Patents

Literature

98results about How to "Fast hole forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

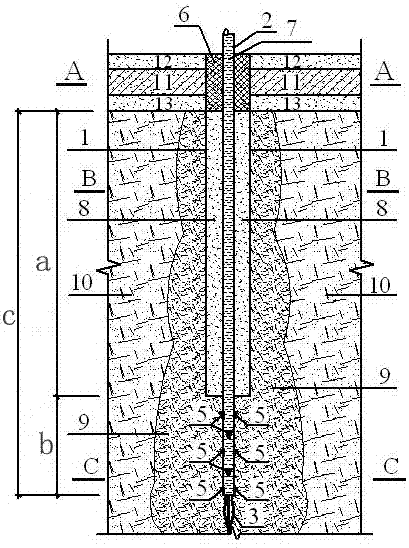

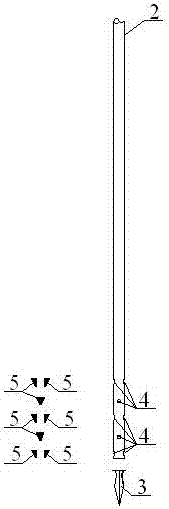

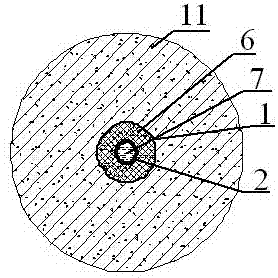

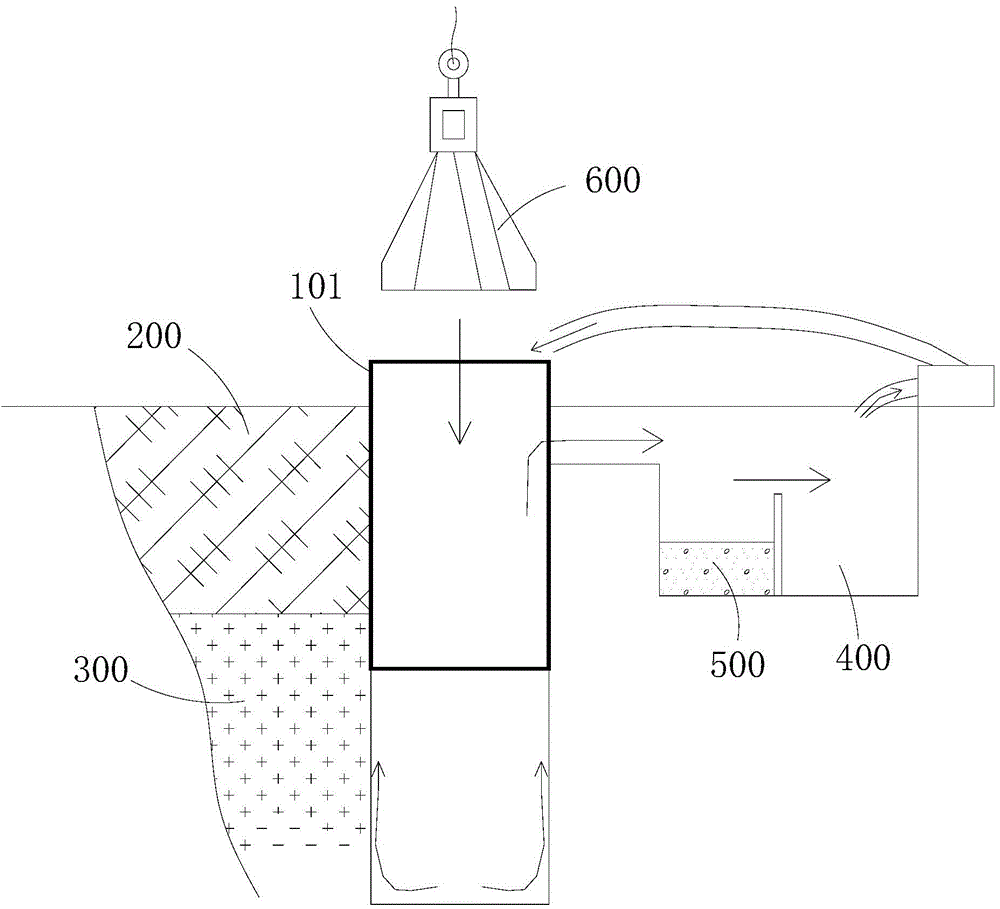

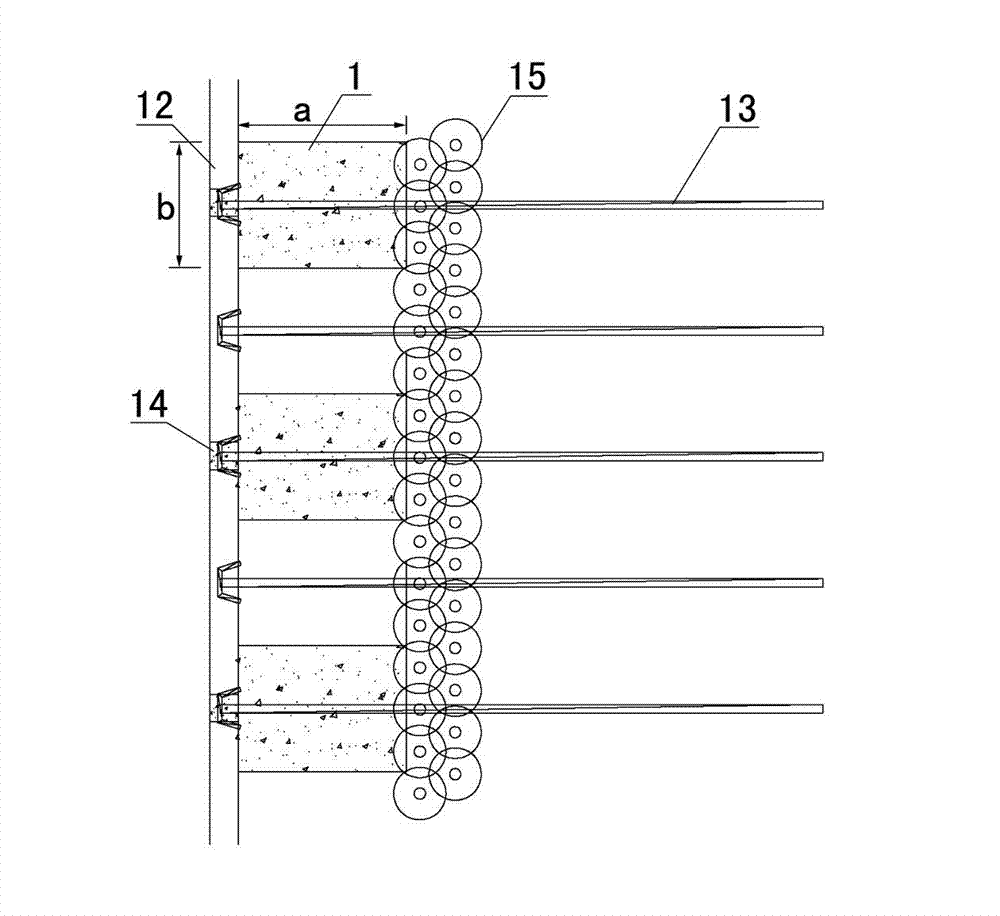

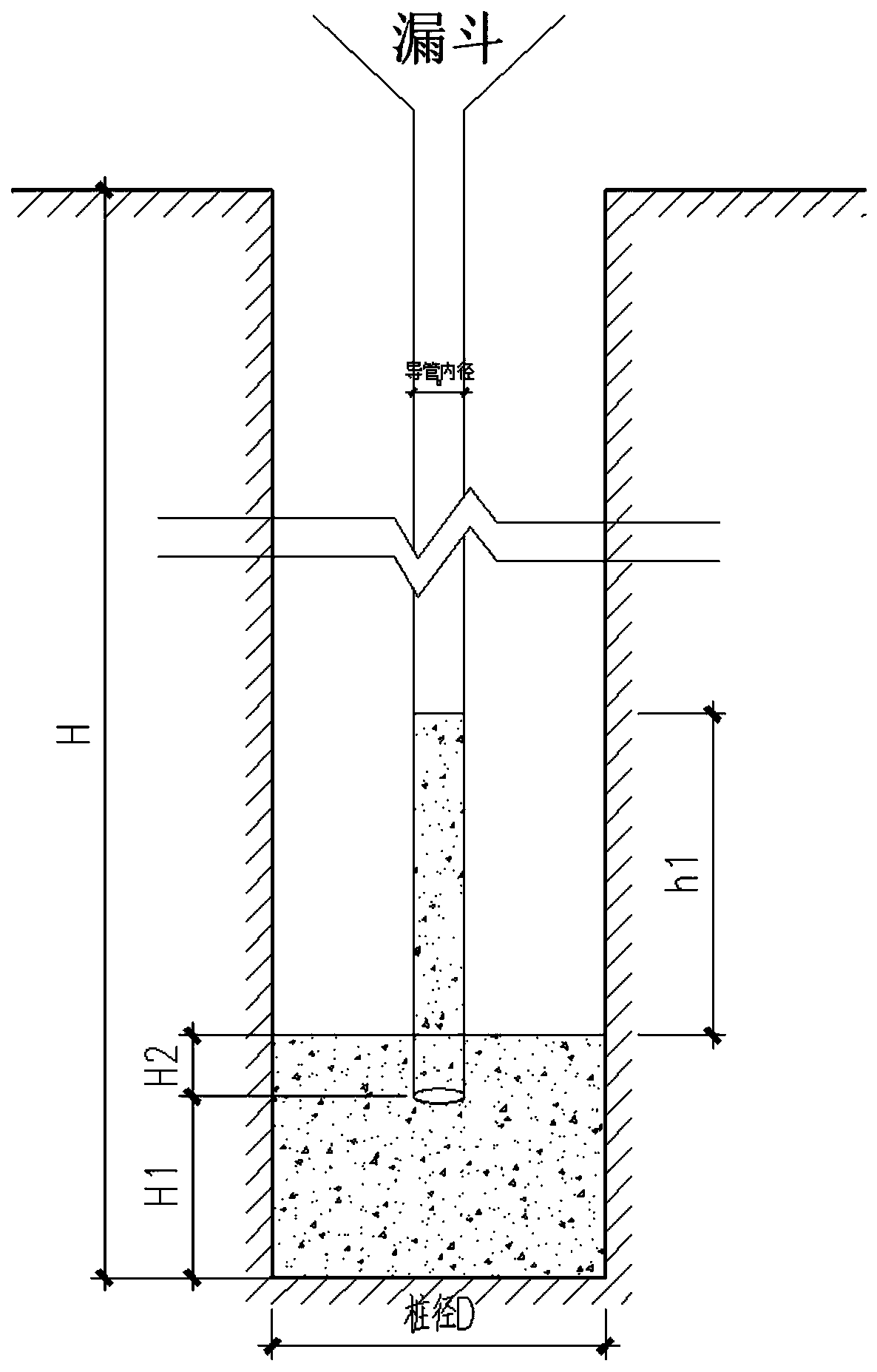

Long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall

ActiveCN106284313AReasonable structural designEasy to operateBulkheads/pilesDrilling machines and methodsUnderwaterHigh pressure

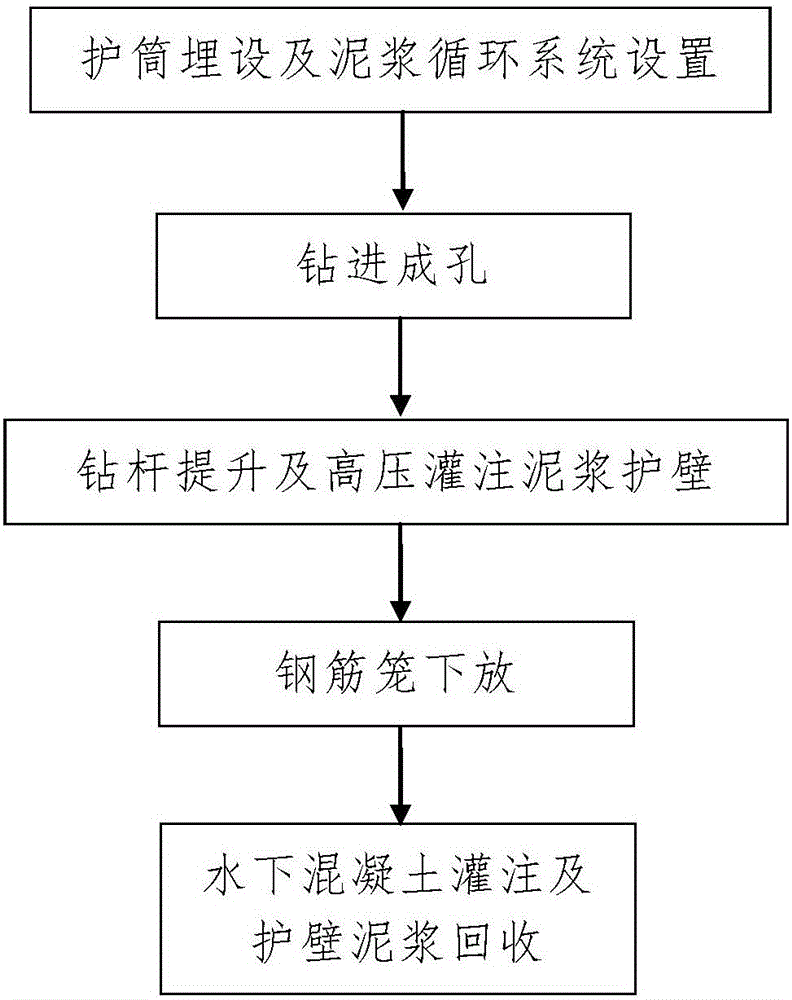

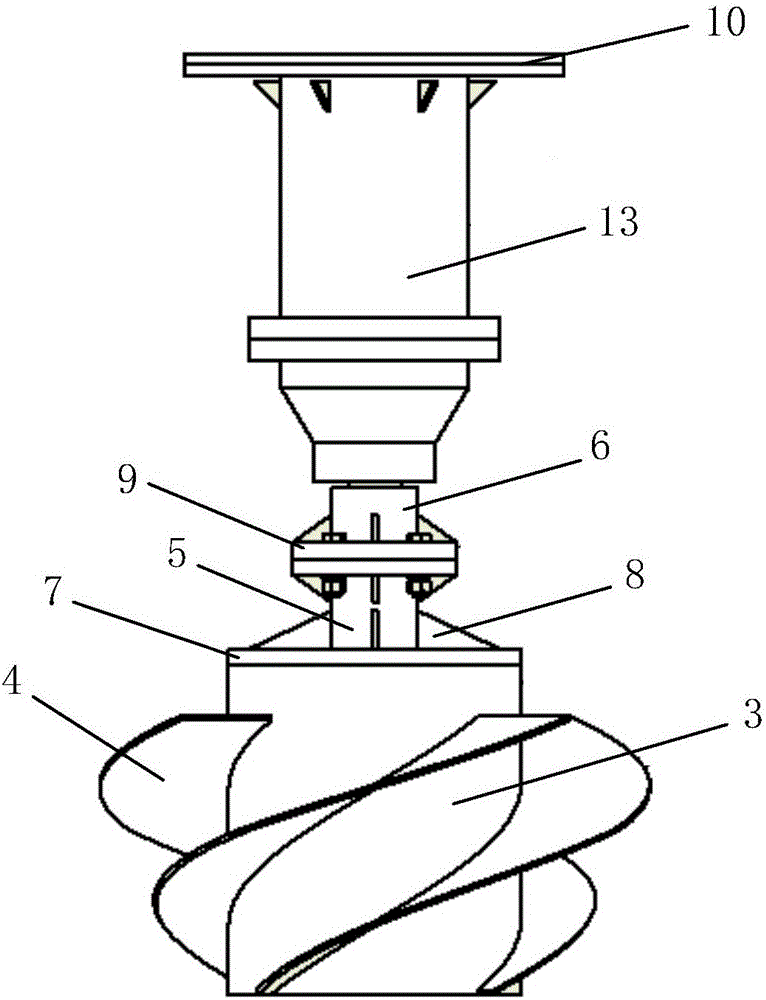

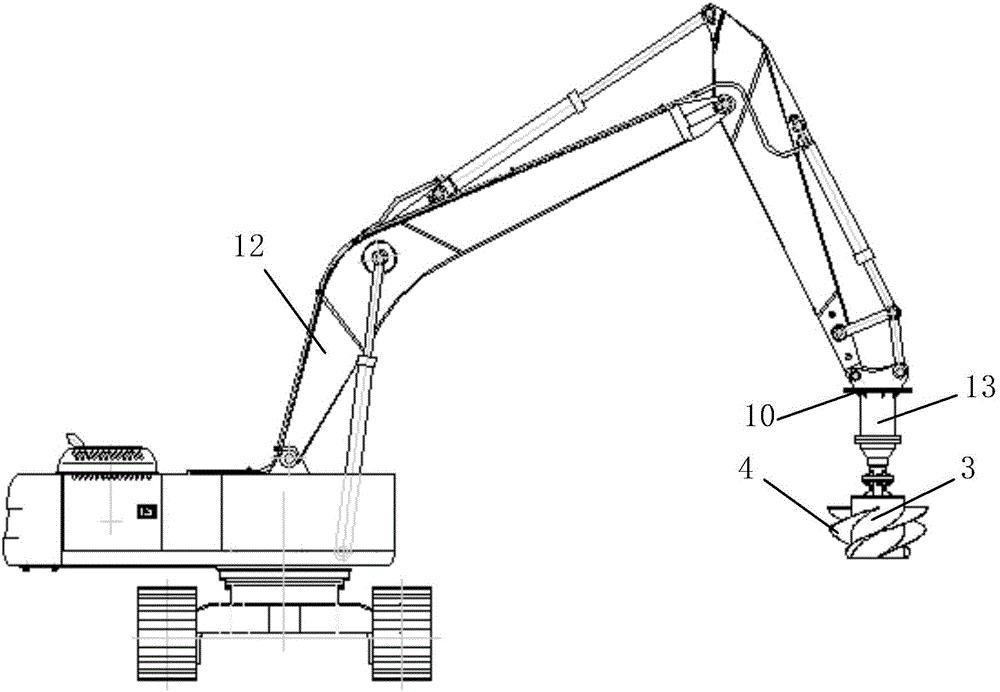

The invention discloses a long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall, comprising the steps of first, burying a protective barrel and setting a slurry circulating system that comprises a slurry storage tank and a slurry pumping device, with the upper portion of the protective barrel provided with an overflow hole; second, drilling to form a borehole; third, lifting a drill pipe, and casting a slurry breast wall under high pressure: lifting up the drill pipe, and continuously casting wall supporting slurry from bottom to top from the borehole bottom through the drill pipe by using the slurry pumping device; fourth, lowering a reinforcement cage; fifth, casting concrete underwater and recycling the wall supporting slurry, and recycling the wall supporting slurry discharged through the overflow hole to the slurry storage tank for backup. The method has simple steps, is easy to implement, has high hole-forming quality and good construction effect, and enables the construction of a long screw extrusion-socketed cast-in-place pile to be finished simply and quickly, and by casting the wall supporting slurry from bottom to top from the borehole bottom in a high-pressure casting manner, it is possible to effectively protect the wall and keep the borehole bottom clean with no deposit; the wall supporting slurry is reusable.

