Towing truss-gravity type combined offshore wind turbine foundation structure and construction method thereof

A technology of gravity foundation and offshore wind turbine, which is applied in the direction of foundation structure engineering, construction, etc., can solve the problems of difficult application of pile foundation type, influence of marine organisms, high consumption of steel materials, etc., so as to avoid easy overturning, reduce offshore construction, and structural rigidity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

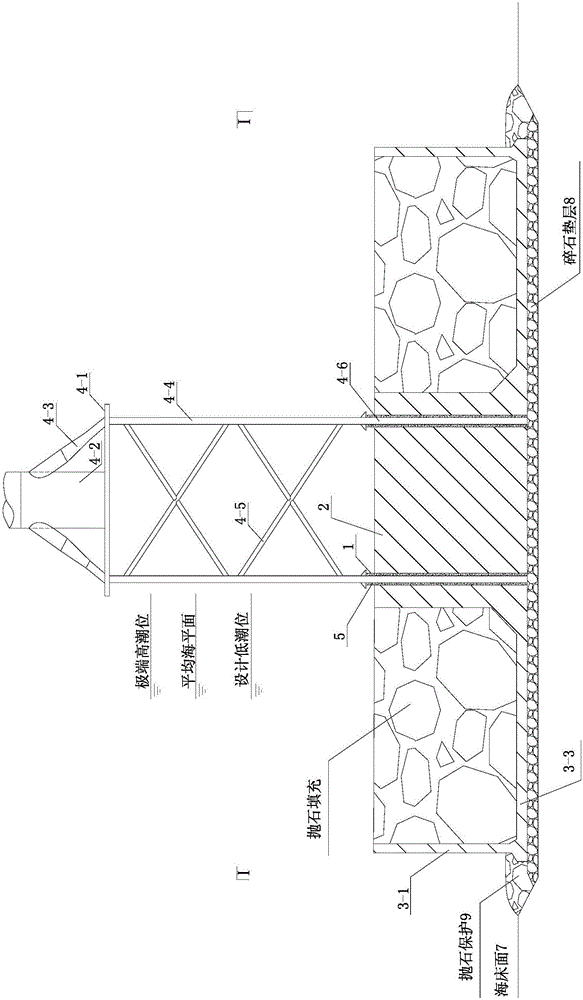

[0028] Embodiment 1, as shown in the figure, is a towable truss-gravity combined offshore wind turbine foundation structure.

