Rectangular anti-sliding pile mechanical and fast hole forming construction method

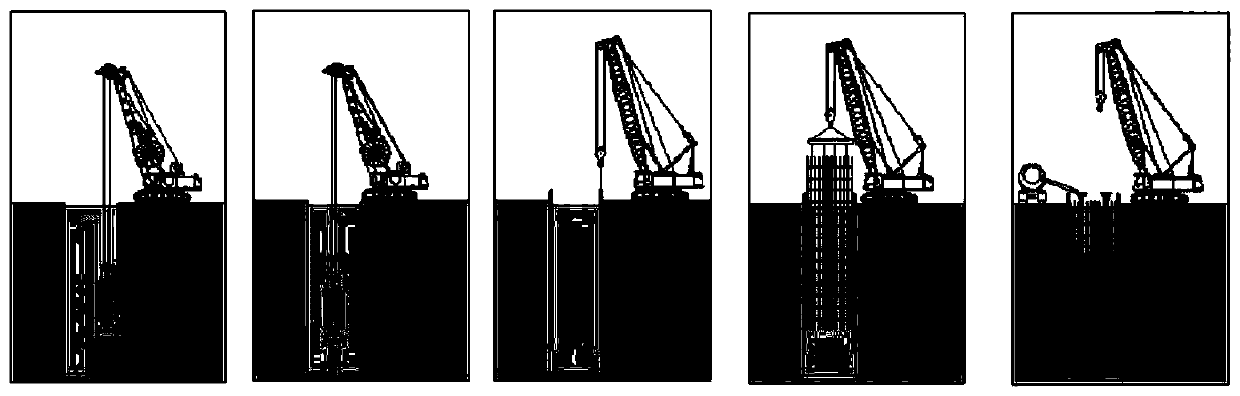

A construction method and technology of anti-slide piles, applied in drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc., can solve problems such as inability to guarantee life safety, poor operation safety performance, and slow construction speed of single piles, and achieve Fast construction, good pile quality and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

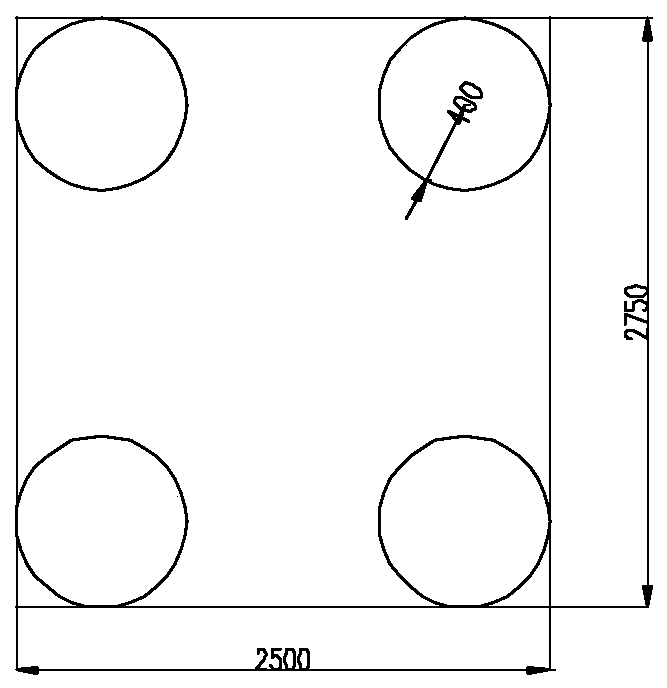

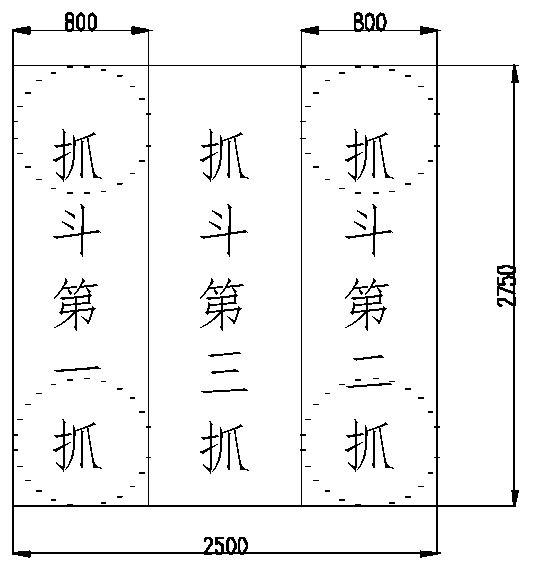

[0061] The Xiaoshan Mingdong in the ZWZQ-3 bid section of the Henan section of the Zhengwan Railway. The total length of the Xiaoshan Mingdong is 950 meters. Both sides are supported by 2.5m×2.75m piles of rectangular anti-sliding piles. There are 368 piles in total, and the pile length varies from 20.0 to 22.0m. , the main geology and lithology of this section of the project are: silty clay, fine round gravel, gingerstone and calcareous cementation layer. The Quaternary Upper Pleistocene cohesive soil layer distributed in the site has many types of rock and soil, and the engineering properties are relatively poor. Poor, there is expansive soil, with medium expansibility, some strong expansibility, significant expansion, softening, disintegration and water shrinkage, cracking, induration after water absorption, and easy instability after long-term exposure. The construction method of the rectangular anti-sliding pile machine of the present invention is used to quickly form hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com