Method for turning over heavy bridge girder steel tower section

A bridge steel tower and section technology, which is applied in the field of turning over heavy bridge steel tower sections, can solve the problem that the lifting capacity is difficult to achieve, and achieve the effect of reducing the lifting capacity requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

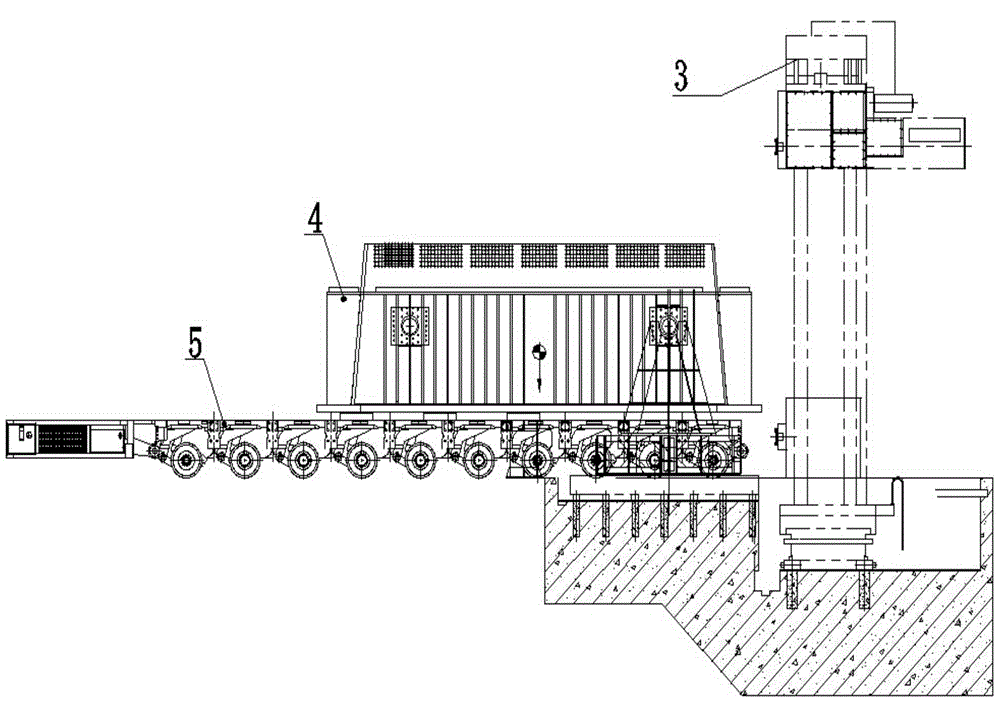

[0018] see Figure 1-Figure 7 , an embodiment of the present invention provides a method for turning over a steel tower segment of a heavy bridge, including:

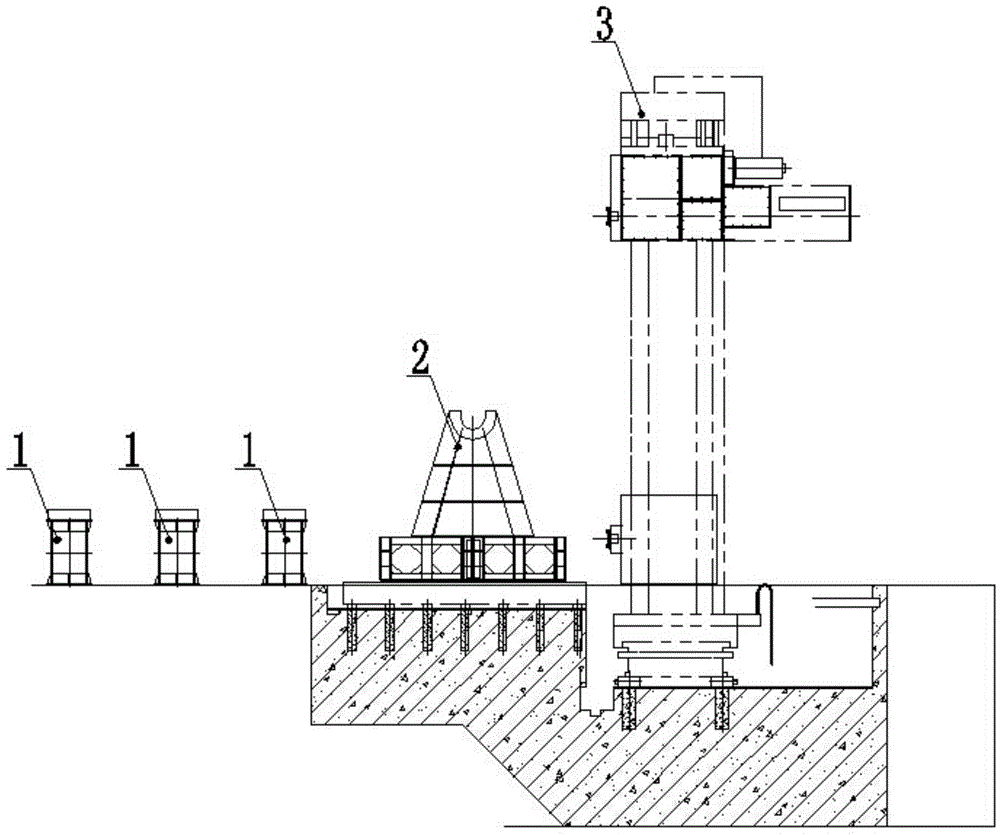

[0019] Step 10, see figure 2 , select or make the rotating bracket 2, select the boring and milling machine 3; fix the rotating bracket 2 on the boring and milling machine 3. The rotating bracket 2 is a frame structure made of steel. In this embodiment, the rotating bracket 2 is fixed on the boring and milling machine 3 through a pressing plate.

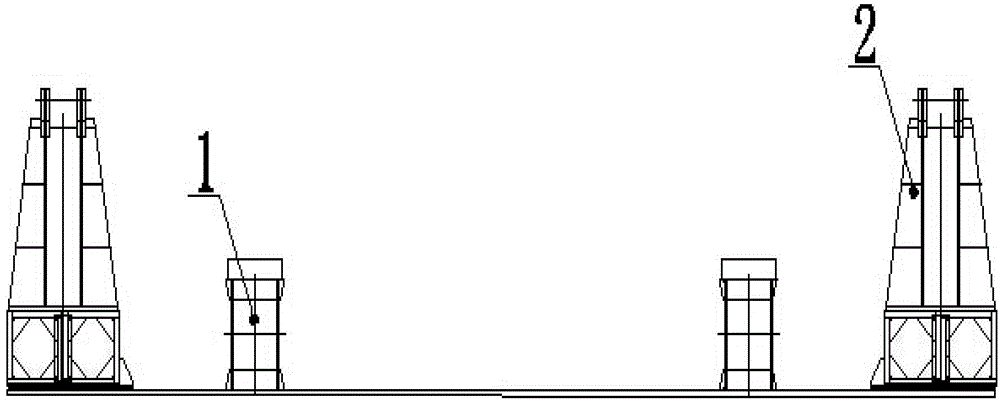

[0020] Step 20, see figure 1 and figure 2 , select or manufacture the supporting steel pier 1, and set the supporting steel pier 1 in the working area of the boring and milling machine 3. The position setting of the supporting steel pier 1 must satisfy that the bridge steel tower segment 4 can be placed on the supporting steel pier 1 and the rotating support 2 at the same time. The number of supporting steel piers 1 is determined according to the size and weight of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com