Owner:SHAANXI ZHUANGXIN CONSTR ENG +4

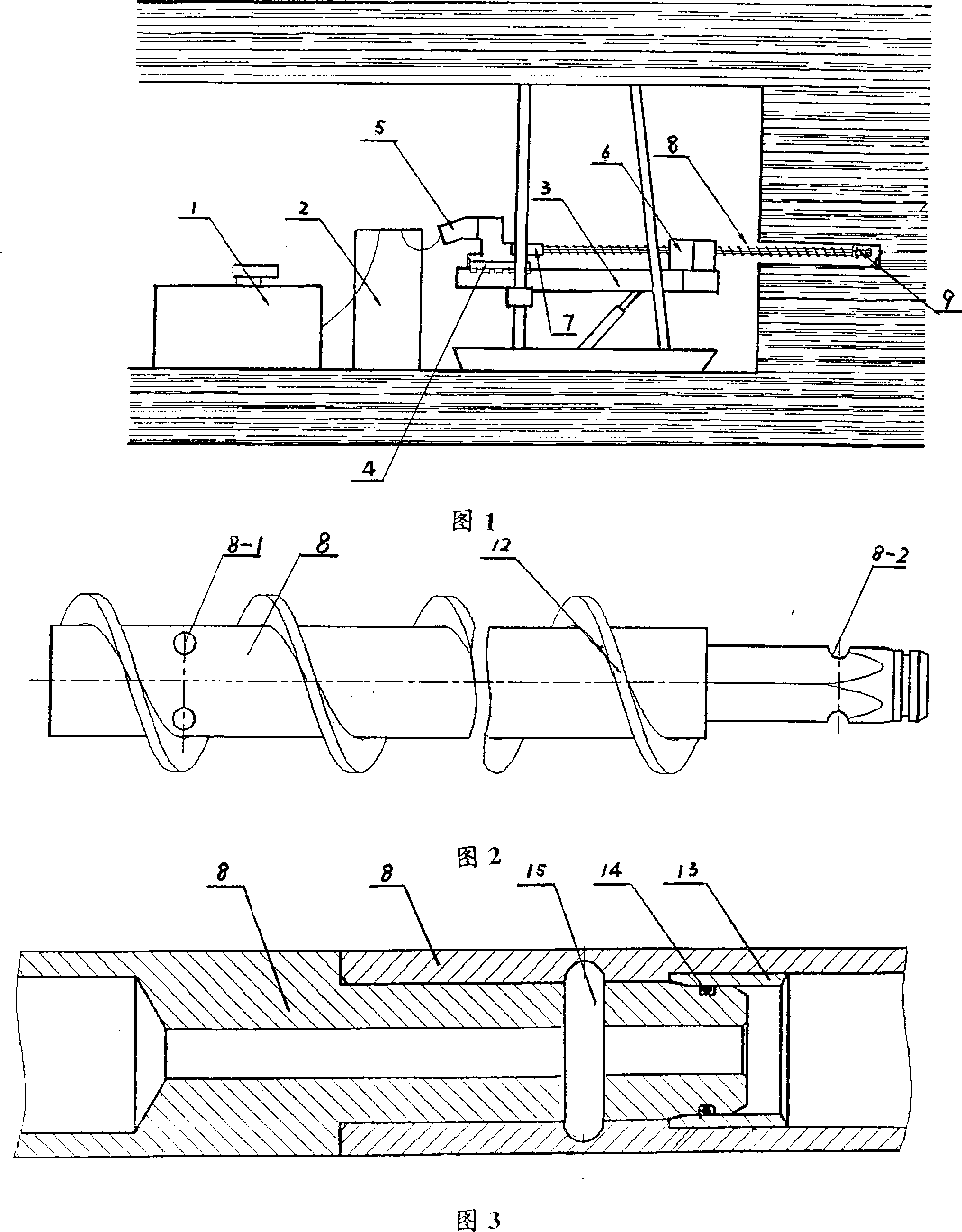

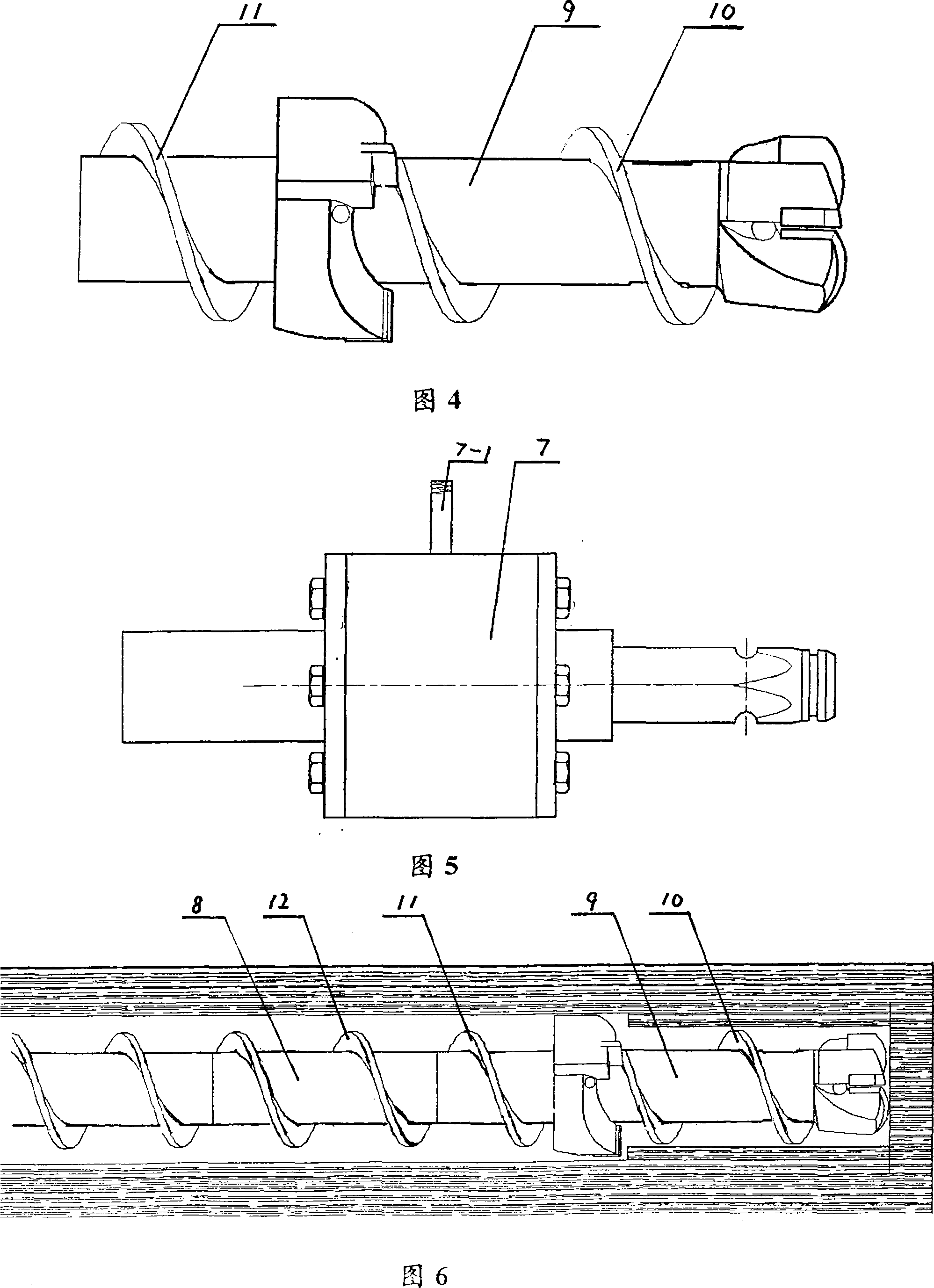

Down-hole coal bed air-pressing helix drilling tools and drilling method using the same

InactiveCN101131091AImprove the pumping effectEnsure safe productionDrill bitsDrilling rodsCoalDrill bit

The present invention relates to compressed air underground coal bed drilling auger, which includes one pump station, one operating console, one machine frame, one traveling unit, and one power head set on the traveling unit. The underground coal bed drilling auger features the air feeding change-over unit with one end fitting to the power head and one compressed air inlet connected the mine air compressing system, the hollow auger stem with one end connected to the air feeding change-over unit and the other end stretched through one gripper, and the two-stage combined drill fitting to the hollow auger stem. The underground coal bed drilling auger has rotation speed of the power head controlled in 180-650 rpm, homogeneous drilling rate controlled in 0.5-1 m / min, and air feeding pressure maintained in 0.2-0.75 MPa. The present invention has great hole forming depth, high hole forming rate, high hole forming rate and high gas exhausting effect.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Expansive-type high-polymer cement paste, grouting reinforcement device and grouting reinforcement method

ActiveCN107417182AImprove mechanical propertiesImprove bearing capacityDrilling compositionSoil preservationDynamic compactionWhole body

The invention provides expansive-type high-polymer cement paste, a grouting reinforcement device and a grouting reinforcement method, aiming to solve the technical problems that dynamic compaction is not uniform, partial compactness does not meet requirements and differential settlement of buildings occur when a dynamic compaction substitution method is used for miscellaneous fill foundation treatment. The expansive-type high-polymer cement paste comprises, by weight, 91-95 parts of Portland cement, 2-4 parts of soundless cracking agents and 3-5 parts of polypropylene fibers. The expansive-type high-polymer cement paste is injected into stratum evenly through a steel grouting pipe, original cracks are filled with grout in the mode of filling, permeating, swelling and compacting, originally-loose soil particles are rapidly solidified into a whole body, and a mini pile is formed in a drill hole, so that mechanical property of foundation soil is improved, and the effects of improving bearing capacity of the foundation soil and consolidating the foundation are achieved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

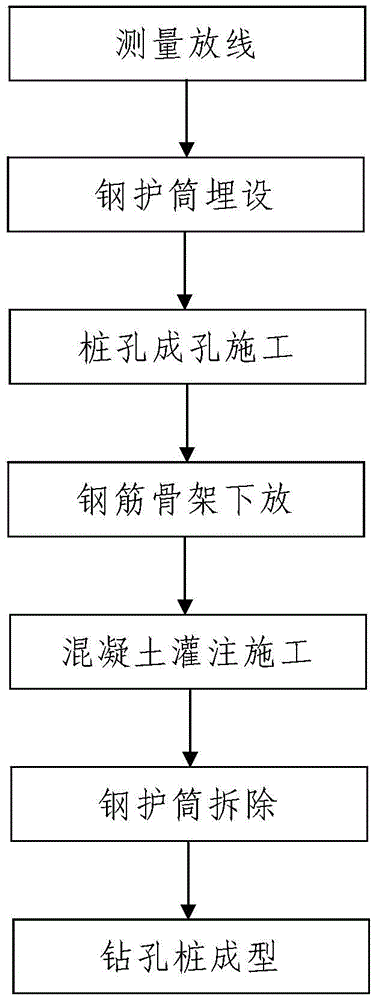

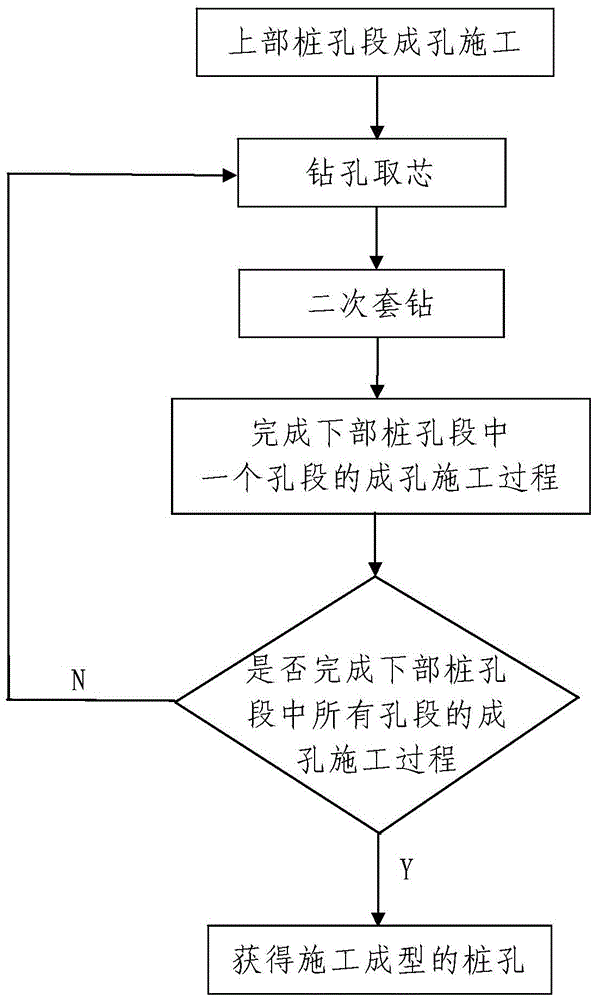

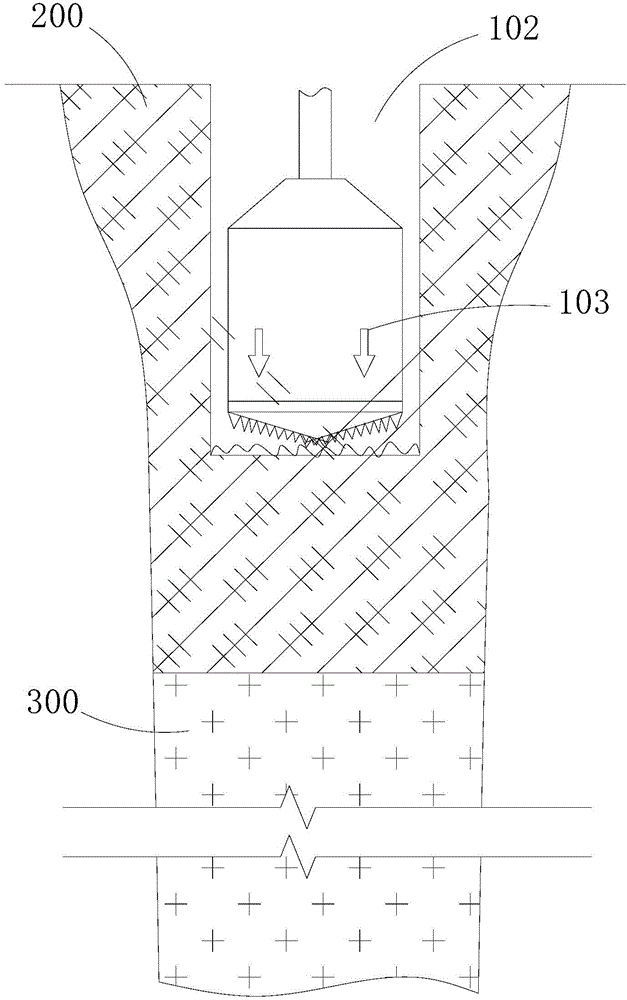

Construction method for bored pile of subway station enclosure structure of upper-soft lower-hard ground

ActiveCN105649012AThe method steps are simpleReasonable designDrill bitsCore removalSubway stationRebar

The invention discloses a construction method for a bored pile of a subway station enclosure structure of upper-soft lower-hard ground. The method includes the steps that firstly, measurement and paying-off are conducted, wherein measurement and paying-off are carried out at a pile position of the bored pile to be constructed, and the bored pile to be constructed is a cast-in-place pile constructed and formed in the upper-soft lower-hard ground; secondly, a steel casing is buried, wherein the steel casing is buried in the soft ground where the bored pile to be constructed is located; thirdly, drilling construction of pile holes is conducted; fourthly, a steel rib frame is laid down; fifthly, concrete pouring construction is conducted; sixthly, the steel casing is detached; seventhly, the bored pile is formed. Drilling construction of the pile holes includes the steps that 301, drilling construction is conducted on an upper pipe hole section and 302, drilling construction is conducted on a lower pile hole section, wherein the lower pile hole section is subjected to drilling construction by being divided into multiple pile hole section bodies from top to bottom, and when any hole section body is subjected to drilling construction, drilling for cores and secondary overcoring are conducted. The method is simple, design is reasonable, construction is easy and convenient, drilling difficulty of the pile holes is low, the use effect is good, and the bored pile construction process of the upper-soft lower-hard ground can be easily, conveniently and quickly completed.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Foundation excavation retaining and protecting cast-in-situ bored pile construction method and equipment thereof

The invention relates to the technical field of foundation excavation retaining and protecting cast-in-situ bored piles and discloses a foundation excavation retaining and protecting cast-in-situ bored pile construction method and equipment thereof. The method comprises the following steps: 1, adopting a rotary excavating drilling tool to guide a hole in advance; 2, adopting a vibratory hammer to convey a pile casing into the soil layer downward from a hole opening ; 3, adopting the rotary excavating drilling tool to drill to the elevation position at the bottom of the pile casing; 4, adopting an air compressor to supply air into the hole till the air comes out of an opening at the upper end of the hole, and then utilizing a down-the-hole hammer to drill on a bed rock layer; 5, after the down-the-hole hammer drills to a final hole, pulling out the down-the-hole hammer, and infusing slurry into the hole; 6, cleaning the interior of the hole, placing a steel reinforcement cage into the hole, and pouring concrete into the hole; 7, utilizing the vibratory hammer to pull out the pile casing. According to the construction method, a pile casing retaining wall is utilized, and the hole collapse and hole shrinkage can be prevented; the down-the-hole hammer is utilized for cooperating with the air compressor to supply the air, great rock breaking capability is achieved, a rotary drilling machine is adopted for cleaning the hole, the hole formation is made to be greatly accelerated, the construction progress is sped up, and the cost is saved.

Owner:SHENZHEN GONGKAN GEOTECHN GRP +1

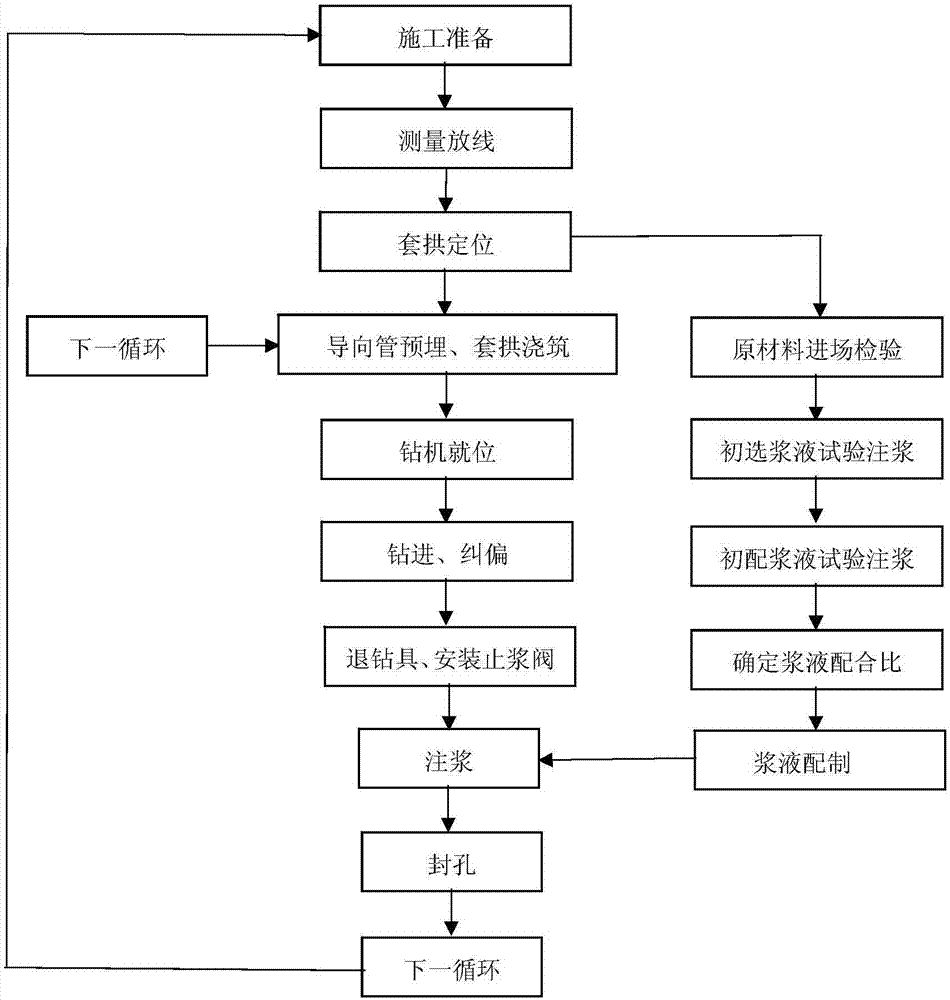

Construction method of super long pipe shed in soft surrounding rock section of tunnel portal

PendingCN106988755APrecise drilling processImprove pore forming efficiencyUnderground chambersDirectional drillingStructural engineeringAir compressor

The invention discloses a construction method of a super long pipe shed in a soft surrounding rock section of a tunnel portal. The accuracy of the construction of the pipe shed is ensured through utilizing a guiding technology, the drilling process records the geography and provides a reference for tunnel excavation, and effective advance support provides technical support for tunnel excavation. Before tunnel excavation and entering the portal, a front slope on the edge of the portal is excavated in place, a pipe shed guiding wall is applied, a guiding pipe is pre-embedded, meanwhile, a drill pipe is machined, a high-speed air compressor is arranged, after a drilling machine is in place, a positioning device is mounted in a drill pipe head for positioning, deviation is rectified in time in the drilling process according to the drilling bias of a rod body, meanwhile, the power is adjusted according to the drilling length and soil layer geological conditions, the depth and the location of the drilling machine are ensured, and after drilling is completed, the drilling machine and the drill pipe are separated and grouting is conducted; and construction of the next pipe shed is started, and a stable arch ring outside excavation is formed. According to the construction method of the super long pipe shed in the soft surrounding rock section of the tunnel portal, the phenomena of hole shifting and hole collision do not exist, the hole-forming efficiency is high, and the construction method is suitable for environments such as complex geological conditions, a loose sand layer and a clay layer.

Owner:THE FIFTH ENGEERING OF CHINA RAILWAY 5TH BUREAU GROUP

Rotary pump perforating piling machine

ActiveCN102251518AImprove compactnessWill not collapse holesDrill bitsDrilling rodsSoil horizonEngineering

The invention provides a rotary pump perforating piling machine which is characterized by comprising a rack, a drill rod is arranged on the rack, a diamond soil suction perforating drill bit is fixedly arranged at the lower end of the drill rod and is internally provided with a power pump, a rotary drill bit is arranged below the diamond soil suction perforating drill bit and connected with the power pump, soil stirring blades evenly distributed at the circumference are arranged around the rotary drill bit, soil suction pipes are arranged at the intervals among the soil stirring blades and are connected with a one-way mud pump valve which is connected with a mud pipe and a high-pressure diamond hydraulic power soil suction pressure pump, and the mud pipe is wound on a mud pipe roll which is arranged on the rack. In the invention, a soil semi-squeezing mode is adopted, namely, soil layers are beaten and stone blocks are crushed by the drill bit, weak soil is pumped to the ground by thesoil suction pipe, broken stones are squeezed and compacted on hole walls under the driving of the soil stirring blades, and the compactness of the squeezed hole walls is improved and collapse hardlyhappens; and the small stones are squeezed towards the hole walls and soil comes from the high-pressure pipe, thus high pore-forming speed and good pore-forming quality are achieved.

