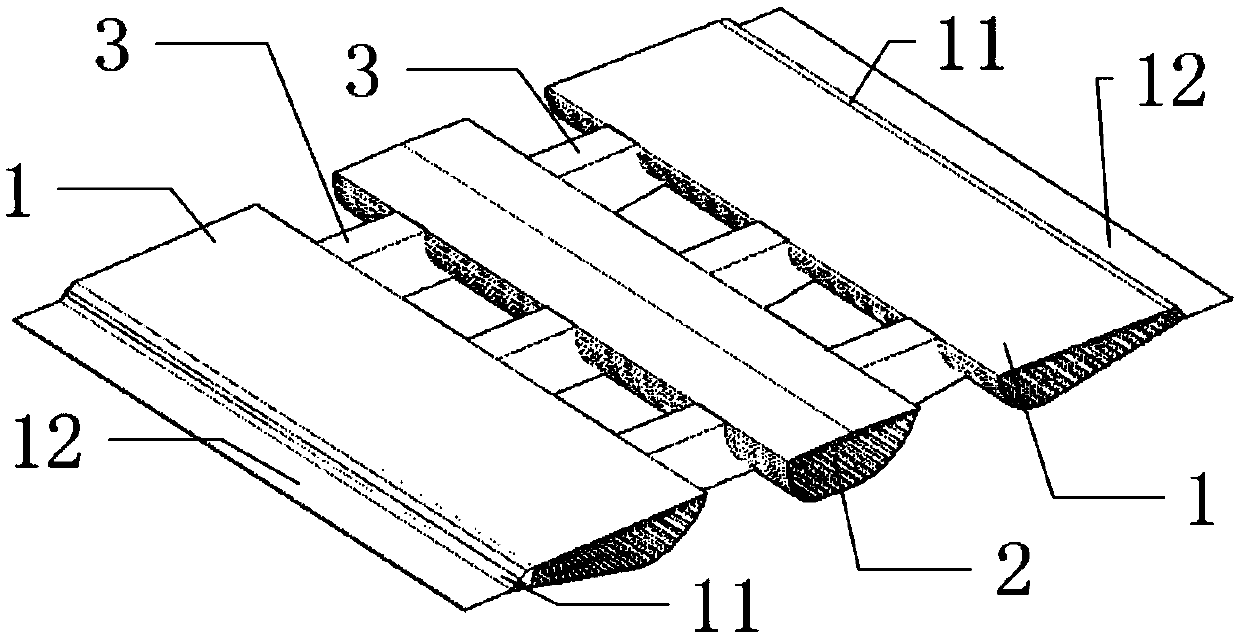

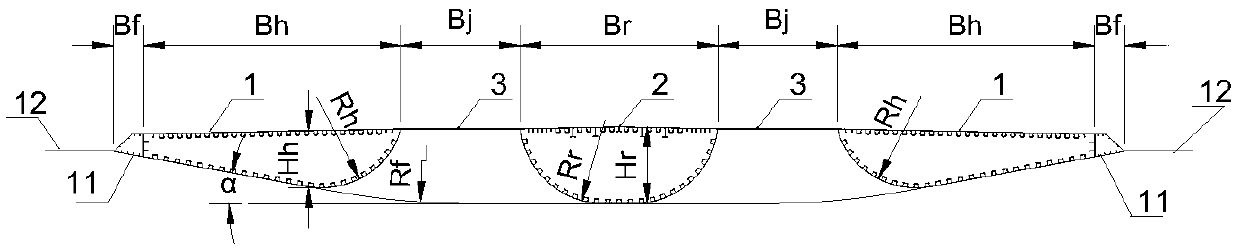

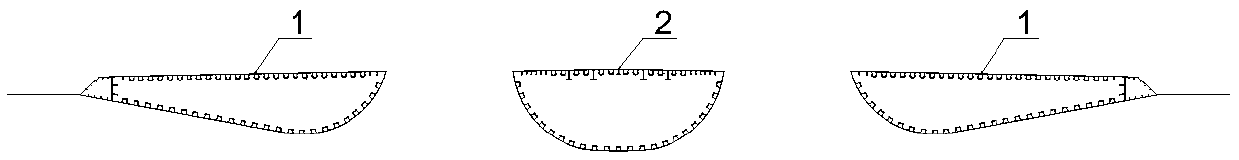

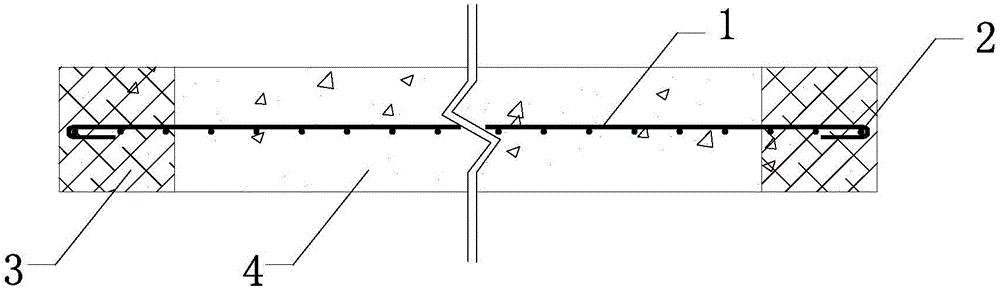

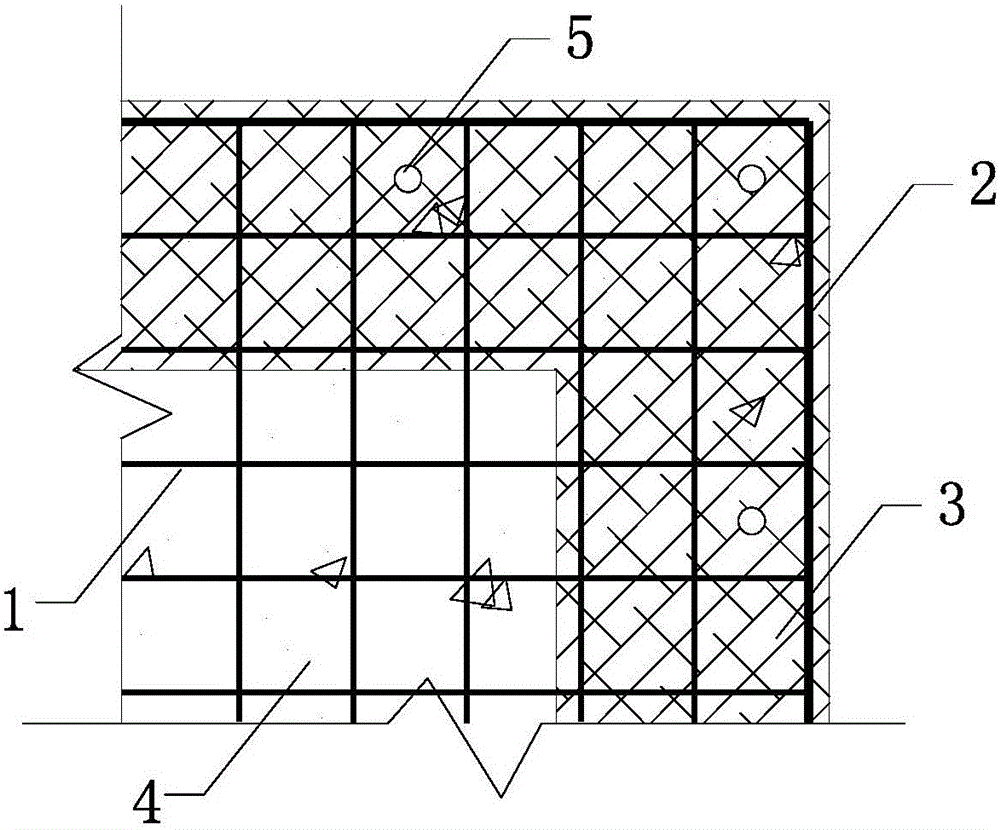

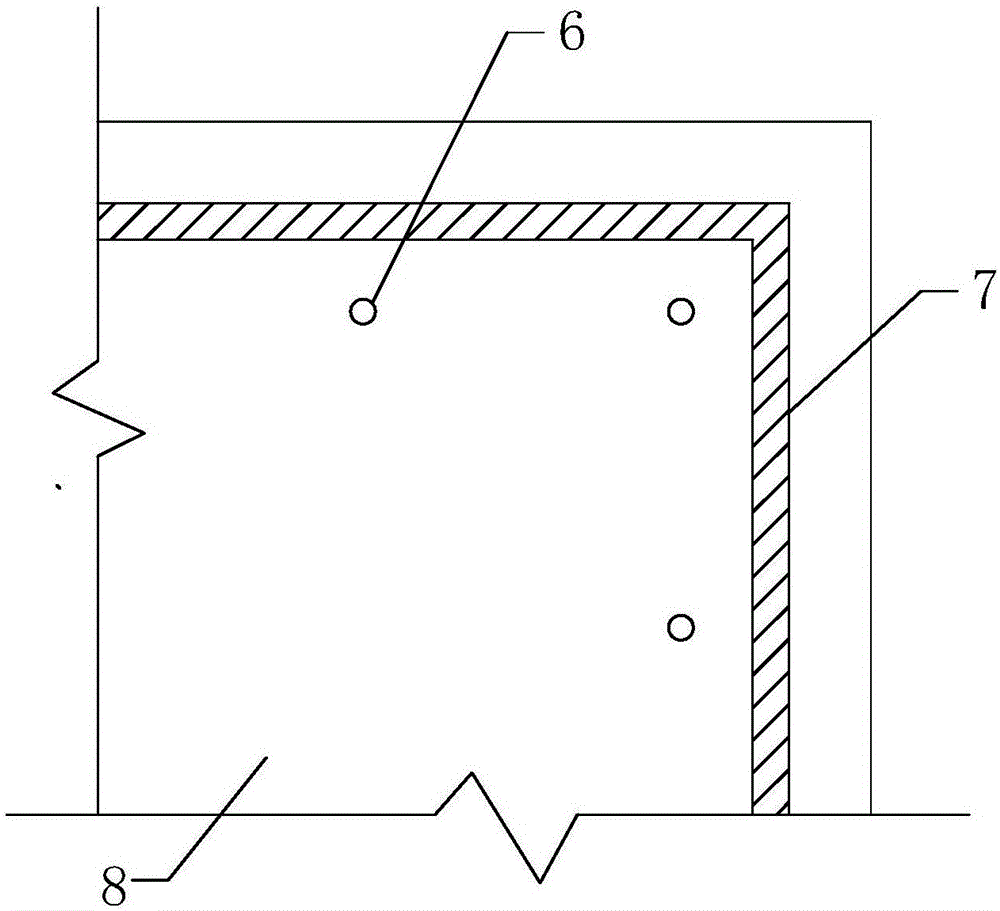

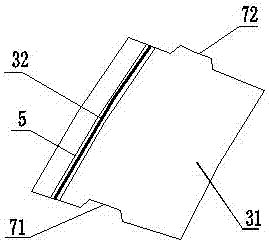

Prefabricated prestressed plate with reinforced truss flange plate and production method thereof

InactiveCN102383512AReduce breakage rateLight weightFloorsCeramic shaping apparatusFloor slabPre stress

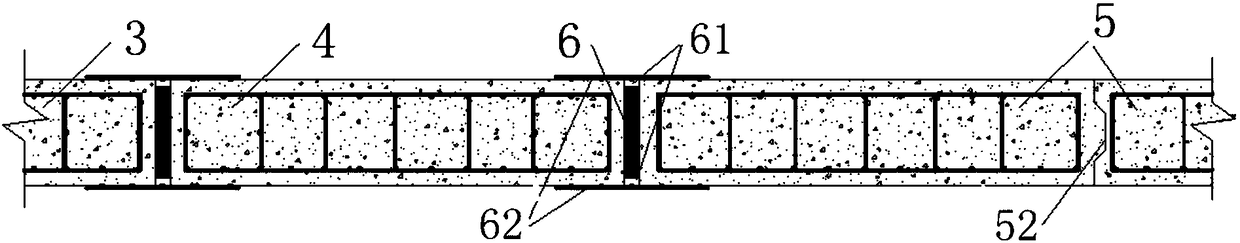

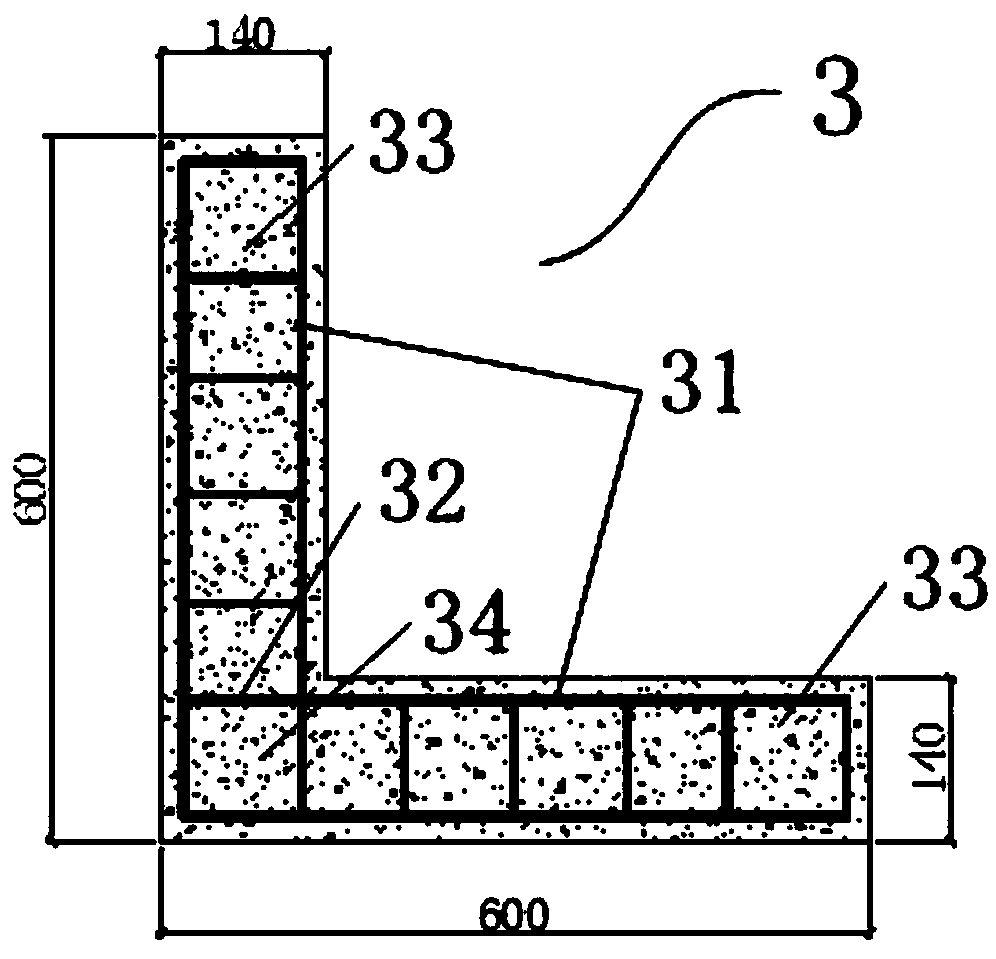

The invention relates to a prefabricated prestressed plate with a reinforced truss flange plate and a production method thereof, in particular to an assembly type concrete overlapped floor slab with a bidirectional mechanical performance and the production method thereof. The prefabricated prestressed plate consists of a prefabricated prestressed concrete base plate, a prefabricated concrete flange strip plate and reinforced trusses which are respectively cast in an upper plate and a lower plate; and a gap through which a wire tube and a reinforcing steel bar penetrate is reserved between the base plate and the flange plate. When the prefabricated prestressed plate is produced, the reinforced trusses are cast with the concrete flange strip plate together; the flange plate with the reinforced truss is turned by 180 degrees and is commonly pressed in the base plate which is provided with stretch-drawing prestressed bars and a concrete material together with a longitudinal reinforcing steel bar positioned at a sharp point of the triangular reinforced truss, a broken line bending part and a transverse distribution bar; and concrete is vibrated and cured to form the prefabricated prestressed concrete plate with the reinforced tress flange plate. According to the prefabricated prestressed plate and the production method thereof disclosed by the invention, high-efficiency streamline production of a factory is realized; the integrity of the cast overlapped floor slab is favorable; a construction process of the floor slab is simplified; and a template and the labor intensity can be saved.

Owner:郭正兴

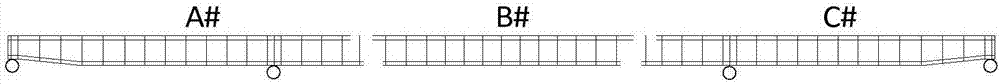

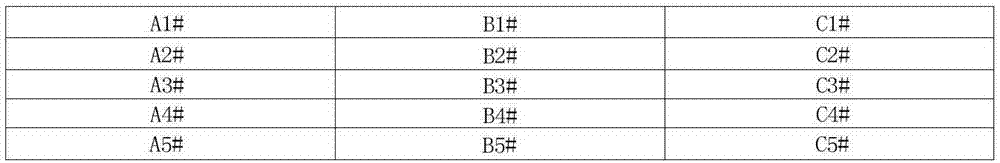

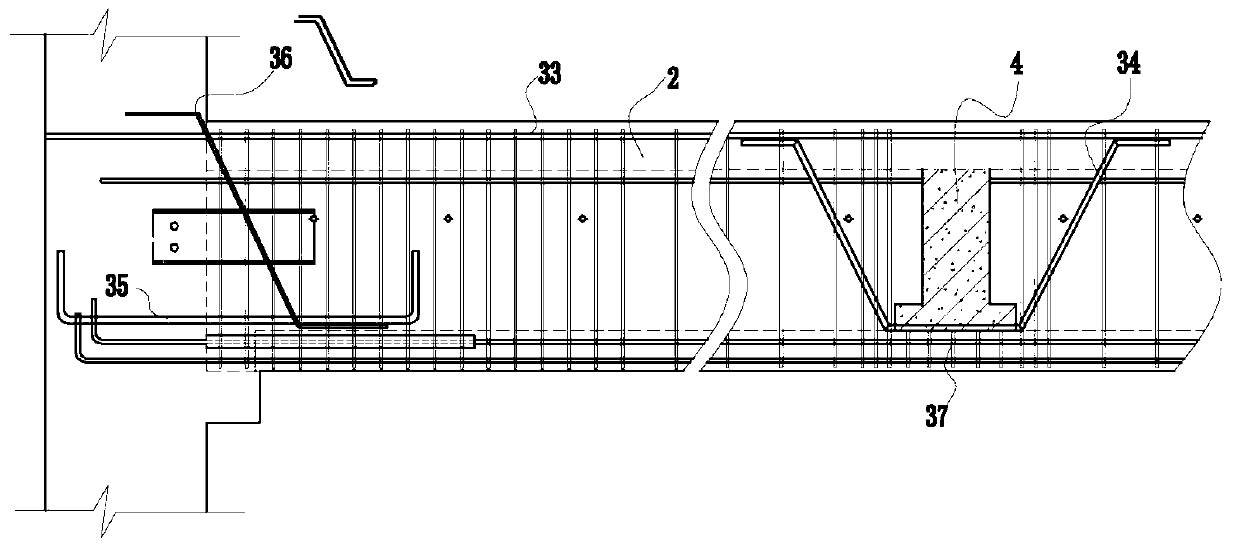

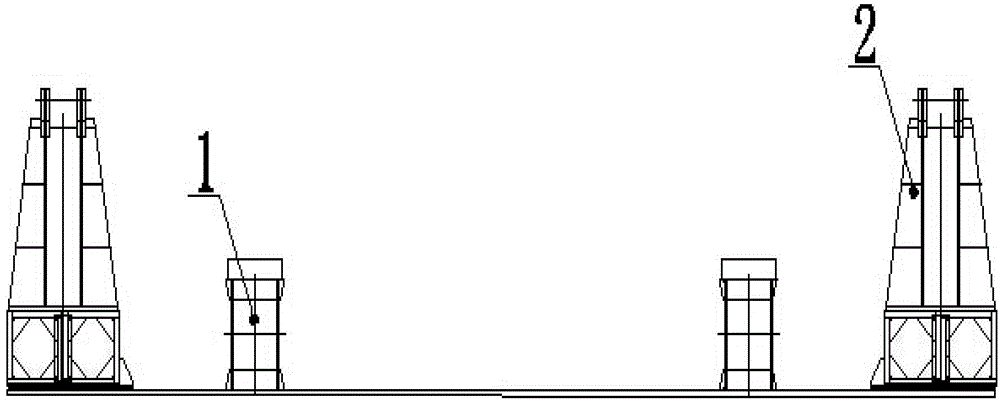

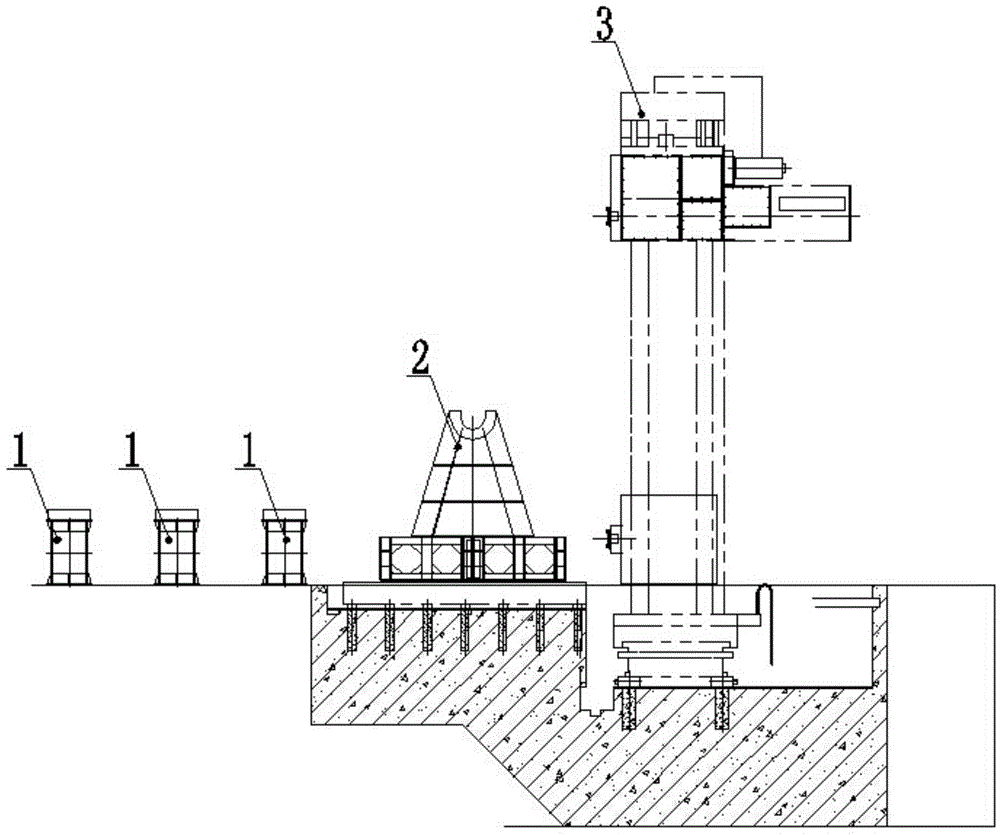

Rapid construction method for transverse partitioning and longitudinal sectioning of urban elevated steel box girder bridge

ActiveCN107059626AReduce the impactReduced lifting capacity requirementsBridge erection/assemblyBridge materialsEngineeringBox girder

The invention discloses a rapid construction method for transverse partitioning and longitudinal sectioning of an urban elevated steel box girder bridge. The rapid construction method particularly comprises the following steps: firstly, determining longitudinal sectioning and transverse partitioning cutting parts, and then, determining longitudinal cutting parts of a steel box girder; transversely partitioning the box girder according to the number of box chambers of the steel box girder, wherein each box chamber serves as a partition; splicing a hoisting unit on a jig, assembling a bottom plate, a transverse diaphragm, a web and a top plate in sequence, and welding the structures; and finally, carrying out hoisting and welding on the site. The hoisting process is carried out from top to bottom in height, from two sides to middle span in longitudinal bridge direction, and from middle to two sides in transverse bridge direction. The rapid construction method disclosed by the invention is capable of reducing the on-site construction time to the maximum limit and reducing the influence on the urban environment; and by virtue of longitudinal sectioning and transverse partitioning, the requirement for the hoisting capacity of hoisting equipment can be reduced, the difficulty of transporting large-section box girders in a city is reduced, and thus the rapid construction method is more suitable for construction of the urban elevated steel box girder bridge.

