Method for assembling whole offshore wind turbine at wharf

A technology for offshore wind turbines and docks, which is applied in the field of assembly of offshore wind turbines and docks, and can solve the problems of increased installation costs of wind turbines, complicated installation procedures and high costs of wind turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

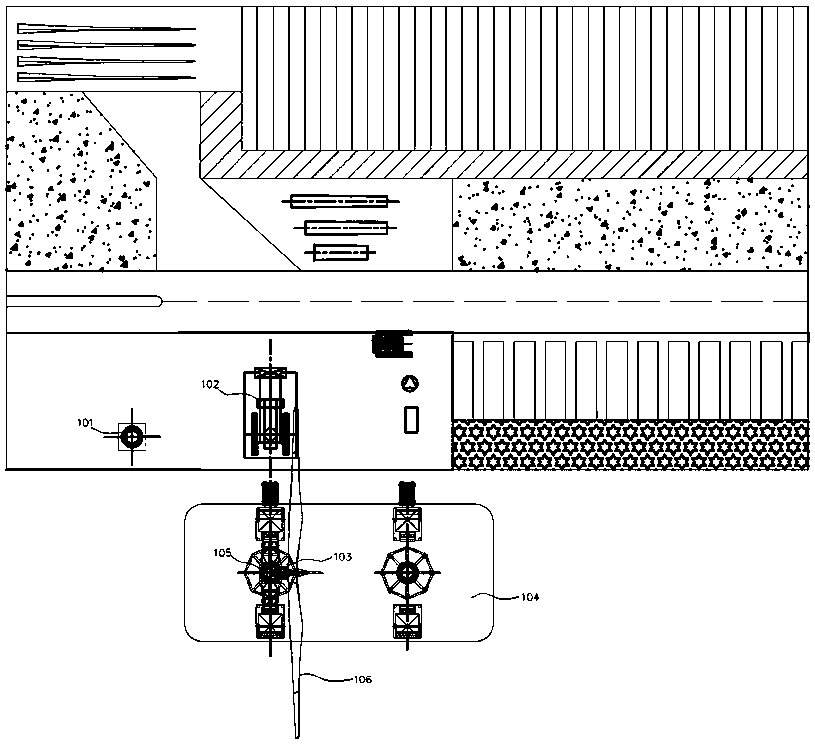

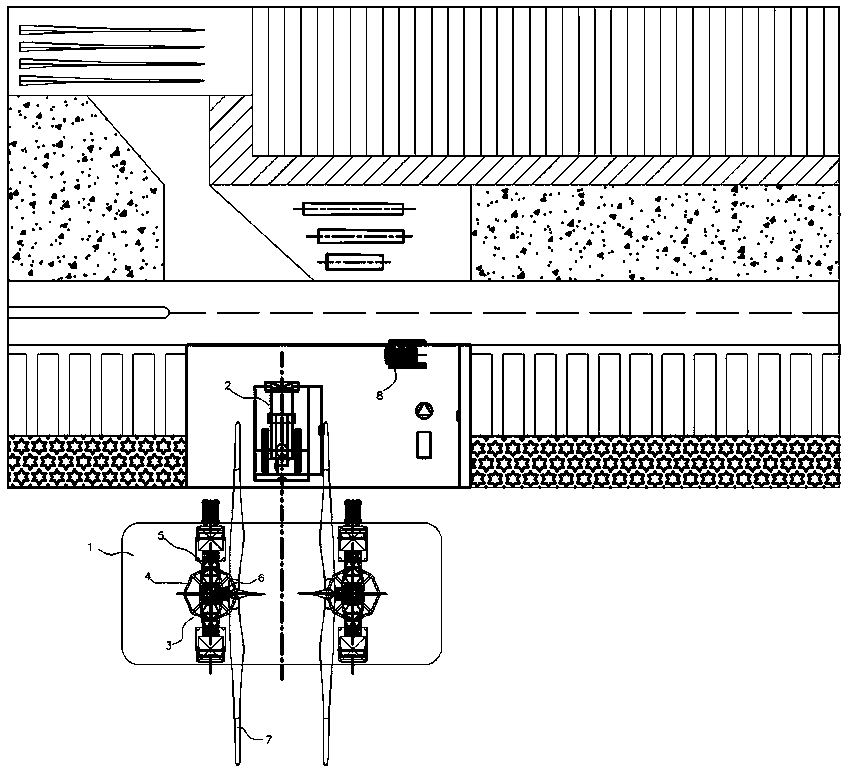

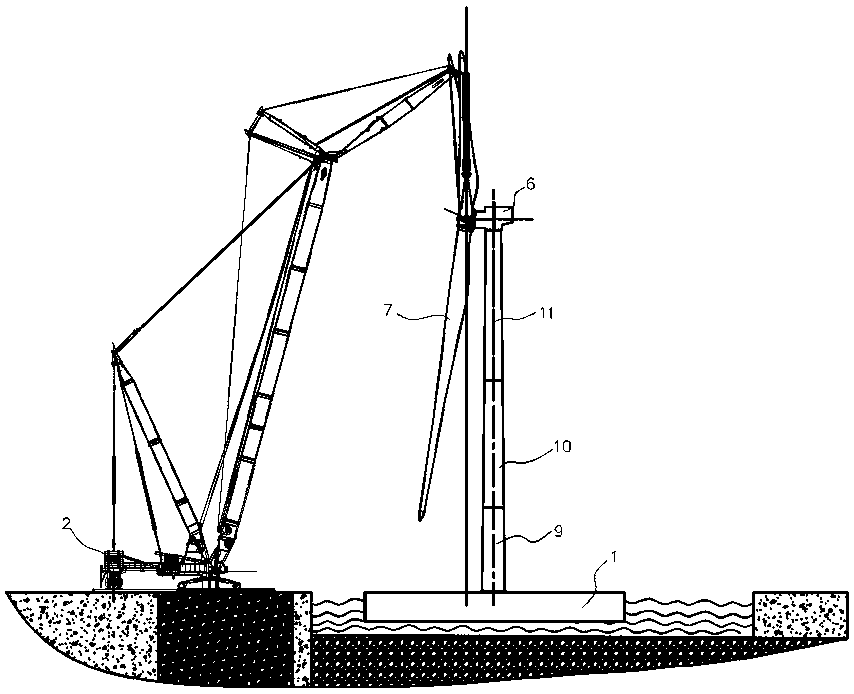

[0022] A method for assembling an offshore wind turbine wharf, such as figure 2 with image 3 As shown, the steps include: (1) The transport ship 1 is parked on the shore of the wharf, and the main crane 2 is parked on the ground at the extension line of the center line of the transport ship 1; (2) The main crane 2 moves the lower section The tower 9 is hoisted and transported to the wind turbine assembly station 3 of the transport ship 1, and the lower tower 9 is fastened to the wind turbine assembly station 3; (3) The main crane 2 lifts the upper hanger 4 and Transport to the wind turbine assembly station 3, fasten the upper hanger 4 on the outer wall of the lower tower 9; (4) The main crane 2 lifts the middle tower 10 and transports it to the wind turbine assembly station 3, Fasten the middle tower 10 to the top of the lower tower 9; (5) The main crane 2 lifts the balance beam 5 and transports it to the wind turbine assembly station 3, and fastens the balance beam 5 to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com