Owner:洪子云

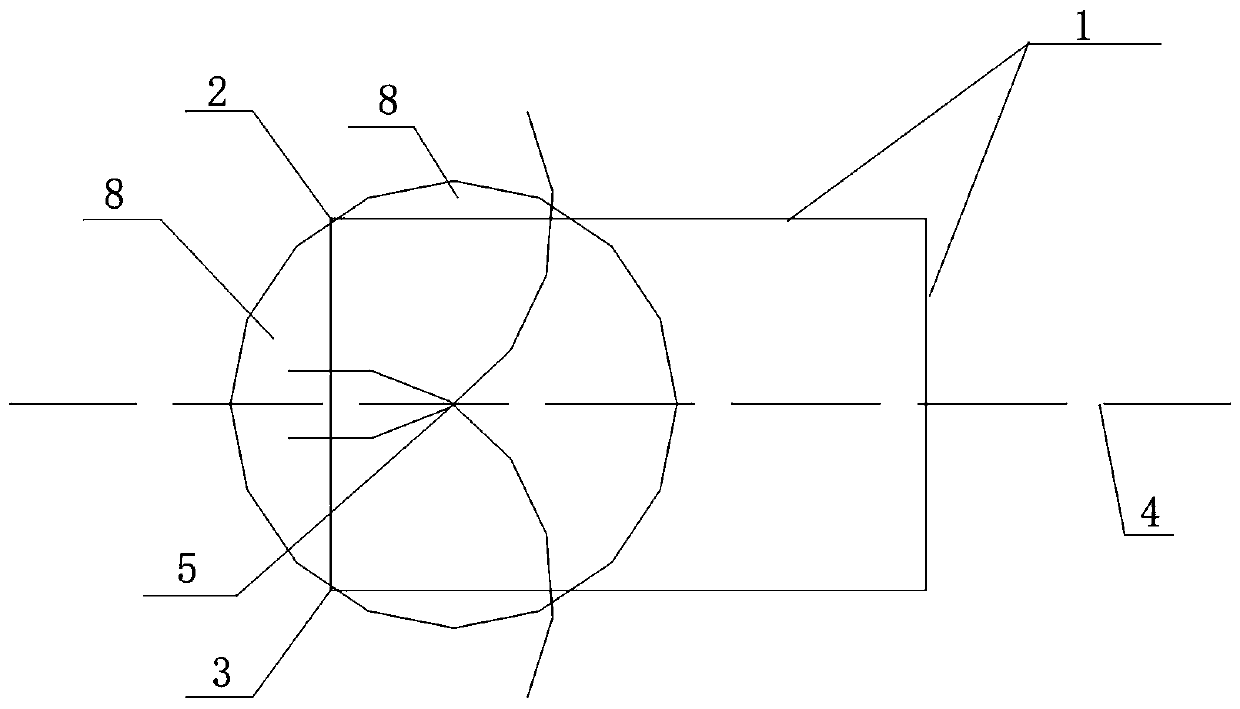

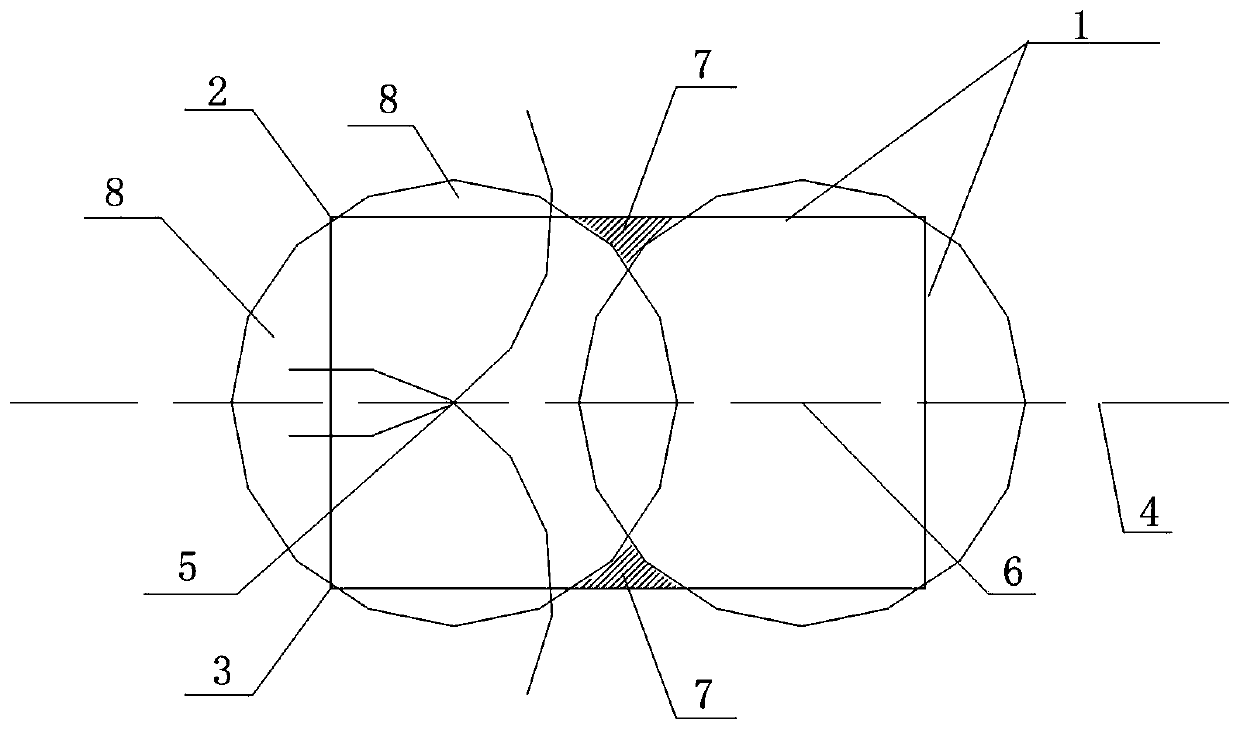

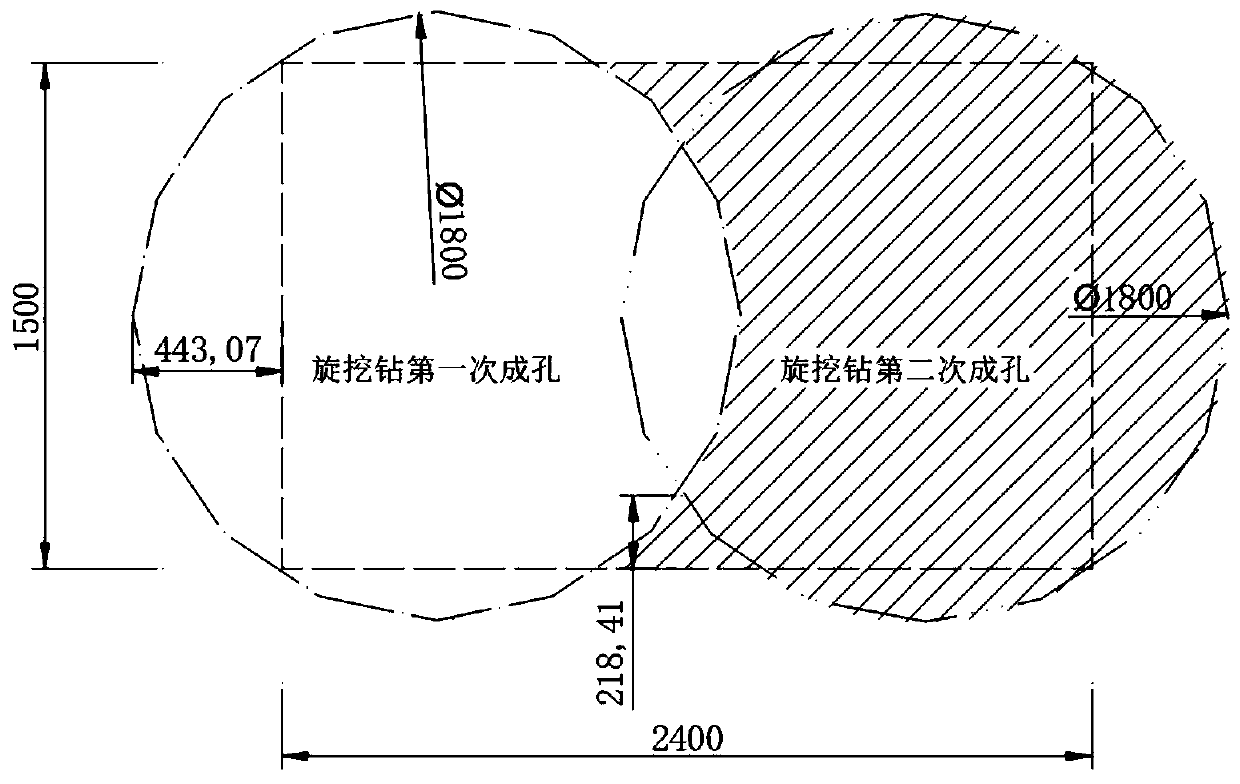

Mechanical hole forming construction method of rectangular slide-resistant pile

ActiveCN110374091AReduce security risksReduce construction costsBulkheads/pilesDrilling machines and methodsMechanical equipmentRebar

The invention discloses a mechanical hole forming construction method of a rectangular slide-resistant pile, and belongs to the technical field of side slope retaining structure construction. The method comprises the following steps of: step A. carrying out setting-out location on a rectangular pile hole; step B. manufacturing a rectangular steel pile casing; step C. digging a hole by using a spun-digging pile machine; step D. lowering the rectangular steel pile casing into the rectangular pile hole by using a mechanical arm, and removing excess earthwork from the side wall; step E. pouring concrete in the over-excavation area outside the steel casing; step F. raising the steel casing by using the mechanical arm; and step G. lowering a rectangular steel reinforcement cage, and pouring theconcrete to form the slide-resistant pile. The construction method solves the problems that the efficiency of causing a manual hole digging pile to break into rock is low, the blasting excavation is not allowed in complicated environments, and the hole forming construction is extremely difficult; and the construction method only needs conventional rotary excavating mechanical equipment, does not increase the construction cost and has the advantages of fast hole formation speed, high construction efficiency, simple operation, low safety risk and the like.

Owner:YUNNAN JIANTOU FOUND ENG CO LTD

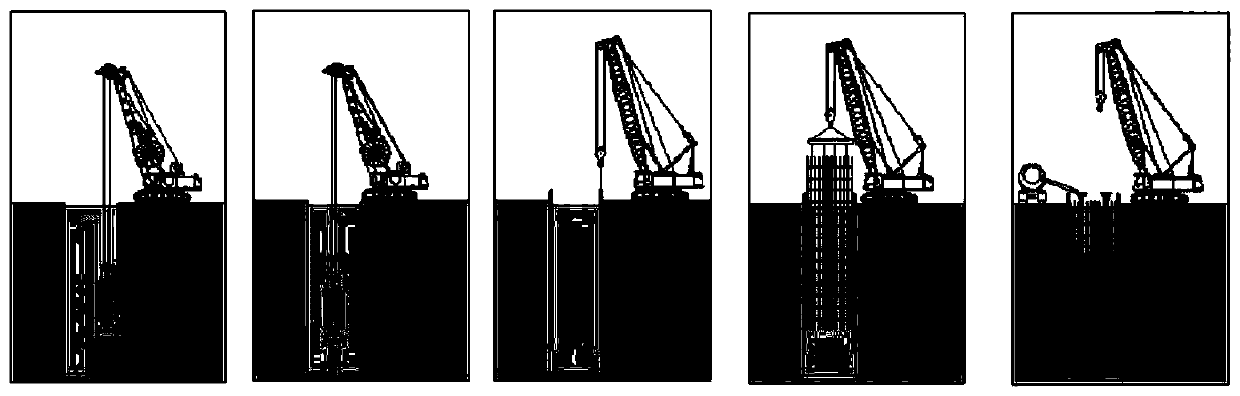

Cast-in-place pile synchronous casing hole-forming constructing method

InactiveCN103015408ASolve the problem of collapse and stickingSolve the problem of verticality skewDrilling rodsBorehole drivesSlurryPollution

The invention belongs to the technical field of building engineering and particularly relates to a cast-in-place pile synchronous casing hole-forming constructing method. The method comprises the following steps of 1, pile position lofting; 2, synchronous follow-up installation; 3, pile machine positioning; and 4, hole forming and hole cleaning. The cast-in-place pile synchronous casing hole-forming constructing method has the beneficial effects that when the stratum has giant-grained soil layers such as erratic boulder, rock block and pebbles, the problems of verticality deflection and drill clamping through rock caving can be effectively solved, the construction speed is high, and the cost is low; for strata such as loose backfill soil and sand layers, the occurrence of pile body hole collapse phenomena can be effectively controlled, and the concrete cost is effectively reduced; the slurry making wall protection is not needed, a synchronous follow-up steel sleeve can effectively prevent the hole collapse, meanwhile, the synchronous follow-up steel sleeve can be embedded into the rock layer in time, an effect of preventing underground water from leaking into the pile holes is realized, and no water exists in the holes after the hole forming; and the method has the characteristics that the construction quality is reliable, the hole forming speed is high, the hole forming rate is high, the adaptability is high, and the like, the noise is low, the pollution is little, and the environment is protected.