Owner:ZHEJIANG UNIV

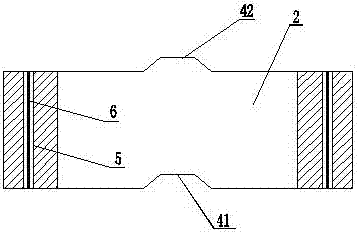

Prestressed reinforced concrete superposed beam having convex-concave superposed surfaces

The invention discloses a prestressed reinforced concrete superposed beam having convex-concave superposed surfaces. The prestressed reinforced concrete superposed beam having convex-concave superposed surfaces comprises an inverted T-shaped precast prestressed beam and an inverted U-shaped post-poured reinforced concrete part. The inverted T-shaped precast prestressed beam and the inverted U-shaped post-poured reinforced concrete part compose a rectangular structure or a rectangular superposed beam of which an upper part is connected to a floor. The prestressed reinforced concrete superposed beam having convex-concave superposed surfaces is characterized in that prestressed steel strands are longitudinally embedded in the inverted T-shaped precast prestressed beam; U-shaped stirrups are embedded in flanges of the inverted T-shaped precast prestressed beam; rectangular stirrups are embedded in a web; a stirrup pouring anchor is fixed in the inverted U-shaped post-poured reinforced concrete part; and the rebars are longitudinally embedded in an upper part of the inverted U-shaped post-poured reinforced concrete part of the prestressed reinforced concrete superposed beam. The prestressed reinforced concrete superposed beam has an inverted T-shaped cross section and small self-weight, is convenient for transport and reduces tower crane hoisting requirements.

Owner:杨众 +1

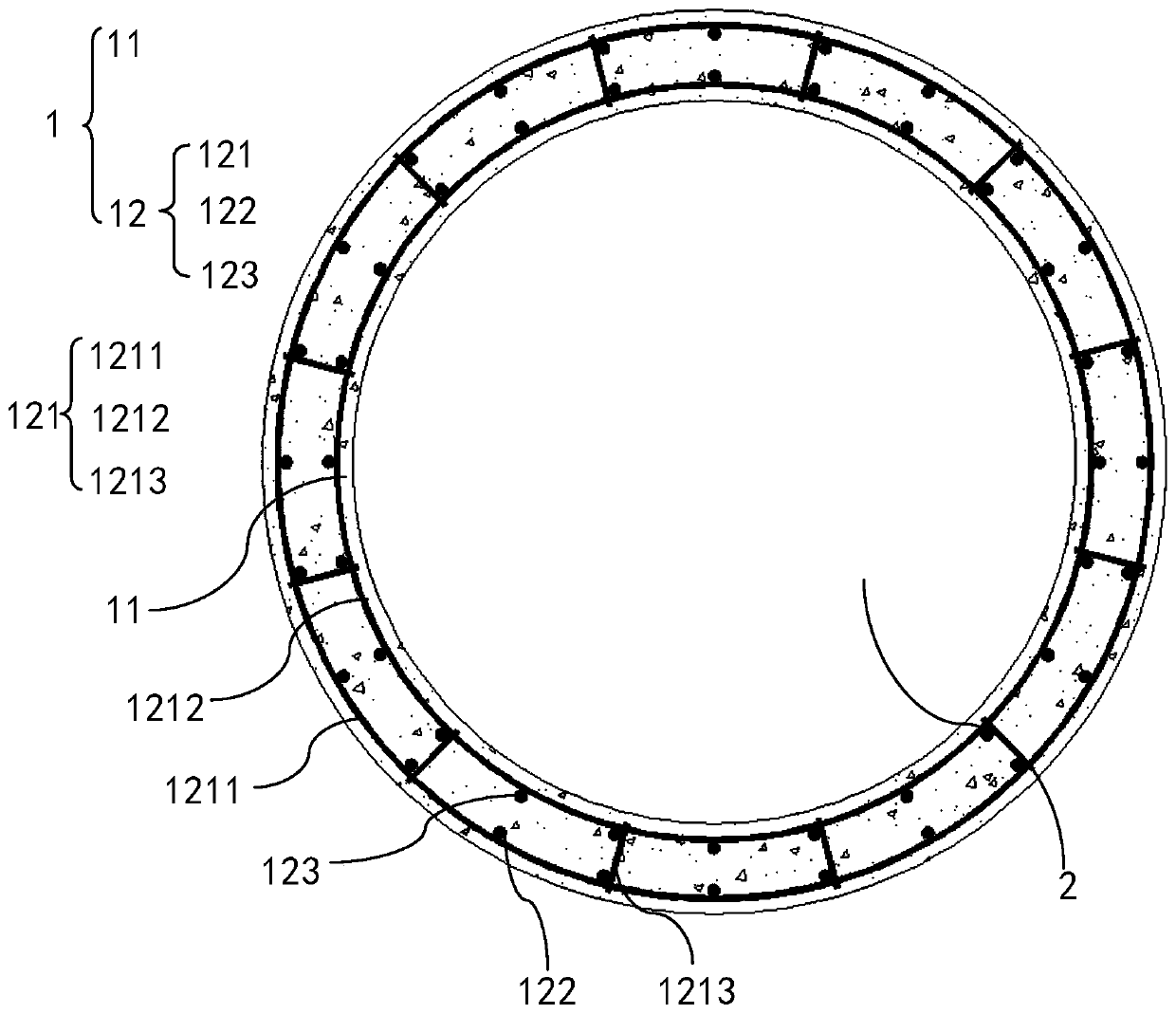

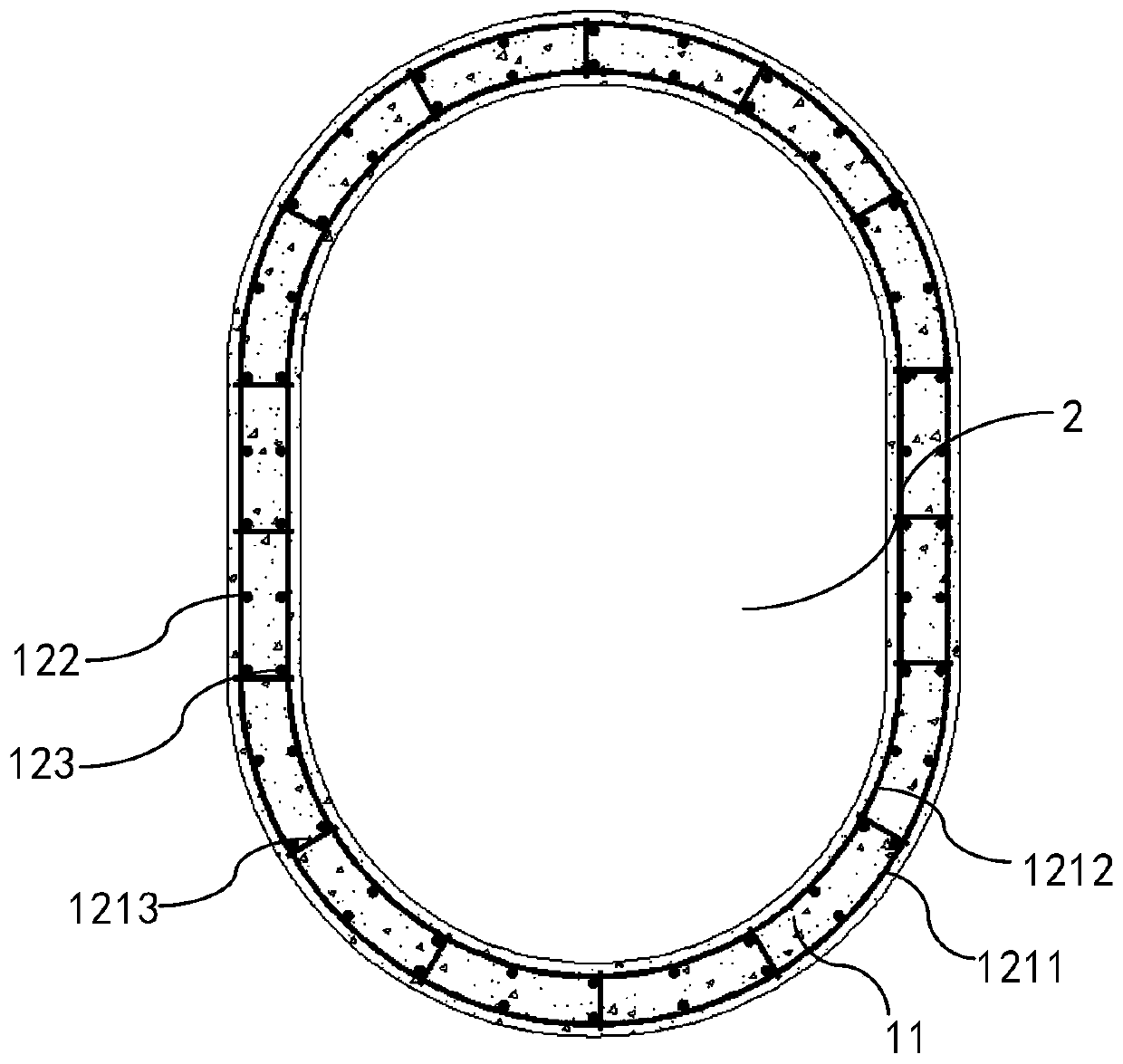

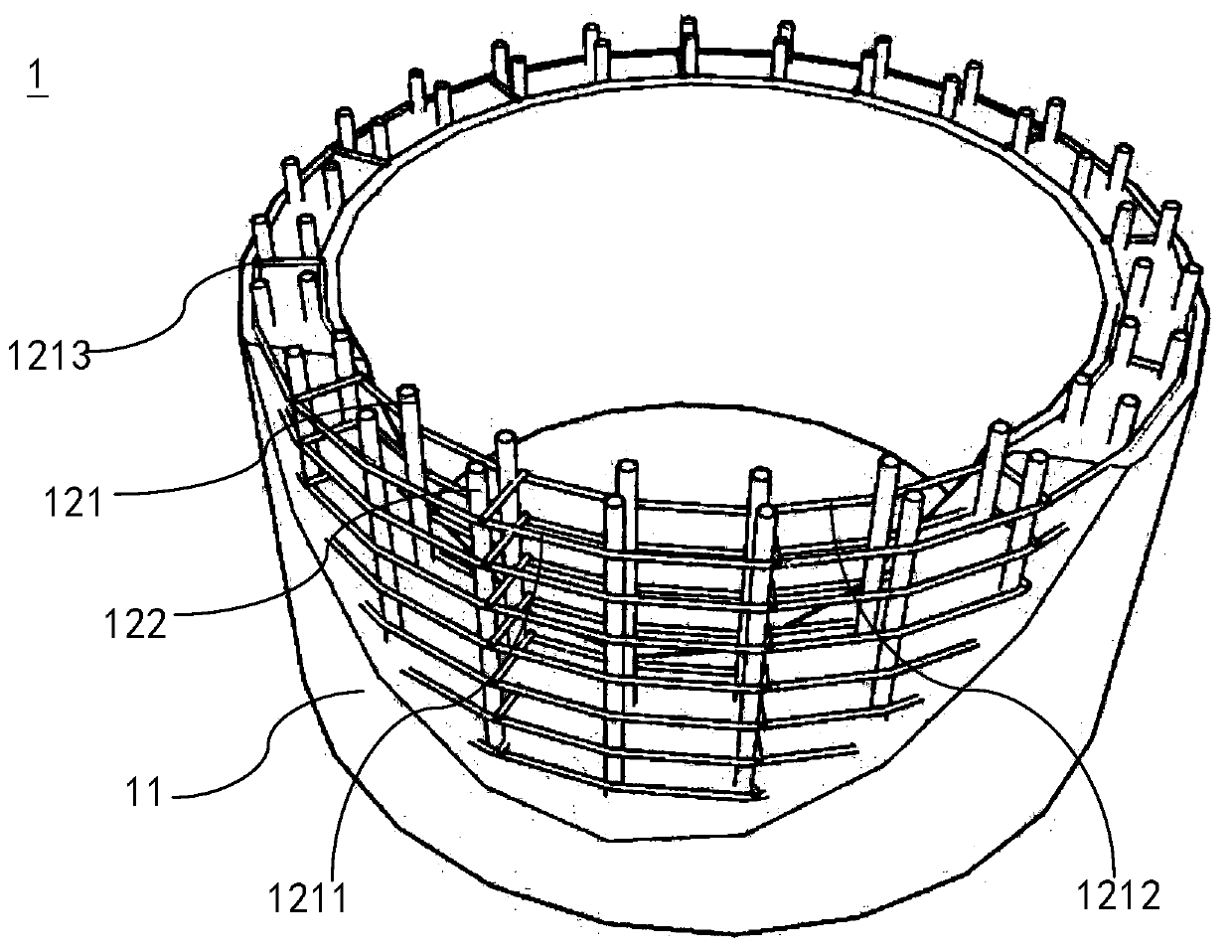

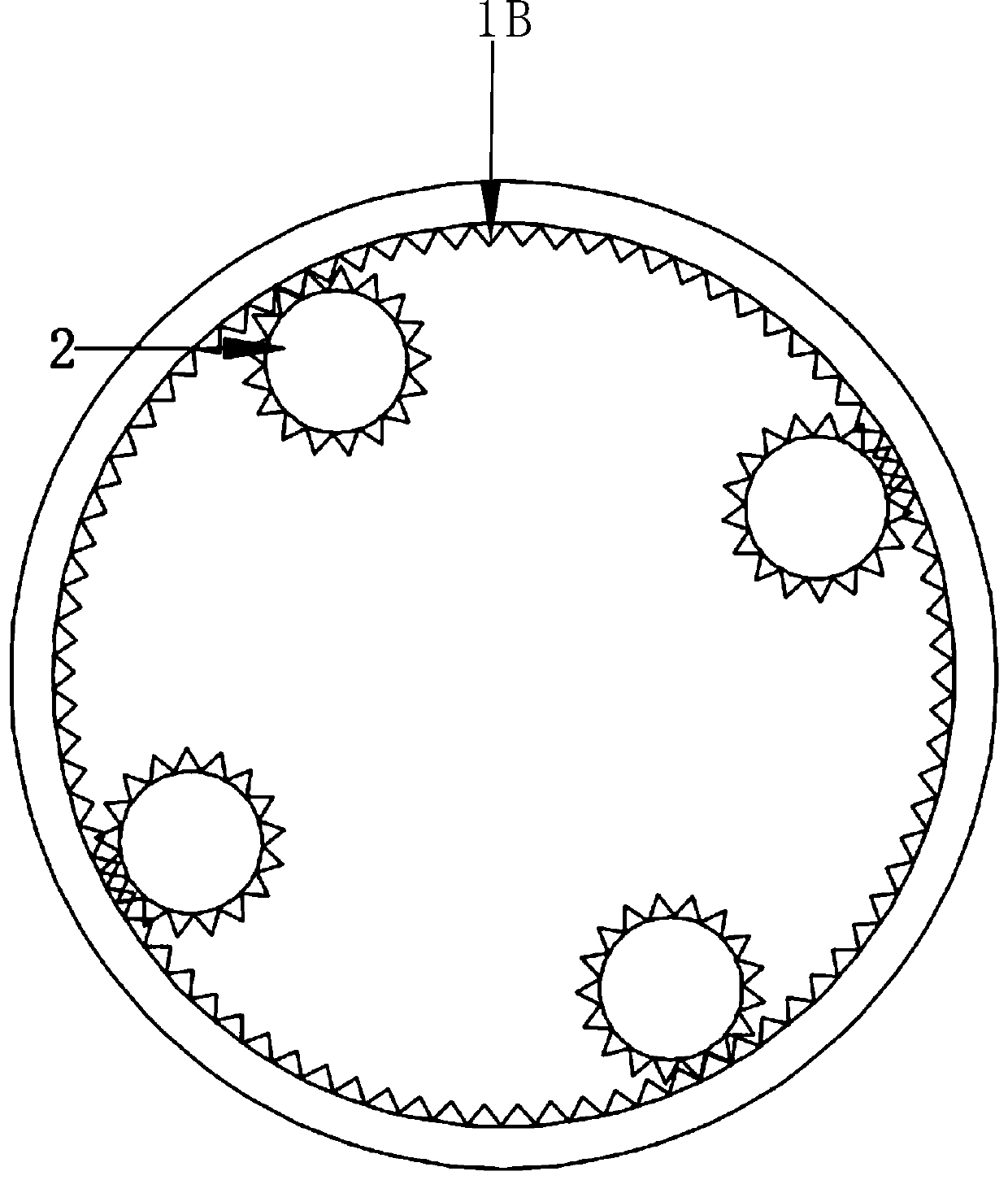

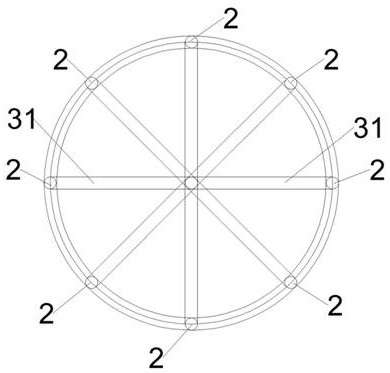

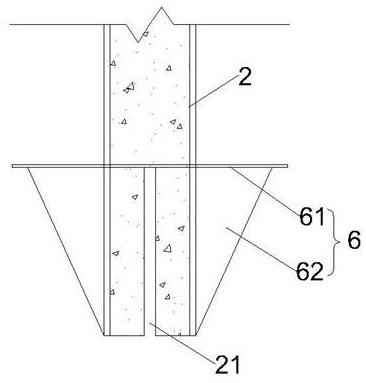

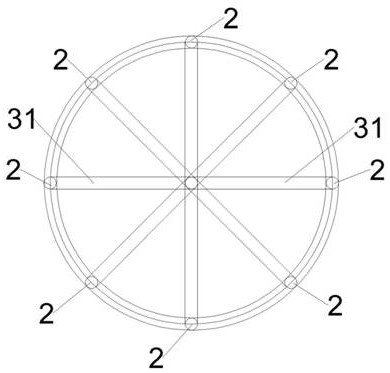

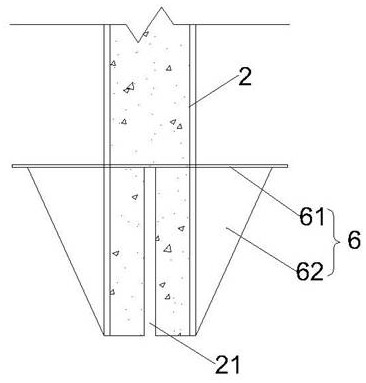

Fabricated reinforced concrete bridge pier and construction method thereof

PendingCN110130212AReduce weightReduce workloadBridge structural detailsBridge erection/assemblyReinforced concreteRebar

The invention provides a fabricated reinforced concrete bridge pier. The fabricated reinforced concrete bridge pier comprises a hollow bridge pier shell and cast-in-place core concrete arranged in thebridge pier shell, the bridge pier shell comprises a concrete layer and a reinforcement cage, and the reinforcement cage is arranged in the concrete layer; and the reinforcement cage comprises a plurality of circumferential stirrup meshes and a plurality of vertical steel bars, the multiple circumferential stirrup meshes are equidistantly arranged at intervals in the vertical direction, and the multiple vertical steel bars are equidistantly arranged at intervals along the circumferential stirrup meshes. The invention provides a construction method of the fabricated reinforced concrete bridgepier, the reinforcement cage and formworks are manufactured, then concrete is poured into spaces between the formworks and congealed into a whole so as to form the integrated bridge pier shell, the bridge pier shell is transported to a construction site, and the cast-in-place core concrete is poured into a hollow hole of the bridge pier shell. According to the fabricated reinforced concrete bridgepier and the construction method thereof, the weight is small, the construction period is short, transporting and hoisting difficulty is greatly reduced, multiple construction ways are provided, andoverall performance after the structure is formed is good.

