Prefabricated prestressed plate with reinforced truss flange plate and production method thereof

A steel truss, prestressing technology, applied in the direction of floor slabs, manufacturing tools, building components, etc., can solve the problem of increased stiffness, and achieve the effect of improving stiffness, reducing consumption, and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

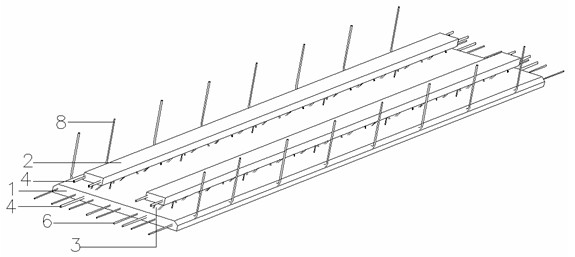

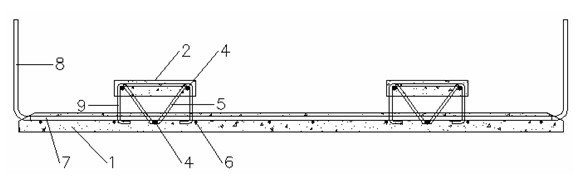

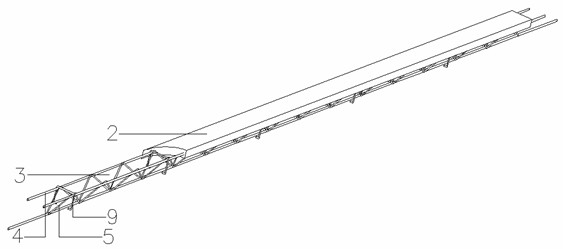

[0018] The prefabricated prestressed plate of the truss flange plate with steel bars and the manufacturing method of the present invention adopt the two longitudinal steel bars at the corners of the bottom edge of the triangular welded steel bar truss produced by the factory assembly line to be poured into the strip concrete slab to form the flange with the steel bar truss The stress unit of the strip plate; on the upper surface of the prestressed concrete bottom plate 1, there are concrete flange strip plates 2 arranged side by side along its length direction, and the distance between the prestressed concrete bottom plate 1 and the concrete flange strip plate 2 can penetrate The gaps between steel bars or wire pipes are distributed horizontally, and the prestressed concrete base plate 1 and the concrete flange strip plate 2 are connected by a triangular steel bar truss 3, that is, the triangular steel bar truss 3 is an inverted equilateral triangle, and the apex of the triangle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com