Owner:SHANDONG WANXIN CONSTR

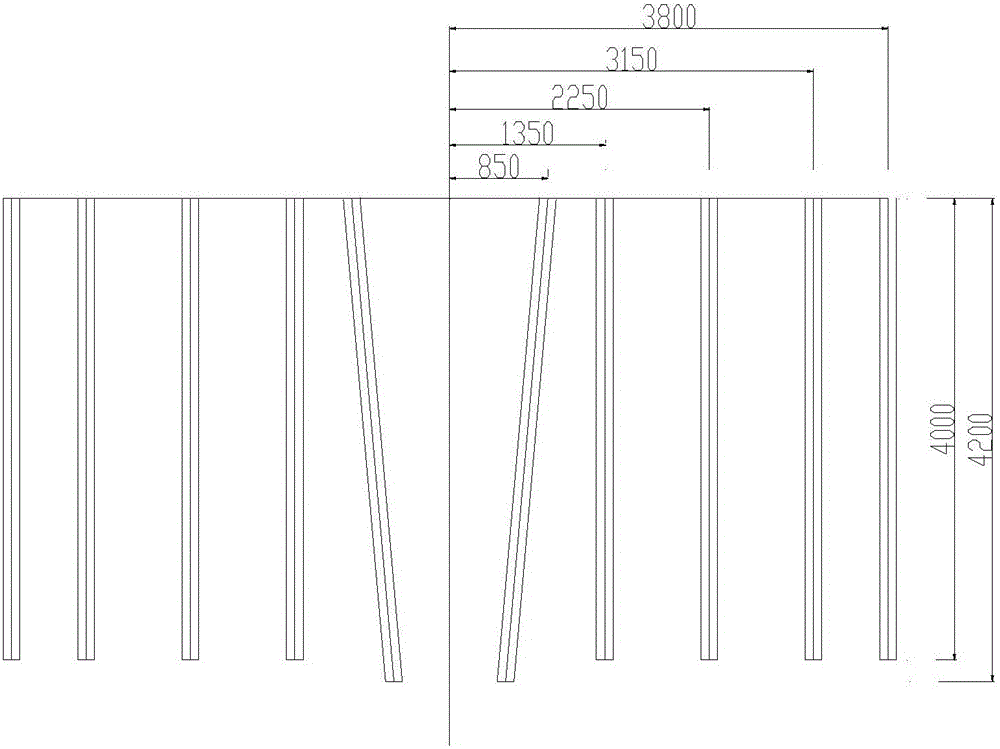

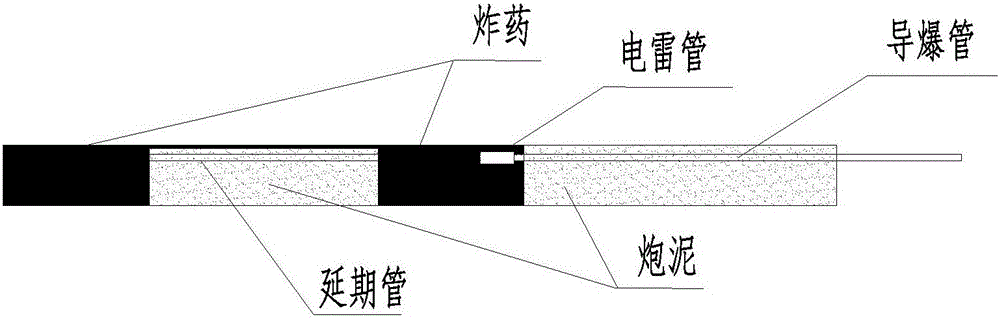

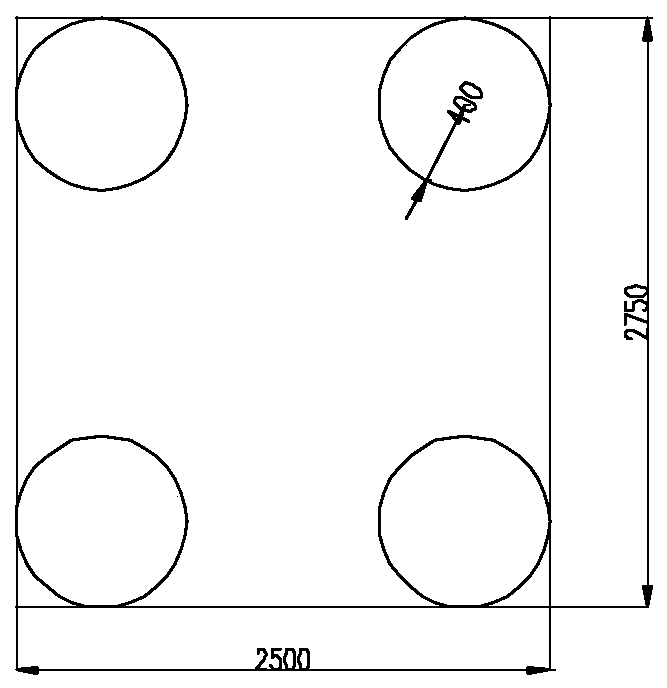

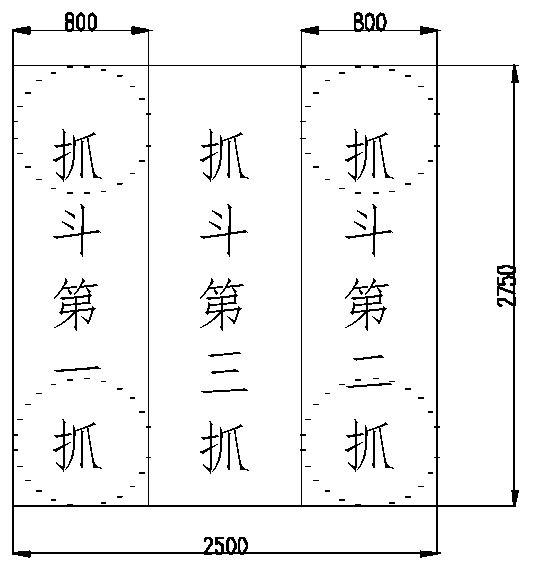

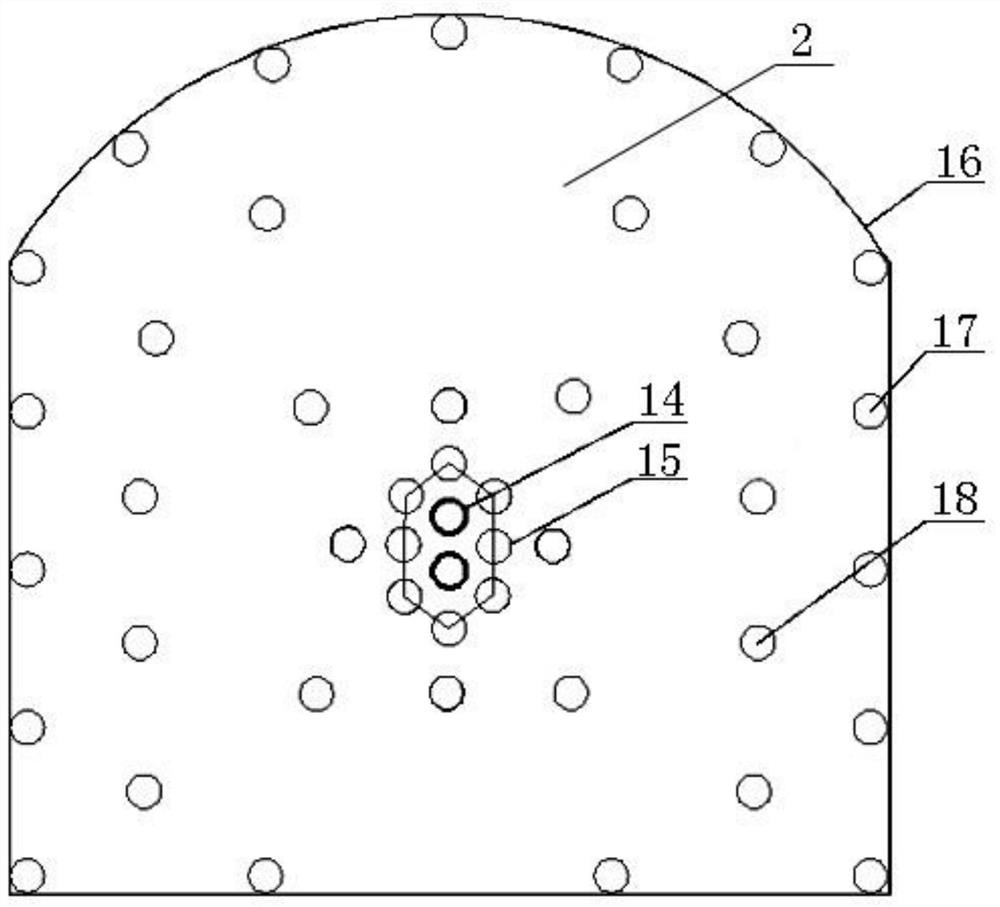

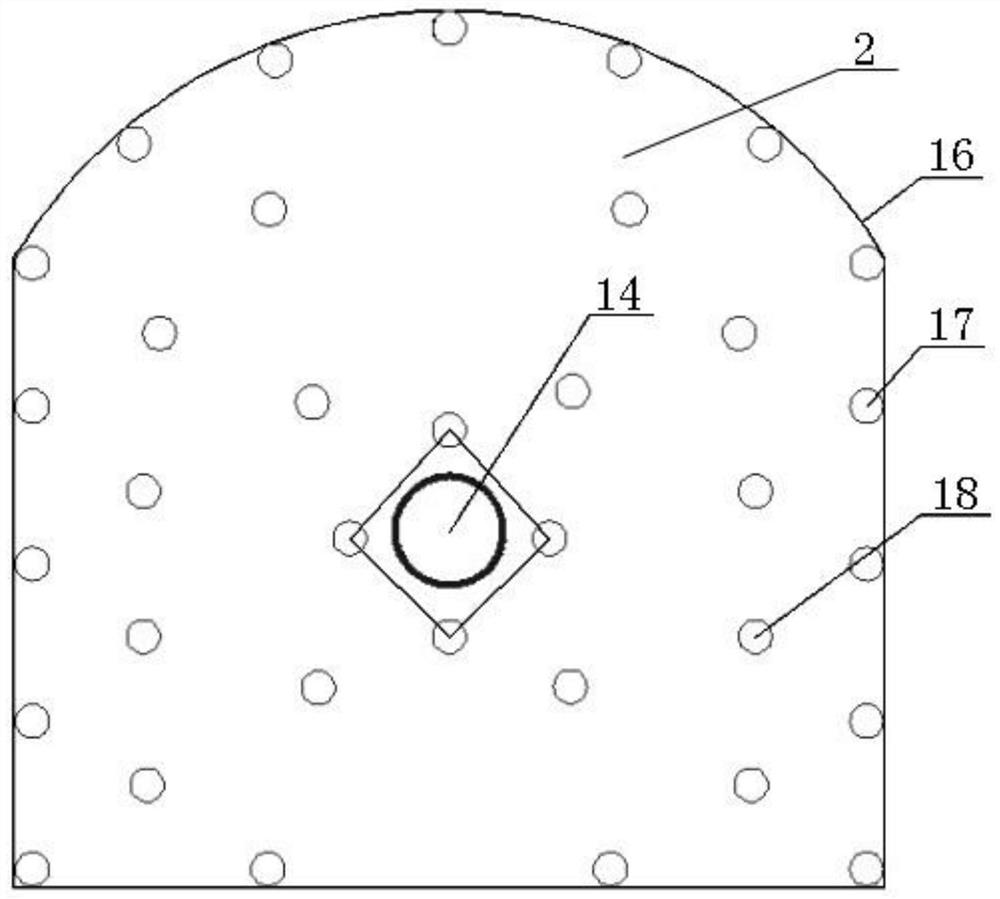

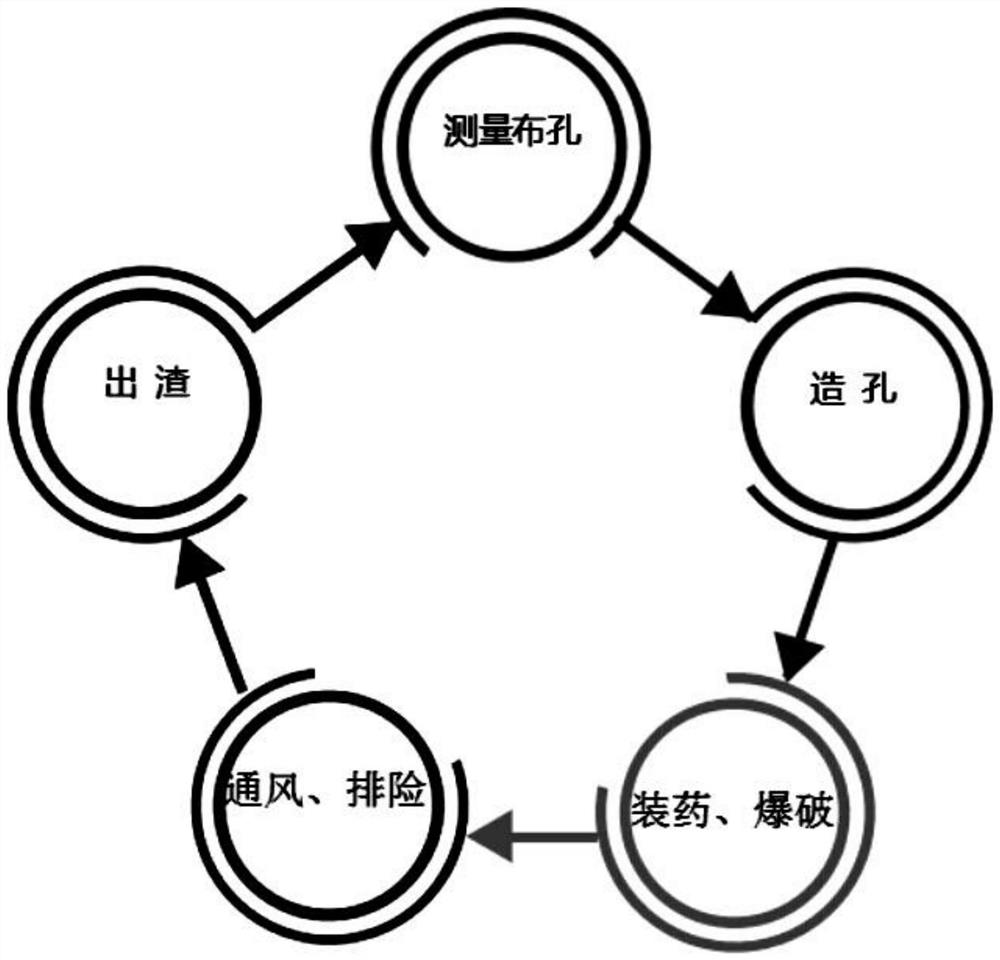

Rapid construction method for deep hole blasting of vertical shaft frozen bedrock

A rapid construction method for deep-hole blasting of frozen bedrock in shafts, in particular to a construction method for rapid excavation of deep-hole blasting in deep holes around bedrock after vertical shafts are frozen without affecting the safe operation of frozen layers or frozen pipes . It overcomes the shortcomings of low efficiency, long construction period and high cost caused by shallow hole blasting in general, and provides a construction method of deep hole differential blasting in bedrock combined with vertical shaft freezing method. A deep hole is formed in one drilling, and the peripheral hole is divided to form a peripheral eye charge structure, which realizes the micro-difference smooth surface blasting in the hole, thereby reducing the blasting vibration and effectively protecting the safety of the frozen pipe and the frozen wall. The drilling and blasting efficiency is improved, the construction progress is accelerated, the construction period is shortened, and the efficiency of equipment mechanization can be exerted.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

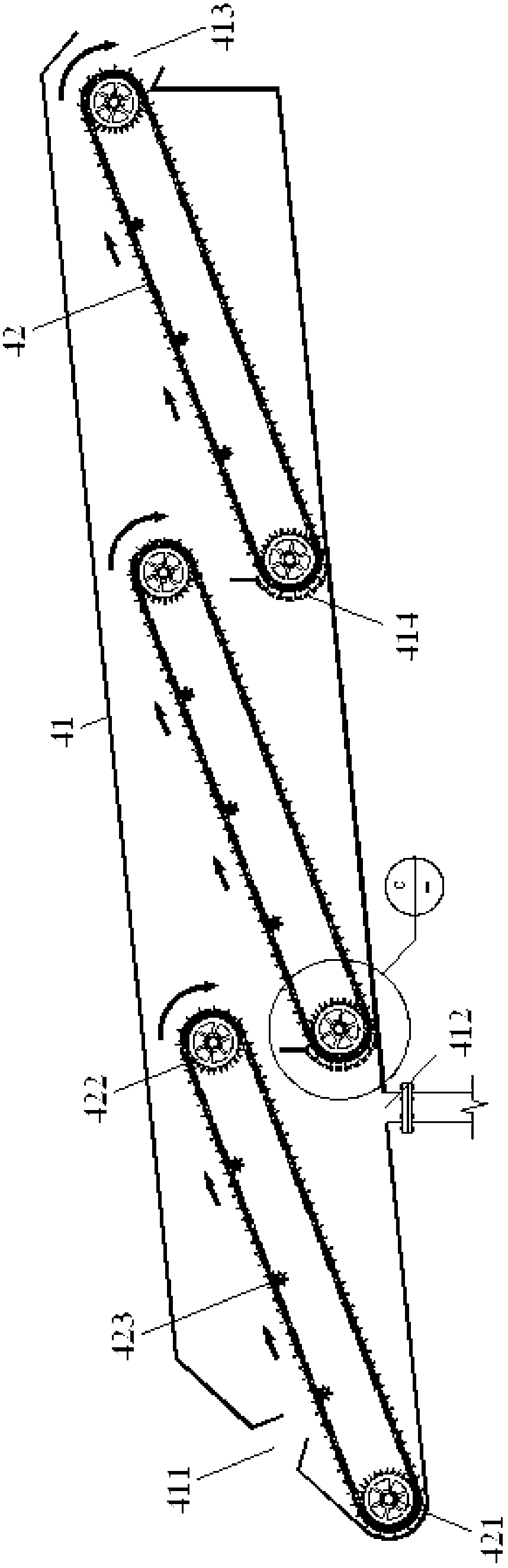

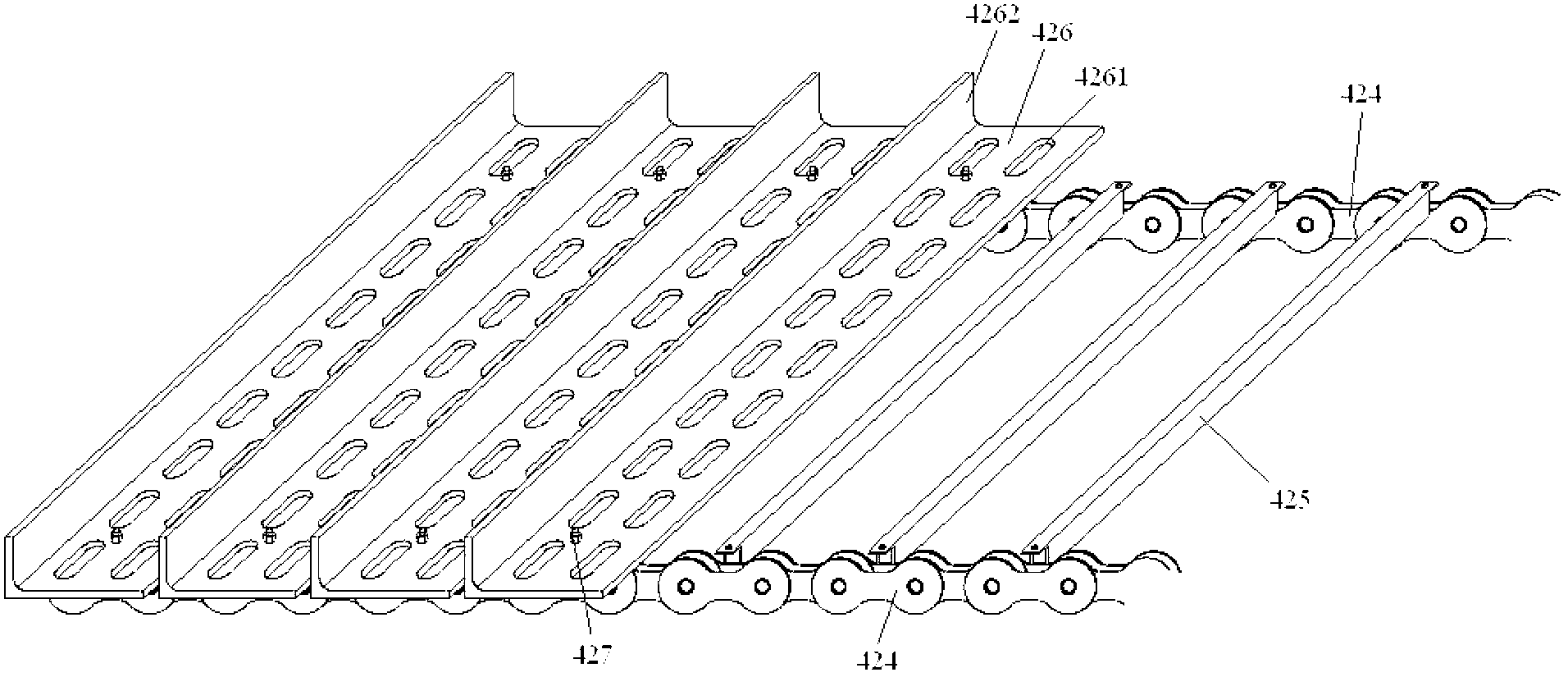

Rectangular anti-sliding pile mechanical and fast hole forming construction method

InactiveCN110593753ALow costMeet the node duration requirementsSurveyRotary drillingRebarDrilling machines

The invention discloses a rectangular anti-sliding pile mechanical and fast hole forming construction method. The method includes the following steps that 1, industry data are prepared; 2, a construction site is prepared; 3, ground leveling is performed; 4, staking out in survey is performed; 5, locking notch construction is performed; 6, hole drilling is performed, specifically, 6.1, a drilling machine is put in place, and 6.2, drilling construction is performed; 7, hole checking is performed after pile forming is finished; 8, making and lifting of a steel reinforcement cage are performed, specifically, 8.1, the steel reinforcement cage is made, and 8.2, the steel reinforcement cage is lifted; and 9, concrete pouring is performed. Drilling machine or manual hole digging construction is replaced by hole forming construction of a trenching machine; and through a trenching machine hole forming rectangular anti-sliding pile construction method, the requirements of shortening the construction period are met, the project cost is reduced, and the construction safety is guaranteed. A research group implements a trenching machine hole forming rectangular anti-sliding pile construction process, that is, a novel technology of combining the trenching machine and a long-arm breaking hammer for anti-sliding pile construction is adopted, and the novel technology has the advantages of being high in applicability, fast, efficient and safe in construction and the like.

Owner:THE SECOND ENG CO LTD OF CHINA RAILWAYSEVENTH GRP PRC

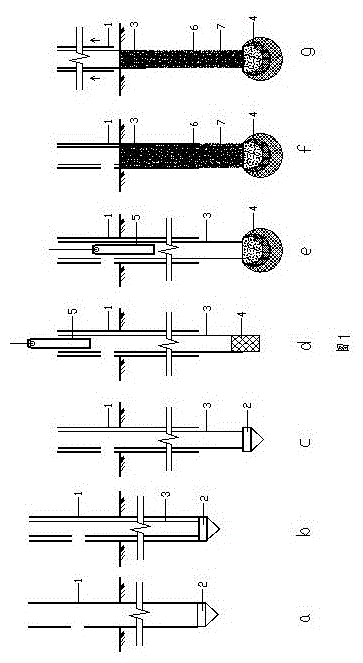

Construction method for carrier pile of major diameter long pile

ActiveCN104988913ALower requirementGuaranteed bearing capacityFoundation testingBulkheads/pilesCarrying capacityMulti method

An objective of the invention is to provide a construction method for a carrier pile of a major diameter long pile. A method of alternate double casing is used, and aimed at different soil layers, a plurality of means are selected, so as to complete large diameter and large depth pile body pore forming. Then carrier construction is performed on a pile tip, obviously improving carrying capacity of a pile and improving work efficiency and saving cost. The method comprises steps: 1) using a double casing pipe method to perform pore forming construction, soil-squeezing pore forming steps: making an A pile casing with a pile tip sink, making a B pile casing sink in the A pile casing and making the B pile casing sink to a set depth, soil-taking pore forming steps: making the open A pile casing sink and then taking soil mass in the A pile casing out, making the B pile casing sink in the A pile casing, and making the B pile casing sink to the set depth again, and taking soil mass in the B pile casing out; 2) according to soil layer property and upper load requirement, performing reinforcement treatment of the pile end through one of a plurality of methods, so that soil mass at a certain depth under the pile end and in a certain range are reinforced and compacted to form a pile end carrier, to realize equivalent calculation area Ae of the carrier pile; 3) and performing cast-in-place or precast concrete pile body construction through one of a plurality of methods.

Owner:王继忠 +1

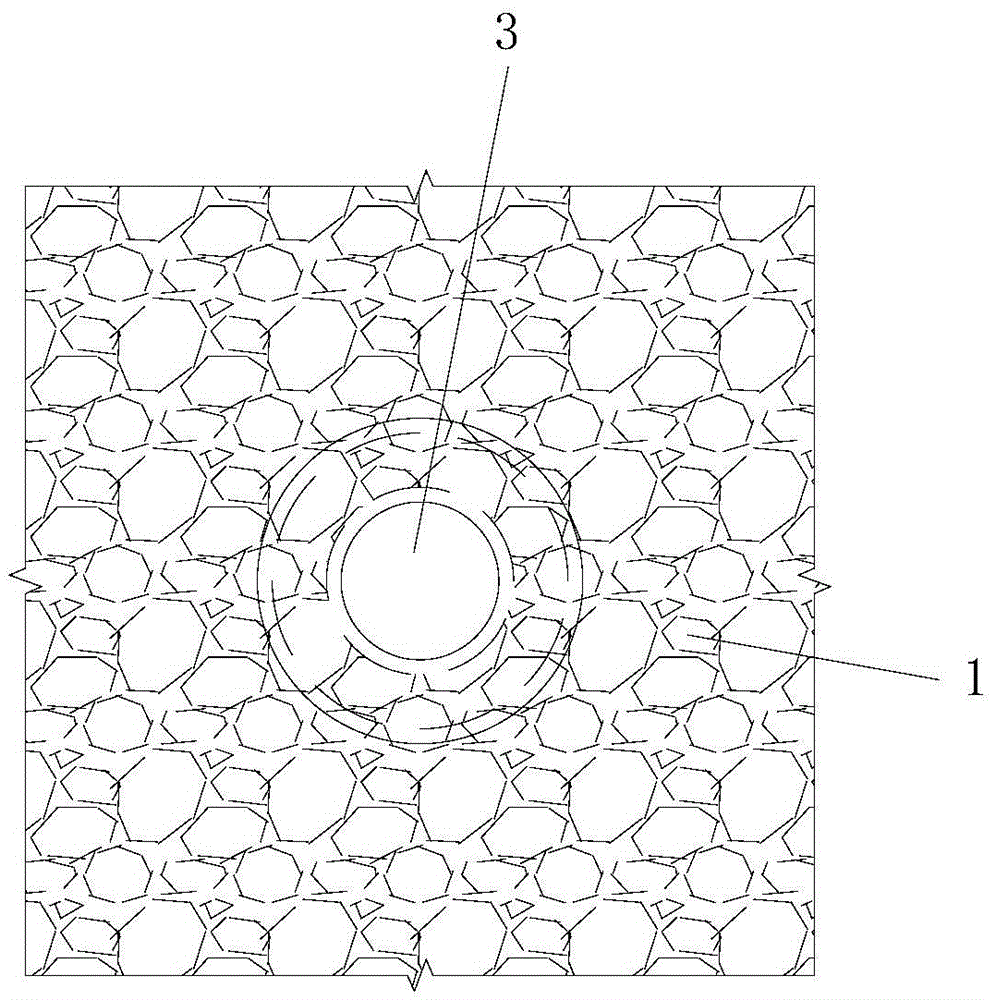

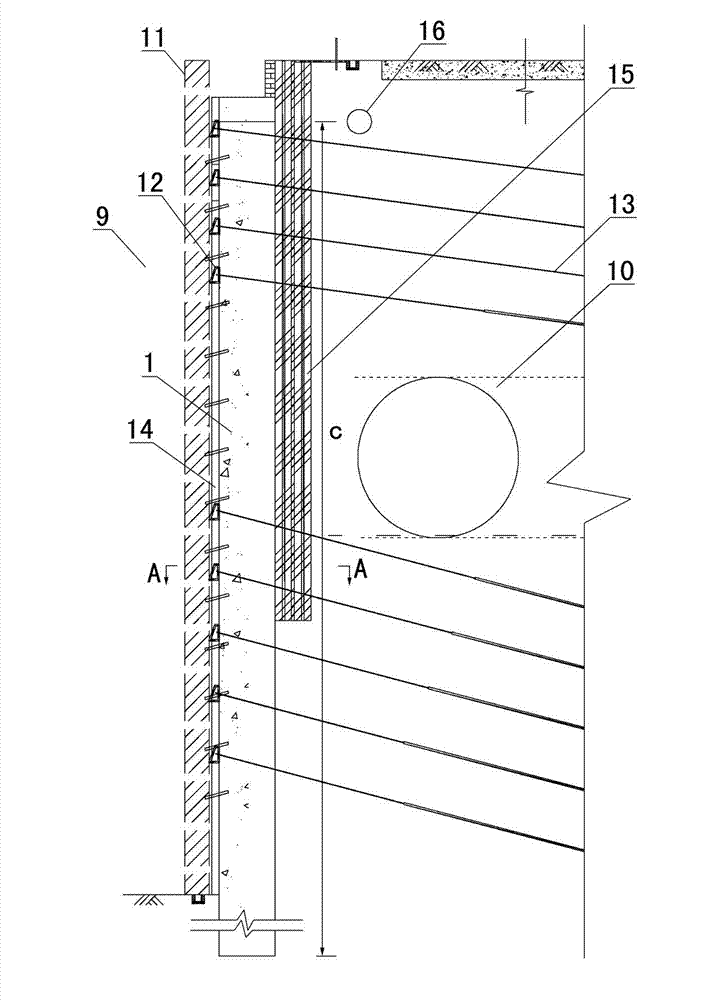

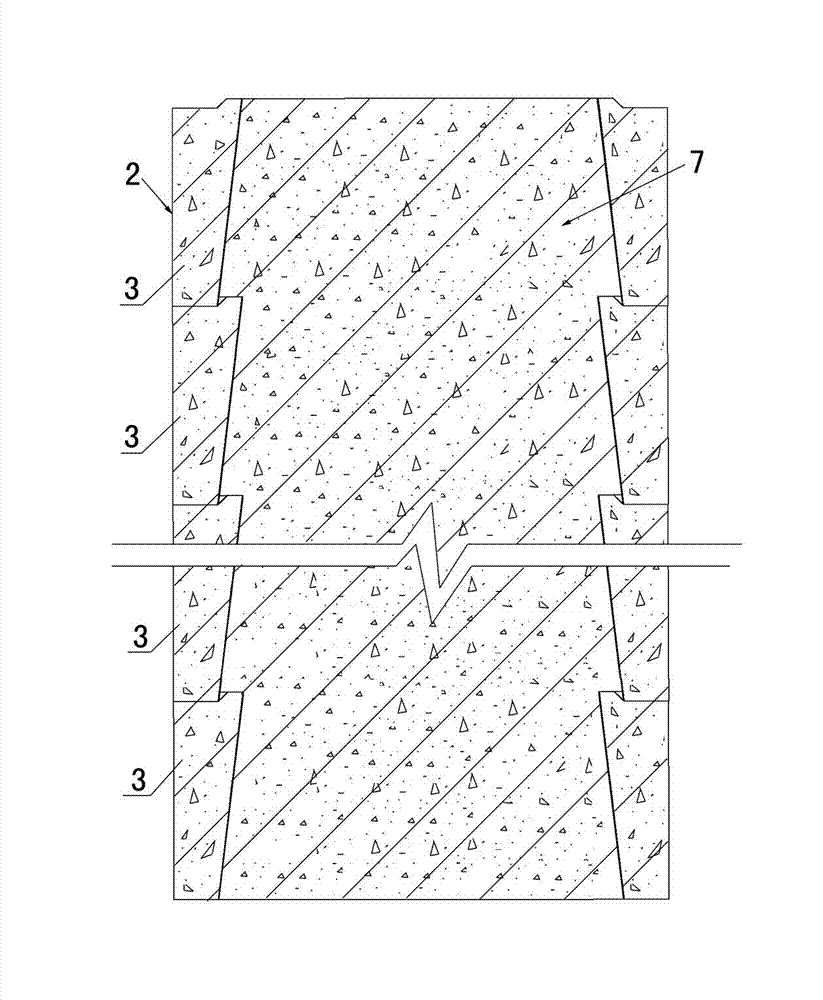

Ultra-deep large-section square supporting pile and construction method thereof

InactiveCN102828506AImprove skid resistanceShorten the construction periodExcavationsBulkheads/pilesReinforced concreteSlurry