Owner:RBS PARTNERS S&T CO LTD

Dry-type hoisting method for fuel-lacking assembly

InactiveCN102568633AReduce shielding requirementsReduced lifting capacity requirementsNuclear energy generationReactor fuel elementsLocking mechanismEngineering

The invention belongs to a hoisting method for a fuel-lacking assembly, in particular relates to a dry-type hoisting method for the fuel-lacking assembly. The method comprises the following procedures: (1) loading the fuel-lacking assembly into a hoisting basket under water; (2) hoisting a shielding transporter above a pool canning position and drawing a lower baffle out; (3) lifting the hoisting basket containing the fuel-lacking assembly into the shielding transporter, closing the lower baffle and locking a safety locking mechanism; (4) draining the water thoroughly; (5) jointing the shielding transporter with a transportation container with an opening; (6) opening the lower baffle of the shielding transporter, and putting the hoisting basket containing the fuel-lacking assembly into the transportation container; (7) hoisting the shielding transporter away from the transportation container; (8) covering the transportation container in a seal manner; and (9) conducting check on the radiation level, air tightness and surface pollution of the transportation container containing the fuel-lacking assembly, after passed examination, loading the transportation container on a vehicle to be transported outwards. The hoisting method provided by the invention has the advantages of not generating safety problems, being lower in requirements on shielding of a plant, volumes of the plant and a water pool, and the hoisting capacity of a crane.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

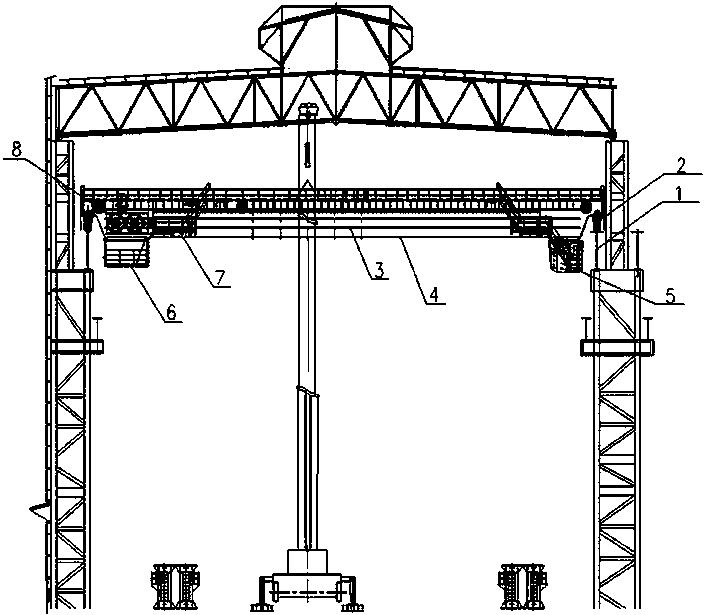

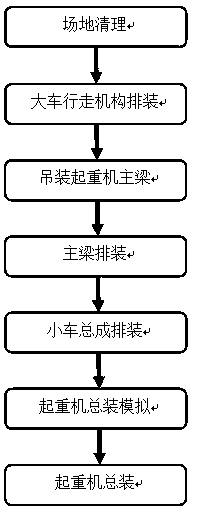

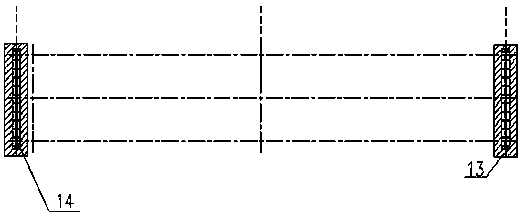

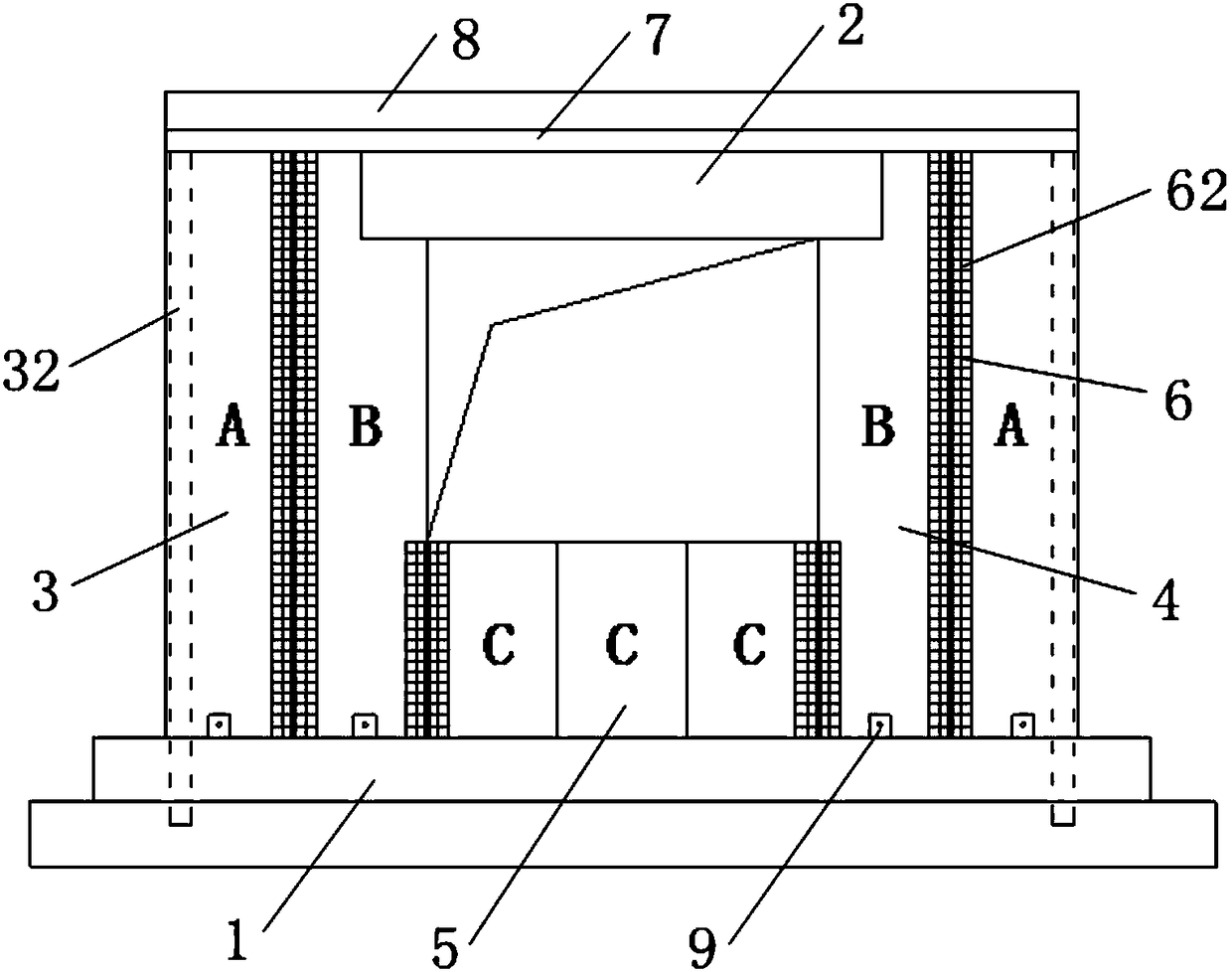

Bridge crane general assembly technology

ActiveCN110104564AReduce construction workloadReduce workloadLoad-engaging girdersTravelling cranesLifting capacityGeneral assembly

The invention relates to a bridge crane general assembly technology. The general assembly technology sequentially includes site cleaning, cart walking mechanism arranging assembling, crane main beam lifting, main beam arranging assembling, trolley assembly arranging assembling, crane general assembling simulating and crane general assembling. Arranging assembling of main beams is conducted correspondingly, and main beam mechanisms are formed, and in addition, the main beam mechanisms are lifted in the crane general assembling process. The bridge crane general assembly technology has the beneficial effects that pre-assembling of main beams and trolleys is completed on the ground surface, the workload of aerial construction is reduced, and the construction difficulty is lowered; and the mainbeam assembly I and the main beam assembly II are subjected to general assembling separately, the requirement for the lifting capability is low, and in addition, the requirement for a bed jig and a foundation is low; and balancing weights are increased for weight balancing, the gravity center of the main beam mechanism I and the gravity center of the main beam mechanism II are accurately calculated, a single truck-mounted crane is adopted for lifting, and the defect that multiple truck-mounted cranes are used for lifting and cannot rotate is overcome.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

Desert-sand light aggregate concrete fabricated shear wall structure

The invention discloses a desert-sand light aggregate concrete fabricated shear wall structure which comprises a foundation, coupling wall columns arranged on the foundation, and coupling beams connected between the coupling wall columns. The coupling wall columns are mainly composed of steel wire nets, thin-wall shape steel, steel wire cages and the like correspondingly. Desert-sand light aggregate concrete is poured on the steel wire nets and the steel wire cages, and the coupling wall columns are connected through asbestos boards, the steel wire nets, the desert-sand light aggregate concrete and the like in a poured mode correspondingly. The desert-sand light aggregate concrete fabricated shear wall structure is light in weight, materials are easy to obtain, the anti-seismic bearing capacity and deformability of components can be reliably ensured, and the good heat-insulating property is also achieved under the situation that the bearing requirement is met. The assembly attributes of simple structure and convenient and rapid transporting and mounting are achieved, and the desert-sand light aggregate concrete fabricated shear wall structure is particularly suitable for remote villages and towns which are insufficient in material supply, low in worker quality and short in technical force in Xinjiang region, and can be self-built by tile teams or farmers of the villages and thetowns.

Owner:SHIHEZI UNIVERSITY

Large angle belt special lifting device

The invention discloses a large angle belt special lifting device. The large angle belt special lifting device comprises a hanging bearing unit and a compacting unit; the hanging bearing unit comprises a fixed panel (5), a movable panel (9), wing edge supporting pipes (11), and a main supporting pipe (12); the compacting unit comprises a cross beam (6), and top rods (7); the cross beam (6) is a channel steel, and the two ends of the channel steel are provided with holes and pin shaft holes; the cross beam (6) is arranged on the fixed panel (5) and above the movable panel (9) via the holes. The large angle belt special lifting device is simple in lifting device structure, is convenient to produce, is excellent in lifting security, and is capable of protecting large angle skirt belts from damage caused by tightening of steel wire rope lifting devices, and avoiding work delay, time delay, and material waste.

Owner:MCC5 GROUP CORP SHANGHAI

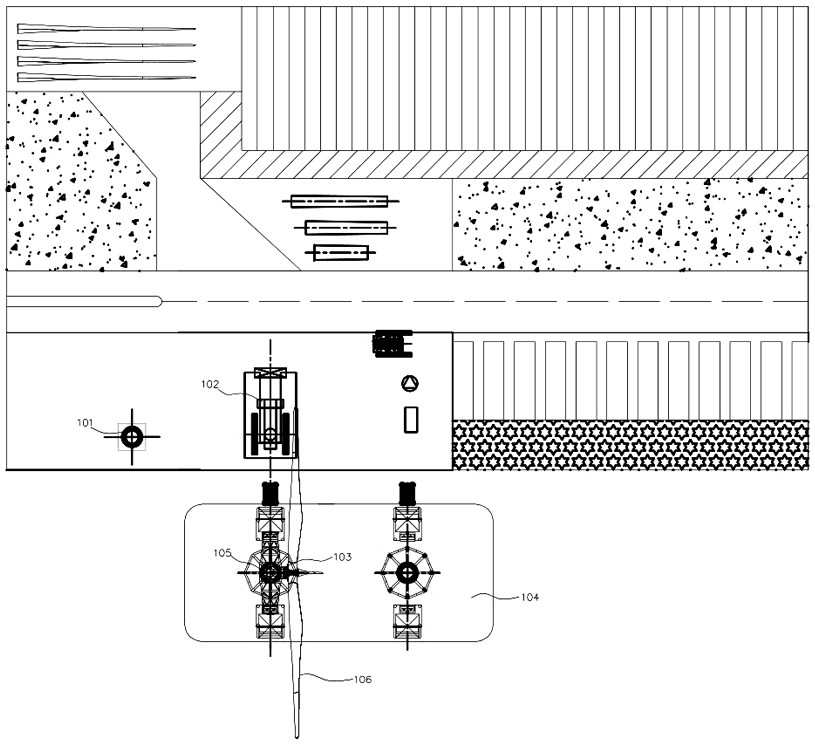

Wheel hub rotating tool for conveniently completing fan impeller assembling

PendingCN109973320ASmall operating space requirementReduced lifting capacity requirementsWind motor assemblyWind energy generationImpellerFree rotation

The invention provides a wheel hub rotating tool for conveniently completing fan impeller assembling. The wheel hub rotating tool comprises a fixed support, a rotating mechanism, a wheel hub tool anda rotating locking device, wherein a wheel hub tool is placed on the fixed support; the rotating mechanism and the locking device are arranged between the wheel hub tool and the fixed support and controlled by an electrical control system; and the equipment wheel hub tool can be freely rotated and locked through the electrical control system. The wheel hub rotating tool has the following advantages that (1) the hoisting feasibility of all blade lifting positions during ship hoisting machine model selection needs to be considered, while the hoisting feasibility of only a single blade lifting needs to be considered through the rotating tool, the lifting performance requirement of equipment is low, and meanwhile, the operating space requirement for a ship deck is low; and (2) by rotating therotating tool, blade lifting is always conducted on the side, close to a transport ship, of a mounting ship, and time is saved.

Owner:CCCC FIRST HARBOR ENG

Method for turning over heavy bridge girder steel tower section

ActiveCN104088231AReduced lifting capacity requirementsBridge structural detailsBridge erection/assemblyManufacturing technologyLifting capacity

The invention relates to the technical field of bridge girder manufacturing, in particular to a method for turning over a heavy bridge girder steel tower section. The method comprises the steps that a rotating support is selected or manufactured, a boring-milling machine is selected, and the rotating support is fixed on the boring-milling machine; a supporting steel pier is selected or manufactured and arranged in a work area of the boring-milling machine; a rotating hinge shaft is selected or manufactured, fixed at the front end of the bridge girder steel tower section, and installed on the rotating support; the bridge girder steel tower section is placed on the supporting steel pier; a crane is connected with the rear end of the bridge girder steel tower section; the crane lifts the bridge girder steel tower section, and the front end of the bridge girder steel tower section rotates around the rotating hinge shaft so that the bridge girder steel tower section can be turned over by 0 degree to 90 degrees. According to the method for turning over the heavy bridge girder steel tower section, the rotating support provides some supporting force for the bridge girder steel tower section, the requirement for the lifting capacity of the crane is lowered, and the heavy bridge girder steel tower section can be lifted by utilizing the crane low in lifting capacity.

Owner:WUCHUAN HEAVY ENG

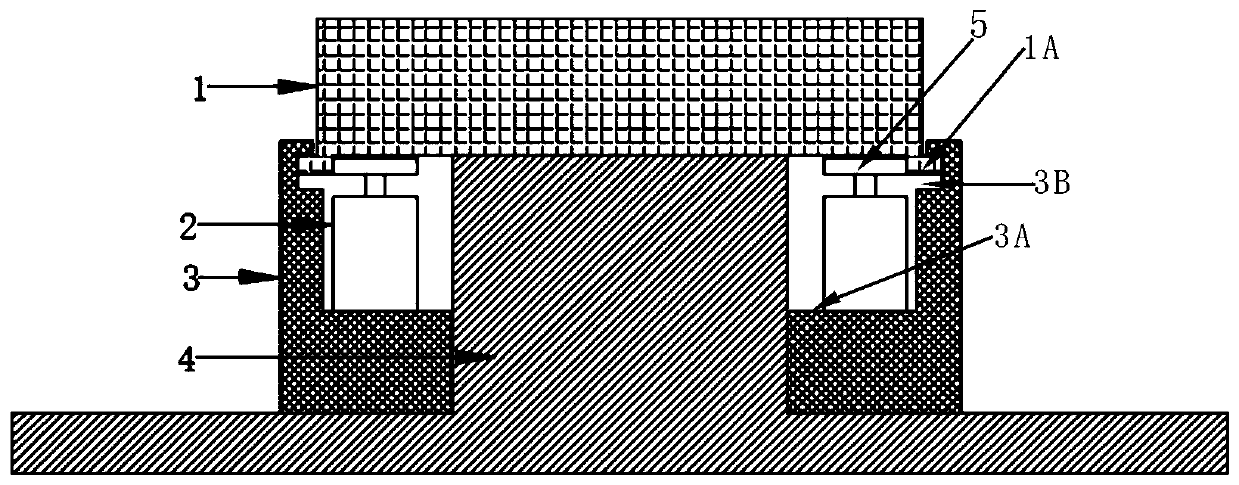

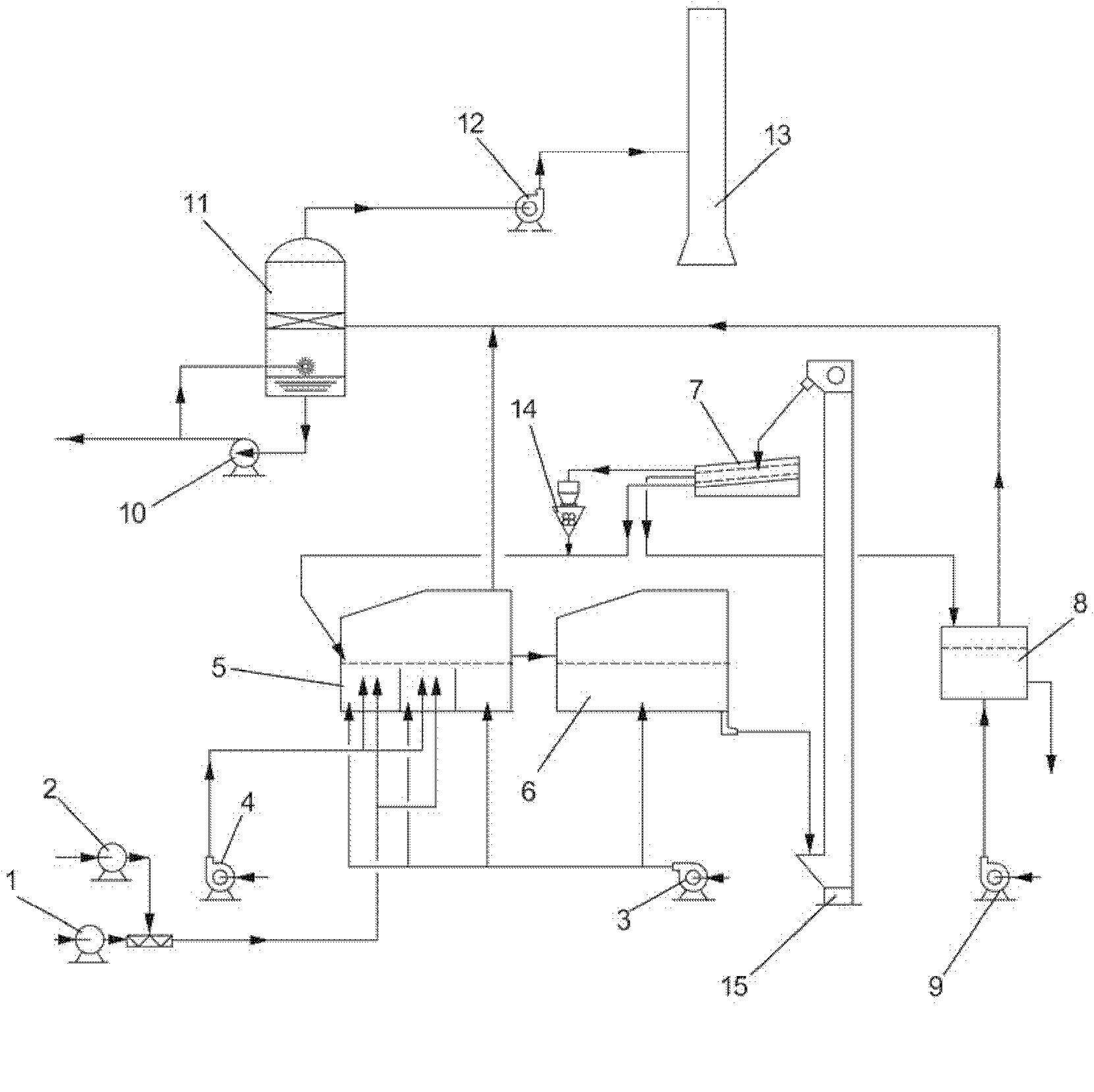

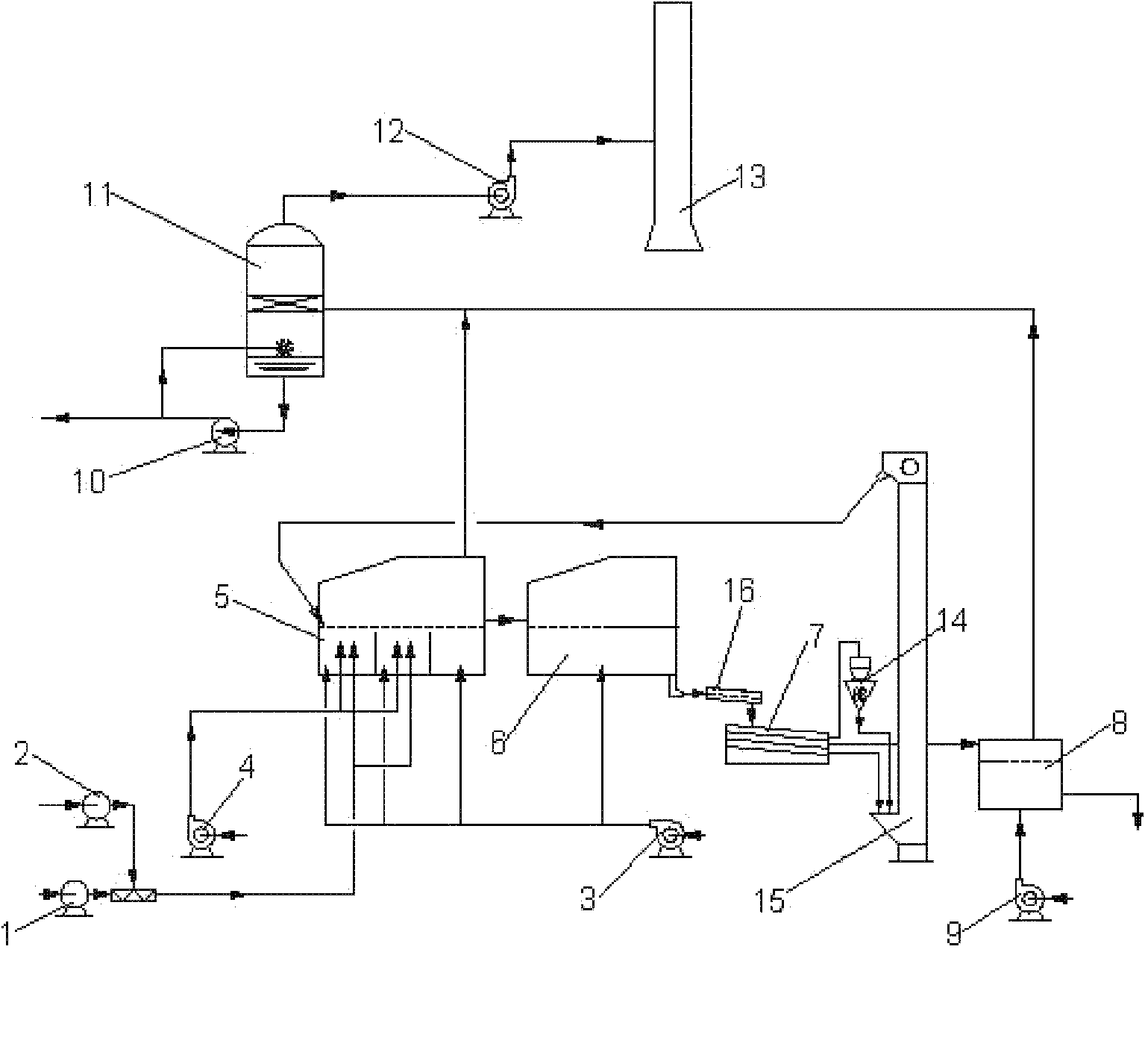

Fluidized bed granulation system

InactiveCN103252195AReduce energy consumptionReduce consumptionGranulation by powder suspensionEngineeringCrusher

The invention relates to the fluidized bed granulation system field, and discloses a fluidized bed granulation system. The fluidized bed granulation system comprises a fluidized bed granulator, a fluidized bed cooler, a vibration feeder and a screener which are sequentially connected in the process flow; the screener comprises a large granule screening outlet, a medium granule screening outlet and a small granule screening outlet; the medium granule screening outlet is connected to the outside battery limit or a final product cooler; the small granule screening outlet is connected to a bucket elevator; the large granule screening outlet is connected to a crusher and then is connected to the bucket elevator; and the material outlet of the bucket elevator is connected to the fluidized bed granulator. Compared with a granulation system obtained through a traditional design, the granulation system disclosed in the invention has the advantages of decrease of above 10m of the height of the structural framework, reduction of above 50% of the required elevation apparatus capability, obvious reduction of the energy consumption required by the material elevation during normal running, substantial engineering and equipment investment saving, and reduction of the running energy consumption of the system.

Owner:BEIJING FUNGHAN ENG CONSULTING

Pre-tensioned deformed reinforced concrete precast main beam

The invention discloses a pre-tensioned deformed reinforced concrete precast main beam. The pre-tensioned deformed reinforced concrete precast main beam is characterized in that a beam body has an inverted T-shaped section and is composed of a horizontal rectangular compression-resistant part and a vertical rectangular shearing-resistant part; stirrups are embedded in the vertical rectangular shearing-resistant part; parts of the stirrups stretch out of an upper surface of the vertical rectangular shearing-resistant part; U-shaped stirrups are embedded in the horizontal compression-resistant part; U-shaped stirrup upper parts having certain length stretch out of an upper surface of the horizontal compression-resistant part; and steel strands are embedded in the horizontal compression-resistant part. A step of the pre-tensioned deformed reinforced concrete precast main beam having the inverted T-shaped section can be straightly provided with a secondary beam so that secondary beam installation is convenient. In construction, when a temporary support is arranged at a lower part of the secondary beam, no additional rebars are arranged at a loading step.

