Desert-sand light aggregate concrete fabricated shear wall structure

A technology of lightweight aggregate concrete and desert sand, applied in the direction of walls, building components, building structures, etc., can solve the problems of high energy consumption of houses, consumption of coal, coal consumption, etc., and achieve far-reaching practical and social significance. , the effect of reducing energy consumption and making full use of local resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

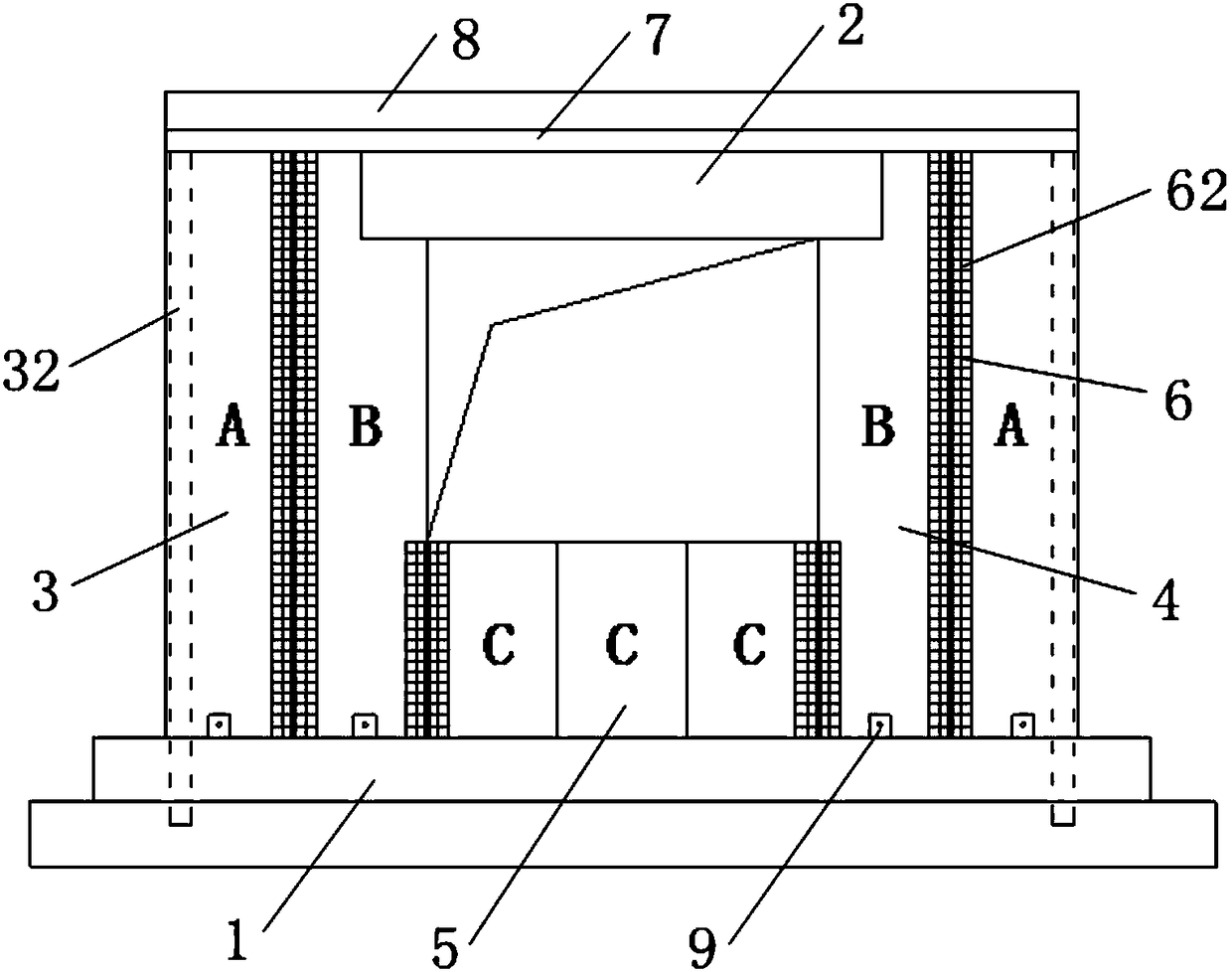

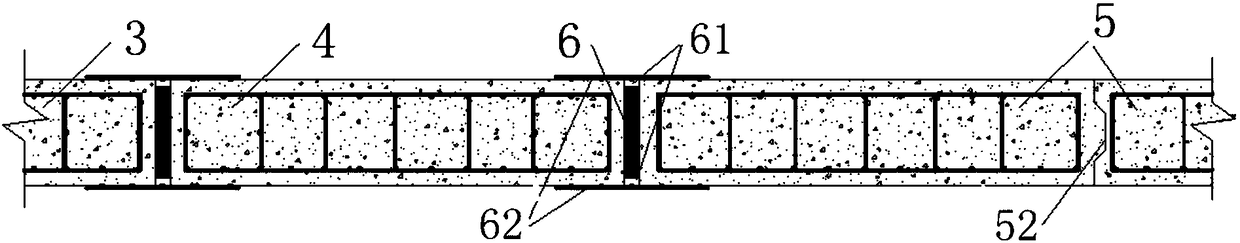

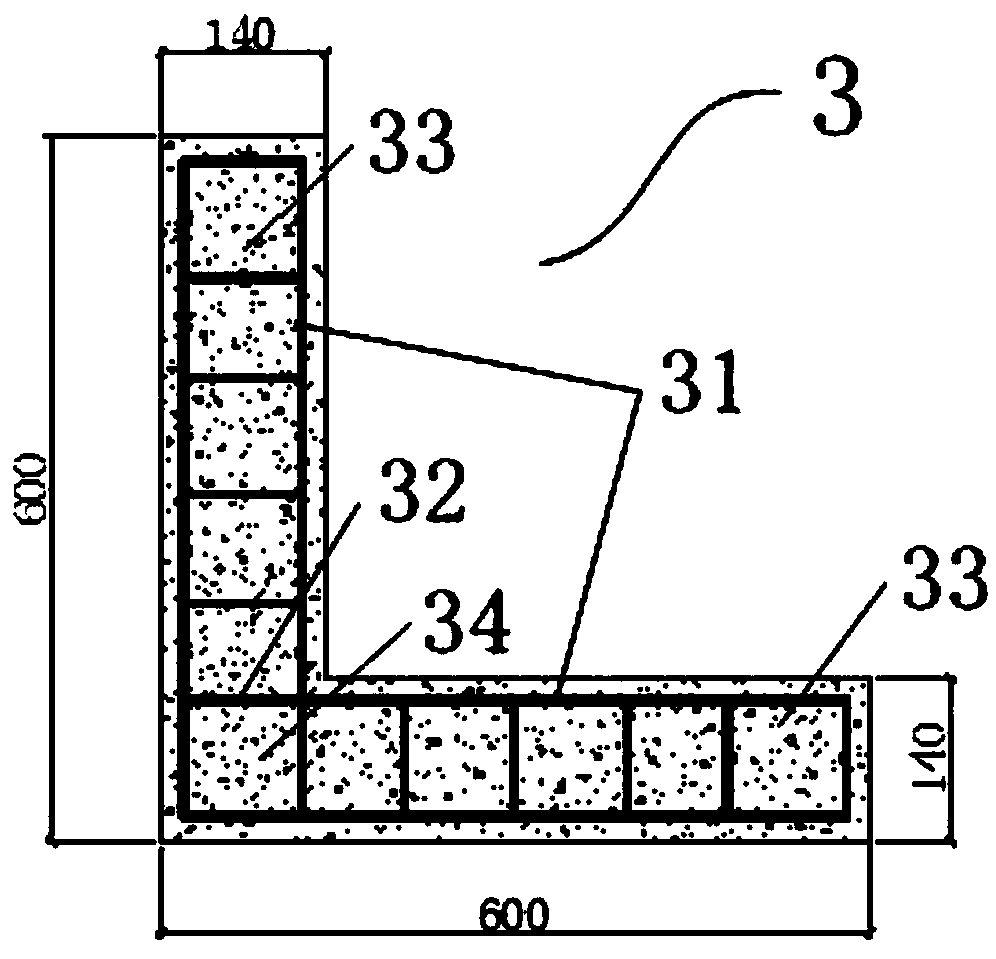

[0029] As shown in the figure, the prefabricated shear wall structure of desert sand lightweight aggregate concrete in the present invention includes foundation 1, wall piers arranged on foundation 1, and connecting beams 2 connected between wall piers, said wall piers Including A-type special-shaped wall pier 3, B-type in-line wall pier 4, and C-type under-window wall pier 5, the B-type in-line wall pier 4 and C-type under-window pier 5 are all slatted structures; The A-type special-shaped wall limb 3 is mainly composed of steel wire mesh 31 as the skeleton of the vertical and horizontal walls, thin-walled steel 32 arranged at the junction of the skeleton of the vertical and horizontal walls, and arranged at the free end of the skeleton of the vertical and horizontal walls and connected with the steel mesh 31 through hidden columns. Combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com