Rotary pump perforating piling machine

A technology of hole forming and pile driving, which is applied in the direction of rotary drilling rig, sheet pile wall, rotary drilling, etc., which can solve the problems of high transportation cost, difficult quality assurance, and high hammering noise of hammer pile machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

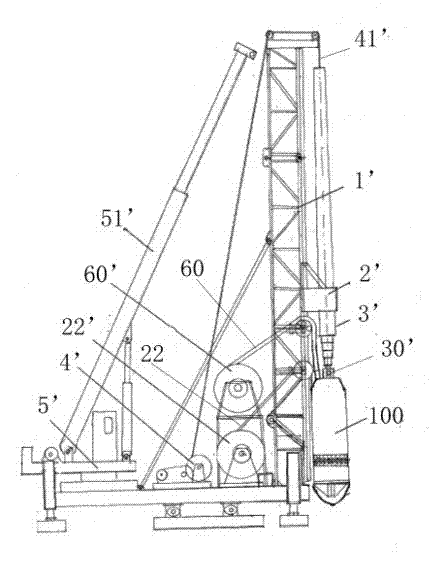

[0017] Such as figure 1 Shown, the present invention has frame 1 ', and frame 1 ' is fixedly provided with directional seat 2 ', and the coiling rope 41 ' of winch 4 ' that is set on frame 1 ' hangs drilling rod 3 ', and drilling rod 3 'Through the orientation seat 2' used for the orientation seat, the lower part of the drill pipe 3' is fixedly connected to the interface 30' at the upper end of the diamond drill bit 100 for absorbing soil and forming a hole.

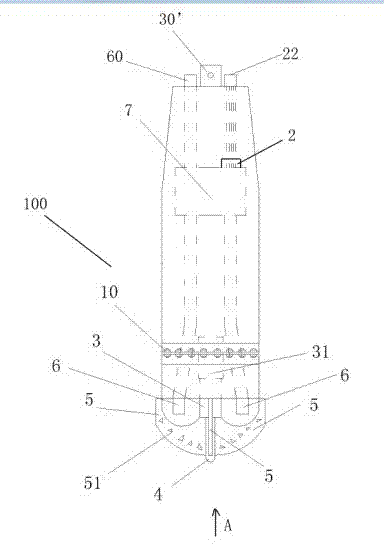

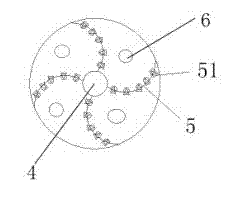

[0018] Such as figure 2 , image 3 The shown gold steel drill bit 100 of the present invention absorbs soil and forms a hole. The submersible protective cover 1 formed by connecting the two parts of the cover body with the maintenance connecting flange 10 is provided with a rotating motor 31, that is, a power pump. The rotating motor 31 is connected. And drive bit rod 3, drill bit rod 3 stretches out diving protection cover 1, the end of drill bit rod 3 is provided with rotary drill bit 4, has four curved eccentri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com