Owner:杨众 +1

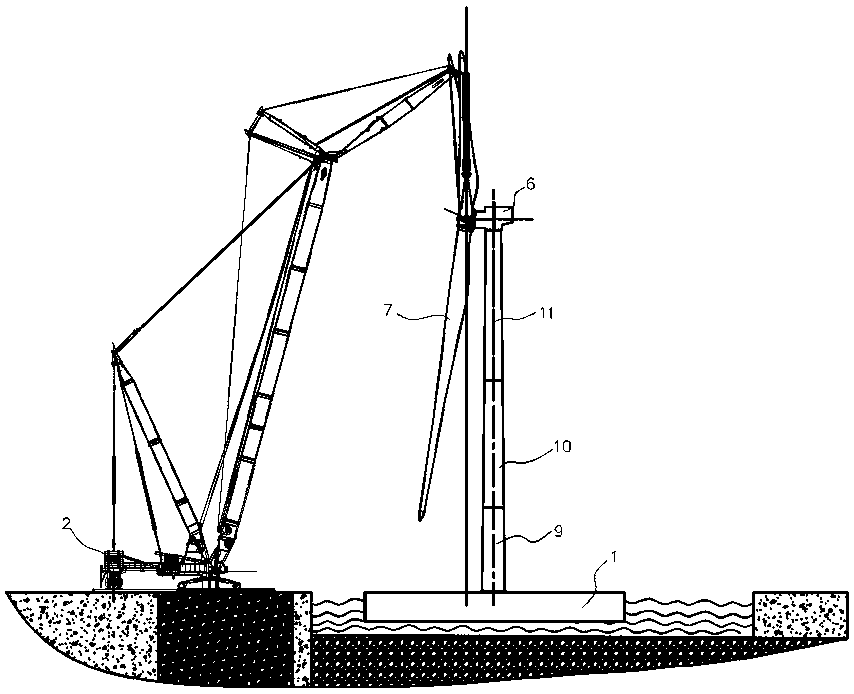

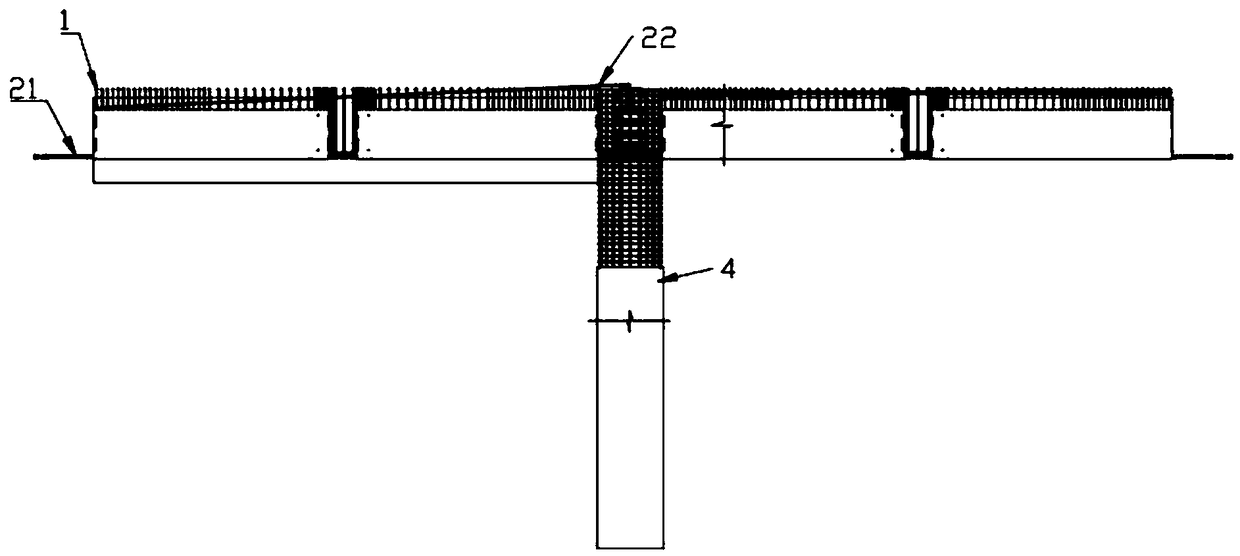

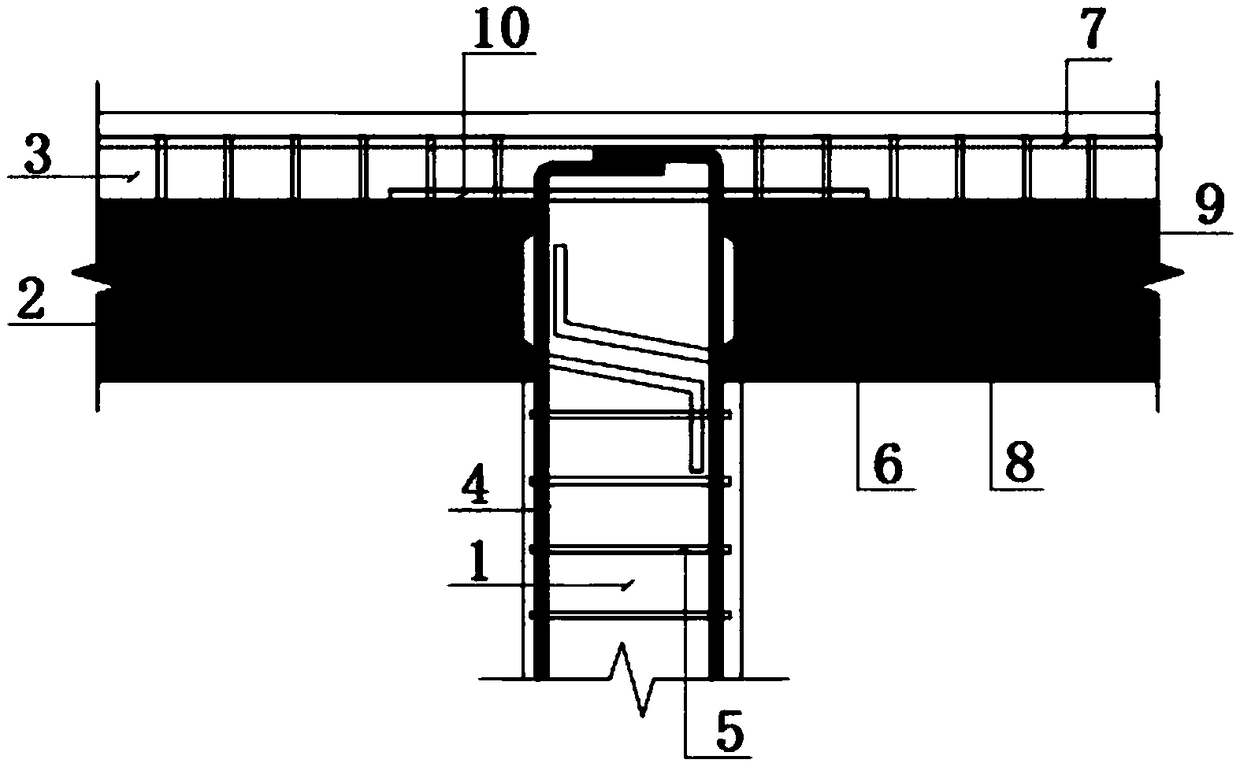

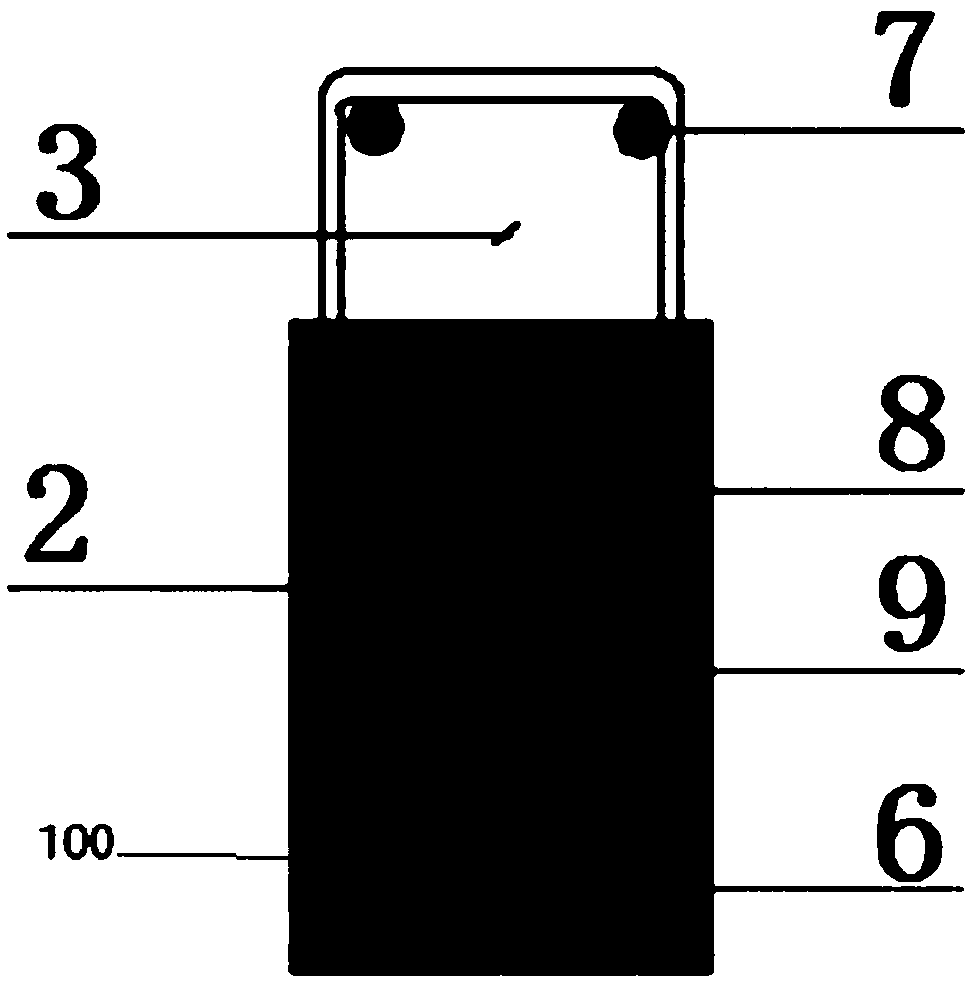

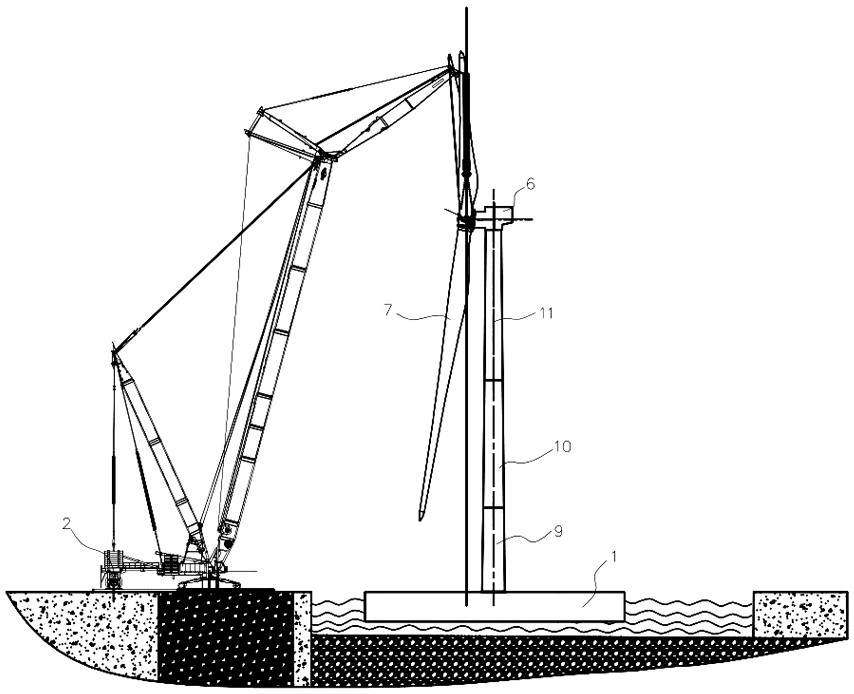

Towing truss-gravity type combined offshore wind turbine foundation structure and construction method thereof

InactiveCN106638659ABasic transportation is convenientLarge capacityFoundation engineeringMarine engineeringArchitectural engineering

The invention provides a towing truss-gravity type combined offshore wind turbine foundation structure. The foundation structure comprises a towing gravity type foundation with a cavity and a truss-type fan supporting structure; the towing gravity type foundation comprises a concrete abutment where butt-joint steel pipes are embedded in advance and a concrete cavity, and the truss-type fan supporting structure is connected with the pre-embedded butt-joint steel pipes through a grouting material. The invention further provides a construction method of a towing truss-gravity type combined offshore wind turbine foundation. The foundation structure can be applied to an offshore wind plant with the water depth of 20-50 m and the subgrade made of hard sandy oil or rock and has the advantages of being suitable for larger water depth, capable of supporting a fan with larger capacity and convenient to install and transport, saving steel and reducing construction cost, wave force borne by the foundation structure is reduced, and piling and piling noise are avoided.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

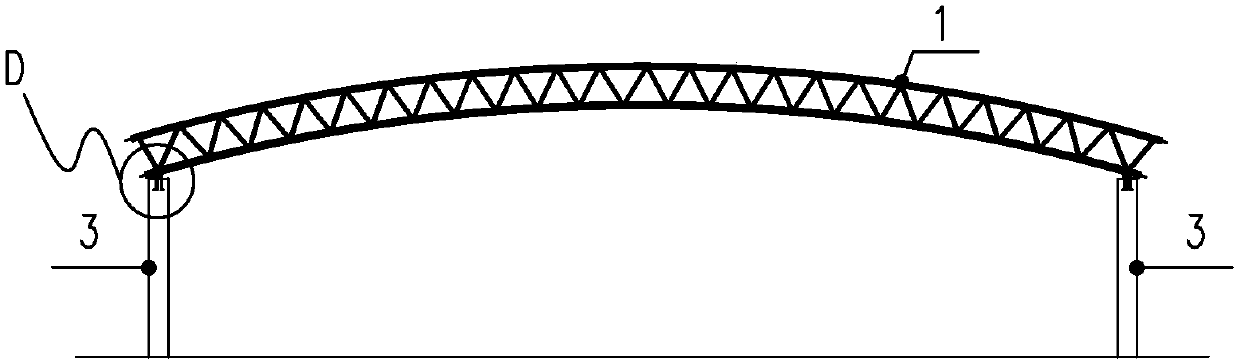

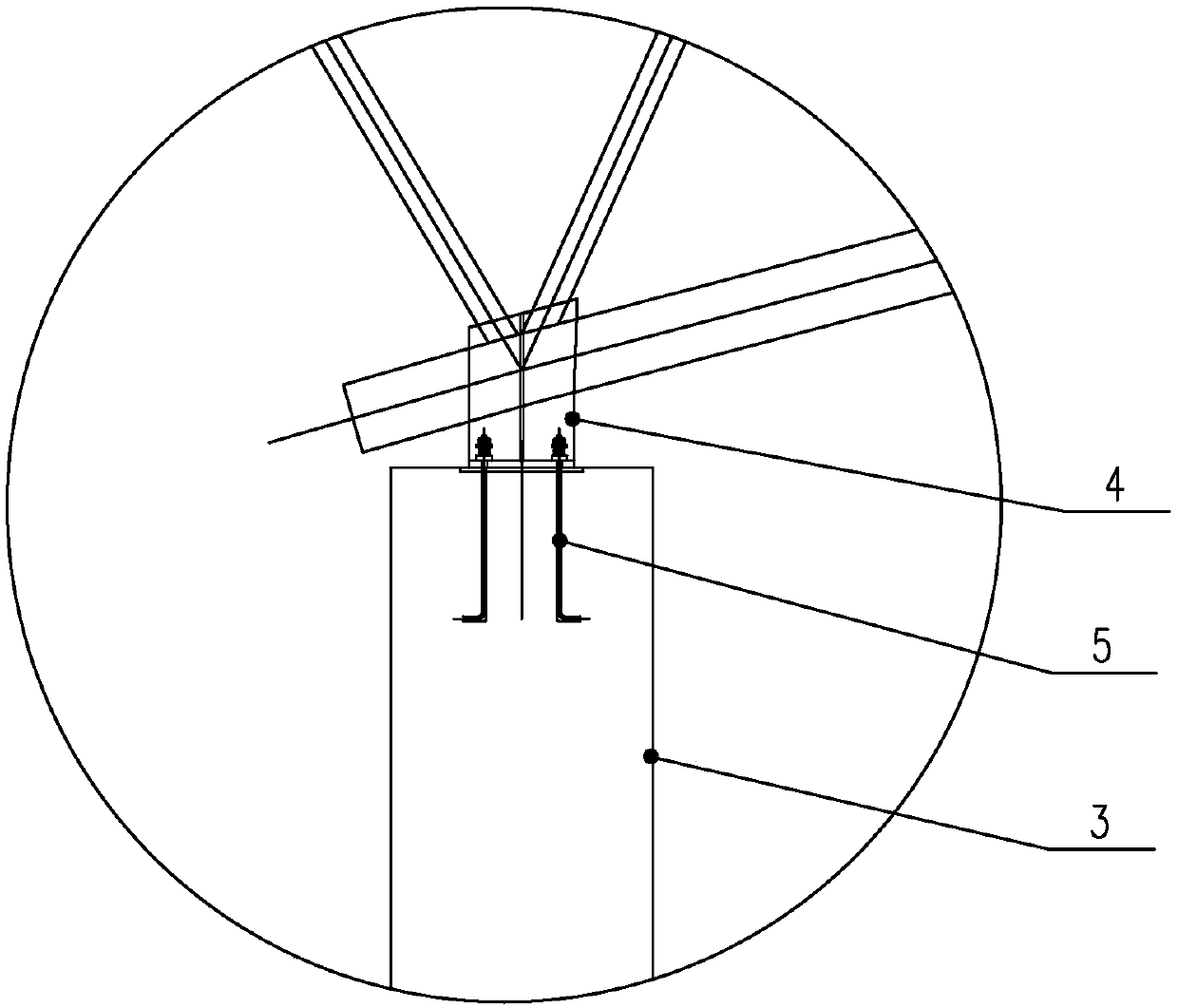

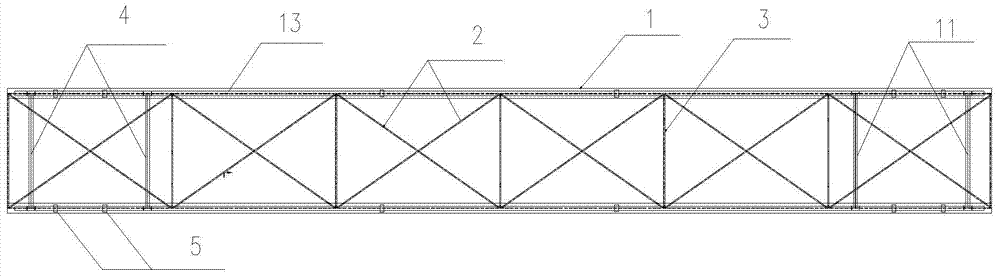

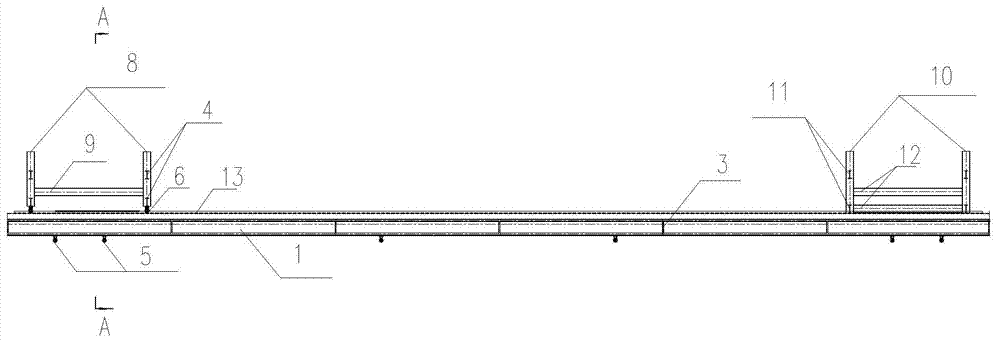

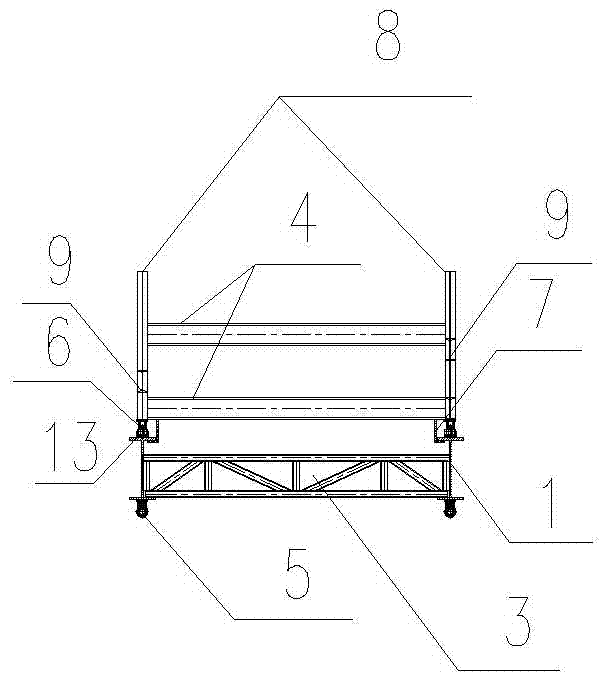

Construction technology for hoisting large-size steel truss roof from two outer sides

ActiveCN107816209AAvoid conflicting contradictions of cross-implementationLow costBuilding material handlingFalseworkLarge size

The invention discloses a construction technology for hoisting a large-size steel truss roof from two outer sides. The construction technology includes the following steps: a, performing constructionpreparation; b, performing primary truss hoisting installation preparation; c, performing primary truss ground assembly; d, performing cycled hoisting on a primary truss from two outer sides in stepsand performing installation; and e, installing a secondary truss according to an installation position of the primary truss. In construction, hoisting devices stand outsides and near two ends of a spatial steel truss to perform hoisting, the hoisting rated capacity demand of the hoisting devices is greatly lowered, the use efficiency of the hoisting devices is improved, and indoor places can be avoided; conflicts of crossed construction between on-site assembly and building of the spatial steel truss and lower other professional workers can be avoided; scaffolds and bearing supports can be avoided; and the construction technology is suitable for assembly and building of the spatial steel structure having a curved or irregular supporting seat, and can reduce the project cost.

