Cutting drilling machine

A drilling rig and drilling stand technology, which is used in rotary drilling rigs, earth-moving drilling, drilling equipment and other directions, can solve the problems of stuck drill bits, poor performance of the whole machine, inconvenient operation, etc., so as to improve the drilling work. The effect of high quality, fast hole forming speed and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

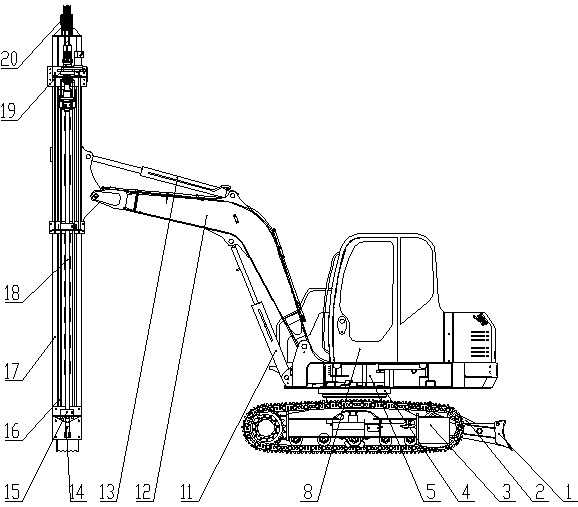

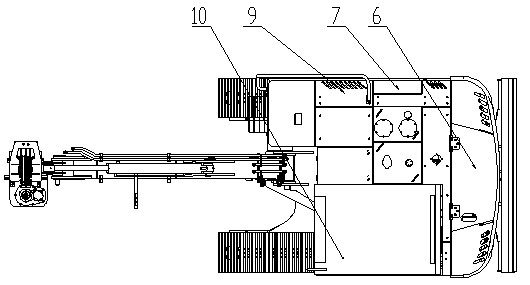

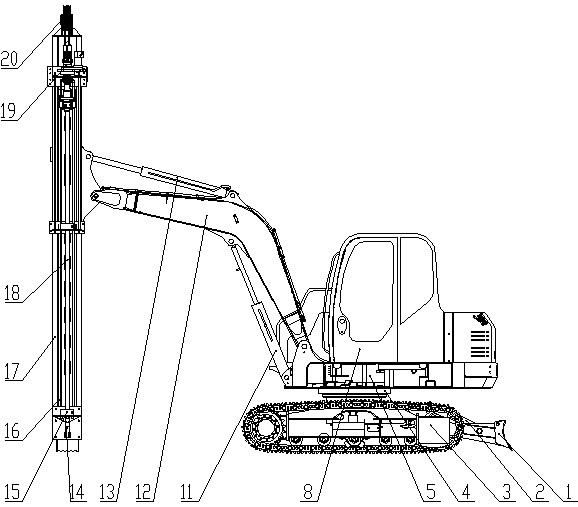

[0017] Example 1: Such as figure 1 , 2 As shown, the cutting drilling rig of this embodiment consists of a bulldozing blade 1, a bulldozing cylinder 2, a chassis assembly 3, a slewing mechanism 4, a platform assembly 5, a power system 6, a hydraulic system 7, a cab 8, an air compressor system 9. Operating system 10, boom cylinder 11, boom 12, drill frame cylinder 13, drill bit 14, guide limit sleeve 15, travel switch 16, drill frame 17, drill rod 18, power head system 19 and drill rod propulsion system 20 composition.

[0018] Chassis assembly 3 is the walking and chassis part of the present invention. It is set at the bottom end and directly touches the ground. It uses 8.5T four wheels and 450mm widened track shoes to reduce the ground pressure and ensure the stability of the whole machine. Larger drill pipe down pressure improves the efficiency of drilling rigs. A slewing mechanism 4 is provided on the top, and the slewing mechanism 4 can freely rotate 360 degrees on the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com