A bionic bridge pier and its construction method

A technology of bridge piers and pier tops, applied in the field of bionic bridge piers and their construction, can solve the problems of increasing bridge construction and maintenance costs, and threats to the safe operation of bridge structures, so as to ensure the safety of bridge structures and traffic operations, and the requirements for lifting capacity are not high. , the effect of mature segment prefabrication process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

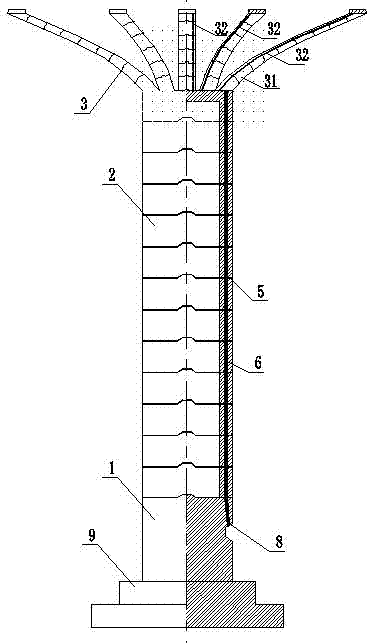

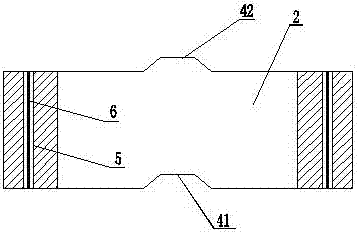

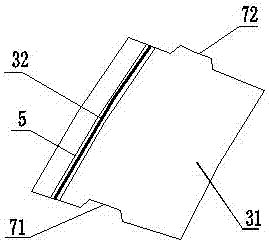

[0032] Such as figure 1 , 2 and image 3 As shown, a bionic pier includes a pier body located on the pier foundation 9. The pier body is composed of a bottom section 1 of a solid pier, a hollow pier body section, and a branch-shaped pier top section sequentially connected from bottom to top. The top section of the branch-shaped pier It is composed of a number of pier branches 3 symmetrically arranged on the upper end surface of the hollow pier body section and extending obliquely upward. The hollow pier body section is composed of prestressed steel beams 6 and several hollow pier body blocks 2, and the adjacent hollow pier body blocks 2 are positioned by mortise and tenon. connection, the prestressed steel beam 6 is arranged in the side wall of the hollow pier body block 2 and runs through the hollow pier body section, the lower end of the prestressed steel beam 6 is anchored on the bottom section 1 of the solid pier, and each pier branch 3 is composed of several assembled co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com