Construction method for bored pile of subway station enclosure structure of upper-soft lower-hard ground

A technology for subway stations and enclosure structures, which is used in infrastructure engineering, drill bits, sheet pile walls, etc., can solve the problems of difficult hole forming, difficult to ensure hole quality, easy to cause hole collapse, etc. Easy to operate, prevent the pile quality from being difficult, and prevent the effect of hole collapse and necking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

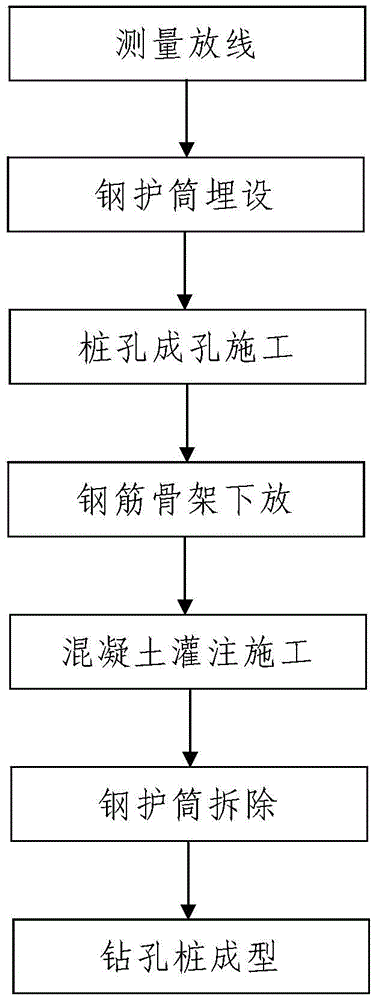

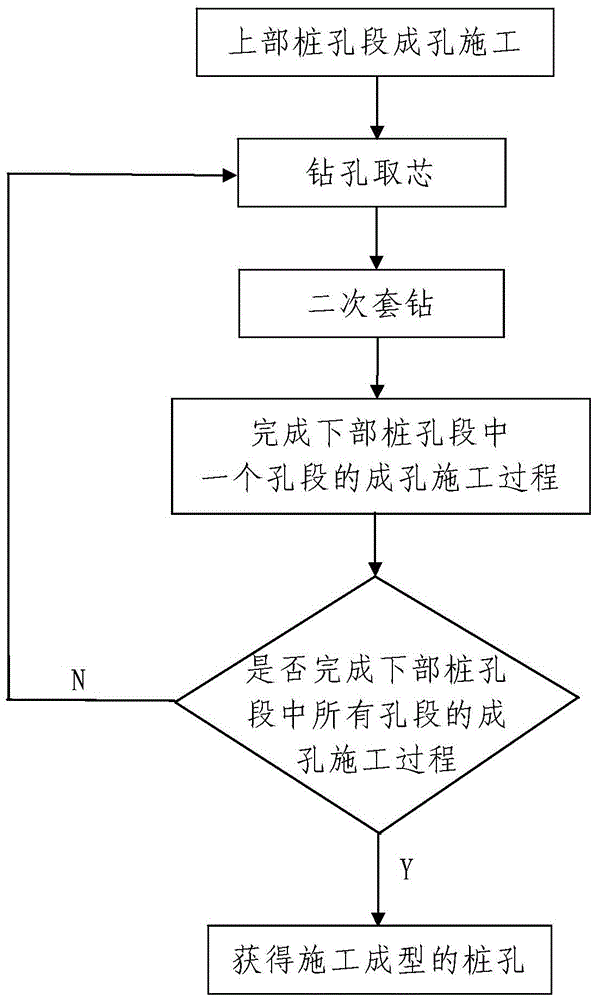

[0063] Such as figure 1 Shown is a construction method of bored piles for the surrounding structure of a subway station in upper soft and lower hard strata, comprising the following steps:

[0064] Step 1, measuring and setting out: measuring and setting out the pile positions of the constructed bored piles;