Owner:浙江中南绿建科技集团有限公司

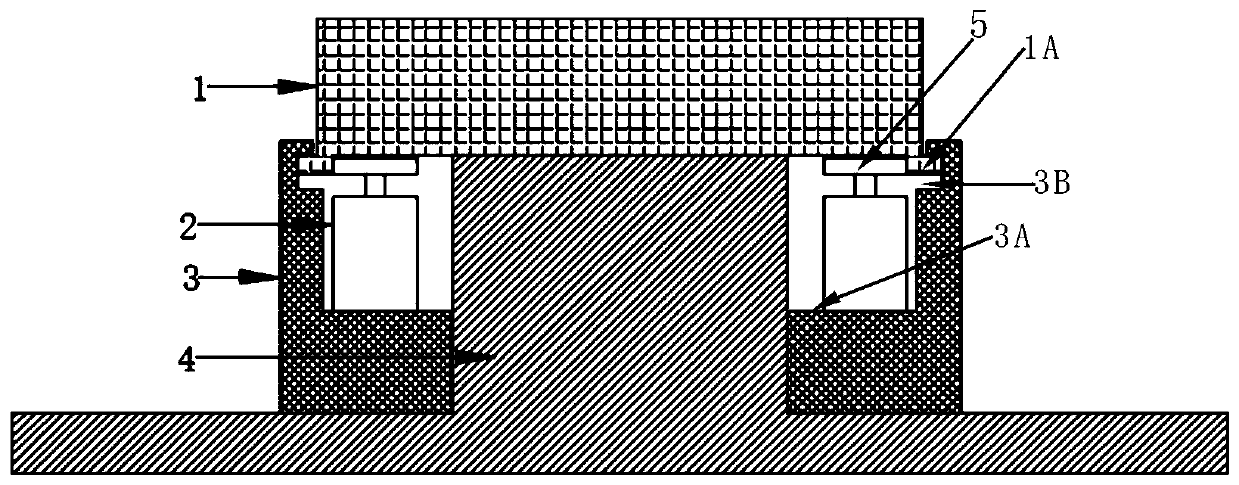

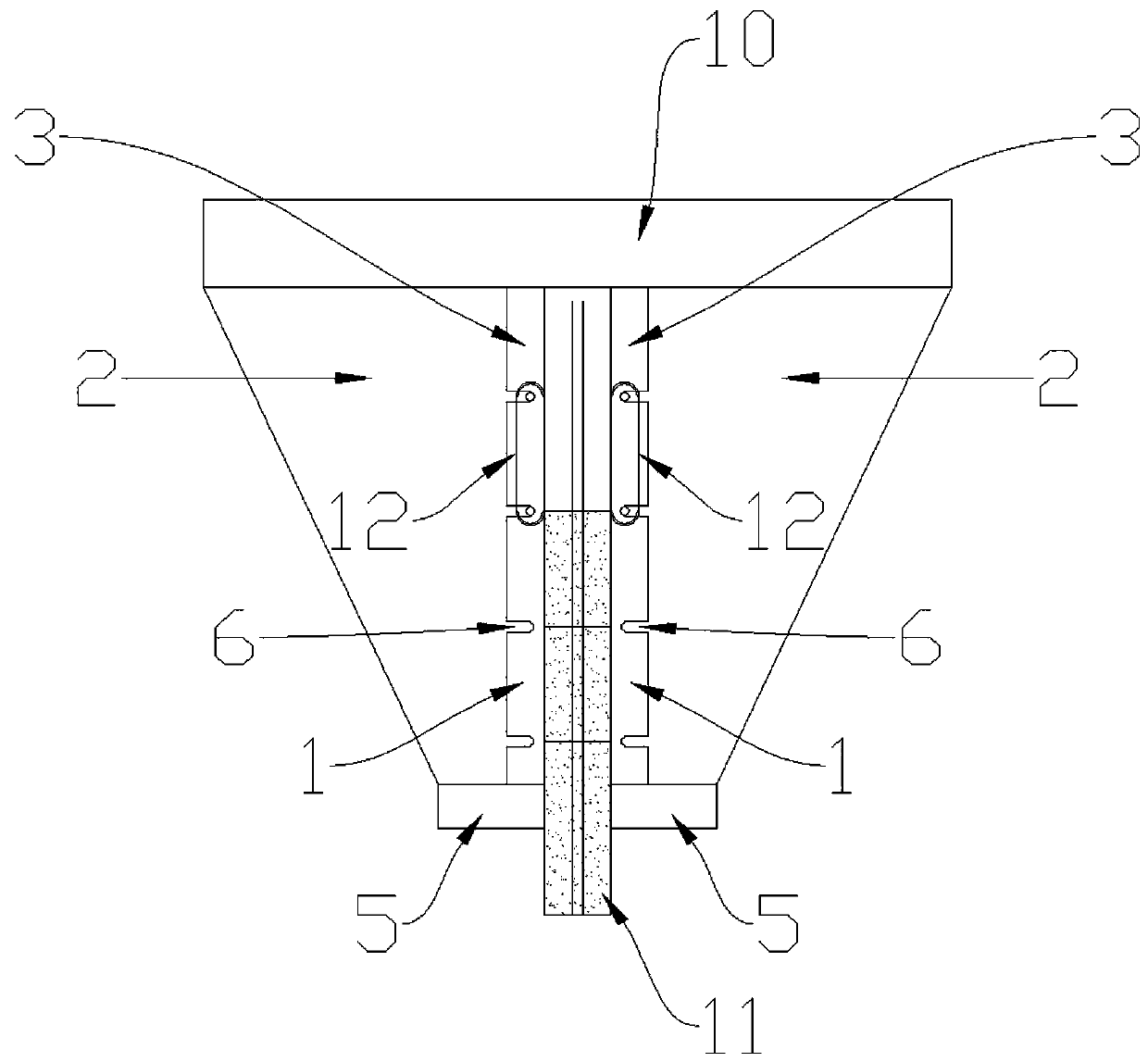

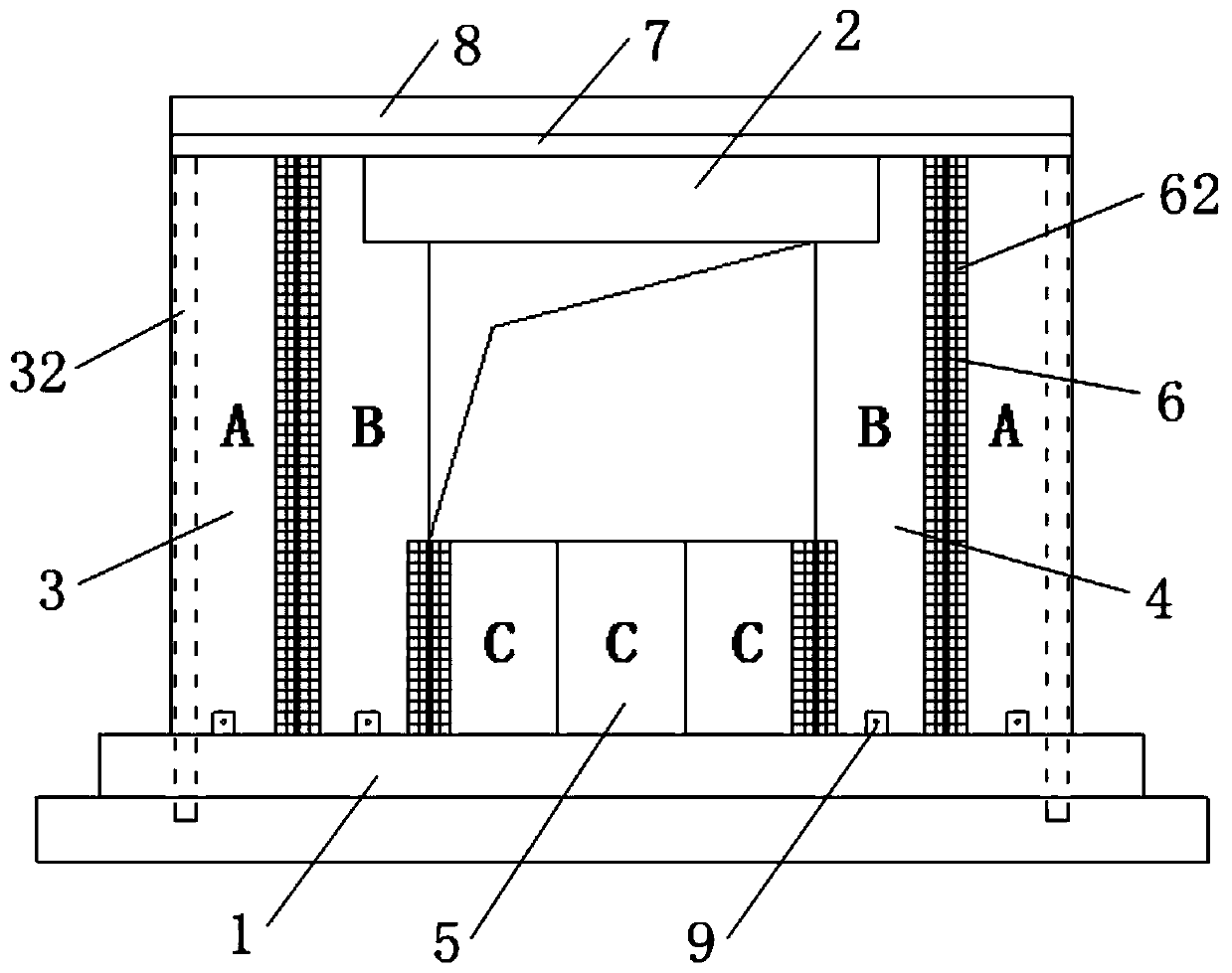

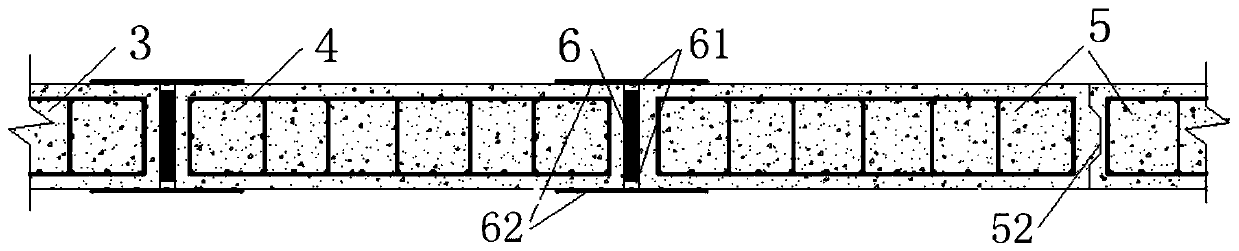

Rollover template capable of lifting and rolling over

InactiveCN110821155AReduced Lifting Capacity RequirementsDoes not affect later strength developmentForms/shuttering/falseworksArchitectural engineeringRebar

The invention discloses a rollover template capable of lifting and rolling over, which is mainly used for cast-in-place barrel body structure construction of the building engineering field, and is quick and convenient in construction. The rollover template mainly comprises a beam, reinforcing plates, channel steel, movable templates and U-shaped pliers. The working principle of the roller templateis as follows: mounting reinforcing steel bars and pouring concrete in a cavity formed by a pair of movable templates, loosening buckles at the lower ends of one pair of movable templates after concrete is finally condensed, lifting the U-shaped pliers to upwards turn over the movable templates, enabling the movable templates to de-mould from cast concrete, putting one pair of pin rolls at the upper ends of one pair of movable templates into a third row of U-shaped slots of a flange after upwards turning over one pair of the movable templates by 180 degrees, pressing the third row of bucklesagain, locking one pair of pin rolls at the upper ends of one pair of the movable templates, pouring concrete in the cavity formed by one pair of the movable templates, continuously upwards turning over the templates and pouring concrete with the same method after the concrete is finally condensed until concrete pouring work of next construction stage is accomplished.

Owner:荆门市佰思机械科技有限公司

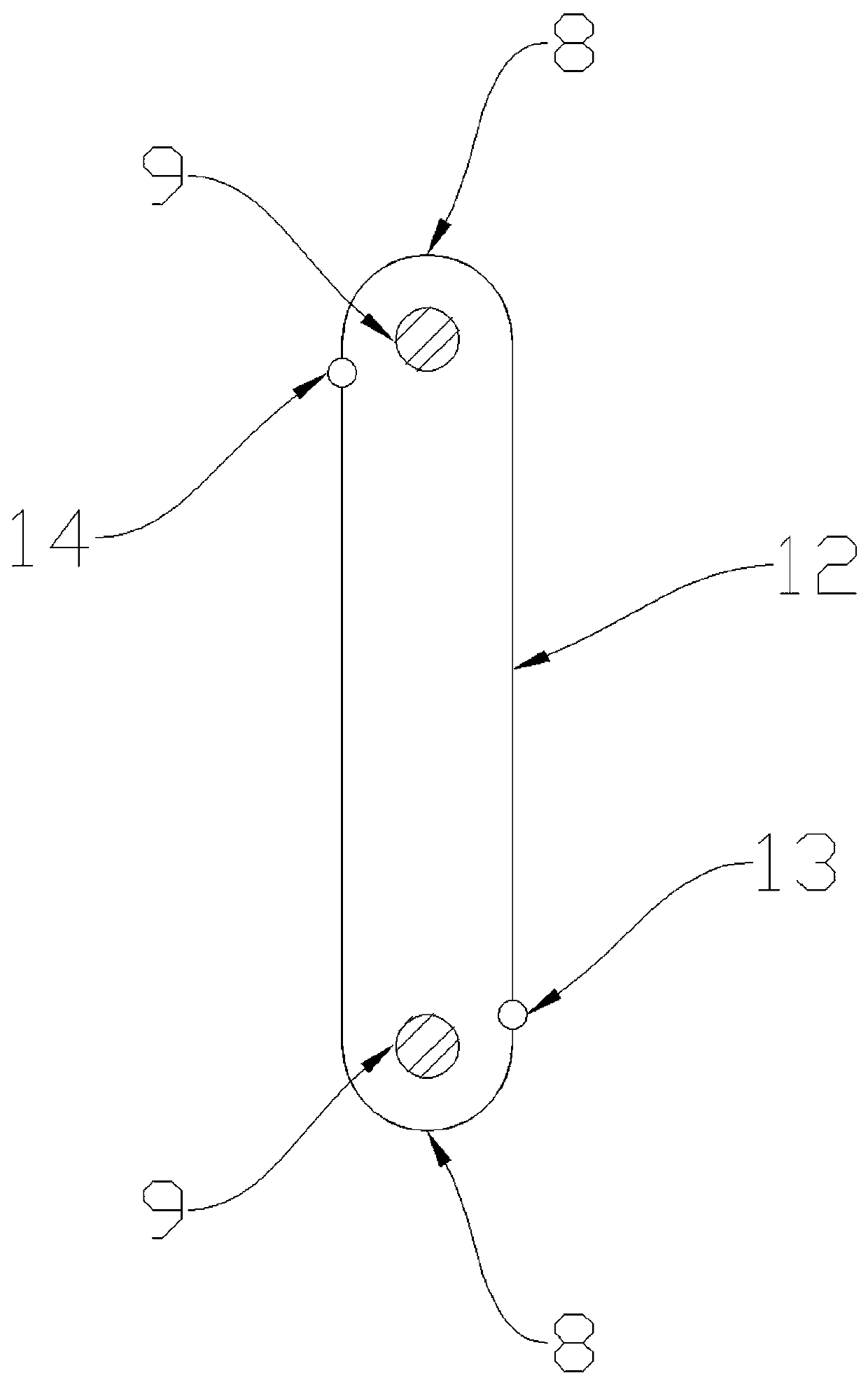

Device for shifting hanging basket assembly pieces and construction method

ActiveCN103498418AImprove assembly efficiencyReduced lifting capacity requirementsBridge erection/assemblyLifting capacityHanging basket

The invention discloses a device for shifting hanging basket assembly pieces and a construction method. The device comprises two main beams connected into a whole. Forwards-shifting idler wheels are arranged on the bottom faces of the main beams. A transversely-shifting trolley and a bracket are arranged on the top face of each main beam, the transversely-shifting trolleys are in sliding connection with the top faces of the main beams, and the brackets are fixed on the top faces of the main beams. According to the device, the transversely-shifting trolleys and forwards-shifting devices (the forwards-shifting idler wheels) are used, a heavy main longitudinal beam front section of a hanging basket can be lifted through a first tower crane with high lifting capacity, a light front transverse beam of the hanging basket is lifted through a second tower crane with low lifting capacity, therefore, the requirements for the lifting capacity of the tower cranes when the hanging basket is assembled can be greatly reduced, the use cost of the tower cranes is greatly reduced, and the hanging basket assembly efficiency is improved.

Owner:CCCC SECOND HARBOR ENG

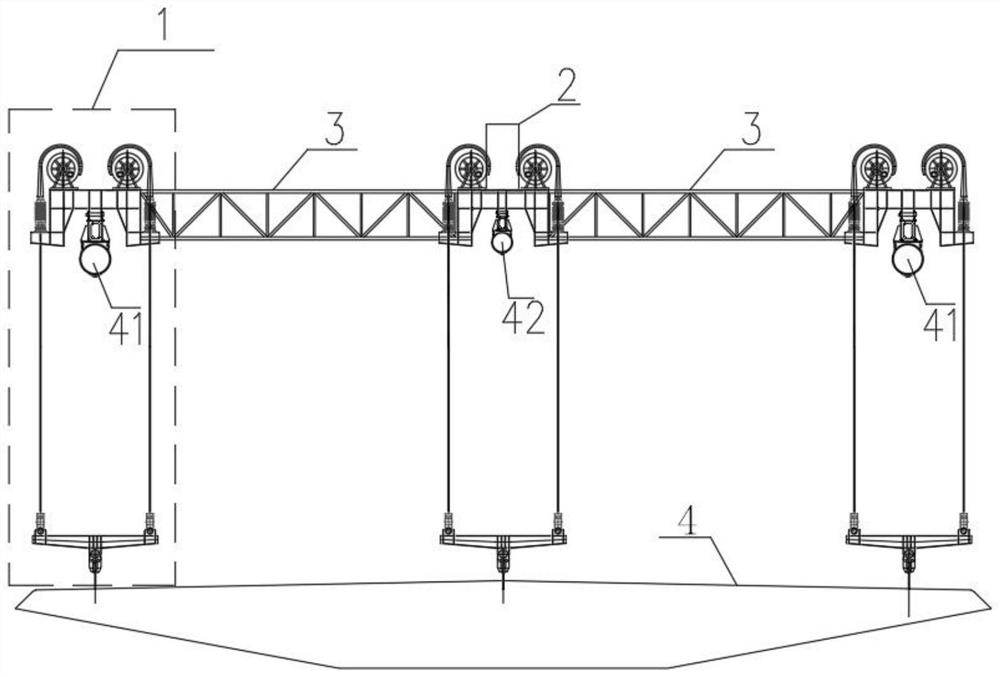

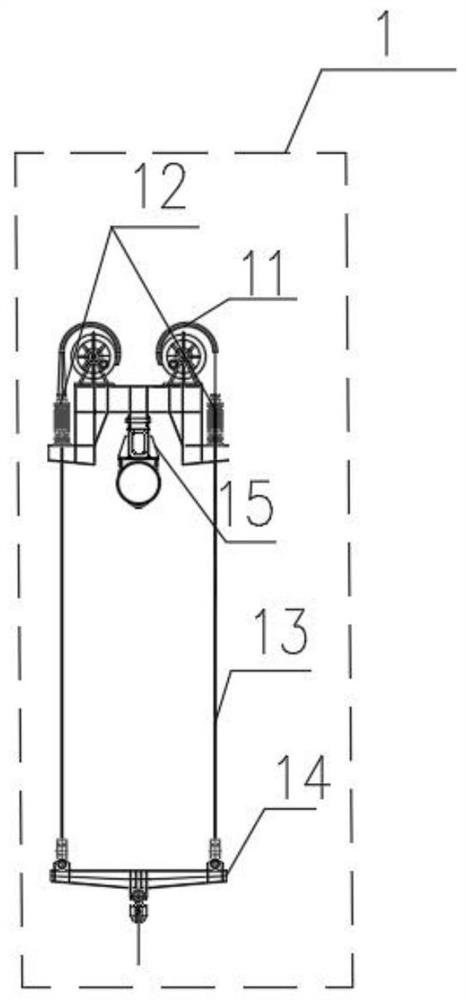

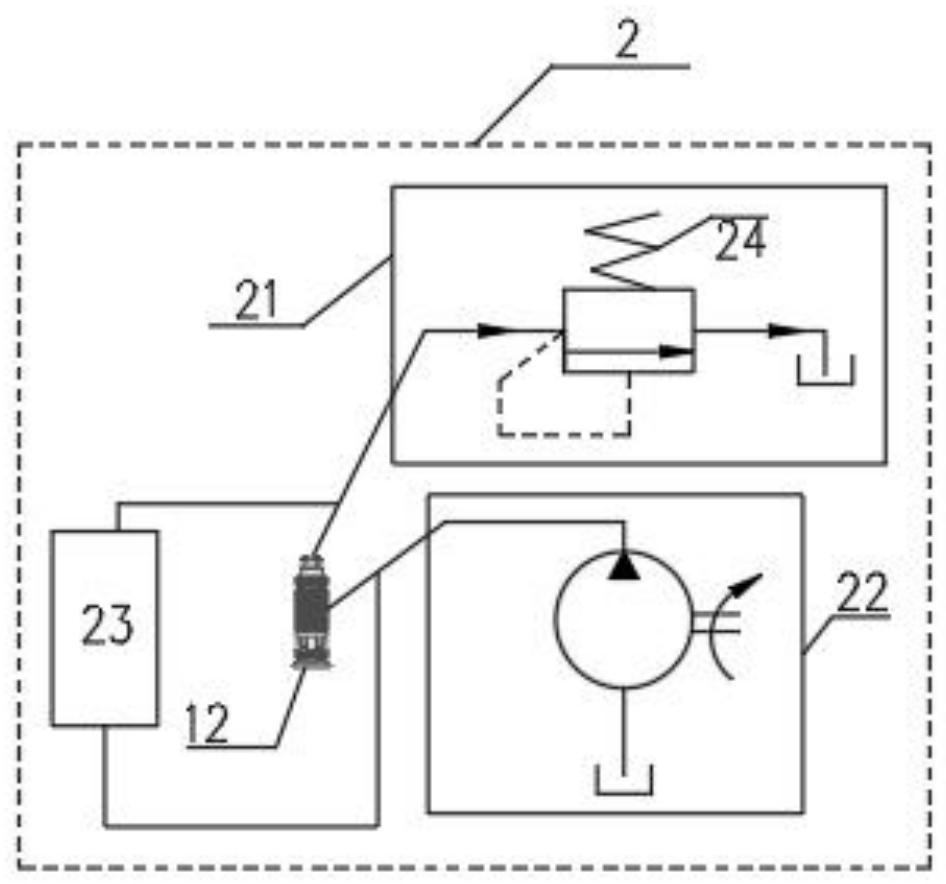

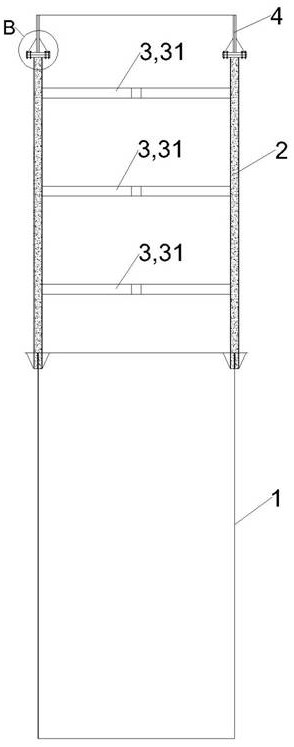

Cable-crossing crane of suspension bridge as well as application and using method of cable-crossing crane

InactiveCN111663450AReduced lifting capacity requirementsImprove economySuspension bridgeBridge erection/assemblyHydraulic control unitBridge engineering

The invention belongs to the technical field of bridge engineering. The invention relates to a cable-crossing crane of a suspension bridge as well as application and a using method of the cable-crossing crane. The cable-crossing crane comprises hoisting units, a hydraulic control unit and a cross beam; the number of the hoisting units is three; the three sets of hoisting units are sequentially connected through the cross beam from left to right; the hydraulic control unit is connected with the middle hoisting unit. According to a three-main-cable suspension bridge in the prior art, during thehoisting construction of a stiffening beam, if a two-supporting-point hoisting mode of a conventional cable-crossing crane is adopted, the requirement on the hoisting capacity of a hoisting unit is very high, and the stiffening beam is largely deformed in the hoisting process. With the cable-crossing crane of the suspension bridge as well the application and using method of the cable-crossing crane adopted, the above problem in the prior art can be solved. According to the cable-crossing crane of the suspension bridge as well the application and using method of the cable-crossing crane, one hoisting unit is arranged at each of the left position, the middle position and the right position, the hoisting unit in the middle shares loads of the hoisting units on the two sides, and therefore, the deformation of the stiffening beam is within a controllable range. The cable-crossing crane has high practical significance and research value.

