Drilling-type quick pore-forming system and drilling-type quick pore-forming process

A drilling and chipping technology, which is applied in the field of hole-forming devices and hole-forming technology, can solve the problems of long hole-forming cycle and slow hole-forming speed, and achieve the effects of reducing the total amount, reducing pollution, and shortening the hole-forming cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

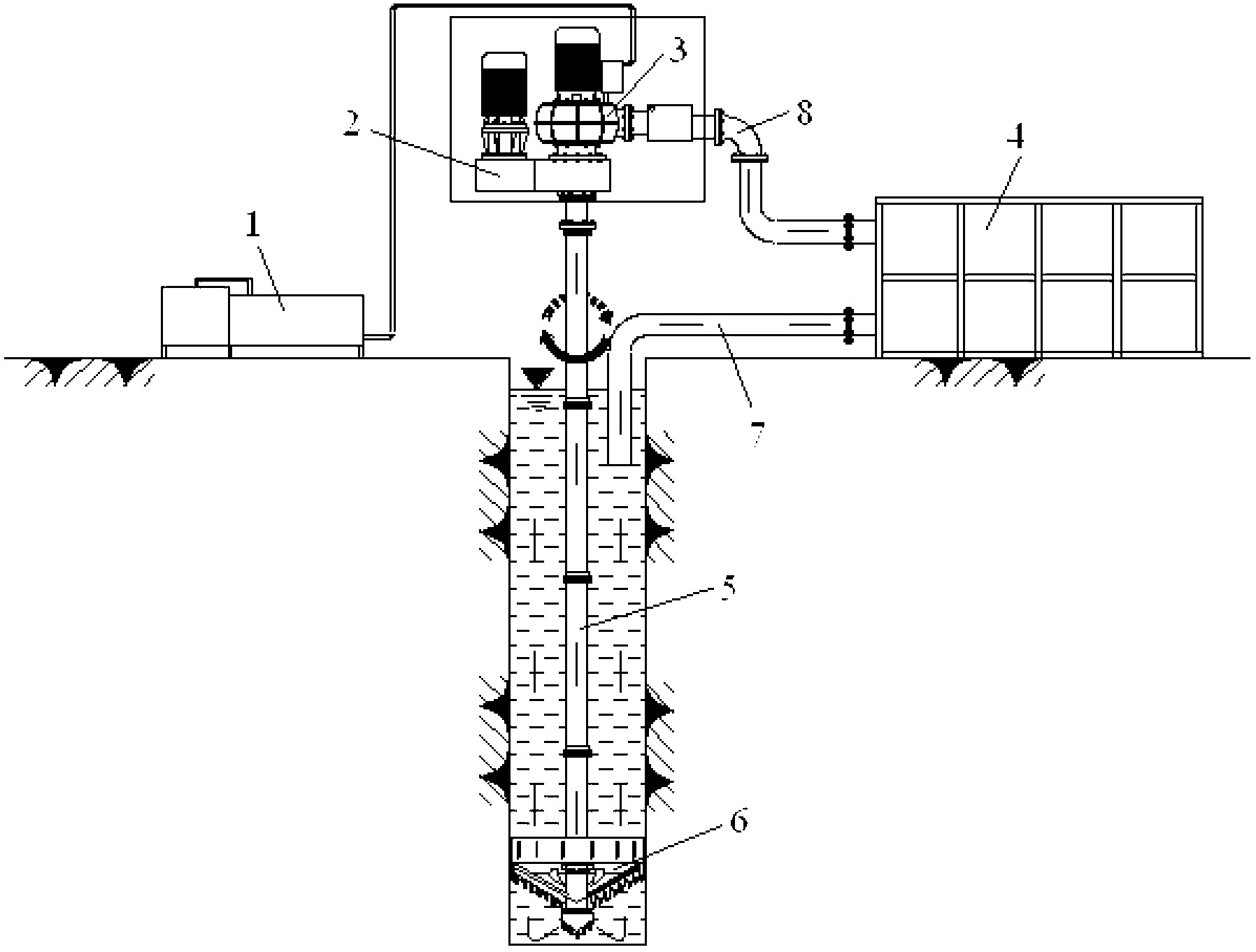

[0032] see figure 1 , the drilling type rapid hole-forming system of the present invention comprises a power unit 2, a hollow drill rod 5, a drill bit 6, a vacuum pump 1 and a dredge pump 3, the power unit 2 is connected to the rear end of the hollow drill rod 5, and the drill bit 6 is connected to the The front end of the hollow drill rod 5 is connected with the vacuum pump 1 and the dredge pump 3 respectively.

[0033] In this example, the power of the power unit is 40-50KW, and the diameter of the hollow drill rod is 20-25cm. Large-diameter hollow drill pipe is used to discharge mud by pump suction reverse circulation principle, with strong suction capacity and fast hole forming speed. The drill bit is a cutting drill bit, which makes the muck after cutting into strips, which can improve the working efficiency. In this example, the combination of a high-power p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com