Tobacco matrix activated carbon and preparation method thereof

A technology of activated carbon and matrix, which is applied in the field of activated carbon and the preparation of activated carbon with tobacco as raw material. It can solve the problems of activated carbon product performance, cumbersome process, and high cost, and achieve the goals of increasing pore-forming efficiency, simplifying process, and increasing pore volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

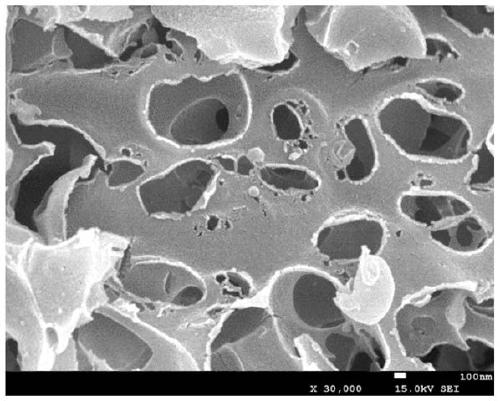

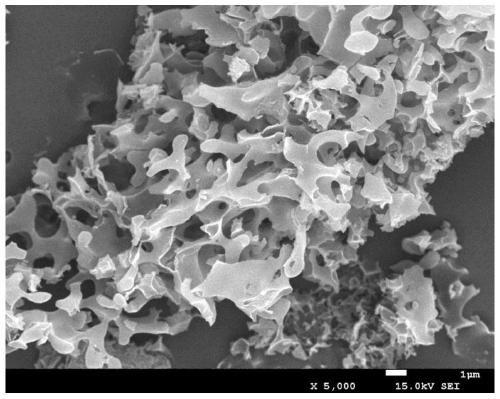

[0045] The tobacco-based activated carbon described in this embodiment is based on anhydrous 35gK 2 CO 3 , 17.5g of tobacco leaf powder and 2.5g of low-density polyethylene powder are mixed, and carbonized at 850°C under nitrogen as a protective gas environment. The density of low-density polyethylene is 0.91g / cm 3 . The adsorption performance of activated carbon is tested according to the national standard GB / T12496.10-1999 "Determination of Methylene Blue Adsorption Value of Wooden Activated Carbon Test Method". Each sample is tested twice and the average value is taken. The iodine adsorption value of tobacco-based activated carbon is 1392mg / g , methylene blue adsorption rate 786mg / g. The microscopic morphology of activated carbon was analyzed by scanning electron microscope. figure 1 and figure 2 as shown, figure 1 30000 times scanning electron microscope picture of tobacco matrix activated carbon in the present embodiment, figure 2 5000 times scanning electron mic...

Embodiment 2

[0047] The tobacco-based activated carbon described in this embodiment is based on anhydrous 40gK 2 CO 3 , 20g tobacco rod and tobacco leaf mixture powder, 3.5g low-density polyethylene powder are mixed, and carbonized at 900°C under nitrogen as a protective gas environment. The density of low density polyethylene is 0.93g / cm 3 .

Embodiment 3

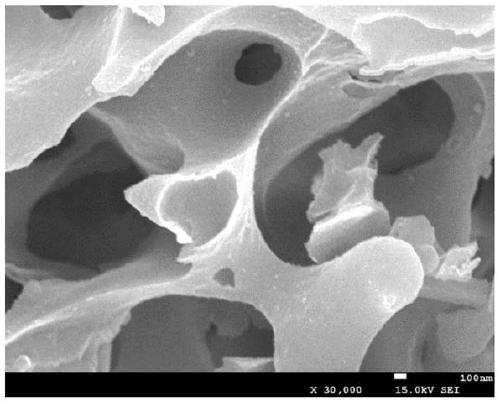

[0049] The tobacco-based activated carbon described in this embodiment is based on anhydrous 38gK 2 CO 3 , 19g tobacco rod powder, and 3g low-density polyethylene powder are mixed, and carbonized at 850°C under nitrogen as a protective gas environment. The density of low-density polyethylene is 0.91g / cm 3 g / cm 3 . The adsorption performance of activated carbon is tested according to the national standard GB / T12496.10-1999 "Determination of Methylene Blue Adsorption Value of Wooden Activated Carbon Test Method". Each sample is tested twice and the average value is taken. The iodine adsorption value of tobacco-based activated carbon is 1421mg / g , methylene blue adsorption rate 806mg / g. The microscopic morphology of activated carbon was analyzed by scanning electron microscope. image 3 and Figure 4 as shown, image 3 30000 times scanning electron microscope picture of tobacco matrix activated carbon in the present embodiment, Figure 4 5000 times scanning electron micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com