Owner:CCCC SECOND HIGHWAY ENG CO LTD +1

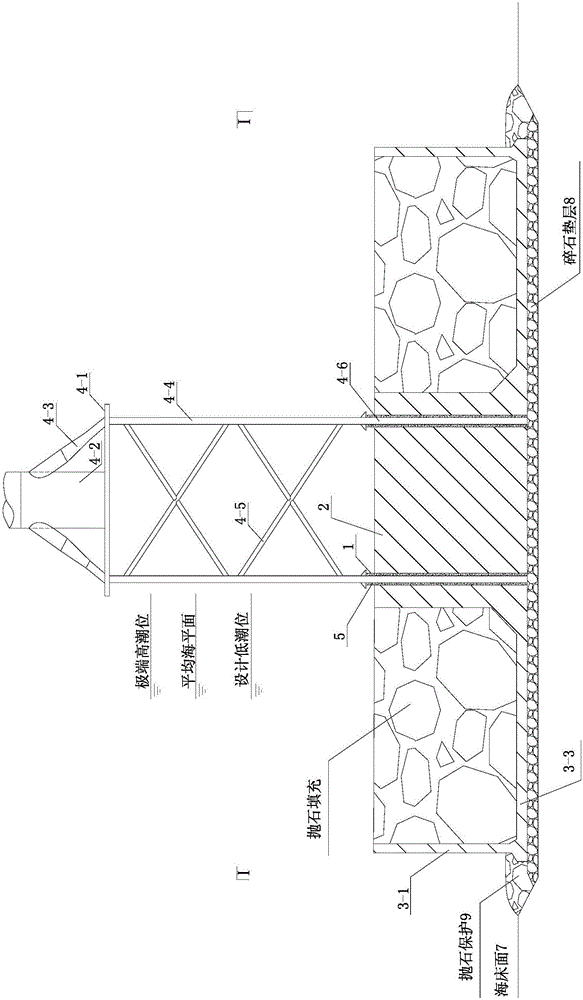

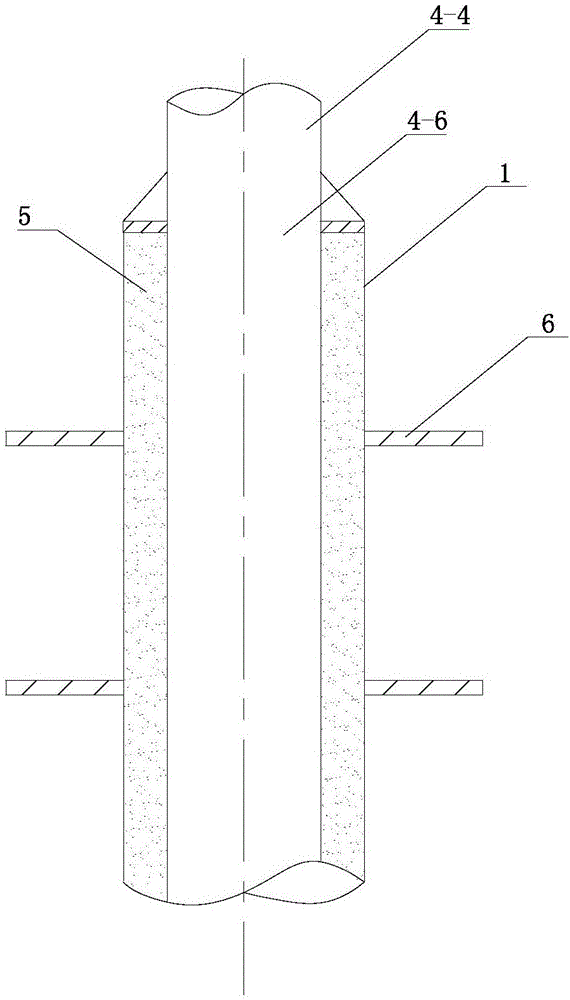

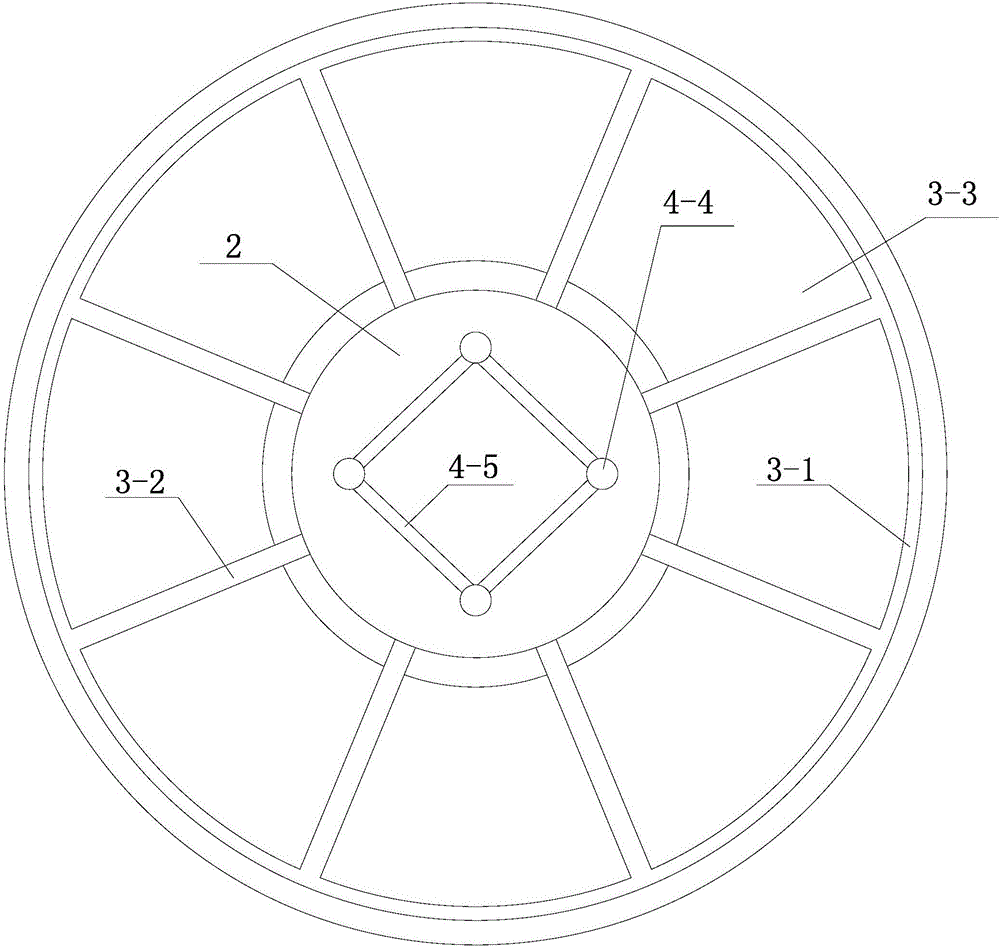

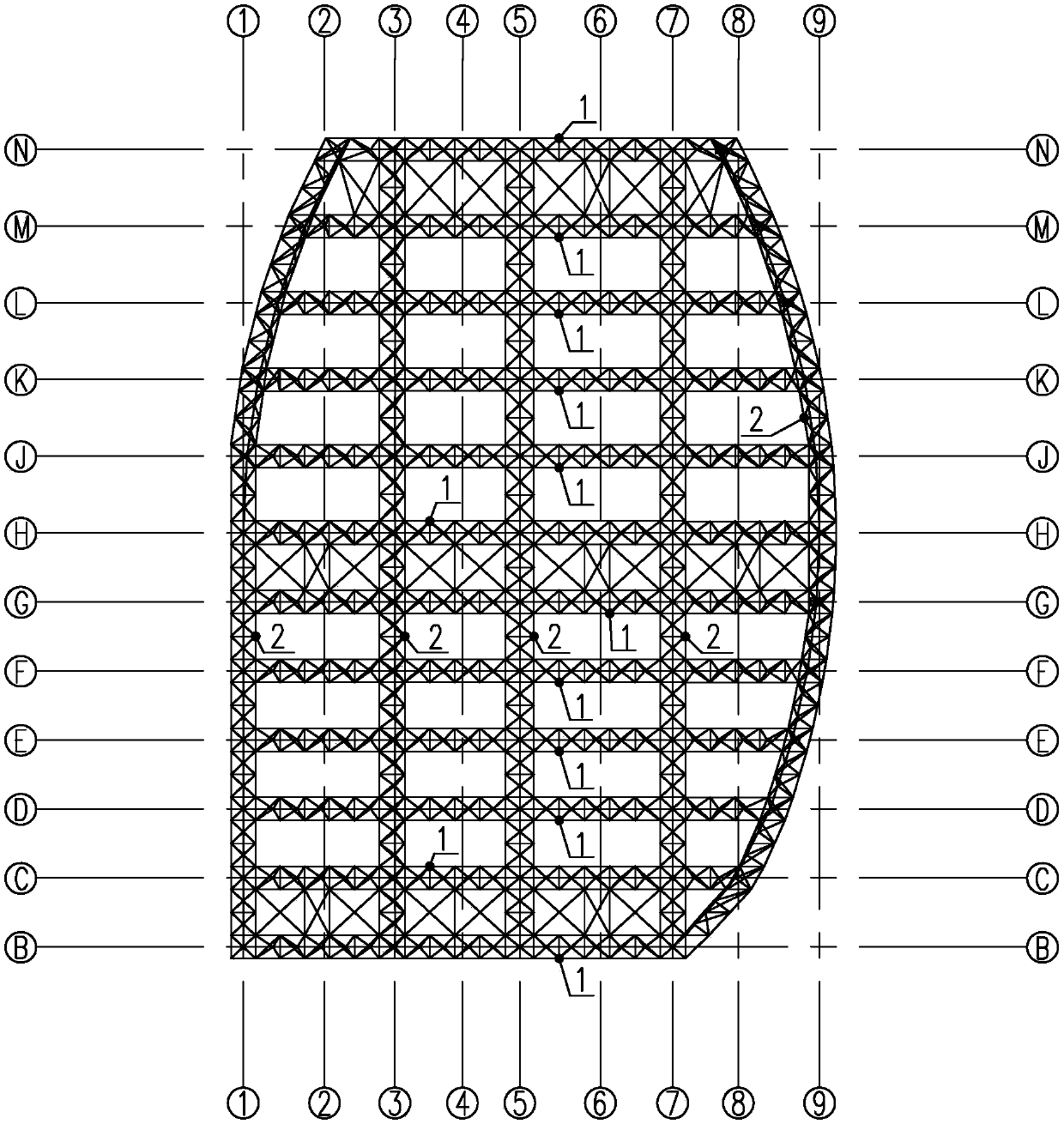

Construction method of large-diameter steel-concrete combined cylindrical structure

ActiveCN114457750ASave steelReduce construction costsArtificial islandsBreakwatersArchitectural engineeringCylinder (engine)

The invention provides a construction method of a large-diameter steel-concrete combined cylindrical structure, which comprises the following steps: manufacturing a steel cylinder body and dowel bars: manufacturing the steel cylinder body and a plurality of dowel bars, and forming a notch in the lower end part of each dowel bar; the dowel bars and the steel cylinder are installed, specifically, the dowel bars are vertically inserted into the upper end of the cylinder wall of the steel cylinder at intervals through the notches to be fixed; the supporting structure comprises a plurality of transversely-arranged supporting rods, one end of each supporting rod is connected with one dowel bar, and the other ends of the supporting rods intersect and are fixed on the central axis of the steel cylinder; manufacturing and mounting of an annular driver: fixedly connecting the annular driver with the upper end part of the dowel bar; vibration sinking construction is conducted, specifically, a vibration sinking tool is installed for vibration sinking, and after vibration sinking construction is completed, the annular replacement hitting structure and the supporting structure are dismantled; prefabricating the concrete cylinder; and mounting the concrete cylinder. According to the construction method, the construction cost can be effectively reduced, engineering manufacturing is easy, and the obtained cylindrical structure is high in durability.

Owner:CCCC FIRST HARBOR ENG

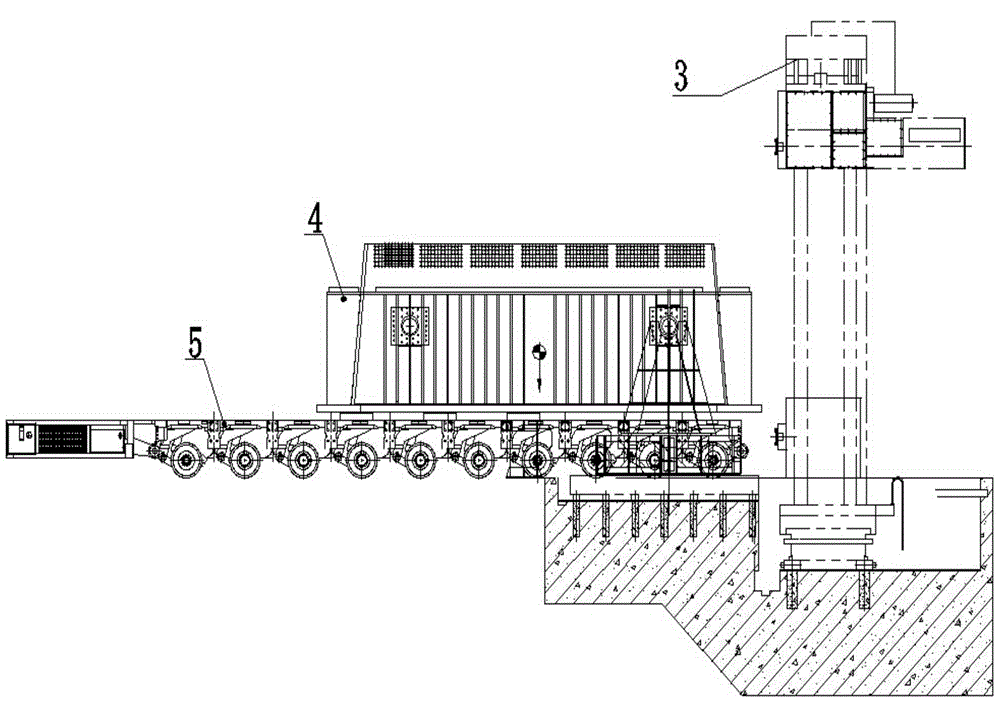

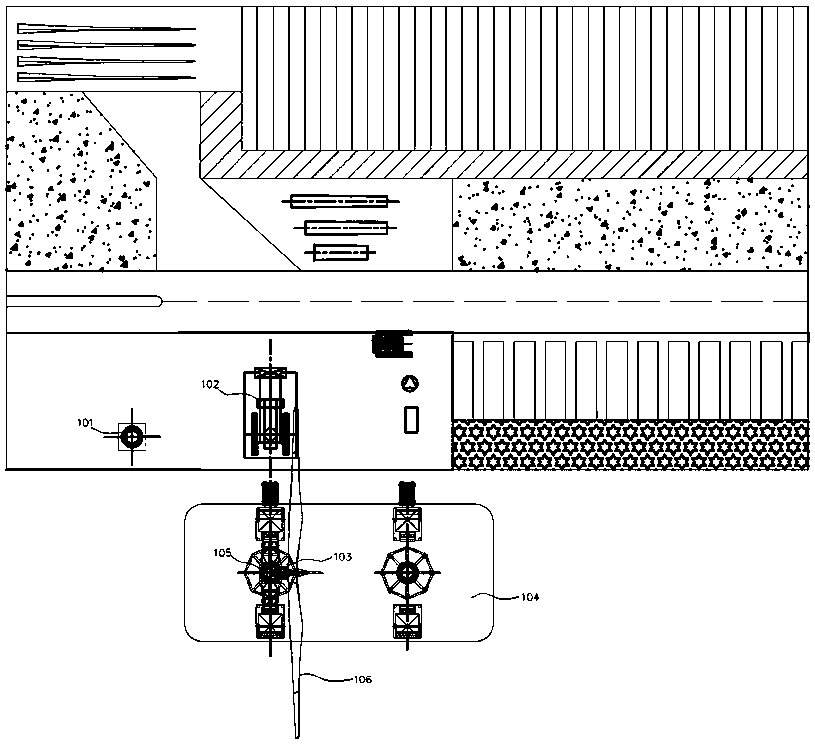

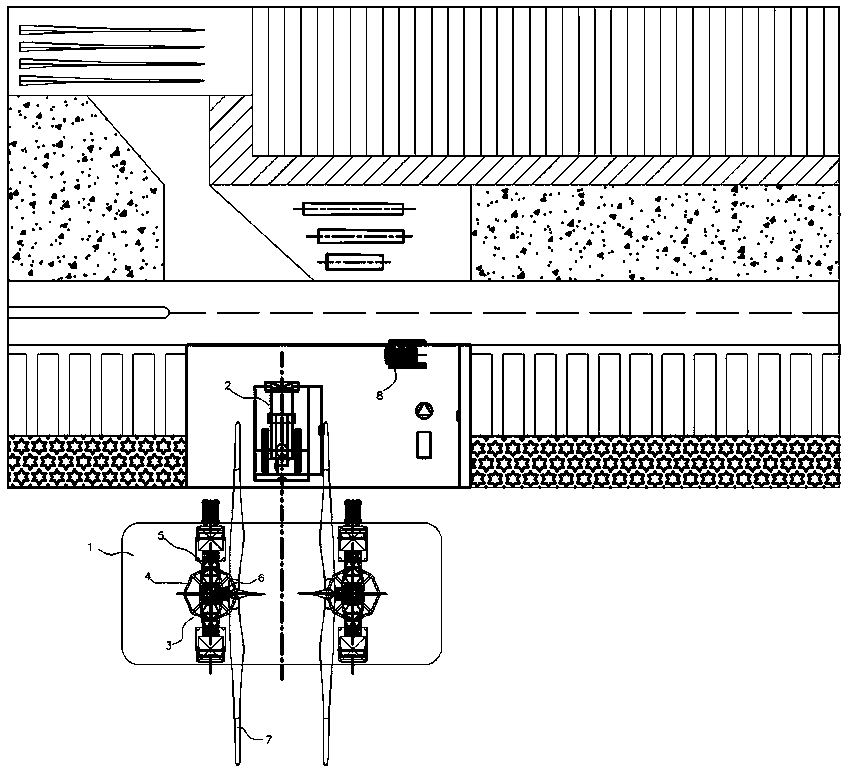

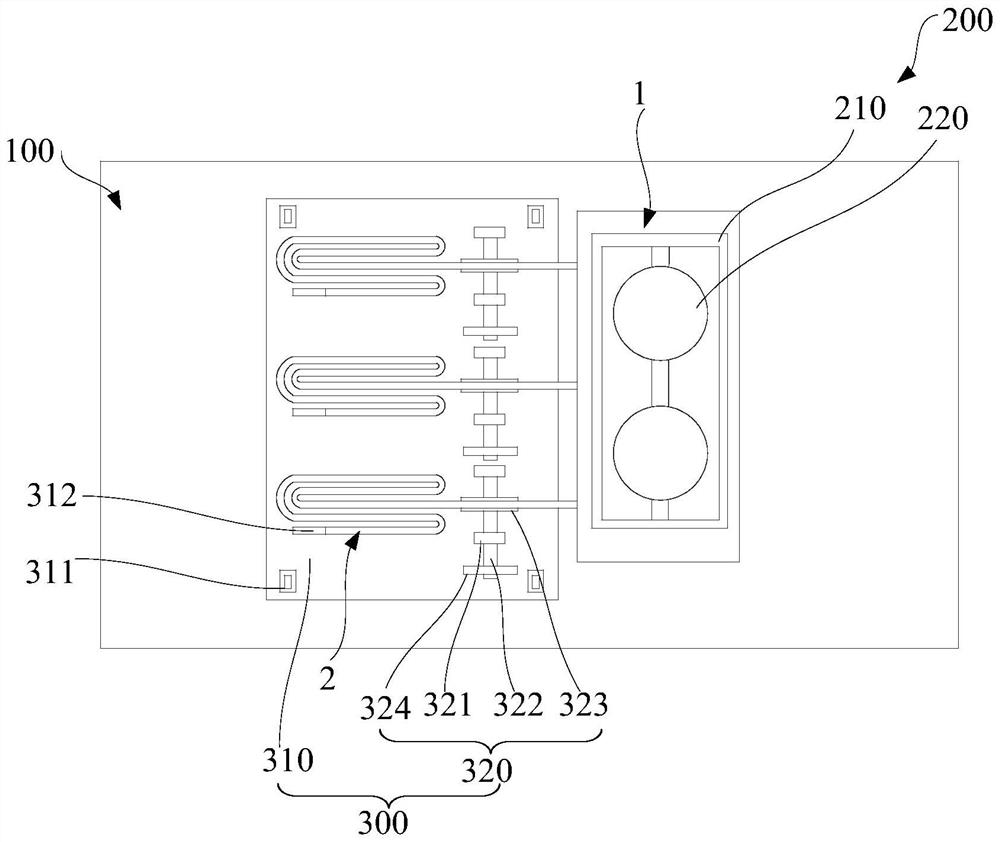

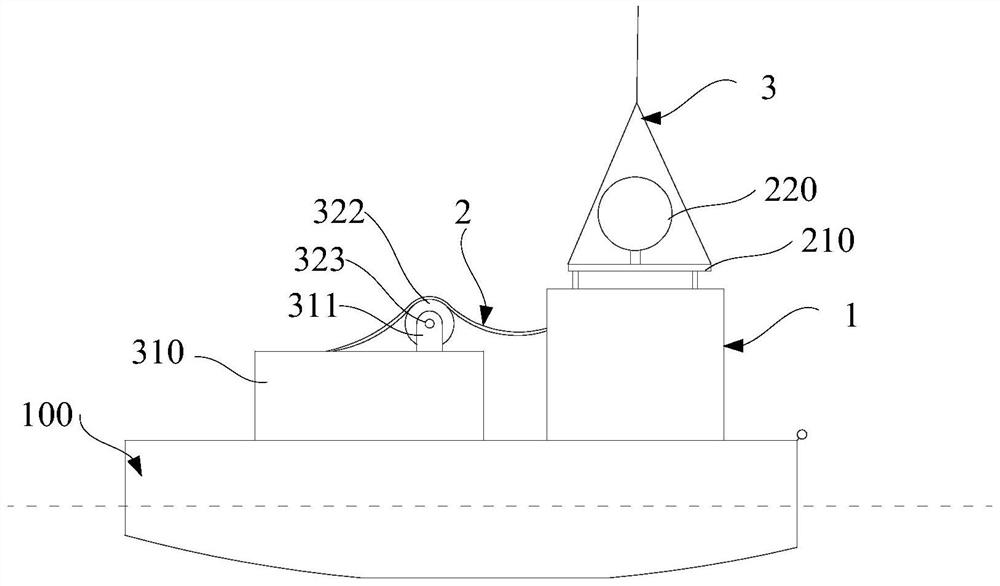

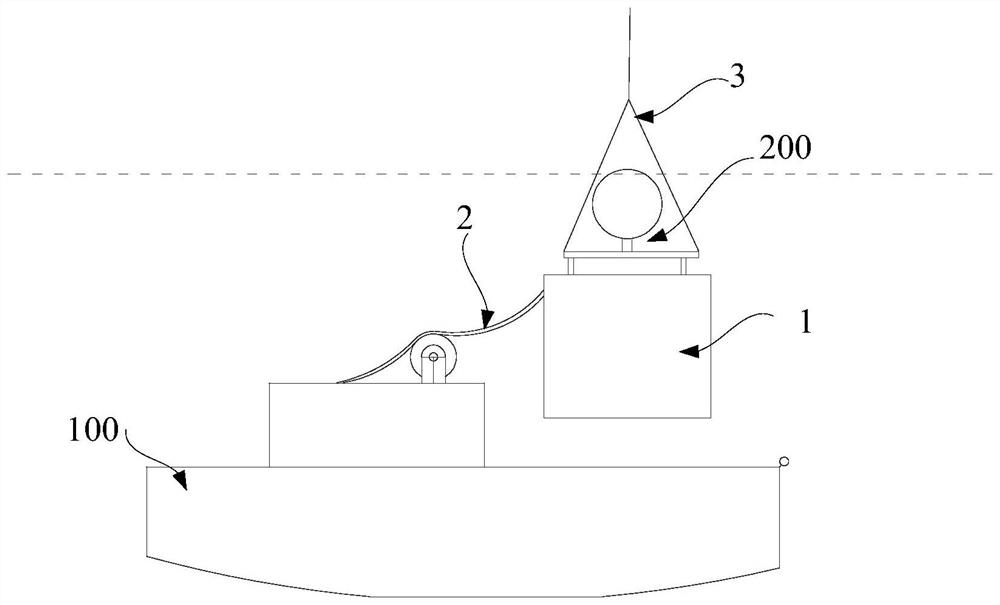

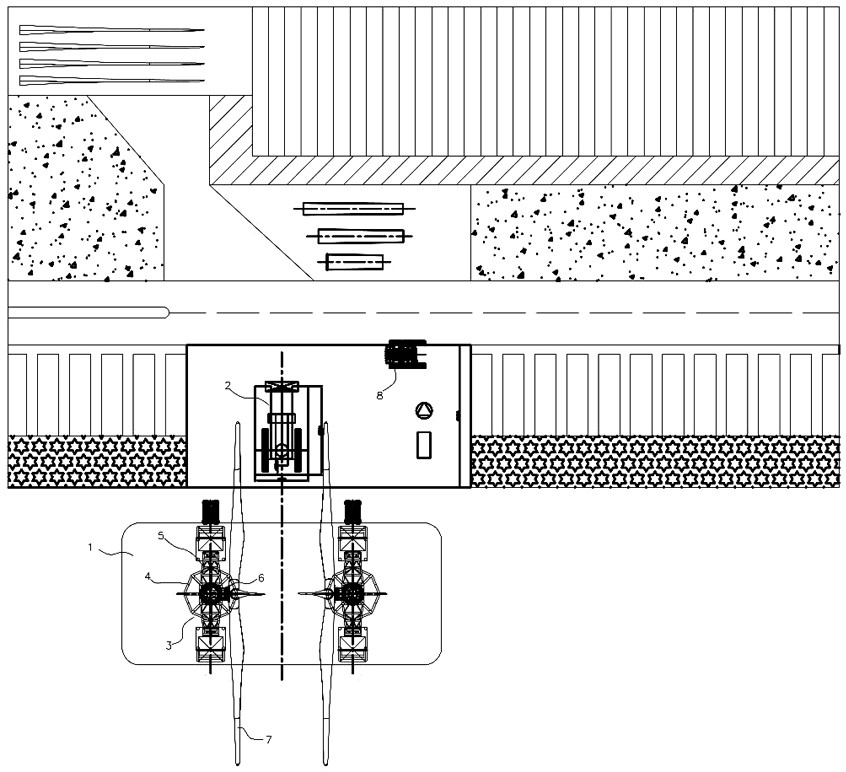

Method for assembling whole offshore wind turbine at wharf

ActiveCN110469458ALower center of gravityReduced lifting capacity requirementsWind motor assemblyWind energy generationImpellerNacelle

