Method for arranging upper steel bars of laminated beam in penetrating mode

A technology of superimposed beams and steel bars, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of many solder joints of steel bars, a large number of upper steel bars 7, and large material loss, and achieve the goal of reducing equipment hoisting capacity Requirements, saving manpower and material resources and time, the effect of reducing the weight of a single piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

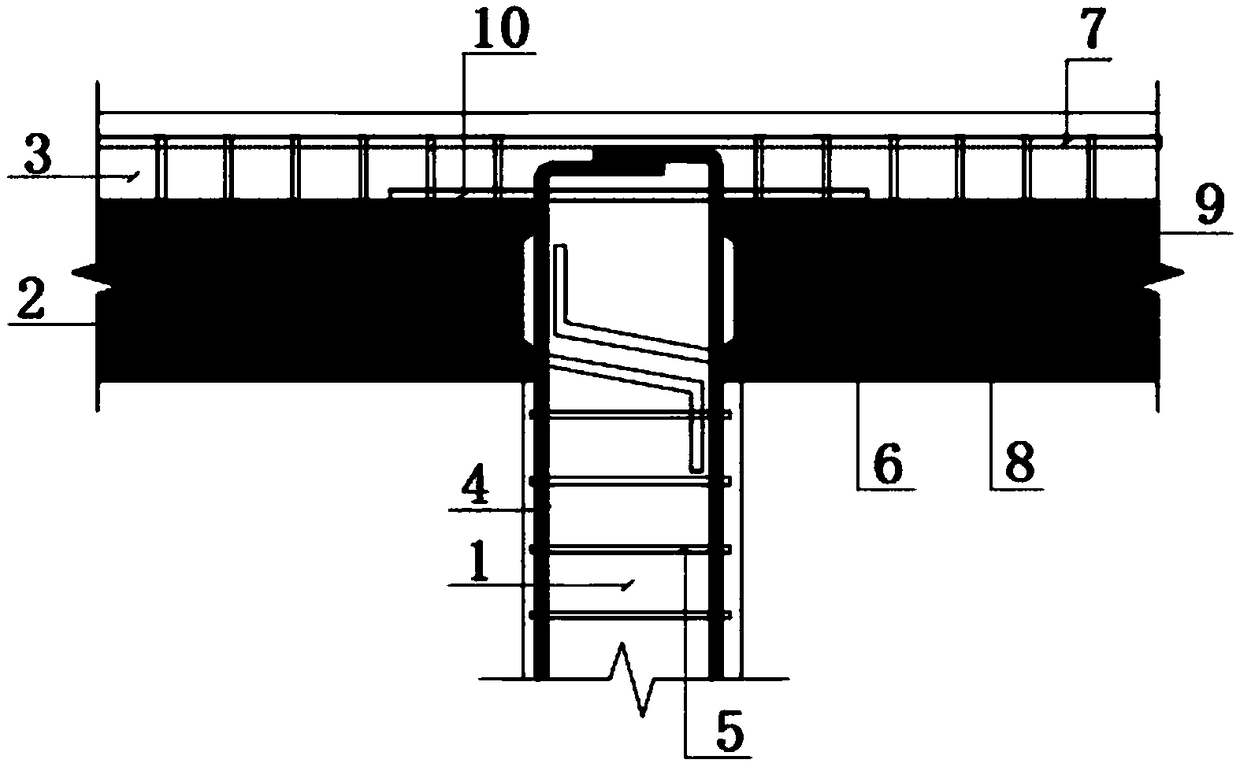

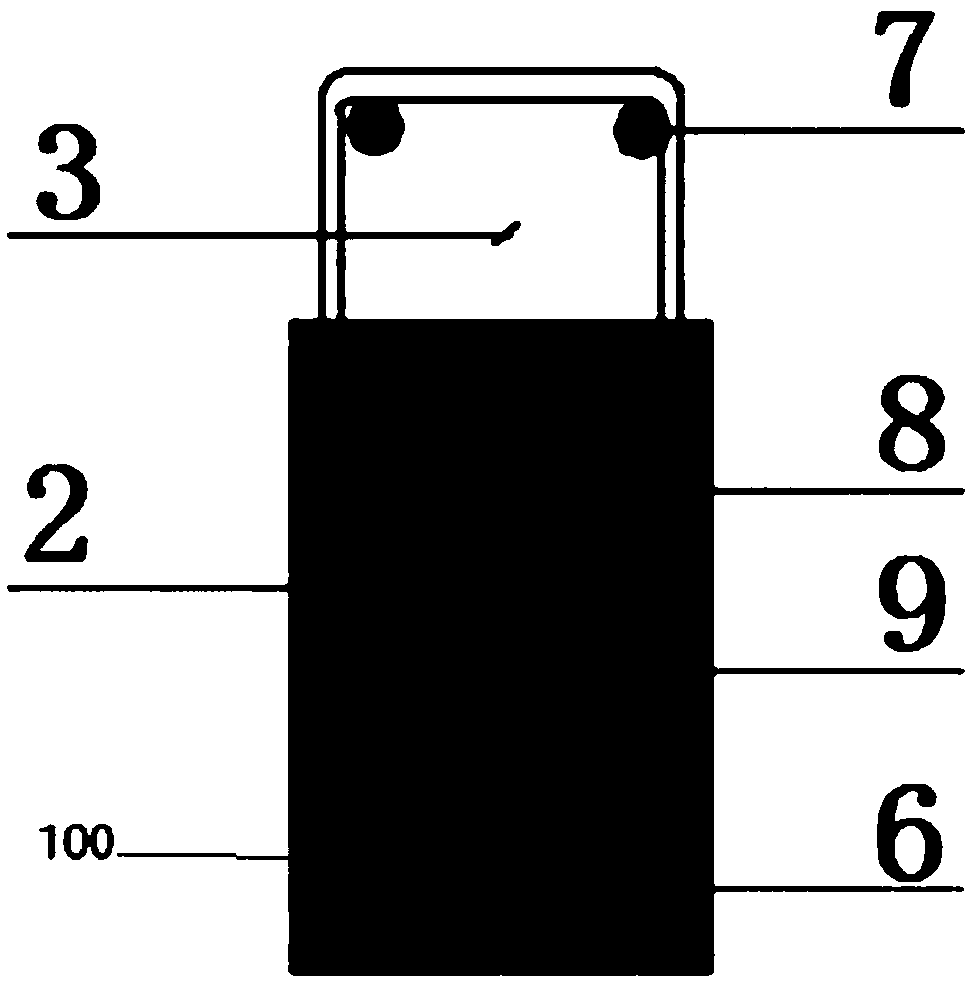

[0023] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

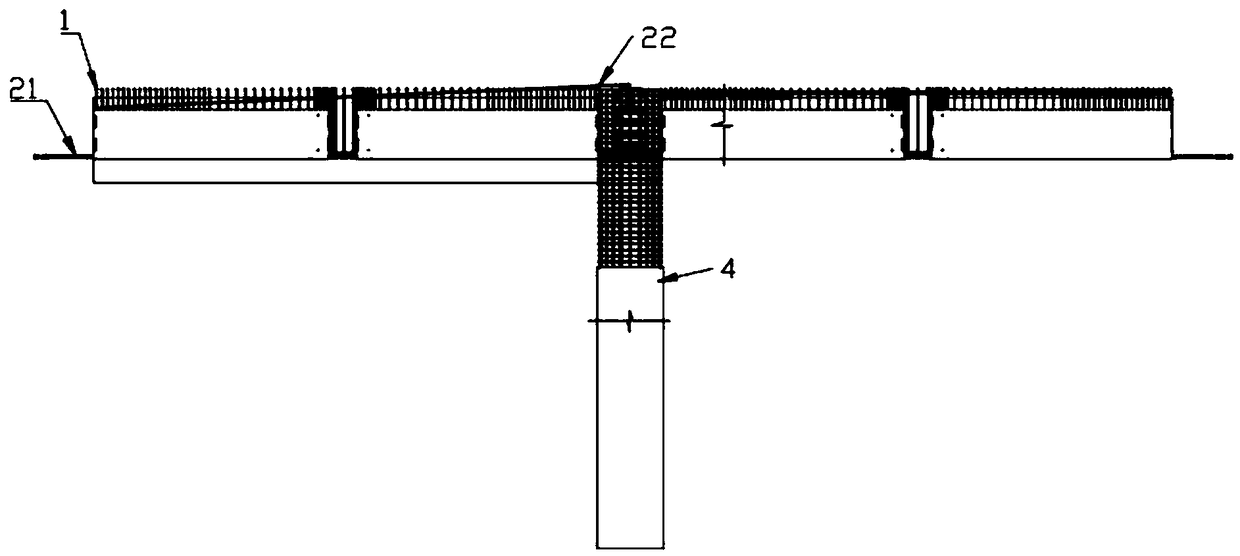

[0024] See image 3 , Figure 4 , the method for piercing the upper reinforcement of the composite beam according to the first embodiment of the present invention, comprising:

[0025] A. Install the stirrup 1 and the lower steel bar 21, and the prefabricated layer 3 of the laminated beam, wherein the lap joint of the two ends of the stirrup 1 near the end region 41 of the cast-in-place column 4 is located in the laminated beam prefabricated layer 3 Above the beam precast layer 3;

[0026] B. Install the prefabricated layer 3 of the laminated beam, open the overlapping joints of the two ends of the stirrup 1 in the end region 41, and form an op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com