The invention relates to an ultra-deep large-section square supporting pile and a construction method thereof. The ultra-deep large-section square supporting pile is arranged on one side of a foundation pit close to a metro shield area and comprises a pile hole retaining wall and a pile core, wherein the pile hole retaining wall and the pile core both have cast-in-place reinforced concrete structures; the pile hole retaining wall is formed by splicing sections of square protecting cylinders; inner lateral surfaces of the square protecting cylinders are inclined planes which are inclined to the pile core from bottom to top; a lug boss is arranged at a seam of upper and lower two sections of square protecting cylinders and on one side of the upper end face of the lower square protecting cylinder close to the pile core; and double-slurry liquid composed of sodium silicate and cement paste is filled in a gap between the lug boss and the square protecting cylinders. The anti-skidding capacity of the ultra-deep large-section square supporting pile is strong, so that the foundation pit support construction and the metro shield construction are no longer conflicted after the supporting pile is adopted; the foundation pit support construction and the metro shield construction can be performed alternately; and the construction period of the foundation pit support is greatly shortened.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

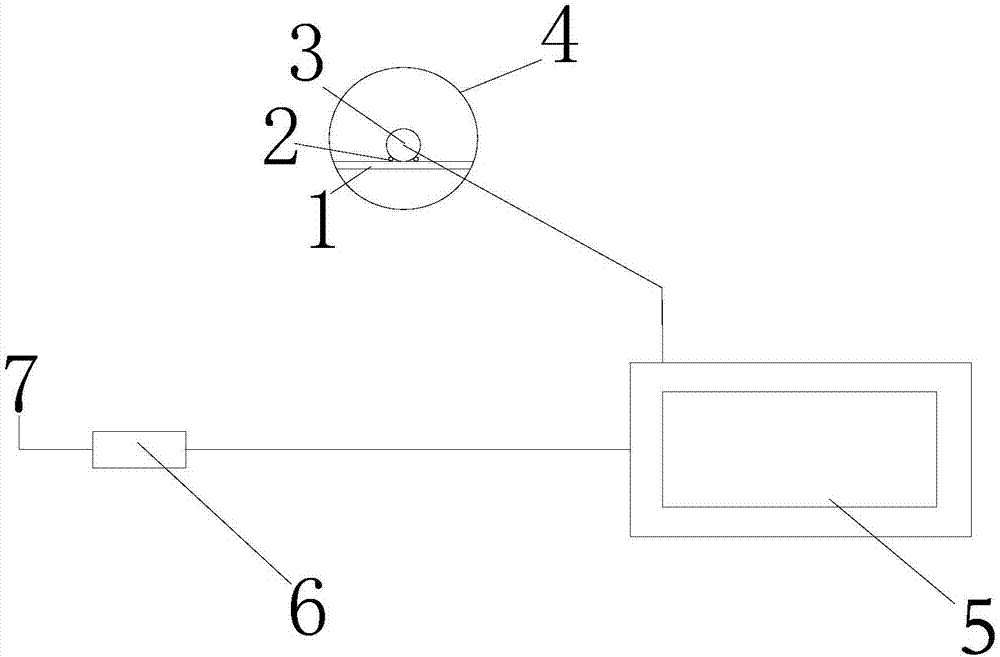

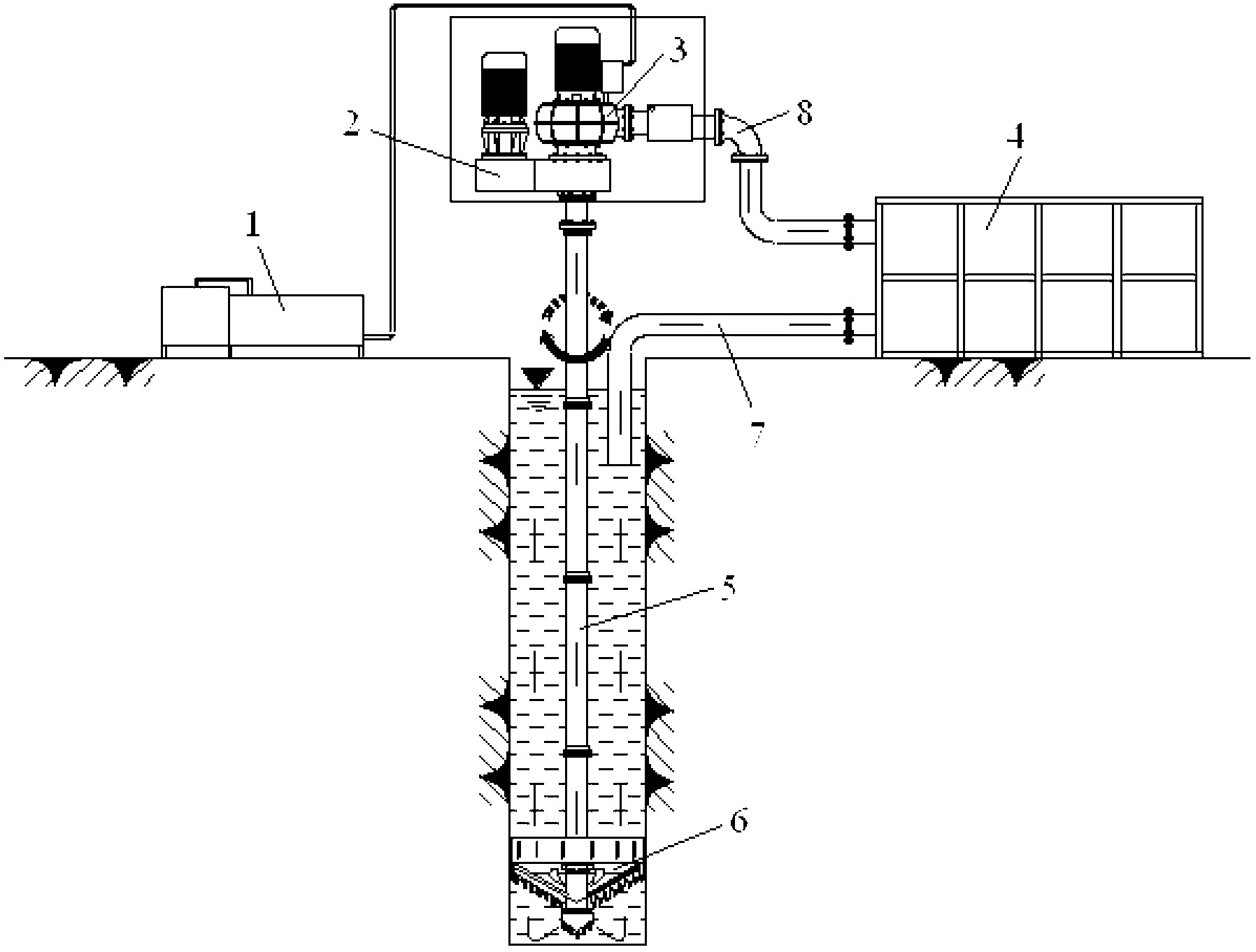

Drilling-type quick pore-forming system and drilling-type quick pore-forming process

ActiveCN103266852AFast hole formingShorten the hole forming cycleSedimentation separationDrilling machines and methodsVacuum pumpForming processes

The invention relates to a pore-forming device and a pore-forming process in civil engineering, in particular to a drilling-type quick pore-forming system and a drilling-type quick pore-forming process. The drilling-type quick pore-forming system comprises a power device, a hollow drilling rod, a drill bit, a vacuum pump and a dredge pump. The power device is connected at the tail end of the hollow drilling rod, the drill bit is connected at the front end of hollow drilling rod, and the hollow drilling rod is respectively connected with the vacuum pump and the dredge pump. Compared with the prior art, the drilling-type quick pore-forming system has the advantages that pore-forming speed is increased by 2.5-3 times those of conventional pore-forming speeds, so that a pore-forming cycle can be shortened, and the drilling-type quick pore-forming system is particularly suitable for being used under circumstances that rapid construction is required or requirements on neighboring environment protection are high.

Owner:SHANGHAI SHANSHUN CIVIL ENG TECH +1

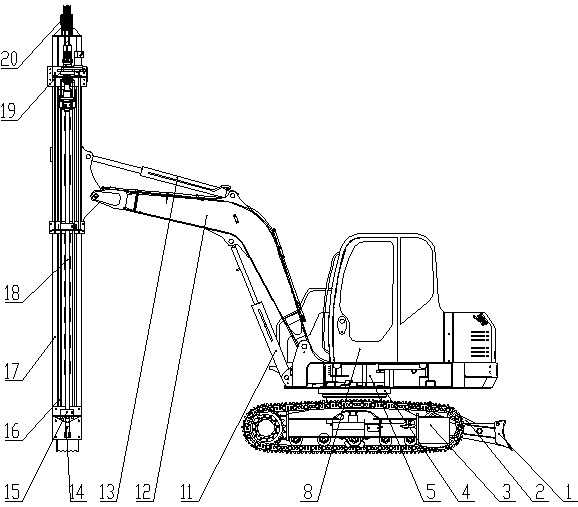

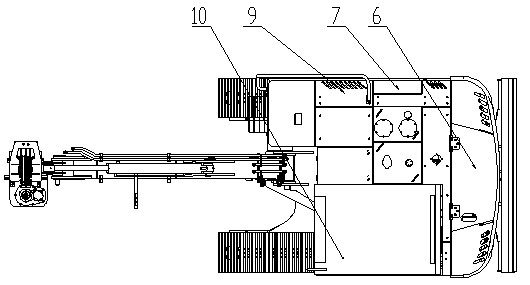

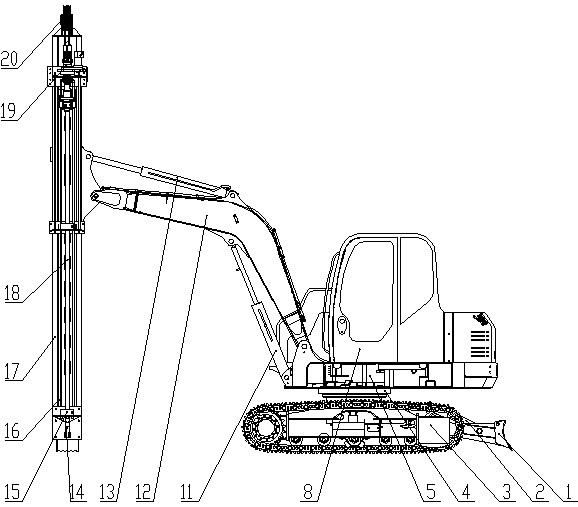

Cutting drilling machine

InactiveCN102134966AGuaranteed visionCompact structureConstructionsDerricks/mastsHeavy dutyDrilling machines

The invention relates to a cutting drilling machine, belonging to the field of heavy-duty machinery. The cutting drilling machine comprises a chassis assembly, a slewing mechanism, a platform assembly, a power system, a hydraulic system, an operating system, a movable arm cylinder, a movable arm, a drilling frame cylinder, a drill, a drilling frame, a drill stem, a power head system and a drill stem propulsion system, wherein the chassis assembly is arranged at the lowest end; the platform assembly is connected with the chassis assembly via the slewing mechanism and is arranged above the chassis assembly; the power system, the hydraulic system and the operating system are connected with each other and are arranged on the platform assembly; the power system is connected with the chassis assembly; one end of the movable arm cylinder is hinged on the platform assembly and the other end of the movable arm cylinder is hinged with the movable arm; one end of the drilling frame cylinder is hinged on the movable arm and the other end of the drilling frame cylinder is hinged with the drilling frame; the movable arm is connected with the drilling frame; the drill stem propulsion system is arranged above the drilling frame; the power head system, the drill stem and the drill are arranged in the drilling frame from top to bottom ins sequence; and the hydraulic system is connected with the drilling frame cylinder, the movable arm cylinder and the drill stem propulsion system respectively.

Owner:HANGZHOU HANGZHONG CONSTR MACHINERY

Method for pore-creating of geology with aleurite layer of upper part and middle, slightly weathered siltstone layer of lower part

ActiveCN101250869AImprove hole qualityPile Hole Cost ReductionExcavationsBulkheads/pilesEngineeringFast speed

The invention relates to a boring method of geology whose upper portion is a silt layer and lower portion is a moderately weathered and a slightly weathered silt strata, which relates to a construction method of pile foundation boring. The invention aims to solve the problems that prior geology whose upper portion is a silt layer and lower portion is a moderately weathered silt strata or a slightly weathered silt strata uses an electric impact drill to impact to form holes, the boring speed is slow, the efficiency is low, the construction is not done using an auger drill, mud which is used when auger construction is prepared by bentonite or clay, the manhole mud concentration is 1.15-1.25, the manhole mud viscosity is 18-24S, and the moderately weathered and the slightly weathered silt strata which are arranged on the lower portion of the pile foundation is punched by the electric impact drill. Compared with the electric impact drill is solely used to punch, the boring method has faster speed, the upper portion 40mm geology of a pile hole whose length is 50mm and diameter is 1.25m is a silt layer, the lower portion is the moderately weathered and the slightly weathered silt strata, and the boring time is only 4-5 days. Compared with the prior art, the cost of the pile hole is capable of being reduced by 50 percent.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP NO 4 ENG

Construction method for cast-in-place concrete pile of soft soil foundation with stone layer

The invention discloses a construction method for a cast-in-place concrete pile of a soft soil foundation with a stone layer. The construction method comprises the following steps: 1), determining the centre position of a cast-in-place reinforcement concrete pile; 2), using a vibration sunken tube method to sink the precast pile tip to the designed position, and enabling the bottom elevation of a steel sleeve to be parallel to that of the pile; 3), putting a reinforcement cage to the steel sleeve; 4), pouring concrete to the designed elevation of the pile top; and 5), waiting for 1-2 hours, pulling out the steel sleeve to form the cast-in-place reinforcement concrete pile. The construction method is simple and easy to operate, high in efficiency, convenient to control project quality, and safe and reliable, thereby the construction cost is greatly reduced, the working efficiency is improved, and manpower, material resources and financial resources are saved; moreover, the construction method is applicable to construction environments such as the soft soil foundation, regions abundant in underground water and the like.

Owner:TIANJIN 20 CONSTR

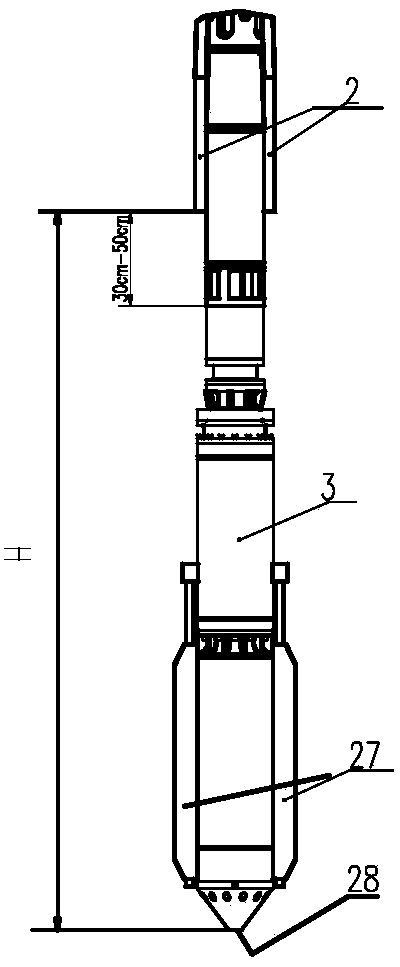

Concrete pile construction equipment and method

The invention aims to provide concrete pile construction equipment comprising a guard cylinder, a delivery pipe and a penetrating hammer. The concrete pile construction equipment is characterized in that an impact hammer is connected to the bottom end of the guard cylinder, the delivery pipe is disposed inside the guard cylinder and is communicated with an inner pipe of the impact hammer, the penetrating hammer is further disposed inside the guard cylinder, the lower half of the impact hammer is a pointed cone, and the upper half of the impact hammer is a cylinder integrally fixed to the guard cylinder. The invention further provides a concrete pile construction method employing the concrete pile construction equipment. The method includes the steps of 1, aligning a pile position; 2, lifting the penetrating hammer to strike the impact hammer which drives the guard cylinder to sink; 3, stopping striking until the guard cylinder sinks to a designed depth; 4, delivering concrete to the delivery pipe; 5, lifting up the guard cylinder while delivering the concrete; 6, stopping lifting until the guard cylinder is out of the surface of a foundation; 7, performing following construction.

Owner:北京波森特岩土工程有限公司

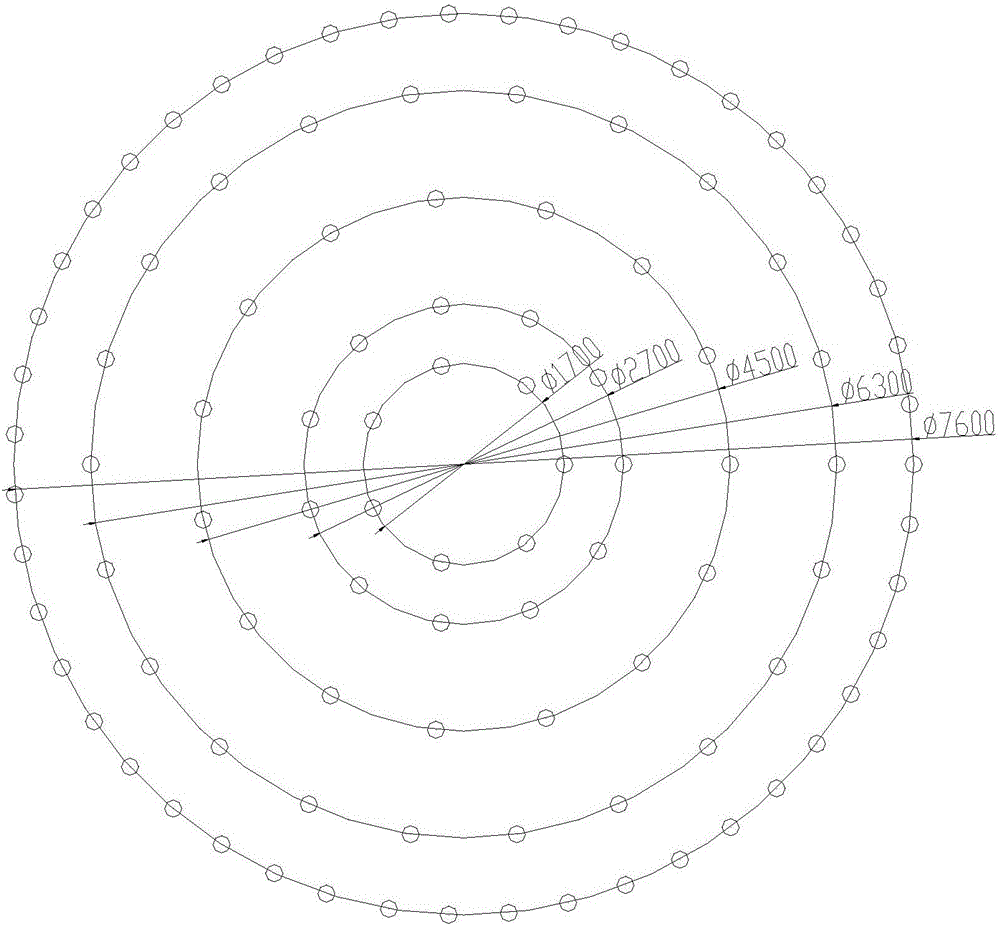

Novel vibroflotation pile construction method, equipment and control method

PendingCN109385998AFast hole formingImprove piling efficiencyBulkheads/pilesSoil preservationAutomatic controlControl system

The invention discloses a novel vibroflotation pile construction method, equipment and a control method. Compared with a conventional construction method, the vibroflotation pile construction method is characterized in that in pore-forming and compacting processes by a vibroflotation device, matched with water and gas linkage, the construction method is achieved by combining water and gas linkage,a unique water spraying mode and reasonable control of feedwater quantity and gas feeding quantity in stages. The construction efficiency is improved obviously while the construction quality is guaranteed. An automatic control system and method control a constant pressure water supply system, action of the vibroflotation device, variable frequency control of a water pump, depth measurement, filler metering, compactness monitoring and the like in the vibroflotation process accurately. The construction tendencies are mastered in real time, and scientific construction and effective management are realized.