The invention provides a method for assembling a whole offshore wind turbine at a wharf. In the process of assembling a wind turbine, a main crane is placed on the ground at a extension line of the center line of a transport ship,when impellersare hoisted in accordance with specific conditions (that is,a high slack tide or a low slack tide period) and a certain rotation angle of an engine room, interference between a lifting arm of the main crane and the impellers during hoisting can be effectively avoided, and the bad influence of offshore waves generated during impeller hoisting can be effectively avoided,after the impellersare installed, the impellersare rotated to an inverted Y-shaped state, the interference between the impellers and the lifting arm of the main crane can be further avoided, and the center of gravity of the whole wind turbine can be made to relatively lower at the same time, the fact thatthe interference between a lifting hook and blades of the impellersis not generatedwhen the whole machine is hoisted in an installation position of the offshore wind turbine is met, and collision between the main crane and the blades when the main crane holds upa mast during assembling the impellers on an adjacent station can be further avoided.

Owner:GUANGDONG POWER ENG

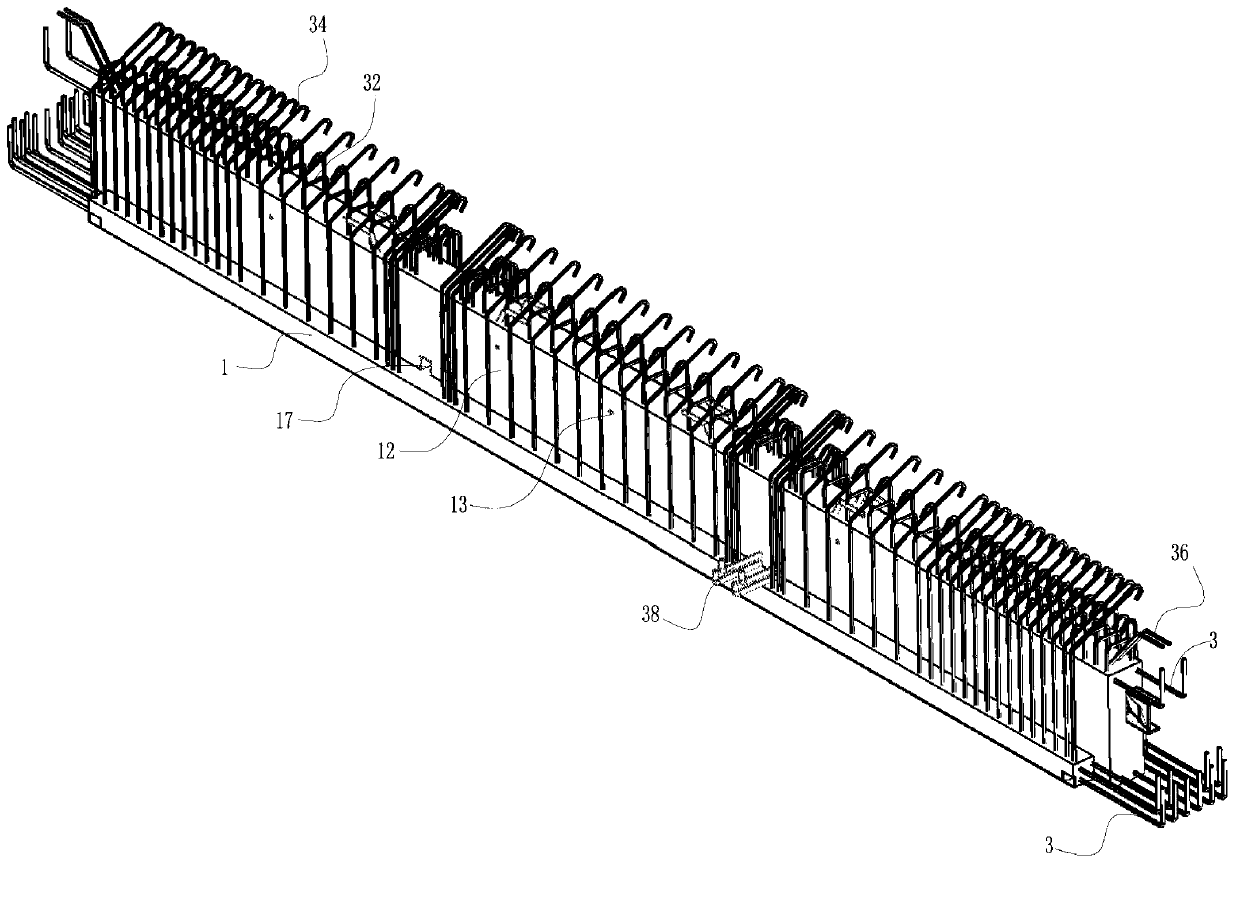

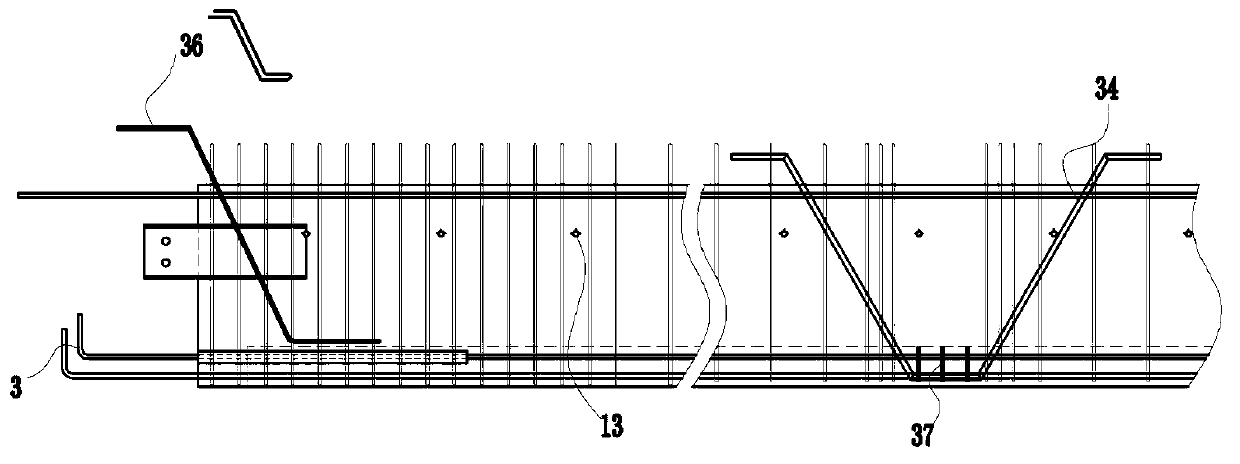

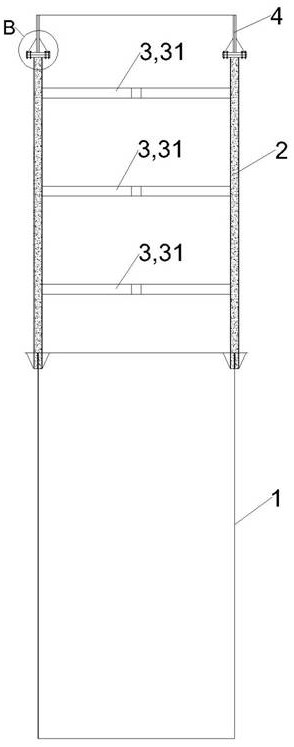

Method for arranging upper steel bars of laminated beam in penetrating mode

The invention provides a method for arranging upper steel bars of a laminated beam in a penetrating mode. The method comprises the steps that A, stirrups and lower steel bars are installed, and a prefabricated layer of the laminated beam is constructed, wherein the positions, close to the overlapped places of both ends of the stirrups of an end portion area of a cast-in-situ column, of the prefabricated layer of the laminated beam are located on the upper part of the prefabricated layer of the laminated beam; B, the prefabricated layer of the laminated beam is installed, and the overlapped places of both ends of the stirrups of the end portion area are opened to form openings for allowing the upper steel bars to be placed; C, the upper steel bars are arranged in a penetrating mode; and D,both ends of the stirrups which are opened are overlapped. According to the method for arranging the upper steel bars of the laminated beam in a penetrating mode, the positions, close to the overlapped places of both ends of the stirrups of the end portion area of the cast-in-situ column, of the prefabricated layer of the laminated beam are located on the upper part of the prefabricated layer of the laminated beam, the overlapped places of both ends of the stirrups of the end portion area are opened after the prefabricated layer of the laminated beam is installed, and the upper steel bars canbe easily inserted into the stirrups, and therefore, the method for arranging the upper steel bars of the laminated beam in a penetrating mode can easily arrange the upper steel bars of the laminatedbeam in a penetrating mode.

Owner:CHINA MCC20 GRP CORP

Installation assistance system and method for large-tonnage gravity type anchoring foundation

ActiveCN113772016AEasy to installReduced lifting capacity requirementsWind energy generationAnchorsAuxiliary systemBuoyant flow

The invention discloses an installation assistance system and method for a large-tonnage gravity type anchoring foundation. The system comprises a semi-submerged ship, a hoisting assistance device and hoisting equipment, and the semi-submerged ship is used for bearing the gravity type anchoring foundation; the hoisting assistance device is detachably mounted on the gravity type anchoring foundation; the hoisting equipment is used for hoisting the gravity type anchoring foundation in the submerging process of the semi-submerged ship, the hoisting assistance device generates buoyancy when encountering water to hoist the gravity type anchoring foundation, and the buoyancy generated by the hoisting assistance device is smaller than the gravity of the gravity type anchoring foundation. By the adoption of the installation assistance system and method for the large-tonnage gravity type anchoring foundation, the requirement of the large-tonnage gravity type anchoring foundation for the hoisting capacity of hoisting equipment can be effectively lowered, and the gravity type anchoring foundation can be smoothly installed.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP +1

