Rollover formwork for climbing formwork device

A formwork and climbing formwork technology, applied in the field of cast-in-place cylinder structure construction, can solve problems such as large tensile stress and affecting the development of concrete strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

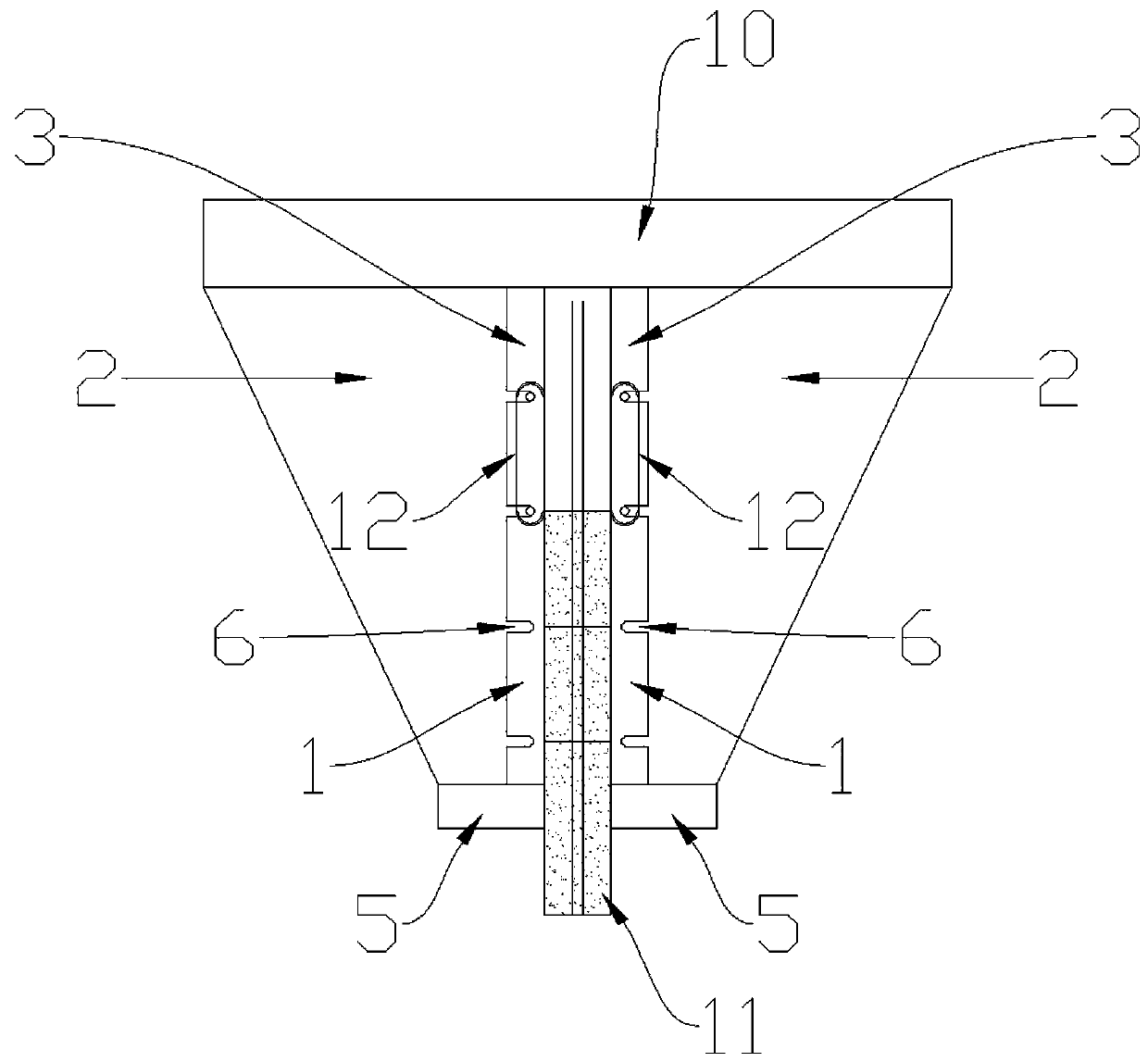

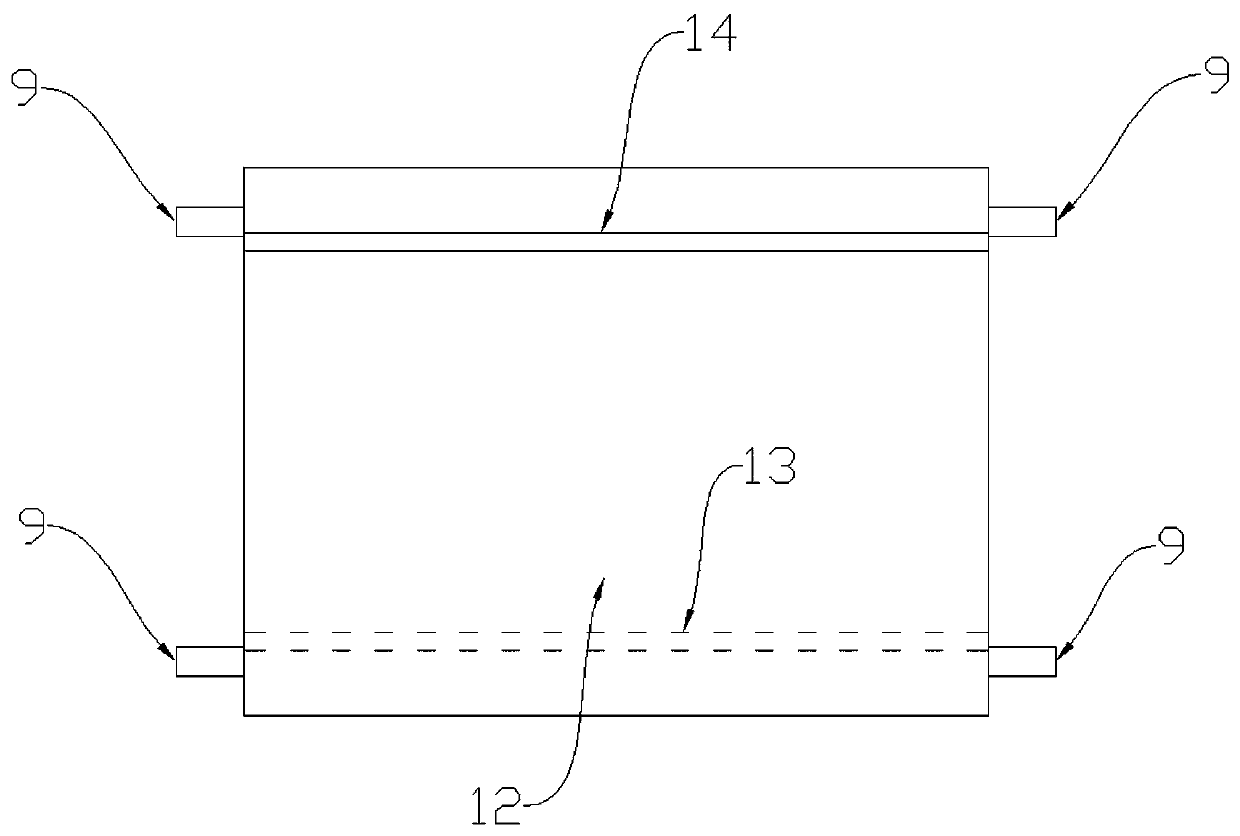

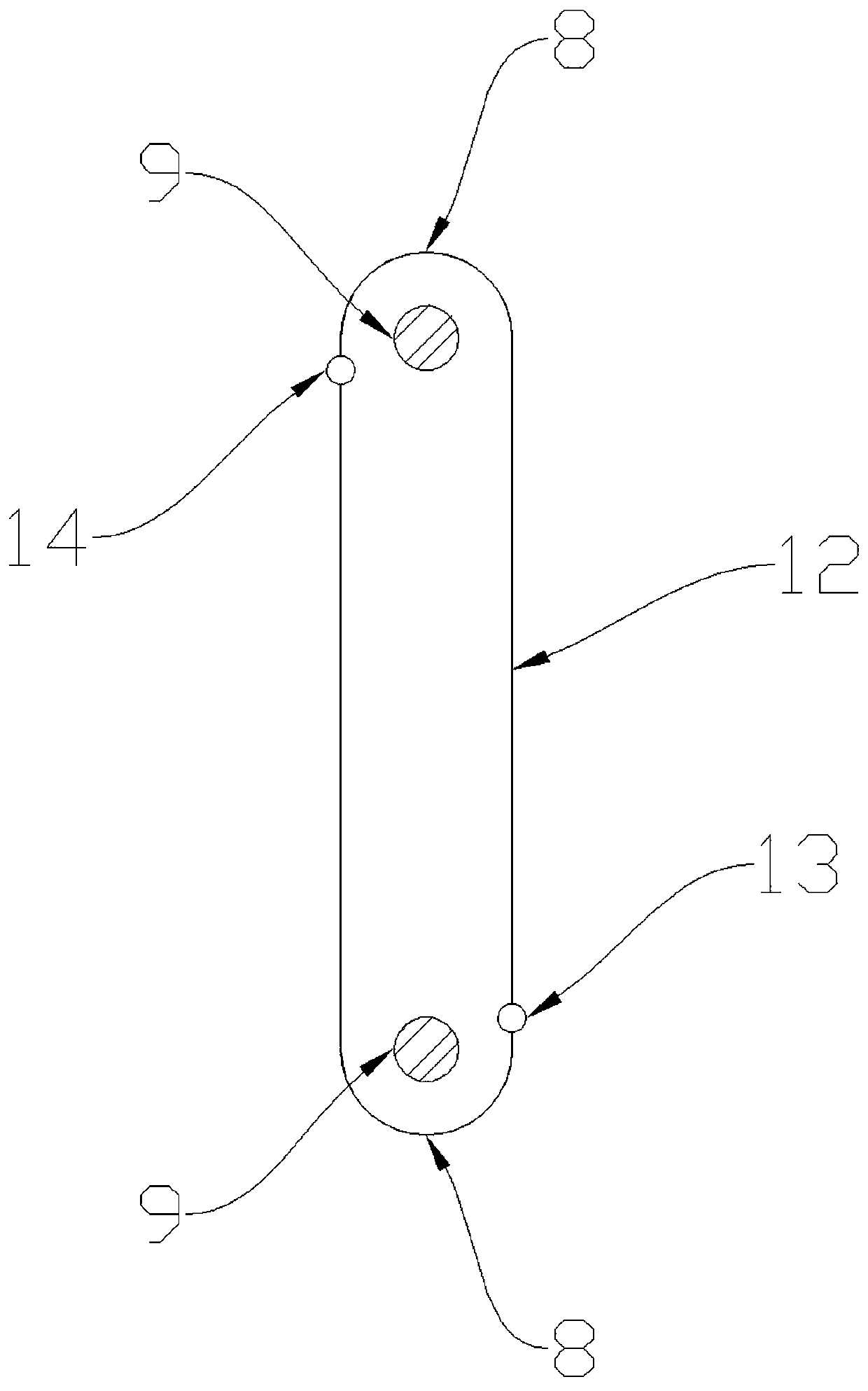

[0013] see Figure 1 to Figure 7 , when the climbing formwork device stays at a certain height of the cylinder wall 11, the temporary fixing parts withstand the lower ends of the pair of bottom beams 5, first install a pair of movable formwork 12 on the bottom row of the turning formwork, and one The upper and lower pin shafts 9 of the movable formwork 12 are all put into the U-shaped groove 6 of the flange 1 of the adjacent channel steel 3, and the upper and lower part buckles 7 are fastened together, and the O-shaped waterstop strip A13 of a pair of movable formwork 12 is Close to the cylinder wall 11 that has been poured and has reached a certain strength, and then install steel bars and pour concrete in the cavity formed by a pair of movable formwork 12, and the O-shaped waterstop strip A13 of the pair of movable formwork 12 prevents concrete from leaking After the concrete is finally set, loosen the fasteners 7 at the lower ends of the pair of movable formworks 12, and tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com