Construction method of super long pipe shed in soft surrounding rock section of tunnel portal

A technology of weak surrounding rock and construction method, applied in tunnels, tunnel lining, earthwork drilling, etc., can solve the problem that the tail of the pipe shed falls into the excavation outline, the track of the drilling process of the pipe shed cannot be grasped, and the surrounding area of the tunnel excavation cannot be grasped. grouting consolidation and other problems, to achieve the effect of obvious excavation deformation, accurate drilling process and less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

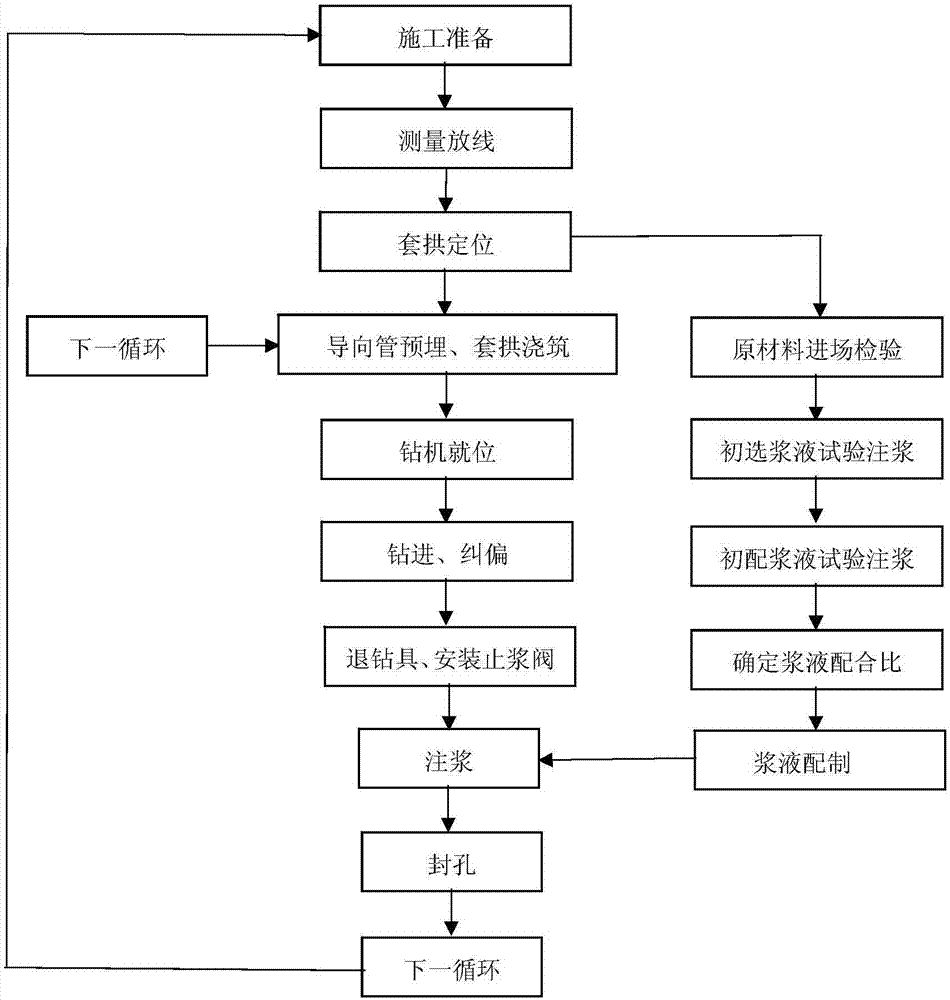

[0022] Example 1: A construction method for an ultra-long pipe shed in the weak surrounding rock section at the entrance of a tunnel. The detailed construction process is shown in the attached figure 1 Shown:

[0023] (1) Construction preparation: Determine the height and width of the excavation platform according to the height of the drilling rig and the required longitudinal length, and dig the steps from the original ground from top to bottom. Carry out grading on the upward slope, and set up temporary ditches on both sides; the excavation method adopts mechanical excavation, manual labor, and excavator clearing ballast;

[0024] (2) Surveying and setting out: According to the requirements of the design documents, use the total station to stake out the tunnel centerline and elevation, and check the accuracy; according to the correct coordinates and elevation of the tunnel centerline after review, mark the excavation range and elevation of the guide wall on site;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com