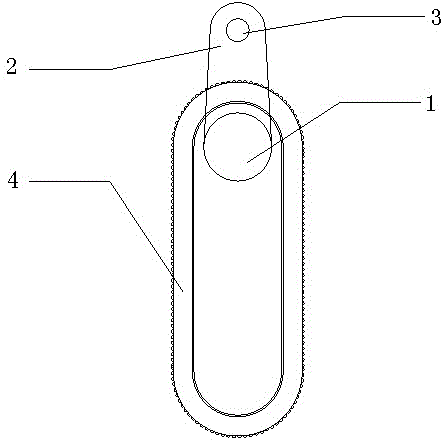

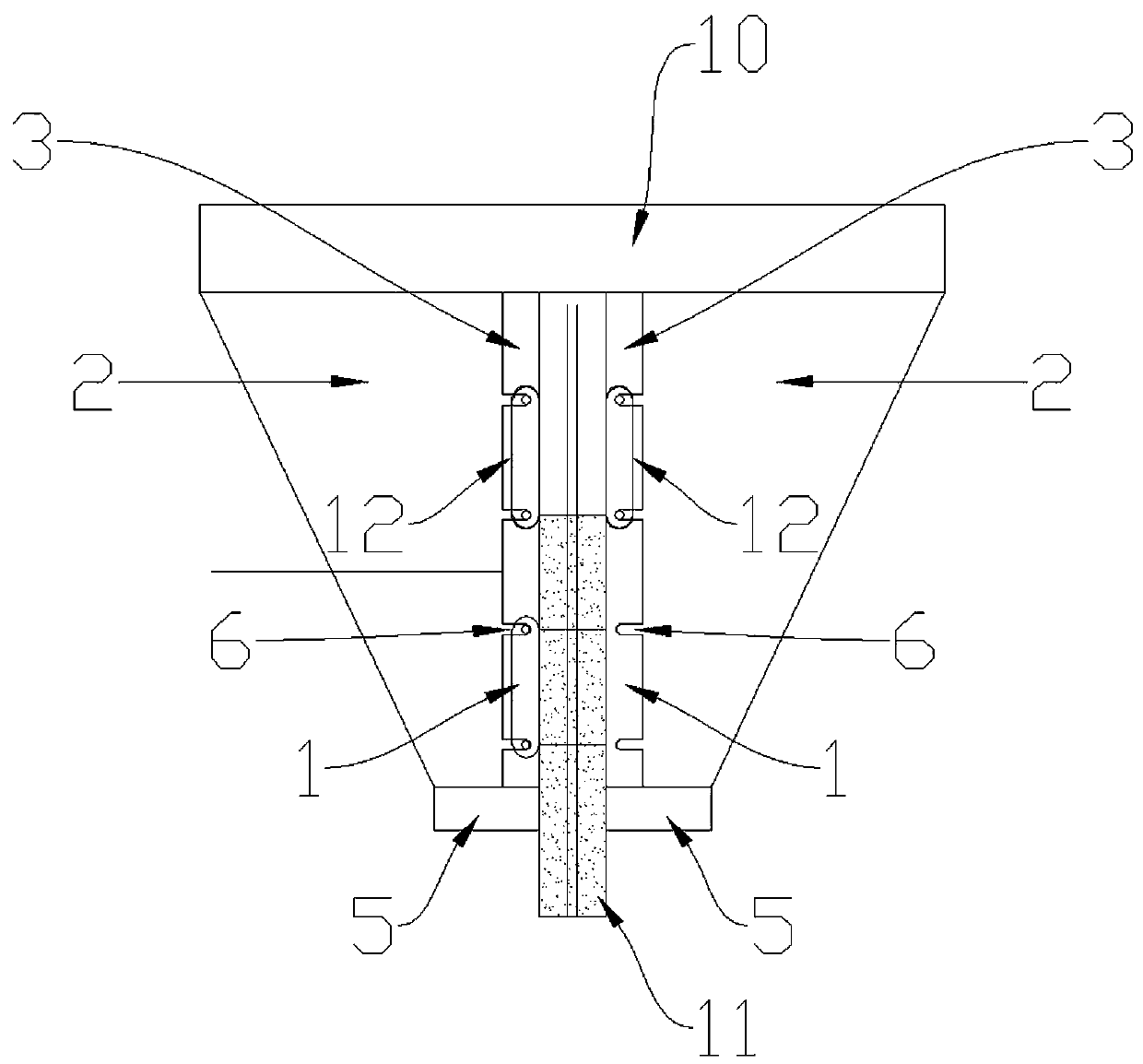

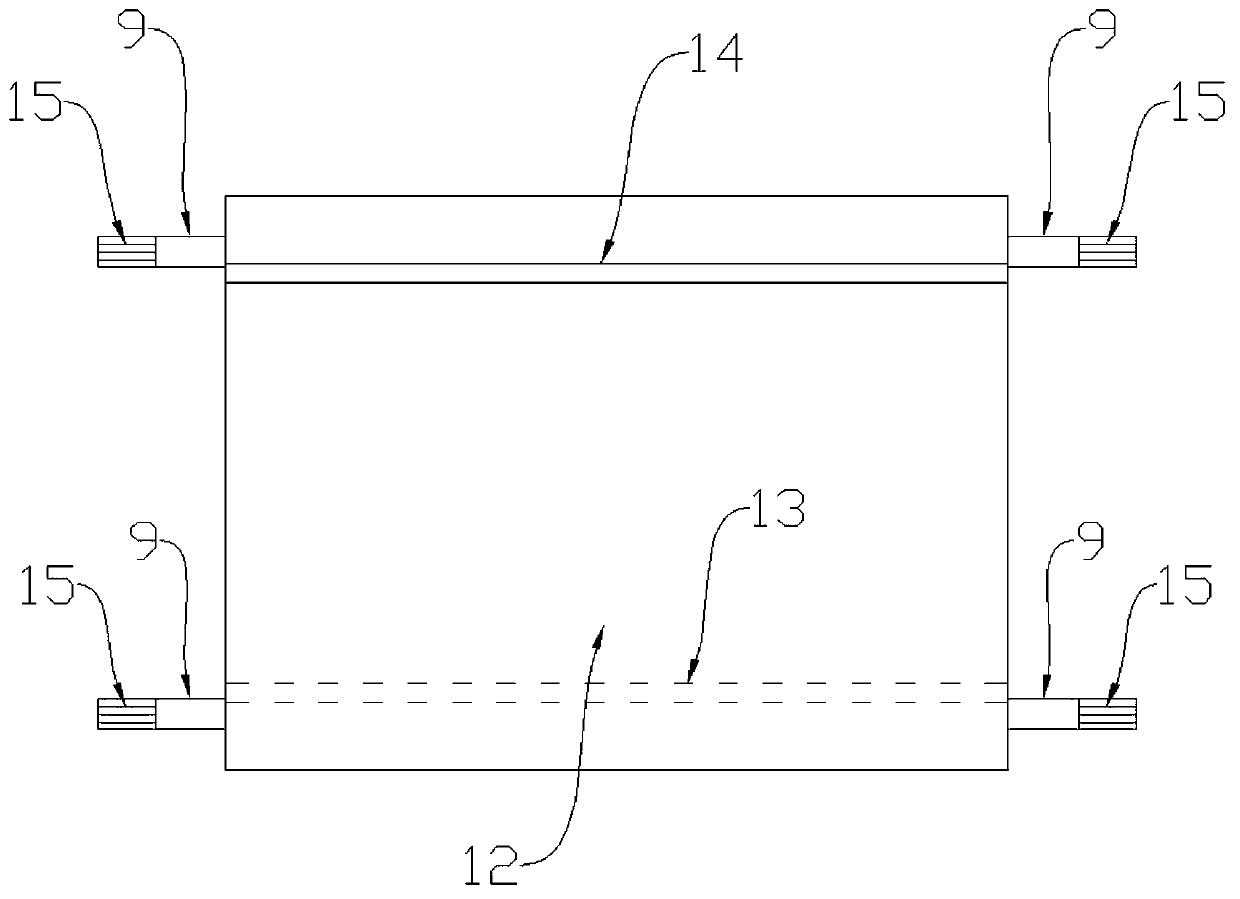

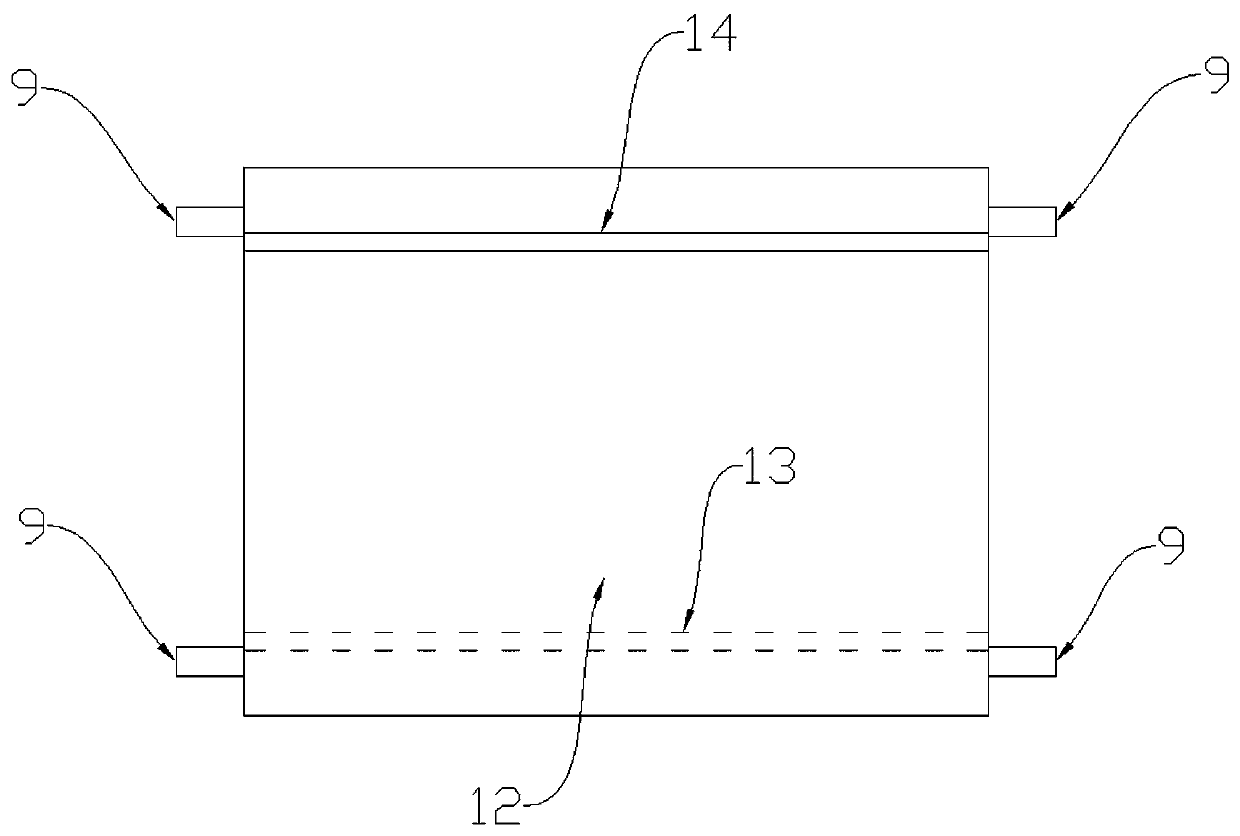

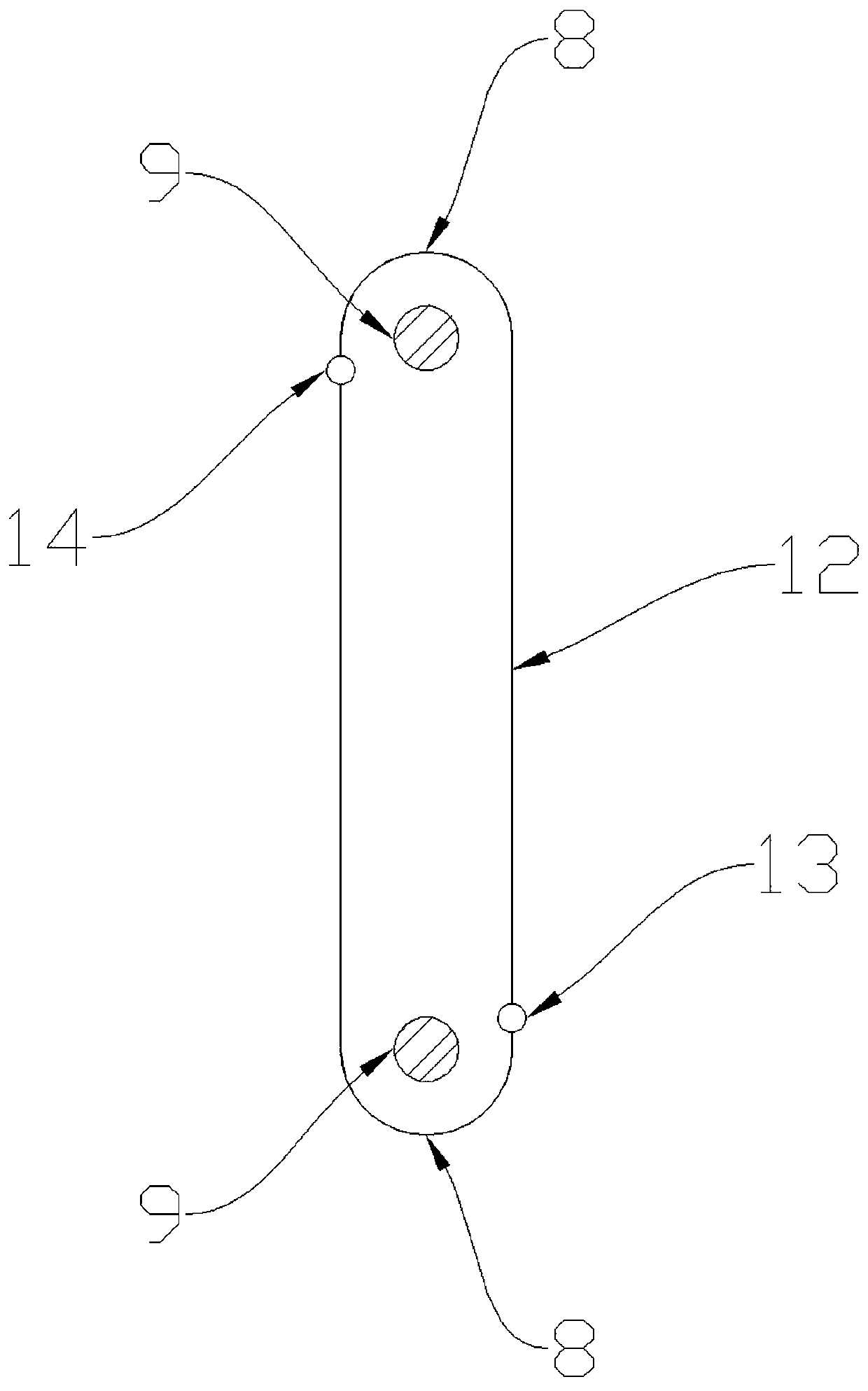

Rollover formwork for climbing formwork device

ActiveCN110821153AReduced Lifting Capacity RequirementsDoes not affect later strength developmentForms/shuttering/falseworksRolloverArchitectural engineering

The invention discloses a rollover formwork for a climbing formwork device, and is mainly used for structural construction of cast-in-place cylinders in the field of constructional engineering. By means of the rollover formwork, convenience is brought to construction. The rollover formwork is composed of a transverse beam 10, stiffening plates 2, U-steel 3, movable formworks 12 and bottom beams. According to the working principle, steel reinforcement bars are installed in a cavity formed by the movable formworks, and concrete is poured into the cavity formed by the movable formworks; after final setting of the concrete, fasteners at the lower ends of the two movable formworks are loosened, the two movable formworks are overturned upwards, at this moment, the movable formworks are separatedfrom the poured concrete, after the two movable formworks are overturned upwards 180 degrees, two pins shafts at the upper ends of the two movable formworks are put into U-shaped grooves in the thirdrow in flanges, fasteners in the third row are pressed down, the two pin shafts at the upper ends of the two movable formworks are locked up, concrete is poured into the cavity formed by the movableformworks, after final setting of the concrete, and in the same way, the formworks continue to be overturned upwards, and the concrete is poured until the concrete pouring work during a construction period is completed.

Owner:兰陵财金产业发展有限公司

A prefabricated shear wall structure of desert sand lightweight aggregate concrete

Owner:SHIHEZI UNIVERSITY

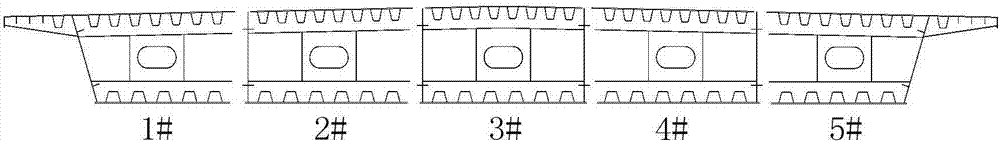

Main girder structure and main girder of streamlined multi-box girder

PendingCN109653075AImprove permeabilityIncrease flutter critical wind speedBridge erection/assemblyRailway transportEngineeringStructural engineering

The invention discloses a main girder structure of a streamlined multi-box girder. The main girder structure comprises at least one middle box grinder, two side box grinders, a plurality of connectingbeams, the bottom of the cross section of each middle box grinder is provided with a first streamlined outward projection from two sides to the middle of the bottom, railways are laid on the middle box grinder, the side box grinders are symmetrically distributed on two sides of the middle box grinders, highways are laid on the side box grinders, the bottom of the cross section of each side box grinder close to one side of the corresponding middle box grinder is provided with a second streamlined outward projection, the cross section of each side box grinder far away from one side of the corresponding middle box grinder is in a shape of a sharp corner, the connecting beams are vertically distributed at intervals and used for horizontally connecting with adjacent side box grinders and middle box grinders or middle box grinders and middle box grinders, and each connecting beam comprises at least one unit connecting beam. The invention further discloses a main grinder of the streamlined multi-box girder. The main girder structure of the streamlined multi-box girder improves wind-resistant stability.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

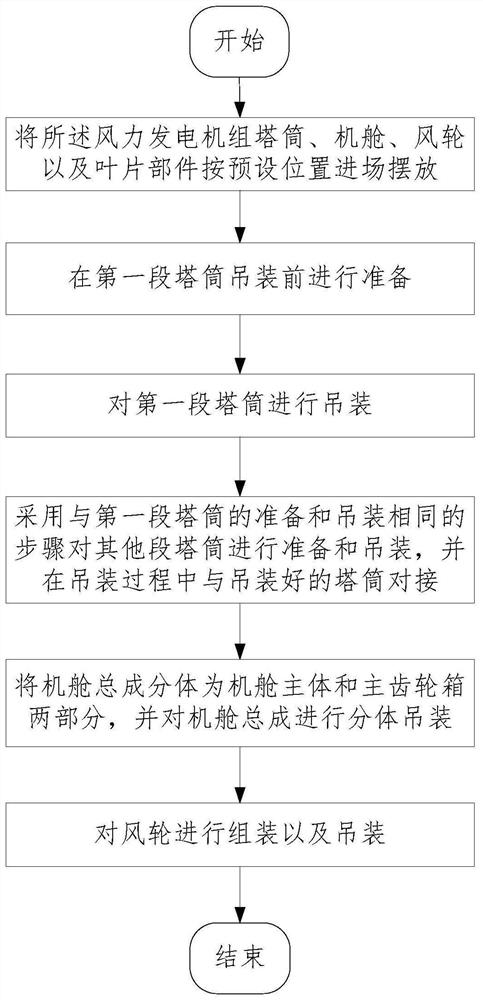

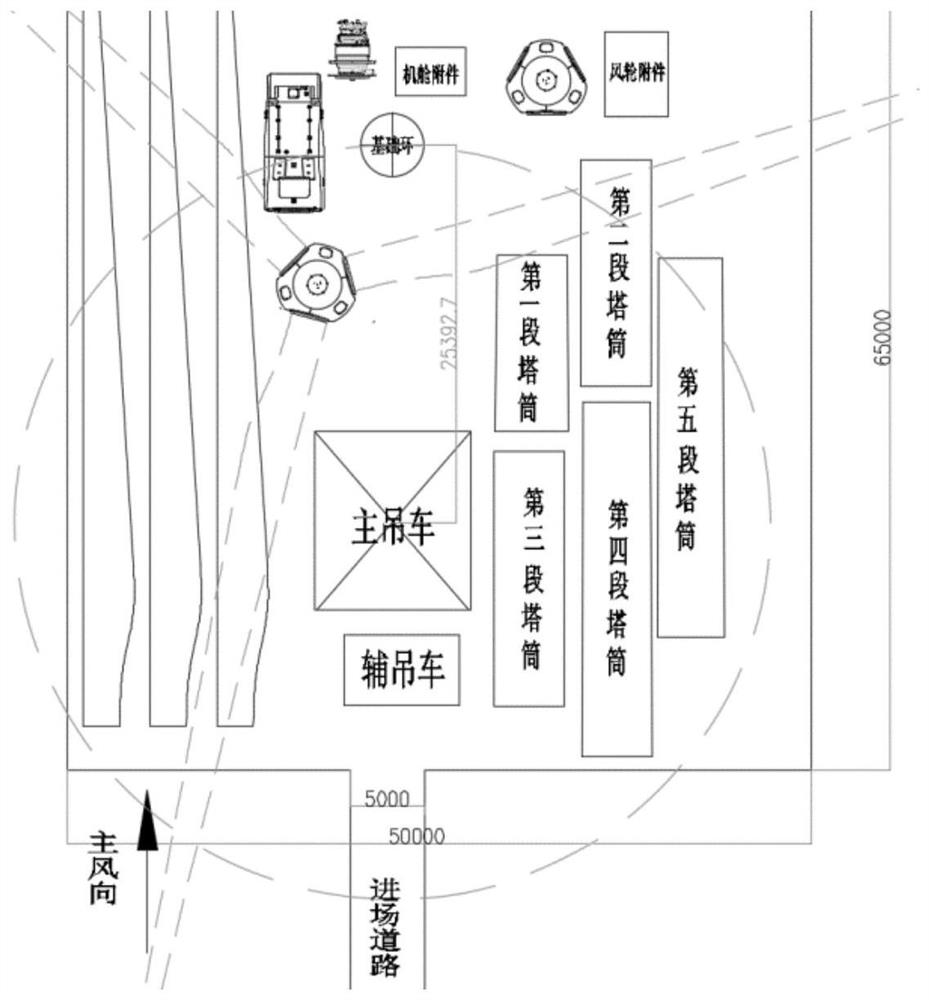

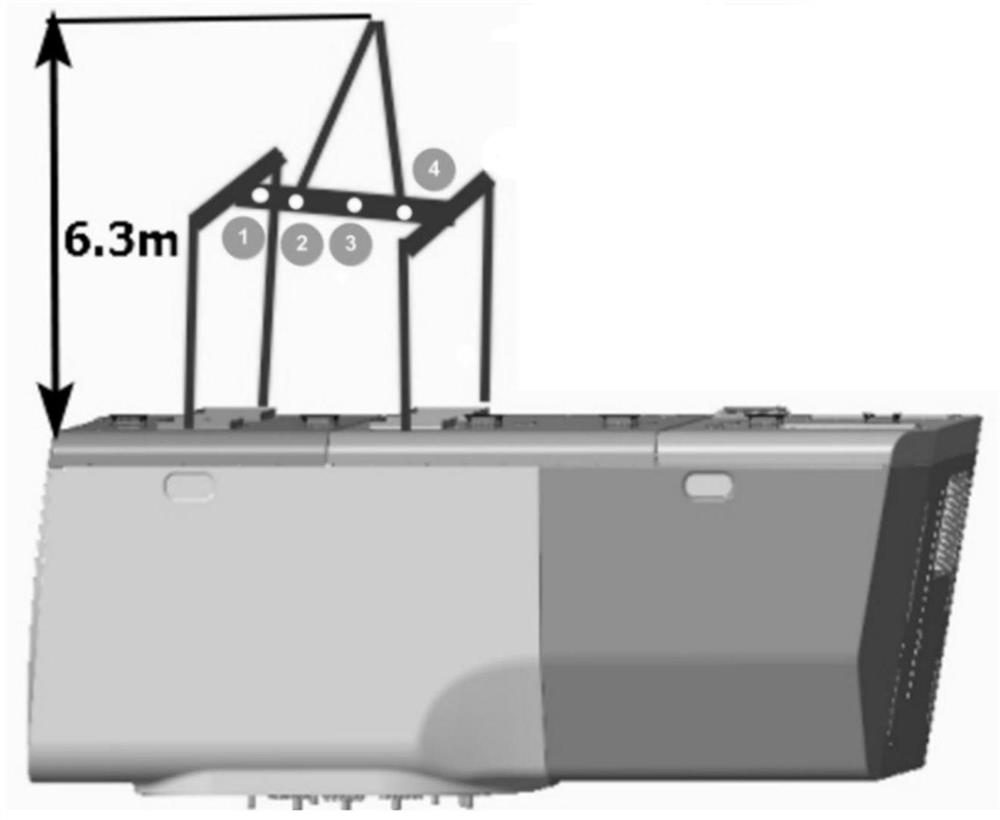

Split type hoisting method for land wind turbine generator set

ActiveCN112249874AImprove hoisting efficiencyMeet the requirements not to exceed 100tWind energy generationLoad-engaging elementsNacelleMarine engineering

The invention relates to a split type hoisting method for a land wind turbine generator set. A cabin of a 3.XMW set is divided into a cabin body and a main gear box for hoisting, so that the weight ofeach part is controlled within 80 t; and the steps of part placement, detection and the like in the hoisting process are further combined, so that split type hoisting of the wind turbine generator set is achieved, the requirement that the total weight of large single-vehicle transportation cannot exceed 100t according to the current national policy can be met, and the hoisting requirement of mainstream large cranes in the market in the prior art can also be met; and meanwhile, the hoisting frequency of a main crane is reduced, the hoisting period of the single wind turbine generator set is shortened, and the hoisting efficiency of the wind turbine generator set is improved.

Owner:XUCHANG XUJI WIND POWER TECH

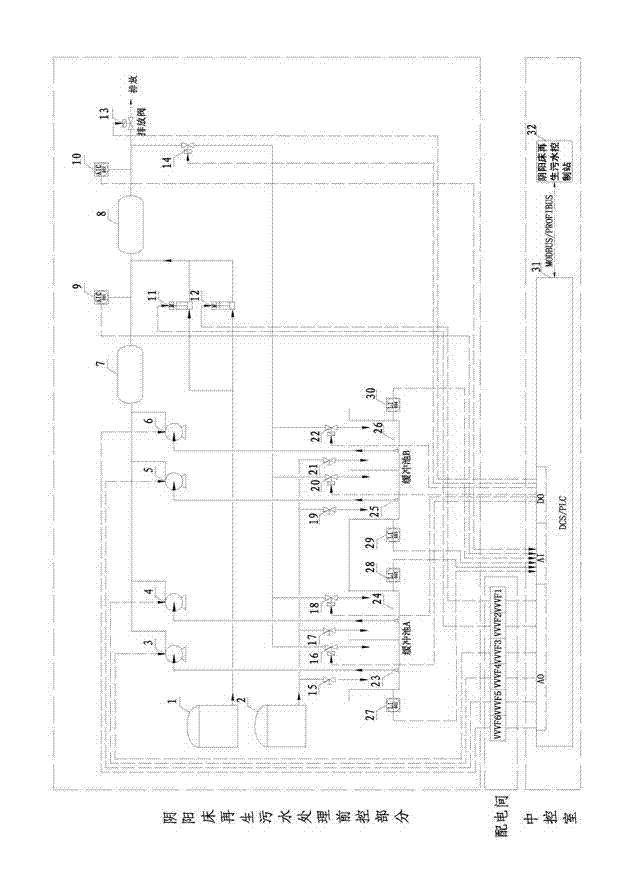

Anion and cation bed regeneration sewage treatment pH control system

InactiveCN102249391BReduced Lifting Capacity RequirementsImprove utilization efficiencyControlling ratio of multiple fluid flowsChemical variable controlPh controlBuffer tank

The invention relates to an anion and cation bed regeneration sewage treatment pH control system. The system comprises an anion and cation bed regeneration sewage treatment front control part, a central control room, an anion and cation bed regeneration sewage control station and a power distribution room. By a complete pipeline neutralization mode and a regulation and control technology, througha control combination with a lift pump, sewage in a buffer tank is mixed and subjected to neutralization reaction by a static mixer, the lift pump is completely or partially controlled by a frequencyconverter to ensure that premixing, dosing and discharging operation can be performed as long as acidic sewage exists in the buffer tank, the existing acid and alkali in the sewage are furthest used for preneutralization, buffering and discharging are performed simultaneously, and the utilization efficiency of the buffer tank is improved.

Owner:SHENYANG KASITE TECH DEV

Single-row reinforcement sheet with fiber concrete on frames and common concrete in middle and manufacturing method

InactiveCN105863152AImprove brittle defectsHigh tensile strengthConstruction materialFiberCrack resistance

The invention provides a single-row reinforcement sheet with fiber concrete on frames and common concrete in the middle and a manufacturing method, and belongs to the field of manufacturing of concrete slabs in building structure engineering. Fibers meeting different structure requirements are adopted by the fiber concrete according to design requirements, the common concrete is adopted except the frames of the sheet, the strength and diameter of reinforcement meshes arranged on the frames are greater than those of steel bars of an orthogonal steel wire mesh in the middle, and therefore the sheet with the fiber concrete on the frames and the common concrete in the middle is formed. The steel bars are arranged in hooks formed by bending steel wires extending from the four sides of the steel wire mesh, and a complete reinforced mesh is precast. The fiber concrete is poured on the periphery of the sheet, and the common concrete is poured in the sheet. The initial cracking resistance of the concrete sheet is improved, shrinkage plastic cracks at the early stage of the concrete are reduced, and the single-row reinforcement sheet has great significance to solution of the prevalent problems that current concrete sheets are low in sheet frame strength, prone to collision loss and high in manufacturing cost. The sheet is easy to construct, the using number of formworks and supports in construction can be greatly reduced, operation intensity of workers is lowered, and the amount of labor used in engineering is reduced.

Owner:BEIJING UNIV OF TECH

Construction method of large-diameter steel-concrete composite cylindrical structure

ActiveCN114457750BSave steelReduce construction costsArtificial islandsBreakwatersArchitectural engineeringPrefabrication

The invention proposes a construction method for a large-diameter steel-concrete composite cylindrical structure, comprising the following steps: making a steel cylinder and dowel bars: making a steel cylinder and a plurality of dowel bars, A gap is opened at the lower end of the steel cylinder; the installation of the dowel rod and the steel cylinder: the dowel rod is vertically inserted into the upper end of the steel cylinder through the gap to fix it; the installation of the support structure: the support structure includes A plurality of support rods arranged horizontally, one end of each support rod is respectively connected with a dowel rod, and the other end of the support rod intersects and is fixed on the central axis of the steel cylinder; the production and installation of the ring substitute: The ring-shaped substitute is fixedly connected with the upper end of the dowel bar; vibration and sinking construction: install the vibration-sinking tool for vibration-settling, and remove the ring-shaped substitute and supporting structure after the vibration-settling construction is completed; prefabrication of the concrete cylinder and installation of the concrete cylinder. The construction method can effectively reduce the construction cost, is easy to engineer and manufacture, and the obtained cylindrical structure has strong durability.

Owner:CCCC FIRST HARBOR ENG

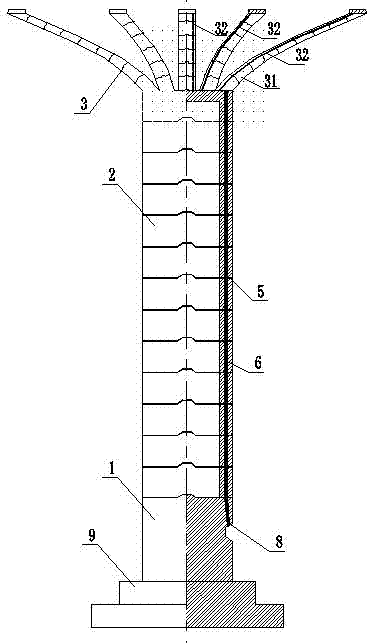

A bionic bridge pier and its construction method

ActiveCN106087714BGuarantee product qualityComply with assembly requirementsBridge structural detailsBridge erection/assemblyNon symmetricMortise and tenon

The invention discloses a bionic bridge pier and a construction method thereof. The bionic bridge pier comprises a bridge pier body arranged on a foundation of the bridge pier, wherein the bridge pier body comprises a solid pier bottom section, a hollow pier body section and a branch-shaped pier top section which are sequentially connected from bottom to top, the branch-shaped pier top section comprises a plurality of pier branches which are arranged on the upper end surface of the hollow pier body section in a symmetric or non-symmetric manner and extend obliquely and upwards, the hollow pier body section comprises prestressed steel strands and a plurality of hollow pier body blocks, adjacent hollow pier body blocks are in positioned mortise-and-tenon joint, the prestressed steel strands are arranged in the side walls of the hollow pier body blocks and penetrate through the hollow pier body section, the lower ends of the prestressed steel strands are anchored in the solid pier bottom section, each pier branch comprises multiple groups of assembling components and a plurality of prestressed ribs, the assembling components are in positioned mortise-and-tenon joint, the cross section of each pier branch is a solid or hollow section, two adjacent assembling components are anchored through the prestressed ribs arranged in the assembling components, and the assembling component at the bottommost end of each pier branch is anchored on the upper end surface of the hollow pier body section through the prestressed ribs arranged in the assembling components.

Owner:ZHENGZHOU UNIV

A method for assembling an offshore wind turbine at a wharf

ActiveCN110469458BLower center of gravityReduced lifting capacity requirementsWind motor assemblyWind energy generationImpellerClassical mechanics

The invention provides a method for assembling a whole offshore wind turbine at a wharf. In the process of assembling a wind turbine, a main crane is placed on the ground at a extension line of the center line of a transport ship,when impellersare hoisted in accordance with specific conditions (that is,a high slack tide or a low slack tide period) and a certain rotation angle of an engine room, interference between a lifting arm of the main crane and the impellers during hoisting can be effectively avoided, and the bad influence of offshore waves generated during impeller hoisting can be effectively avoided,after the impellersare installed, the impellersare rotated to an inverted Y-shaped state, the interference between the impellers and the lifting arm of the main crane can be further avoided, and the center of gravity of the whole wind turbine can be made to relatively lower at the same time, the fact thatthe interference between a lifting hook and blades of the impellersis not generatedwhen the whole machine is hoisted in an installation position of the offshore wind turbine is met, and collision between the main crane and the blades when the main crane holds upa mast during assembling the impellers on an adjacent station can be further avoided.

Owner:GUANGDONG POWER ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com