Owner:BEIJING VIBROFLOTATION ENG

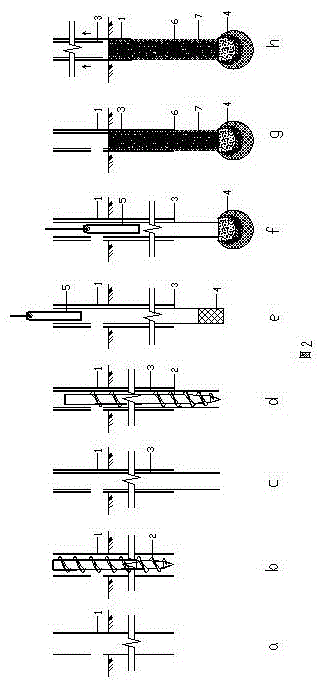

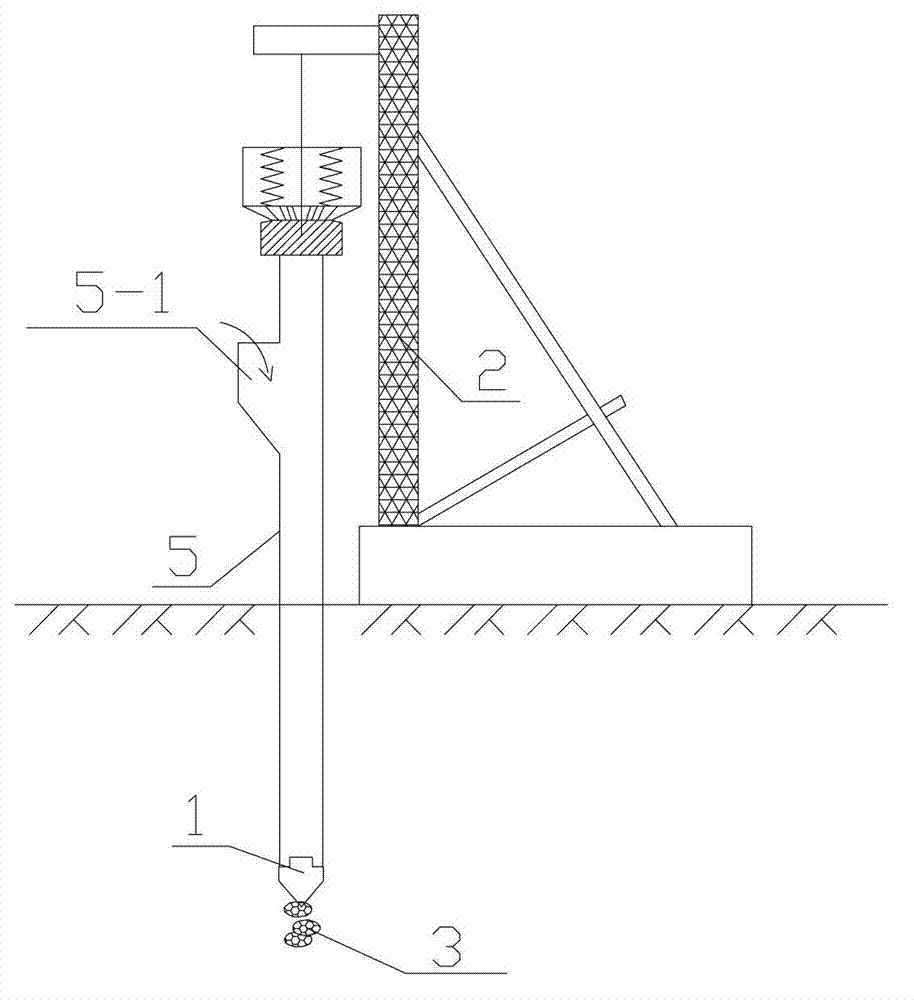

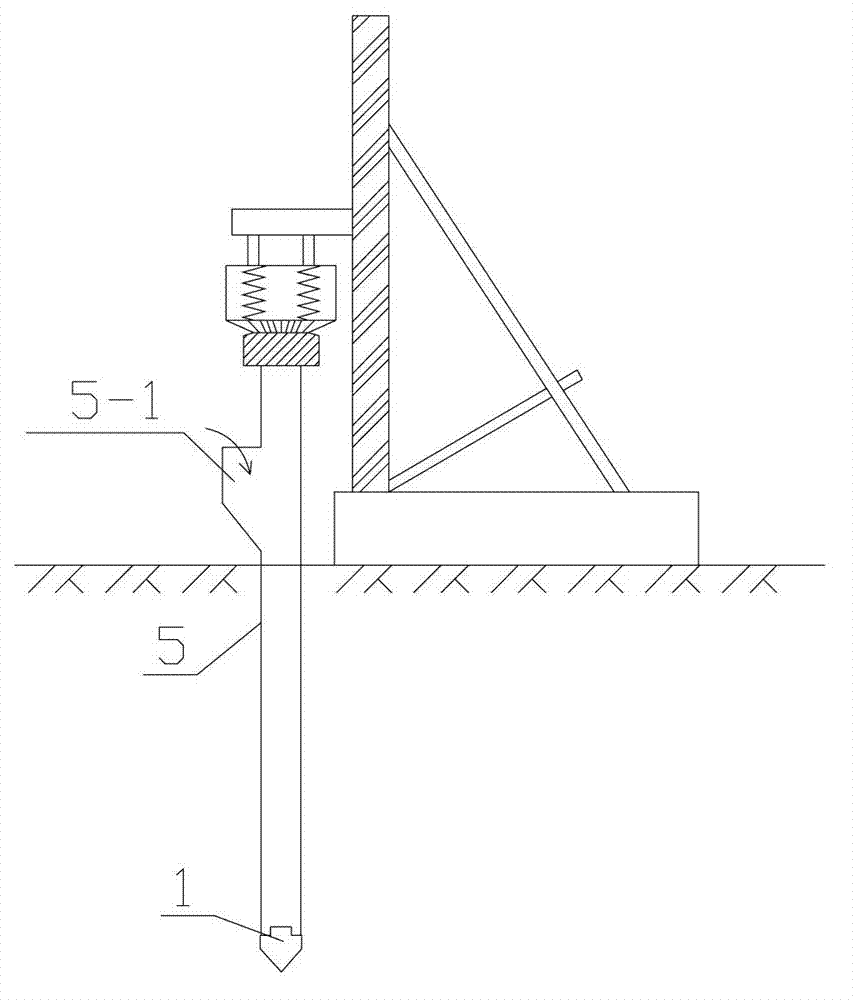

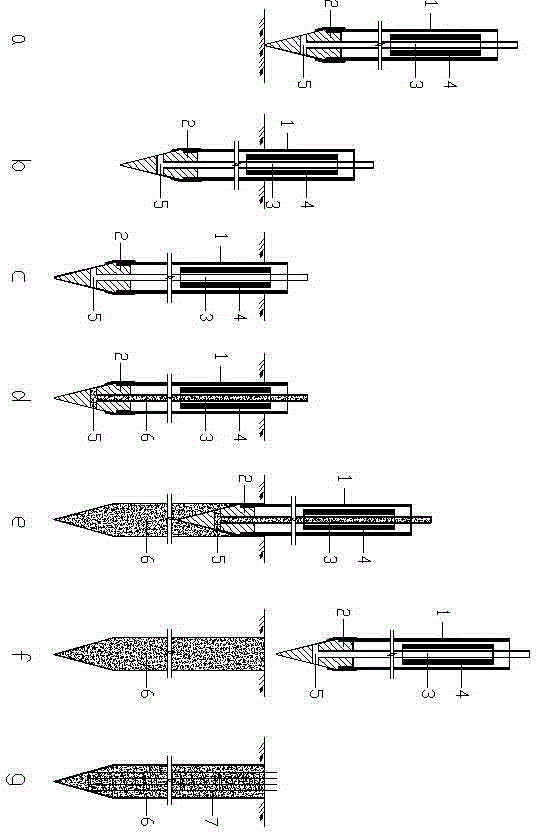

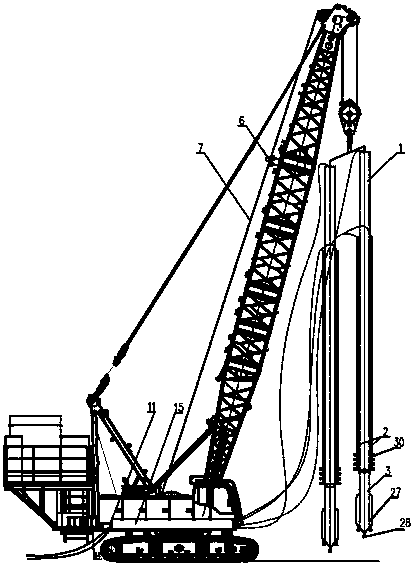

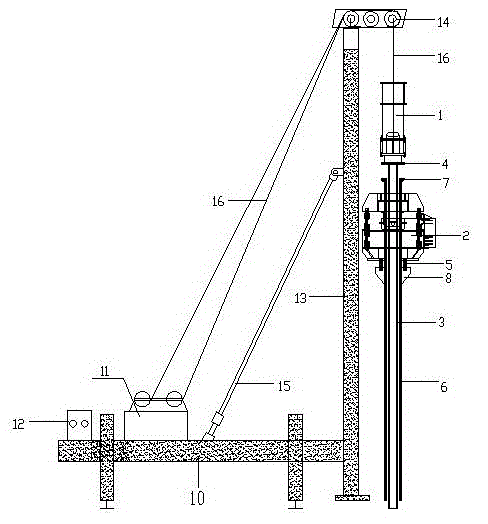

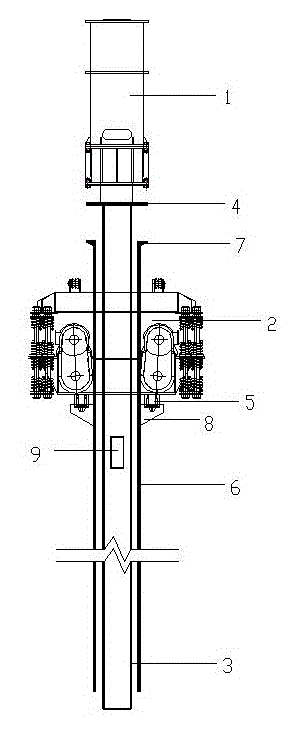

Carrier pile construction equipment and carrier pile construction method

InactiveCN104929125AExpand application typesAvoid frictionBulkheads/pilesFilling materialsArchitectural engineering

The invention provides carrier pile construction equipment which comprises a chassis, a bracket, a support rod, an inner pipe and an outer pipe. The carrier pile construction equipment is characterized in that a hammering device, a vibrating device and a lifting device are arranged on the bracket; the hammering device comprises a pile hammer, the inner pipe and the outer pipe and is used for realizing the functions of sinking the inner pipe and the outer pipe synchronously and compacting filling materials; the vibrating device comprises a mesoporous vibratory hammer and a pair of hydraulic calipers and is used for realizing the functions of lifting out and sinking the outer pipe in a vibrating way; and the lifting device comprises a windlass, a rope and a pulley block and is used for realizing the function of moving the pile hammer and the mesoporous vibratory hammer up and down. The invention further provides a carrier pile construction method which comprises the following steps: 1) sinking the inner pipe and the outer pipe synchronously, and meanwhile vibrating the outer pipe to help to form a hole; 2) sinking the inner pipe and the outer pipe to a preset depth; 3) performing reinforcing treatment of a pile end by one of various methods; 4) repeating the operation in step 3), forming a carrier at the pile end by one of various control methods, and realizing equivalent calculation of the area Ae; and 5) constructing a pile shaft by one of various methods.

Owner:王继忠

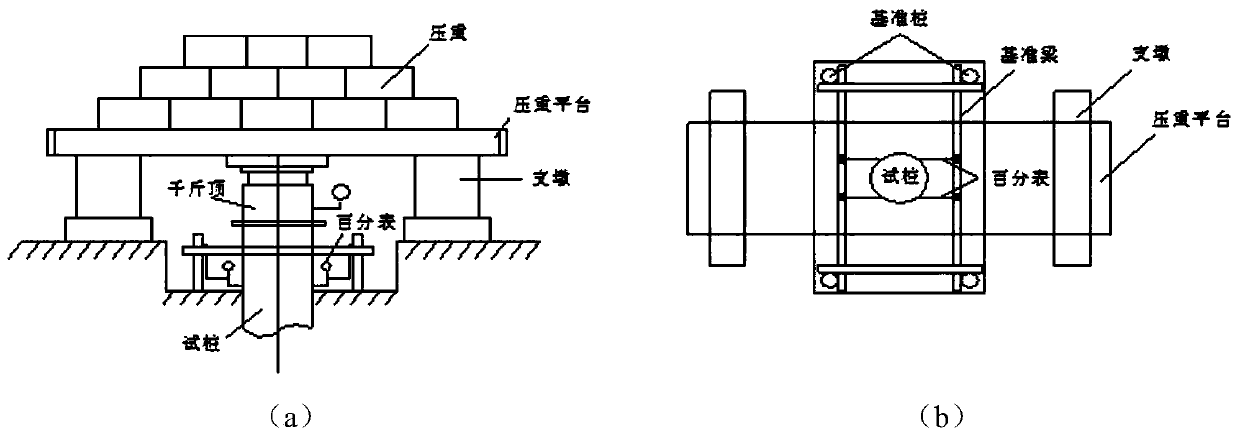

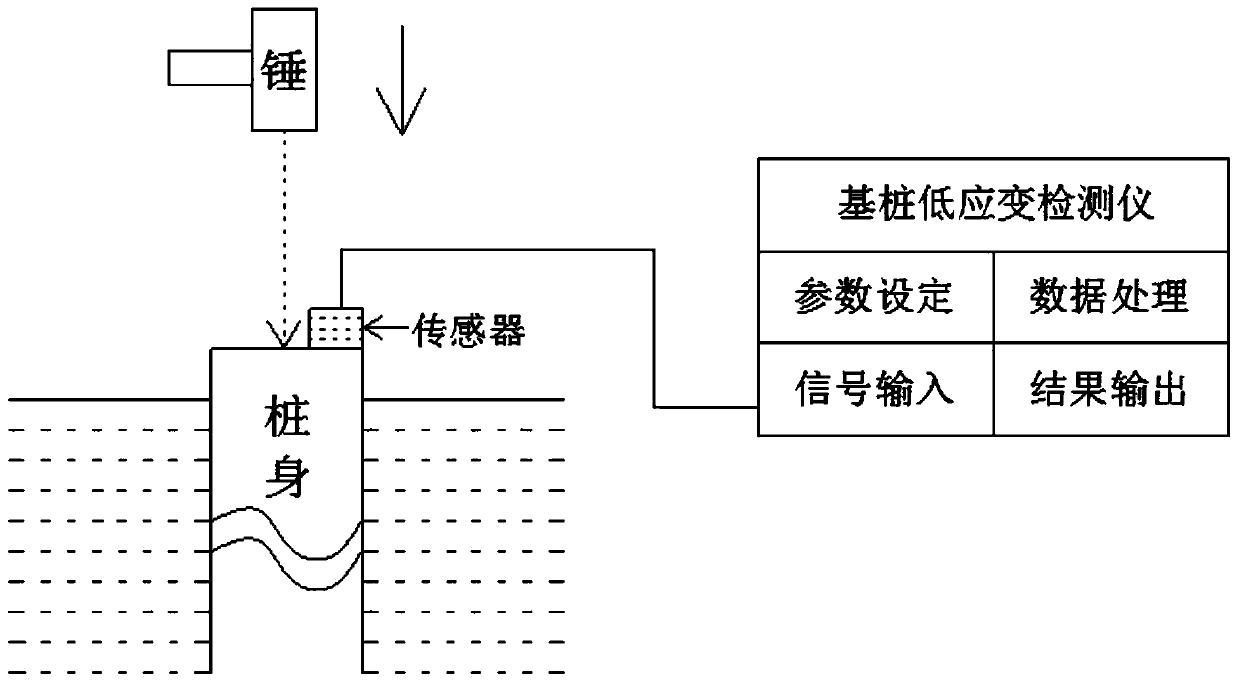

Construction method of mechanical hole filling pile

InactiveCN110374094AEnsure stabilityAchieve initial positioningFoundation testingBulkheads/pilesTerrainWater flow

The invention discloses a construction method of a mechanical hole filling pile. The construction method particularly comprises the steps of leveling the ground, removing sundries, lofting a pile, embedding a steel pile casing, carrying out drilling construction, cleaning a hole, lifting a reinforcing cage, and pouring concrete, obtaining a filling pile foundation, and detecting the pile foundation. The pile foundation is detected by adopting a method of combing a single pile vertical compression resistance static test with low strain method integrity detection, so that the detection is more complete, and detection data is more complete; the construction method can adapt special terrains such as a mountainous area and an underground flow very well, has the very high adaptability, and is high in construction efficiency; the automation degree is high, and the displacement is flexible and convenient; the construction method is low in noise, low in vibration, large in torque, high in holeforming speed and high in efficiency; the safety performance is high; the construction method is free of mud circulation and is small in environmental pollution; and the construction method is a greenconstruction technology.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

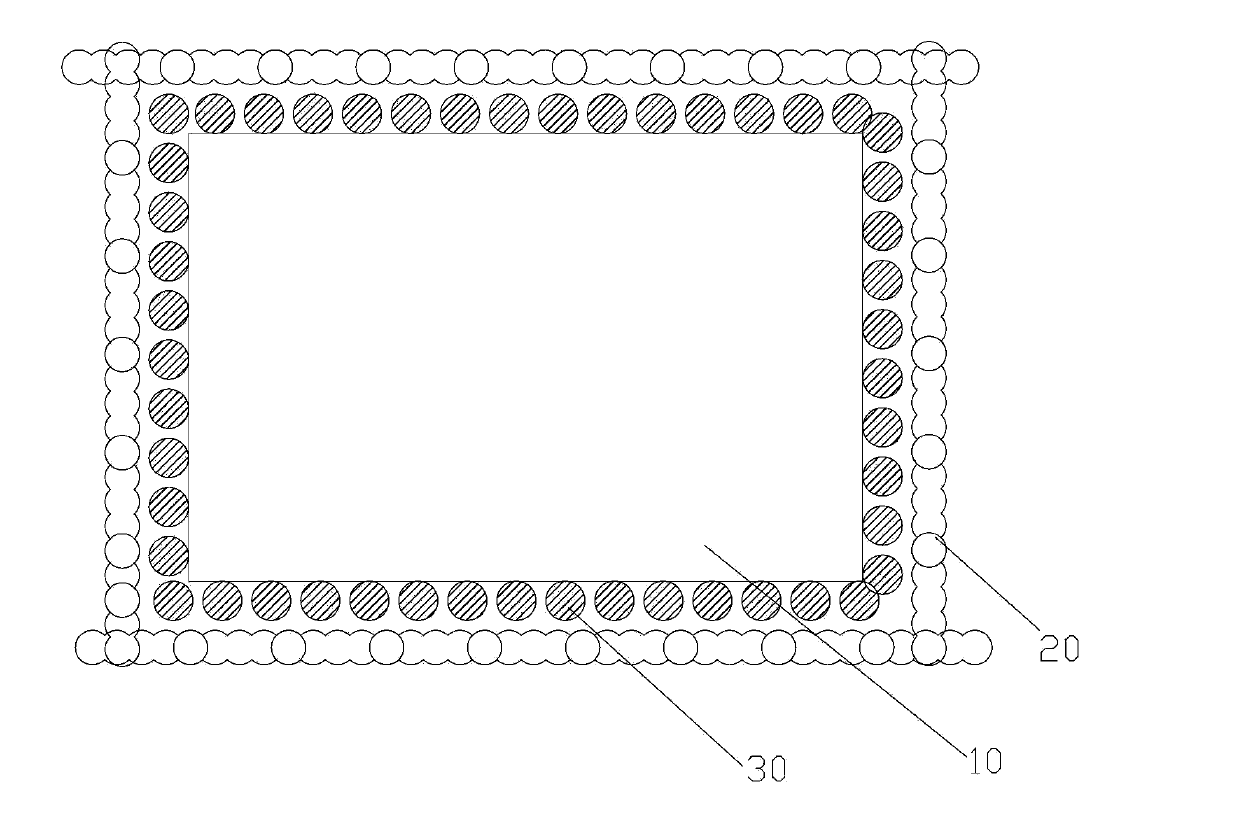

Novel vertical pit support structure and construction method thereof

InactiveCN103967016AReduce labor intensityImprove ergonomicsExcavationsBulkheads/pilesEnvironment effectEngineering

The invention relates to a novel vertical pit support structure and a construction method thereof. The novel vertical pit support structure comprises an outer novel efficient replacement-free intelligent five-axis or six-axis cement soil stirring wall (hereinafter referred to as FCW construction method) and an inner novel cast-in-situ bored piles made of special high-strength reinforcing steel bars. The outer novel FCW construction method multi-axis cement soil stirring wall serves as a water stopping curtain, and the inner cast-in-situ bored piles made of the special high-strength reinforcing steel bars serve as vertical stress components. The invention further provides a construction method of the novel vertical pit support structure. Compared with the prior art, the novel vertical pit support structure is small in influence on environments, good in pile forming quality, high in construction efficiency, evident in economic advantage, and the like.

Owner:SHANGHAI CHENGDI CONSTR +1

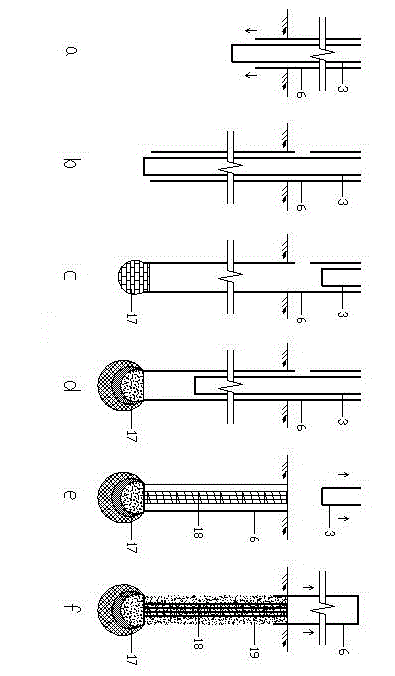

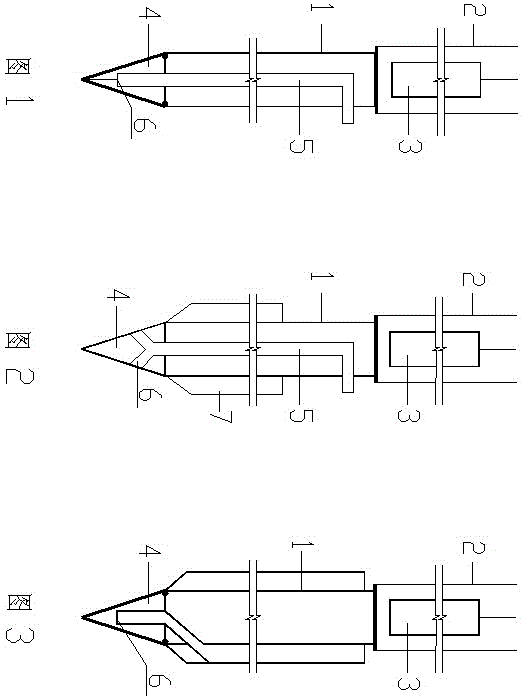

Concrete pile construction equipment and method

ActiveCN104153356AIncreased side friction areaImprove firmnessBulkheads/pilesBuilding constructionStructural engineering

The invention aims to provide concrete pile construction equipment comprising a guard cylinder which is round, a tamp sleeve, a tamper, a delivery pipe, and an impact peen. The concrete pile construction equipment has two structural modes I and II. The concrete pile construction equipment is characterize in that in the structural mode I, the tamp sleeve and the tamper are disposed at the top end of the guard cylinder, the impact peen is disposed at the bottom end of the guard cylinder, the delivery pipe is disposed inside the guard cylinder, the impact peen is provided with a discharge opening, and an additional part is added to the outside of the guard cylinder to obtain a special-shaped guard cylinder; in the structural mode II, two cylinder tamping manners are used, the impact peen is disposed at the bottom end of the guard cylinder, a plurality of steel pipes or U-shaped pipes, one of which is the delivery pipe, are arranged on the outer wall of the guard cylinder, and the impact peen is provided with a discharge opening . The invention further provides a construction method employing the concrete pile construction equipment. The method includes the steps of 1, aligning a pile position; 2, hammering the tamp sleeve to obtain a pile hole; 3, stopping hammering until the guard cylinder sinks to a designed depth; 4, lifting up the guard cylinder while delivering concrete into the delivery pipe; 5, stopping lifting until the guard cylinder is completely out; 6, performing following construction.

