Concrete pile construction equipment and method

A technology for concrete piles and construction devices, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as pile hole water ingress, environmental pollution, hole wall collapse, etc. Good hole quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

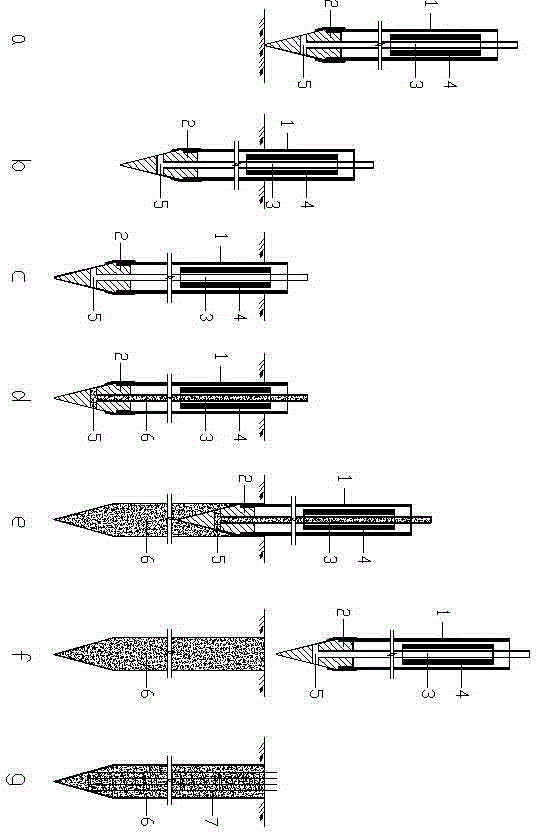

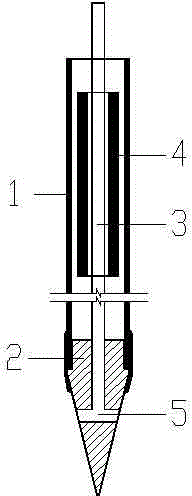

[0026] figure 1 It is the front section view of an embodiment of the construction device of the concrete pile of the present invention, as figure 1 As shown, the bottom end of the casing 1 is connected with an impact hammer 2, and the inside of the casing 1 is provided with a delivery pipe 3 capable of transporting concrete. The delivery pipe 3 communicates with the internal pipe 5 of the impact hammer 2. There is also a liftable core-piercing hammer 4 that passes through the feeding pipe 3 inside; the lower half of the impact hammer 2 is a pointed cone with a diameter greater than or equal to the outer diameter of the casing 1, the tip of the pointed cone is downward, and the upper The half part is a cylinder with a diameter smaller than the inner diameter of the casing, which is welded together with the bottom of the casing, and fixed by welding strip steel plates at the junction. A vertical pipe 5 is provided inside the impact hammer and connected to several branch pipes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com