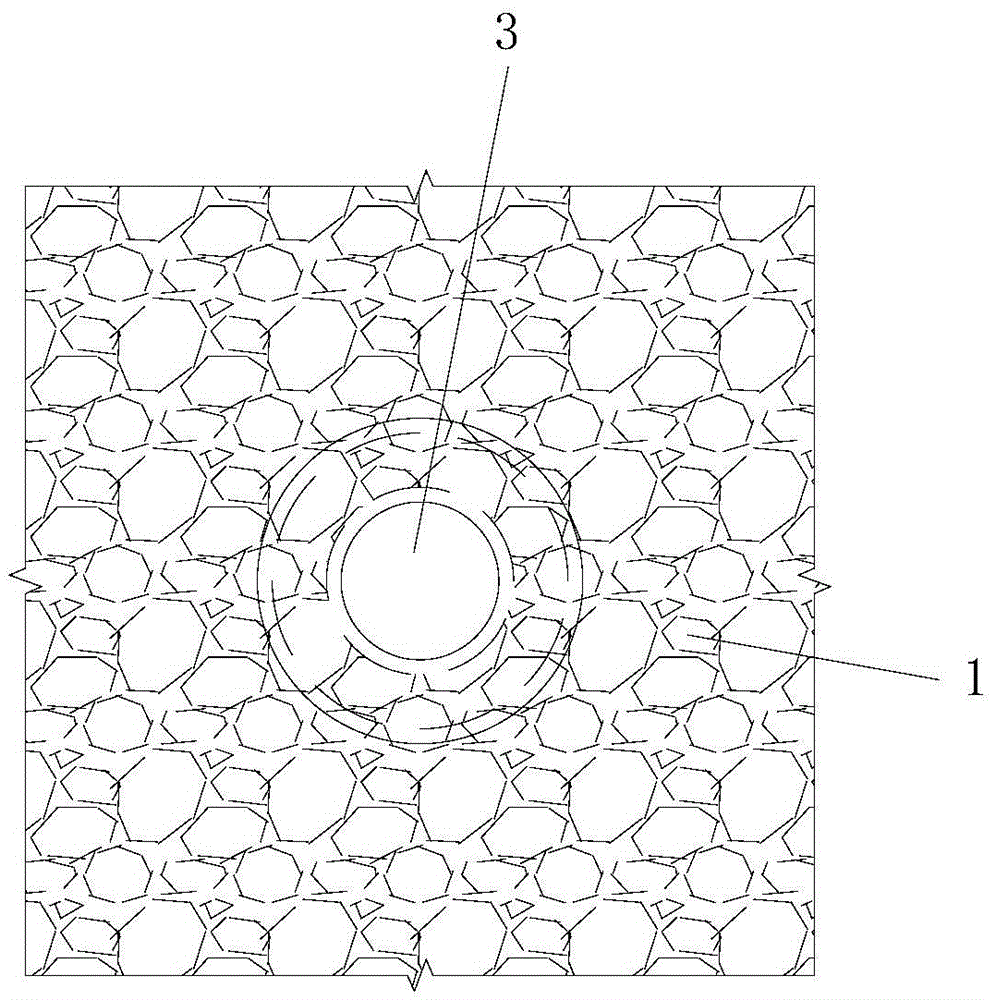

[0065] The bored piles constructed are cast-in-situ bored piles formed in the upper soft and lower hard strata. The constructed bored piles are arranged vertically and the pile length is 25m-30m. The pile body diameter of the constructed bored piles is D1 =Φ1200mm~Φ1800mm; the upper part of the upper soft and lower hard strata is a soft soil stratum and the lower part is a hard rock stratum 1, and the depth of the lower part of the bored pile entering the hard rock stratum 1 is not less than 10m;

[0066] Step 2. Embedding of steel casing: According to the measurement and setting-out results in step 1, bury a steel casing in the soft soil stratum where the bored pile is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com