Owner:北京波森特岩土工程有限公司

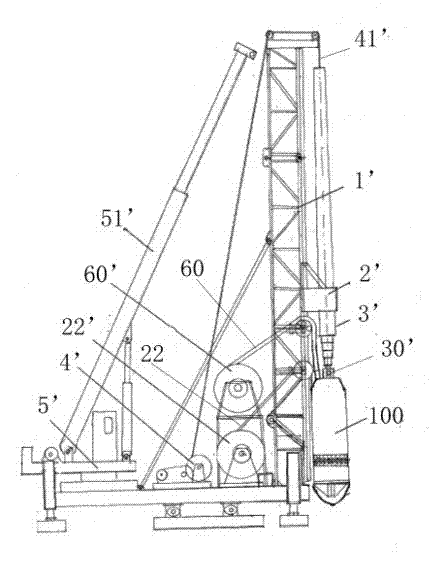

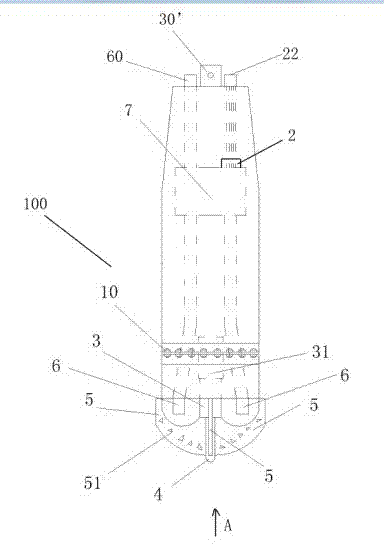

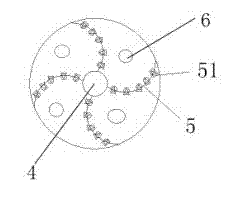

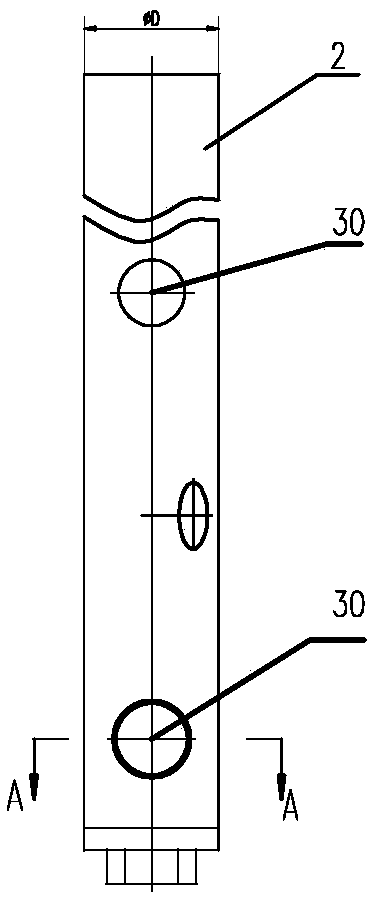

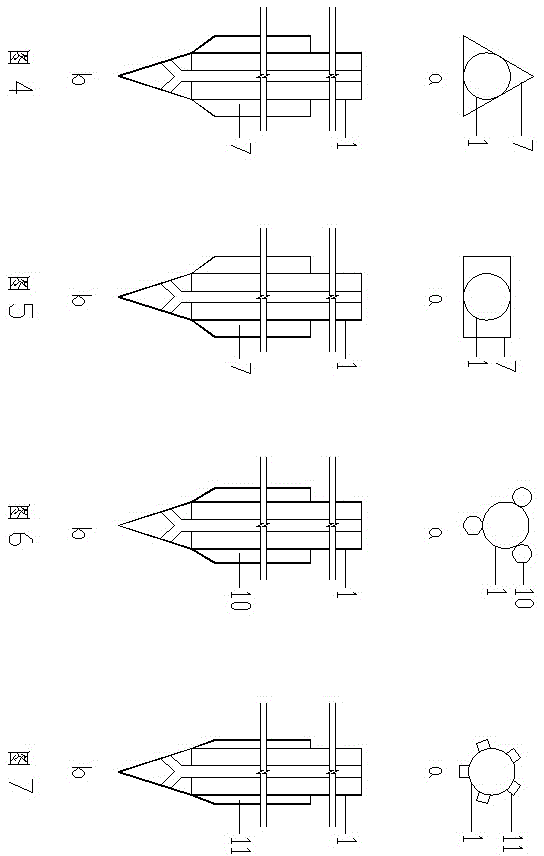

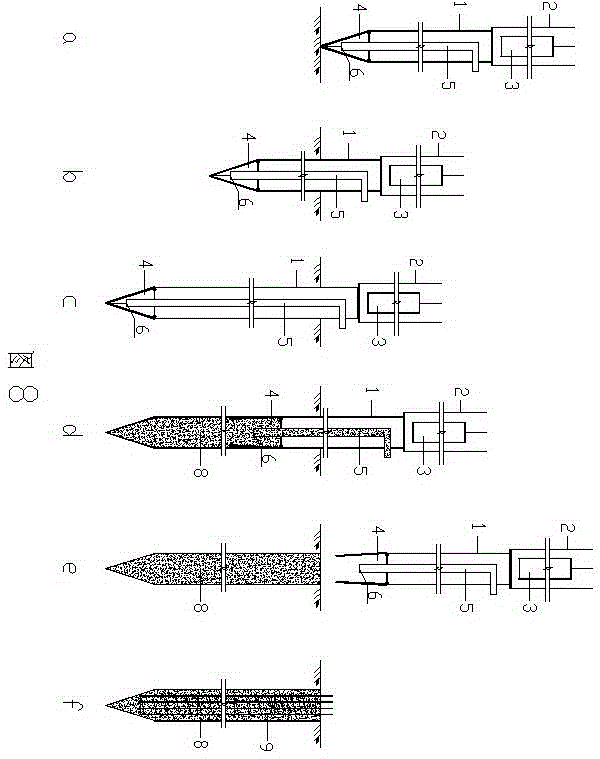

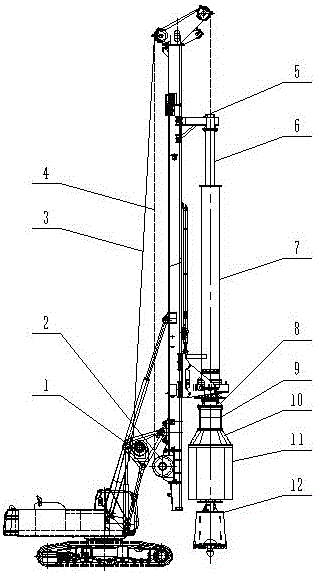

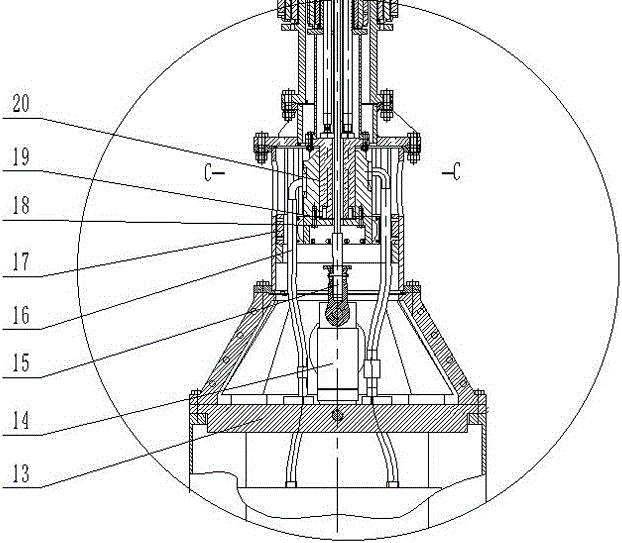

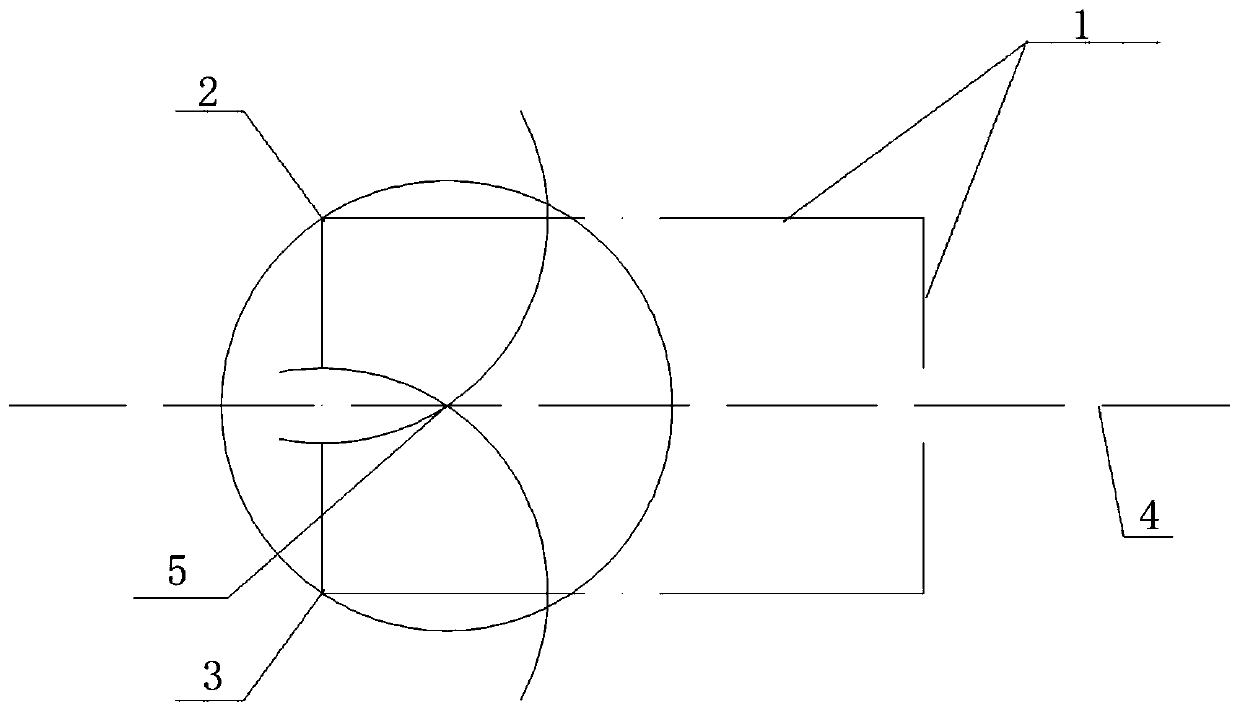

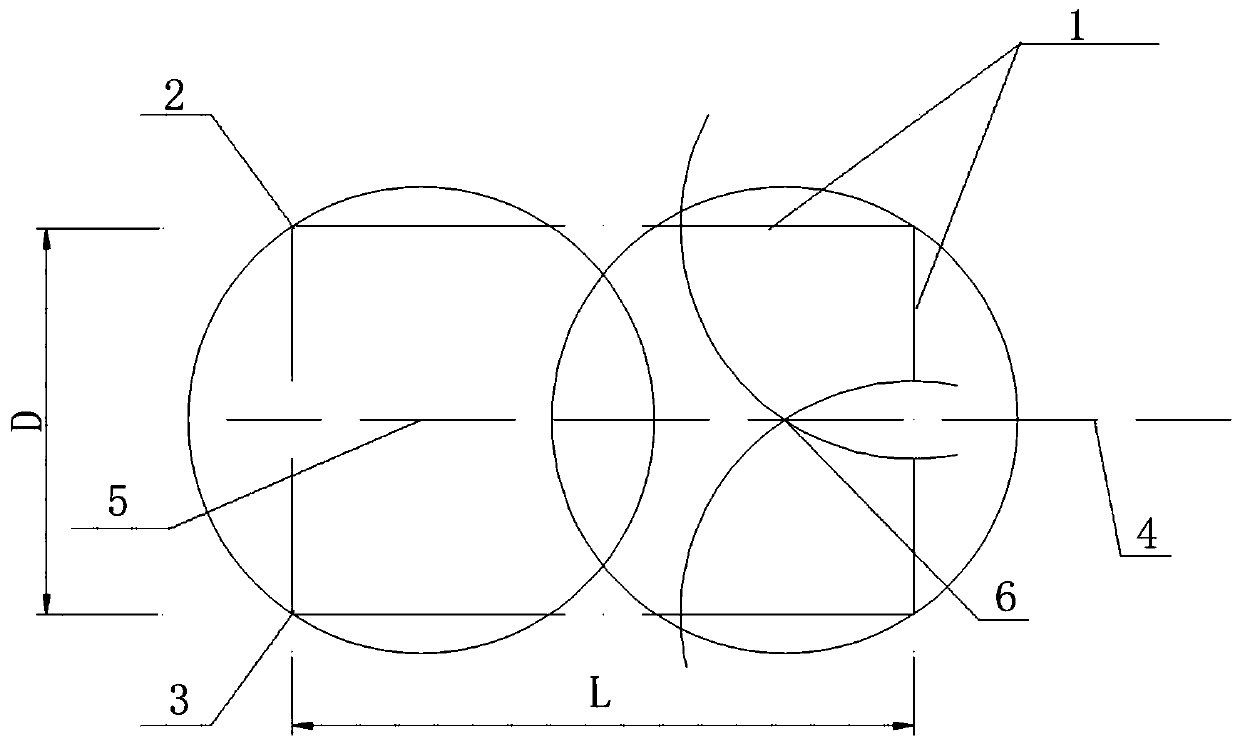

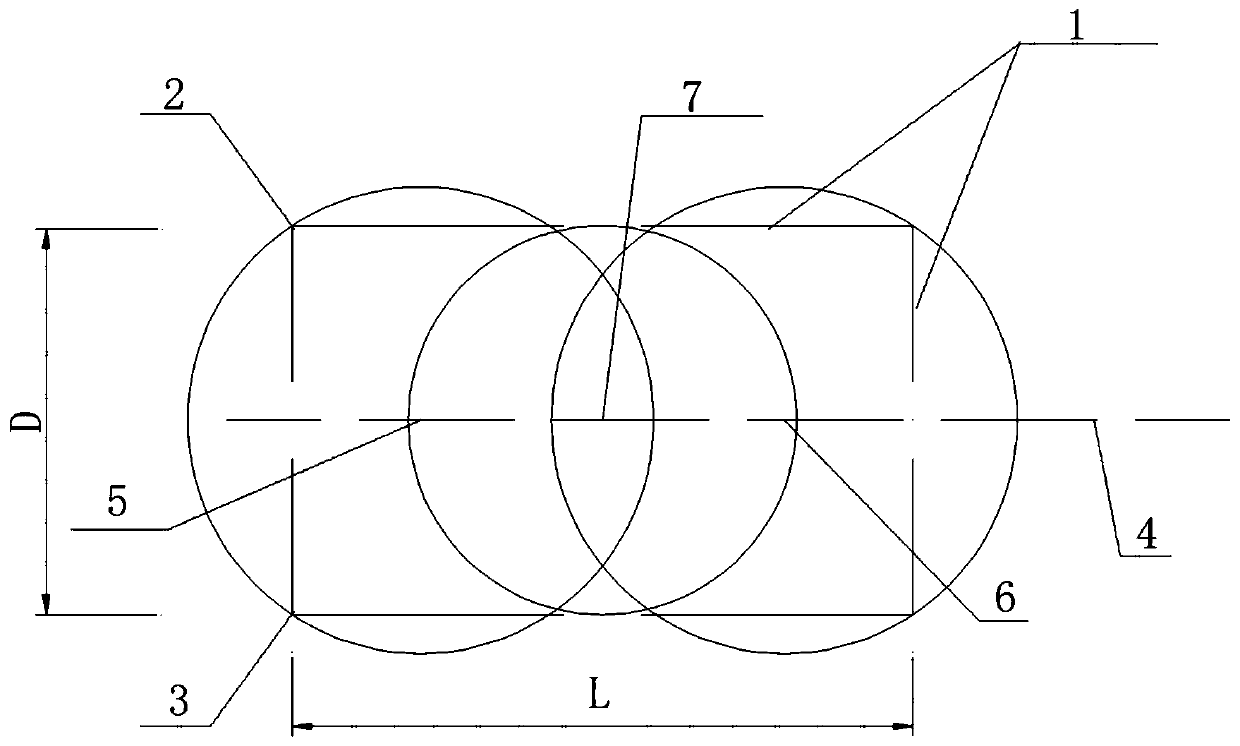

Rotary excavating pile machine hole bottom hydraulic high-frequency in-the-hole rock breaking drill of rotating joint inner and outer drill rod rotation stopping type

ActiveCN105971495AExtended service lifeFast hole formingBorehole drivesRotary drillingFlangeDrilling machines

The invention relates to a rock breaking device on a rotary excavating pile machine, in particular to a rotary excavating pile machine hole bottom hydraulic high-frequency in-the-hole rock breaking drill of a rotating joint inner and outer drill rod rotation stopping type. The problems that a hole cannot be formed at a time when a hydraulic impact drill of the rotary excavating pile machine is drilled into rock, and rock penetrating speed is low are solved. An inner telescopic drill rod is sleeved with an outer telescopic drill rod, the upper end of a rotating joint of the rock breaking drill is connected to the lower end of an inner telescopic drill rod, the lower end of the rotating joint is connected to a shock-absorbing seat in a sliding barrel, the upper end of the sliding barrel is connected to the outer telescopic drill rod, the lower end of the sliding barrel is connected with a hoisting swivel elevator base through a reducing flange, the upper end and the lower end of the hoisting swivel elevator base are connected with a hoisting swivel elevator and a vibrating hammer respectively, and the other end of the hoisting swivel elevator is connected to a steel wire rope winding base of the drilling machine through a steel wire rope. The rock breaking drill is large in impact force, high in hole forming speed, capable of achieving the effect as a common drill bit of the rotary excavating pile machine on a soil layer, good in rotation stopping effect and high in response speed.