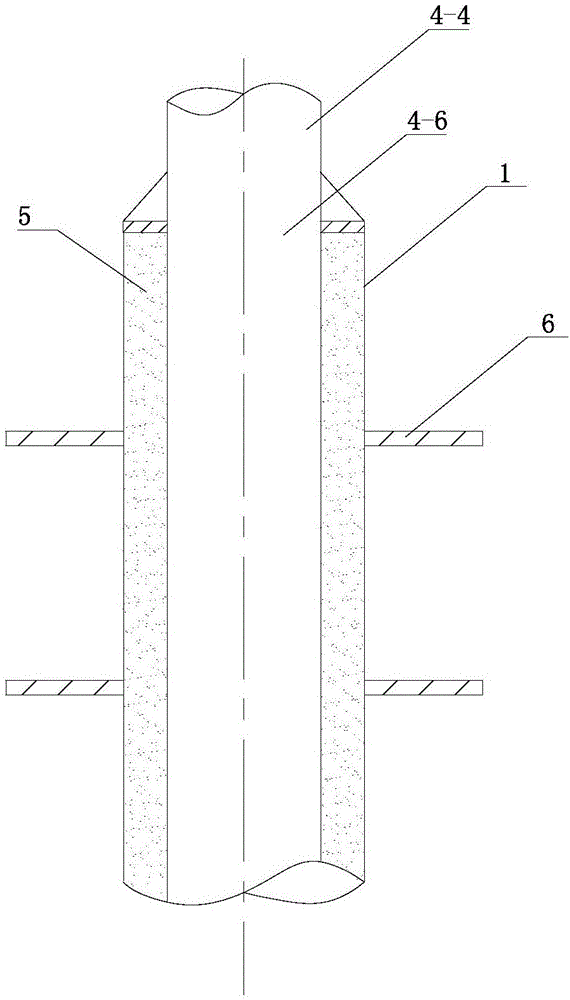

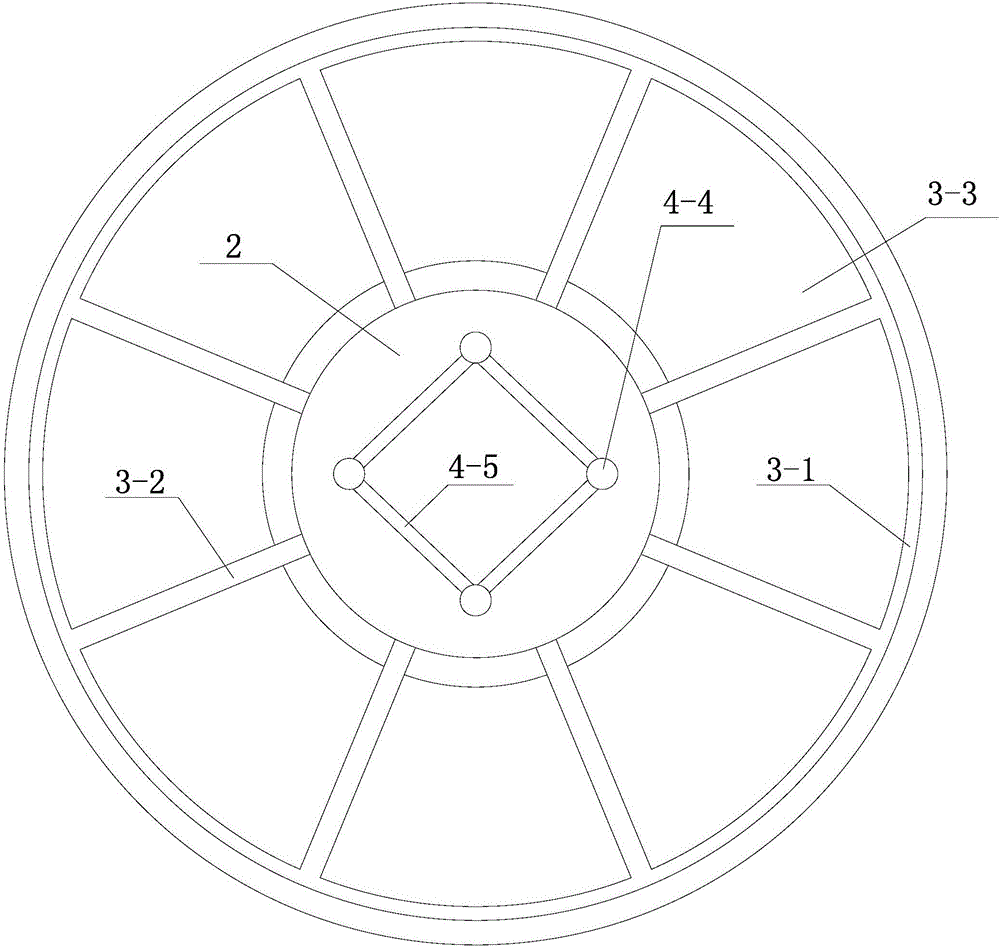

[0029] This embodiment is a towable truss-gravity combination offshore wind turbine foundation structure applied to offshore wind power, including: a gravity foundation with a cavity that can be towed and a truss wind turbine support structure. The gravity foundation includes a pre-buried There are concrete piers 2 and concrete cavities 3 connected to steel pipes 1, the truss fan support structure 4 is connected to the pre-embedded butt steel pipe 1 through grouting material 5, and the gravity foundation and truss fan structure are connected into one As a whole, as the foundation of offshore wind turbines, it supports the upper wind turbine structure.

[0030] The butt steel pipes (1) are steel pipes of equal diameter, the diameter of which is larger than that of the main legs of the truss fan support structure (4), and the number of the butt steel pip...

Embodiment 2

[0038] Embodiment 2, split type construction method.

[0039] Present embodiment is directed at the construction method under the first situation in embodiment 1, and its concrete construction steps are as follows:

[0040] a. Make a gravity foundation and a truss fan support structure on land respectively.

[0041] b. Clean up the seabed of the wind turbine stand, including seabed leveling and foundation laying of crushed stone cushion.

[0042] c. According to the equipment conditions of the wharf, the well-cured gravity concrete foundation can be hoisted into the sea by means of crane or air bag rolling into the water, and the whole gravity concrete foundation will be self-floating on the sea surface by relying on the buoyancy of the cavity; then use The tugboat will tow the gravity concrete foundation to the corresponding machine position of the wind farm, and slowly inject water into the cavity to make the gravity foundation sink to the seabed; Full of rocks.

[0043] ...

Embodiment 3

[0044] Embodiment 3, monolithic construction method.

[0045] The present embodiment is directed at the construction method under the second situation in embodiment 1, and its concrete construction steps are as follows:

[0046] a. Make a gravity foundation and a truss fan support structure on land respectively.

[0047] b. Clean up the seabed of the wind turbine stand, including seabed leveling and foundation laying of crushed stone cushion.

[0048] c. Make the truss-type fan support structure 4 and the prefabricated cavity gravity concrete foundation respectively on land, and then insert the prepared truss-type fan support structure 4 into the pre-embedded butt joint steel pipe 1 of the concrete pier 2 on the wharf, and pass The grouting makes the truss fan support structure 4 and the cavity gravity foundation integral to support the upper fan.

[0049] d. According to the equipment conditions of the wharf, the truss-gravity combined offshore wind turbine foundation can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com