Prestressed reinforced concrete superposed beam having convex-concave superposed surfaces

A technology of prestressed steel bars and composite beams, applied in the field of reinforced concrete beams, which can solve the problems of complex structure at the joints, heavy weight of prefabricated beams, and poor shear resistance, and achieve light weight, improved seismic performance, and high bending rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

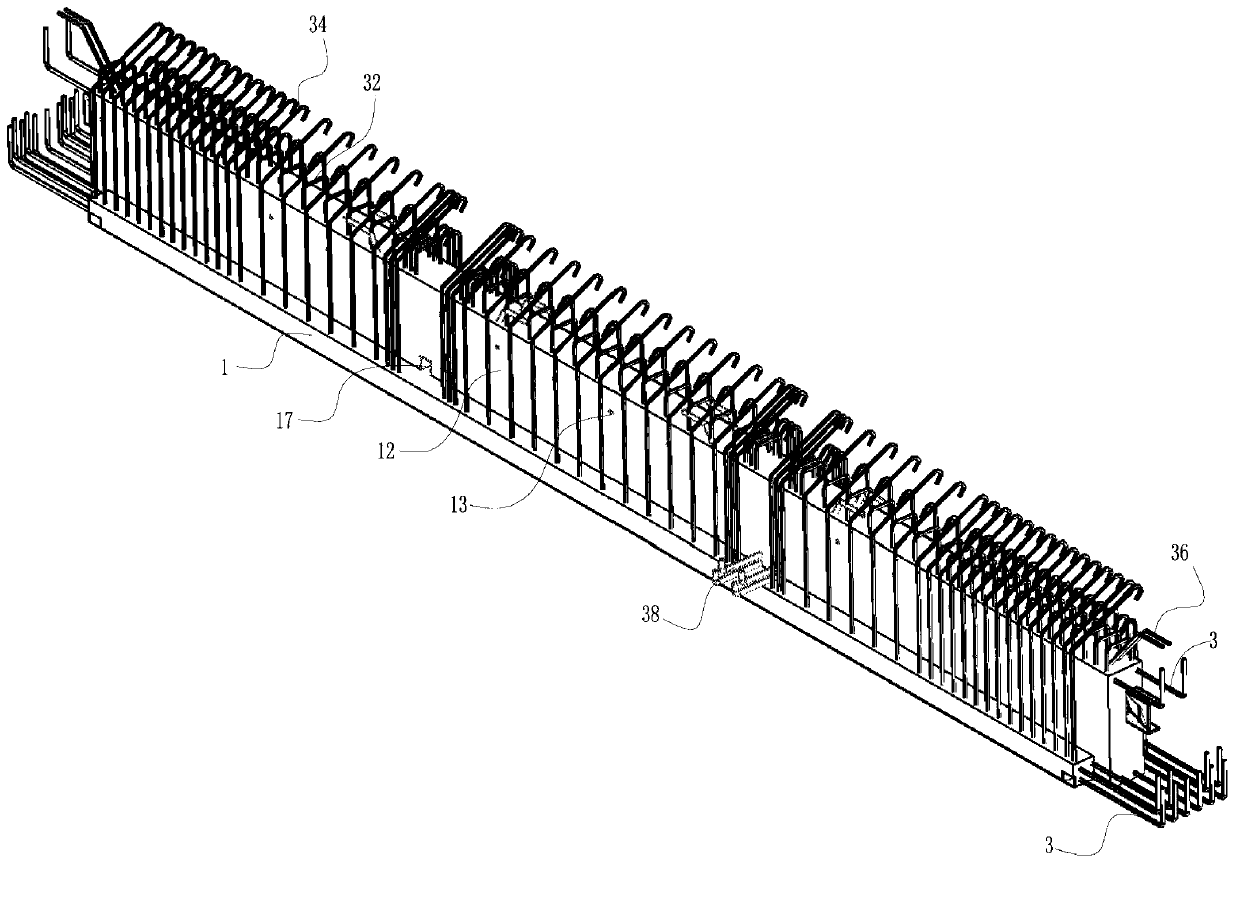

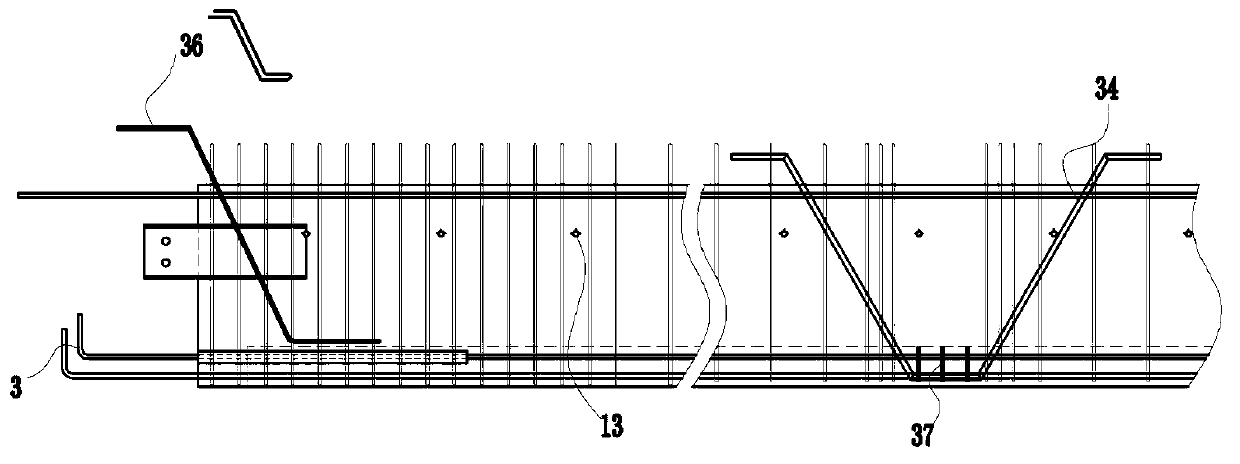

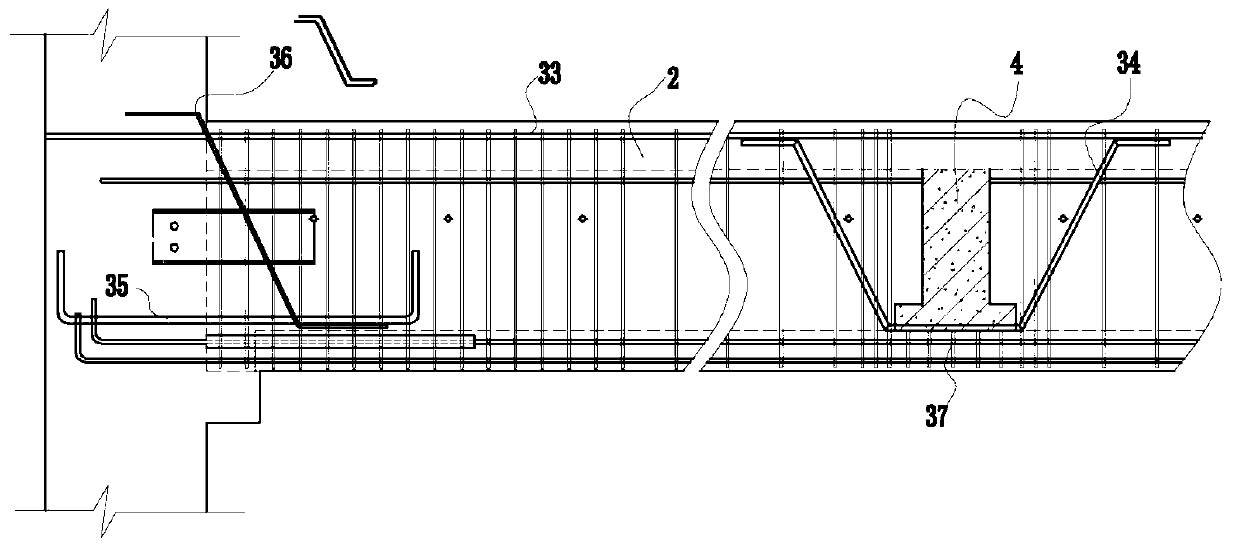

[0029] see Figure 1 to Figure 6 , an embodiment of a prestressed reinforced concrete composite beam with a convex-concave composite surface provided in the present invention, comprising an inverted T-shaped prestressed prefabricated beam body 1 and Shaped post-cast reinforced concrete part 2, the two form a rectangular or rectangular composite beam with the upper part connected to the floor. The prefabricated beam body 1 is embedded with prestressed steel strands 3 longitudinally, and the Stirrups 31 are buried, and rectangular stirrups 32 are embedded on the web 12 of the prefabricated beam body 1, and the stirrups 31 and the rectangular stirrups 32 are anchored in the post-cast reinforced concrete part 2, and the post-cast The upper part of the reinforced concrete part 2 is embedded with reinforcing bars 33 longitudinally. The composite beam of the present invention adopts an inverted T-shaped prestressed prefabricated beam body 1 and casts formed on the prefabricated bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com