Owner:XIANGYANG CHANGKAN INTELLIGENT MACHINERY

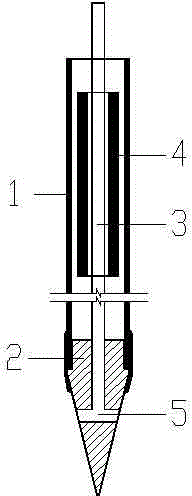

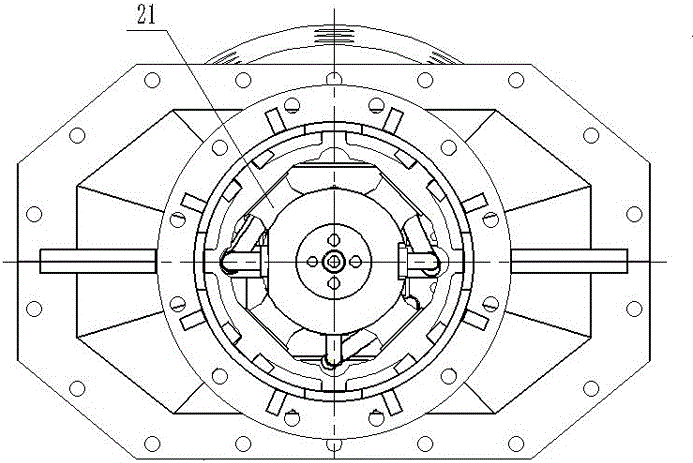

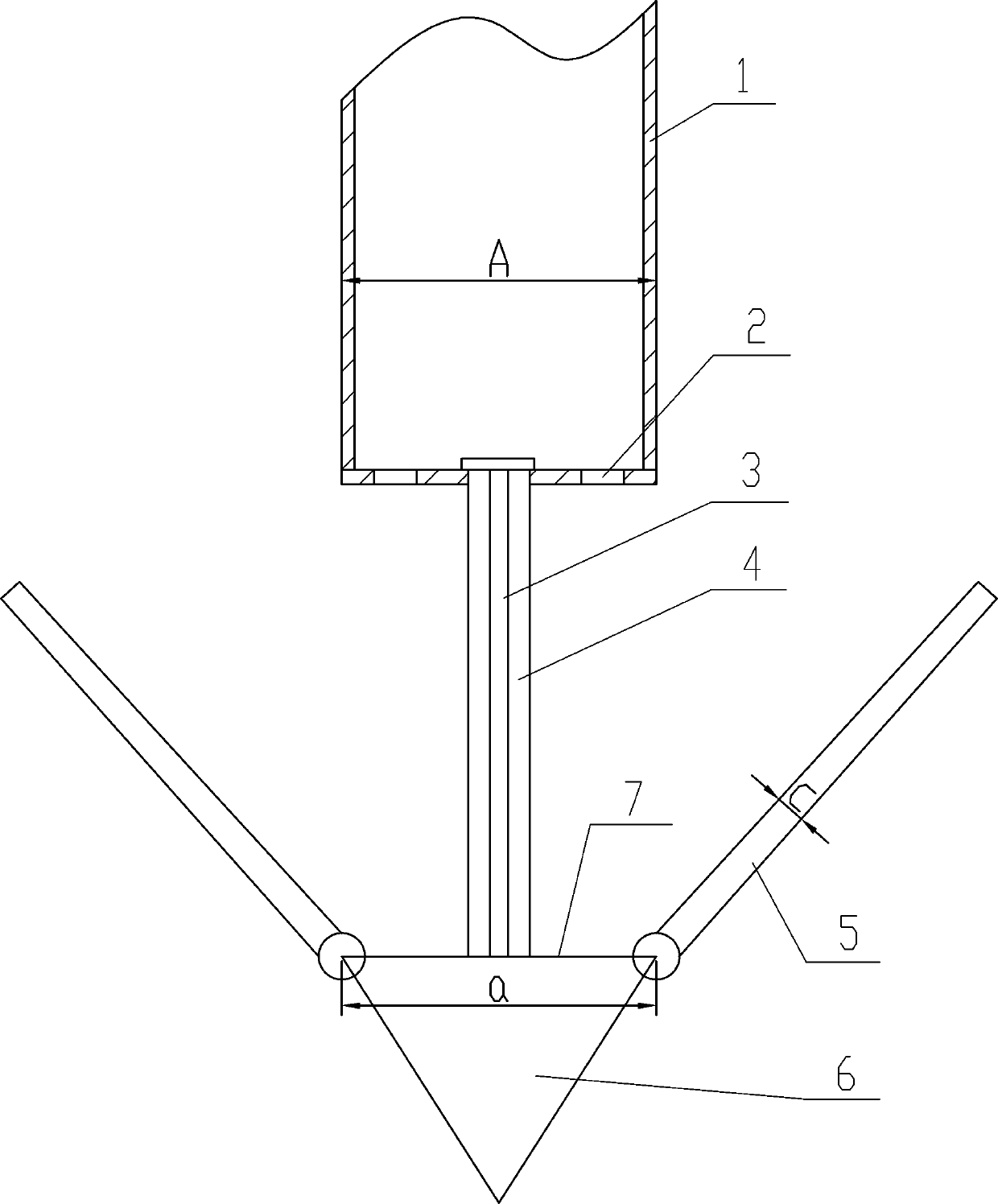

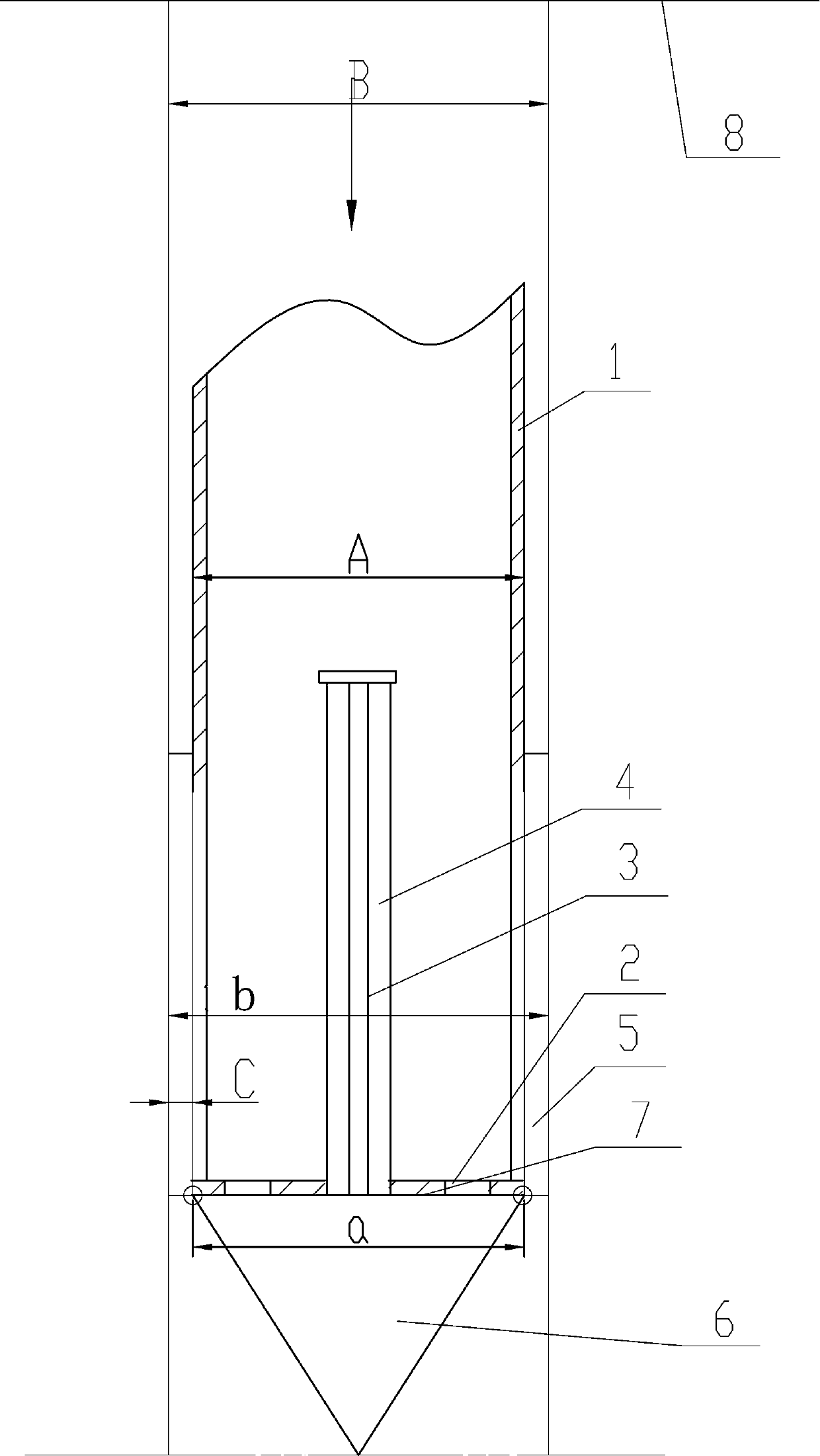

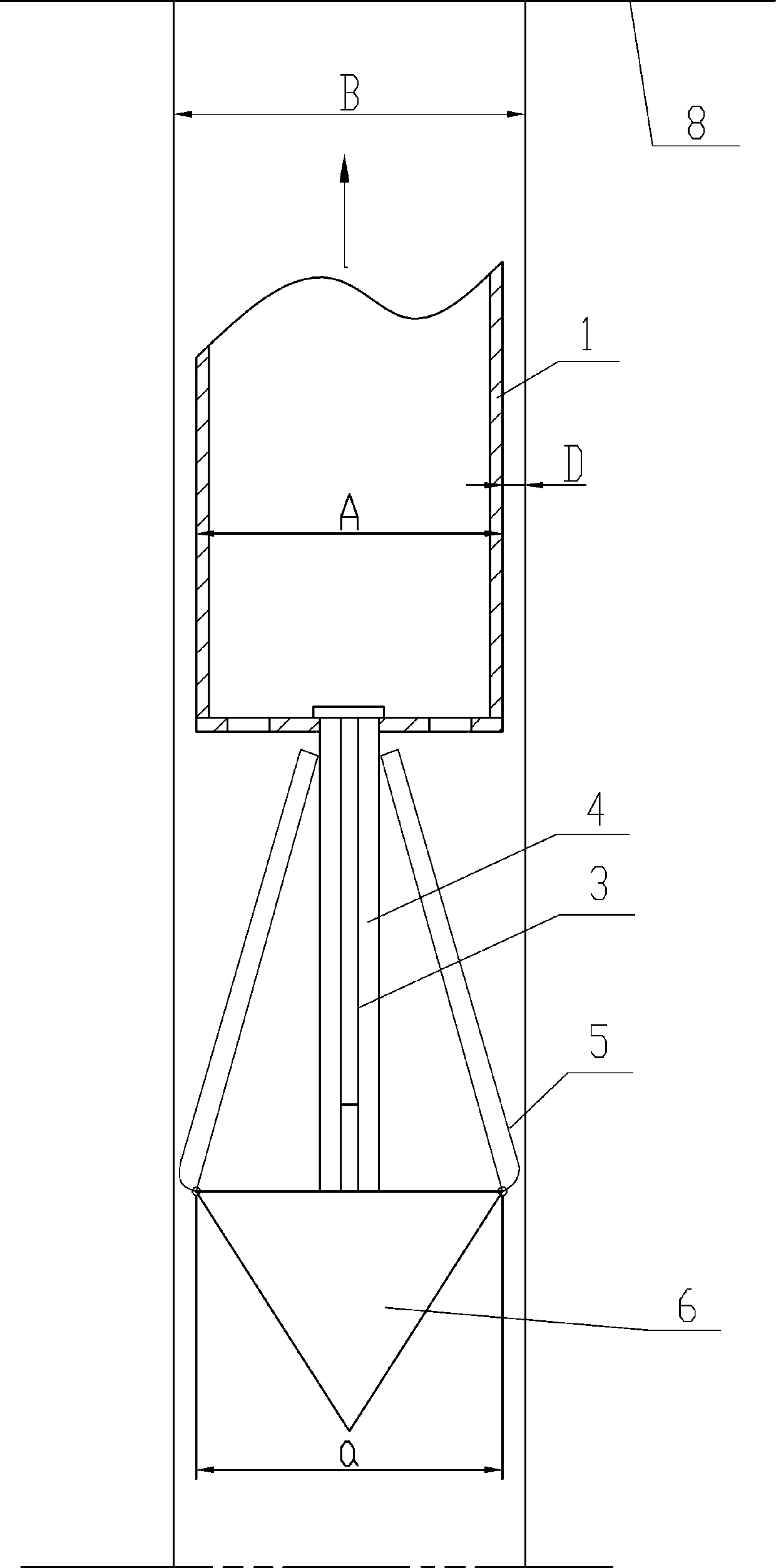

Automatic reducing pore-forming device mounted on drilling machine

InactiveCN103774997AReduce consumptionReduce purchasing costsDrill bitsForming processesDrilling machines

The invention discloses an automatic reducing pore-forming device mounted on a drilling machine. The automatic reducing pore-forming device comprises a pile pipe, a guide rod, movable boards and an inverted conical pile tip, the guide rod is movably connected to the lower portion of the pile pipe, the lower end of the guide rod is fixedly connected with the pile tip, 3-6 movable boards are hinged to the edge of the upper end face of the pile tip and arranged side by side, a 5-6cm distance is reserved between every two adjacent movable boards, the movable boards are arc-shaped and are closed and tightly hold the pile pipe when pores are formed, and the diameter a of the upper end face of the pile tip is not larger than the diameter A of the pile pipe. The automatic reducing pore-forming device is simple, convenient to operate, low in lifting resistance and high in pore-forming speed, and labor productivity is greatly improved. The pore-forming process can be widely applied to construction of foundations such as civil and industrial building foundations, railways, roads, bridges and harbors.

Owner:赵小勇

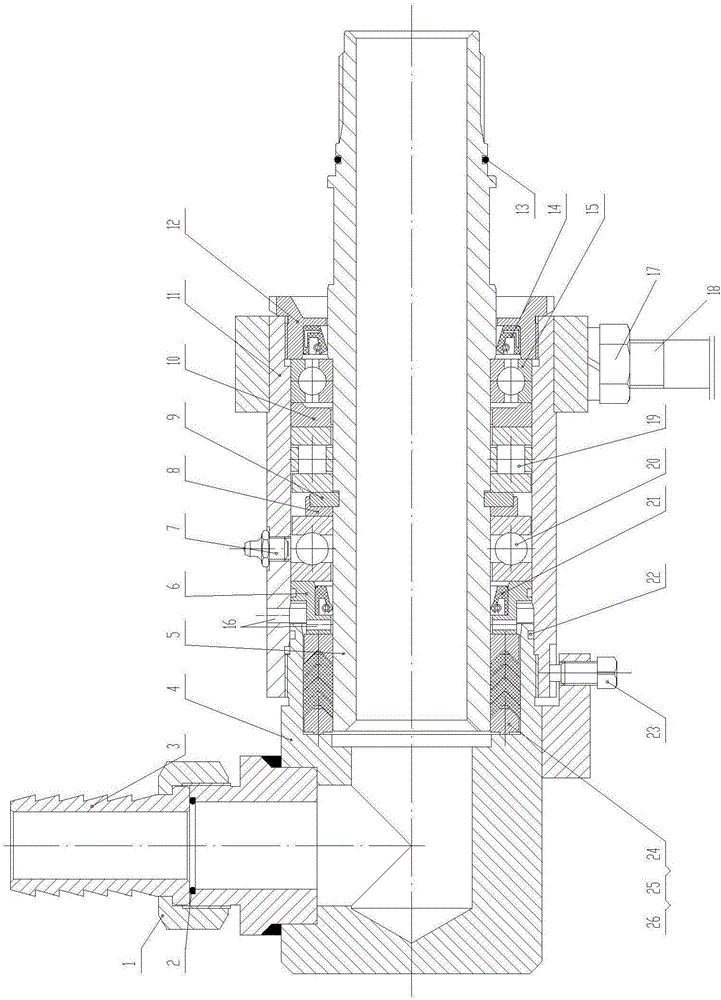

Large-drift-diameter high-pressure rotation joint used for drilling machine

InactiveCN106593321ASimple structureEasy to installDrilling rodsDrilling casingsHigh pressureThroughput

The invention provides a large-drift-diameter high-pressure rotation joint used for a drilling machine. The large-drift-diameter high-pressure rotation joint used for the drilling machine comprises a mull-coupling nut, a first O-shaped ring, a connecting pipe, a gland joint, a main shaft, a first pad, a retainer ring, a clamping key, a second pad, a shell, a lower cover, a first oil seal, a first bearing, a second bearing, a third bearing, a second oil seal, a third O-shaped ring, a compression ring, a V-shaped ring and a supporting ring. The supporting ring, the V-shaped ring and the compression ring are sequentially compressed into an inner stage of one joint end of the gland joint. The second oil seal is compressed into the first pad. The first oil seal is compressed into the lower cover. The first bearing, the second pad, the second bearing, the clamping key, the retainer ring, the third bearing and the first pad are sequentially arranged on the main shaft in a sleeving mode. The clamping key is clamped into a key groove formed in the surface of the main shaft. The main shaft is riveted into the shell. The supporting ring, the V-shaped ring and the compression ring are arranged at one end of the main shaft in a sleeving mode. One end of the shell is connected with and fastened to one joint end of the gland joint. The throughput is increased since the sealing positions are ingeniously and reasonably arranged.

Owner:JIANGSU WUXI MINERAL EXPLORATION MASCH GENERAL FAB CO LTD

Efficient and safe fast hole formation method adopting rotary excavating machinery for slide-resistant piles

ActiveCN110820729AIncrease construction costsEasy to operateRotary drillingRotary-drilling machinesRebarEnvironmental geology

The invention discloses an efficient and safe fast hole formation method adopting rotary excavating machinery for slide-resistant piles. The method comprises the following steps that A, paying off andpositioning of slide-resistant pile holes or site lofting is carried out; B, hole digging by a rotary excavating pile machine is carried out according to pile core serial number and position or the holes are formed adopting rotary excavating machinery; C, excess earthwork on a side wall is cleaned and sediment at the bottom of the pile is removed; D, a reinforcement cage is lowered; and E, the slide-resistant piles are formed through pouring concrete. According to the efficient and safe fast hole formation method adopting rotary excavating machinery for the slide-resistant piles, the problemsthat the efficiency of manual hole digging pile breaking into a rock is low, no blasting excavation is allowed under complex environment and the hole formation construction is very difficult are solved, on the one hand, the fact that hole formation adopting machinery can be carried out without using a pile casing and retaining wall is realized, so that the construction cost is greatly reduced; and on the other hand, the slide-resistant pile construction is completed quickly in the limited time when the self-stabilizing capacity of a hole wall after hole formation adopting machinery supports until the concrete pouring forming, and the construction safety and quality are ensured.

Owner:YUNNAN JIANTOU FOUND ENG CO LTD

Hydraulic tunnel drilling trolley excavation construction method and device

PendingCN113338979ASolving the problem of complex look-ahead detectionSolve the problem of complex and advanced detection of tunnel geological conditionsTunnelsDrilling machinesDrill hole

The invention discloses a hydraulic tunnel drilling trolley excavation construction method and device. According to the method, a simple down-the-hole drill trolley combining a down-the-hole drill and a vehicle is used for drilling advanced geological forecast holes, and the advanced geological forecast holes are used as central cut holes. The device comprises the vehicle and the down-the-hole drill installed at the position of a container of the vehicle, and the down-the-hole drill is connected to the vehicle through a drilling machine platform; the drilling machine platform is provided with a supporting base used for supporting and controlling the drilling direction of a drill rod of the down-the-hole drill; and the down-the-hole drill is connected with the drilling machine platform through a connecting plate and a fastening bolt. The tunnel drilling trolley (the simple down-the-hole drill trolley) combining the down-the-hole drill and the vehicle is used for drilling the advanced geological forecast holes, the problem of complex tunnel geological conditions for advanced detection is solved, the advanced geological forecast holes are used as the central cut holes, drilling and chemical use of the cut holes are reduced, and the tunnel single-wheel circulation footage length is increased.

Owner:贵州水利实业有限公司

Hard rock stratum drilled pile radial grading hole forming construction method and application

PendingCN112709529AFast hole formingImprove rock penetration abilityDrill bitsBorehole/well accessoriesStructural engineeringDrill bit

The invention relates to the technical field of rock stratum drilling, and provides a hard rock stratum drilled pile radial grading hole forming construction method and application. According to the hard rock stratum drilled pile radial grading hole forming construction method, when pile diameter pile foundation construction is carried out through a rotary drilling rig, firstly, a barrel drill bit is arranged for drilling construction, after drilling is carried out to the designed depth, cutting tooth bailing hopper drill bits with the gradually-increased diameters are sequentially replaced for hole expanding drilling till a hole is formed, and the hole forming efficiency of large-pile diameter and larger-pile diameter hard rock stratum is improved. According to the hard rock stratum drilled pile radial grading hole forming construction method, the rock entering capacity of the rotary drilling rig is improved, and the hole forming speed of the hard rock stratum is increased.

Owner:RAILWAY TENTH GROUP NORTHWEST ENG

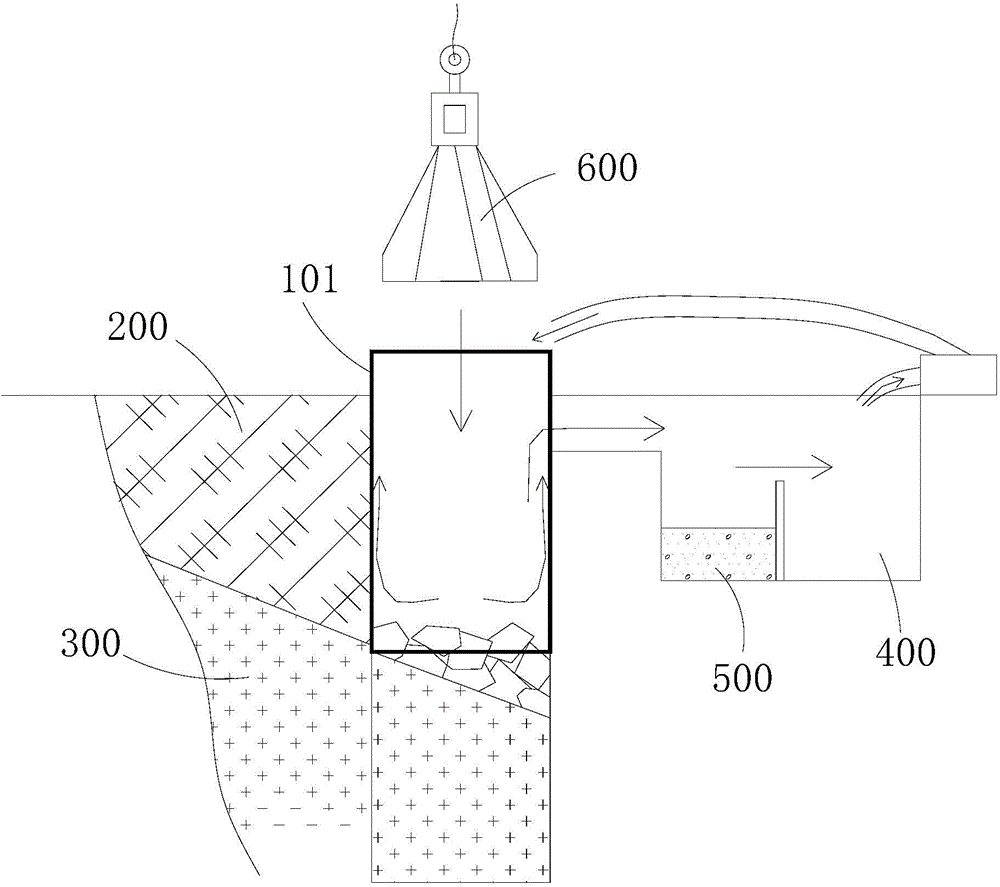

Rotary excavating pile construction method in combined construction

The invention discloses a rotary excavating pile construction method in combined construction. The method comprises the following steps: flattening a field, laying wires in pile positions, arranging a rotary excavation machine in place, burying a protecting cylinder, re-measuring the pile position, preparing slurry, drilling, crushing the rubble layer by using a hole punching pile machine and a punching grasp hammer in a combined manner when encountering a rubble layer, continuously putting down a full-steel protecting cylinder after grasping small crushed stone pieces from the hole, continuously drilling the hole by using the rotary excavation machine after hitting the full-steel protecting cylinder in place, repeatedly using the rotary excavation machine to drill in, stamping and smashing by using the hole punching pile machine, and grasping by using a grab machine till a designed depth is achieved. The method comprehensively adopts the rotary excavation pile machine for forming the hole, the full-steel protecting cylinder, the punching pile machine and the grab machine for combined working, a comprehensive support pile construction process that crushed stone pieces are grasped off is accomplished, the rubble layer can be effectively processed, the mechanical automation efficiency is high, the hole forming speed is fast, a small amount of slurry is needed, the environment is slightly polluted, and various requirements of construction can be sufficiently met.

Owner:SHENZHEN GEOTECHN INVESTIGATION & SURVEYING INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com