Down-hole coal bed air-pressing helix drilling tools and drilling method using the same

An auger rod and screw technology is applied in the field of underground coal-layered air auger drilling equipment and the drilling field using the equipment, which can solve the problems of difficult drilling construction, small hole forming depth, broken hole and stuck drilling, etc. Hole speed and gas drainage effect, improve hole depth and porosity rate, and ensure the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

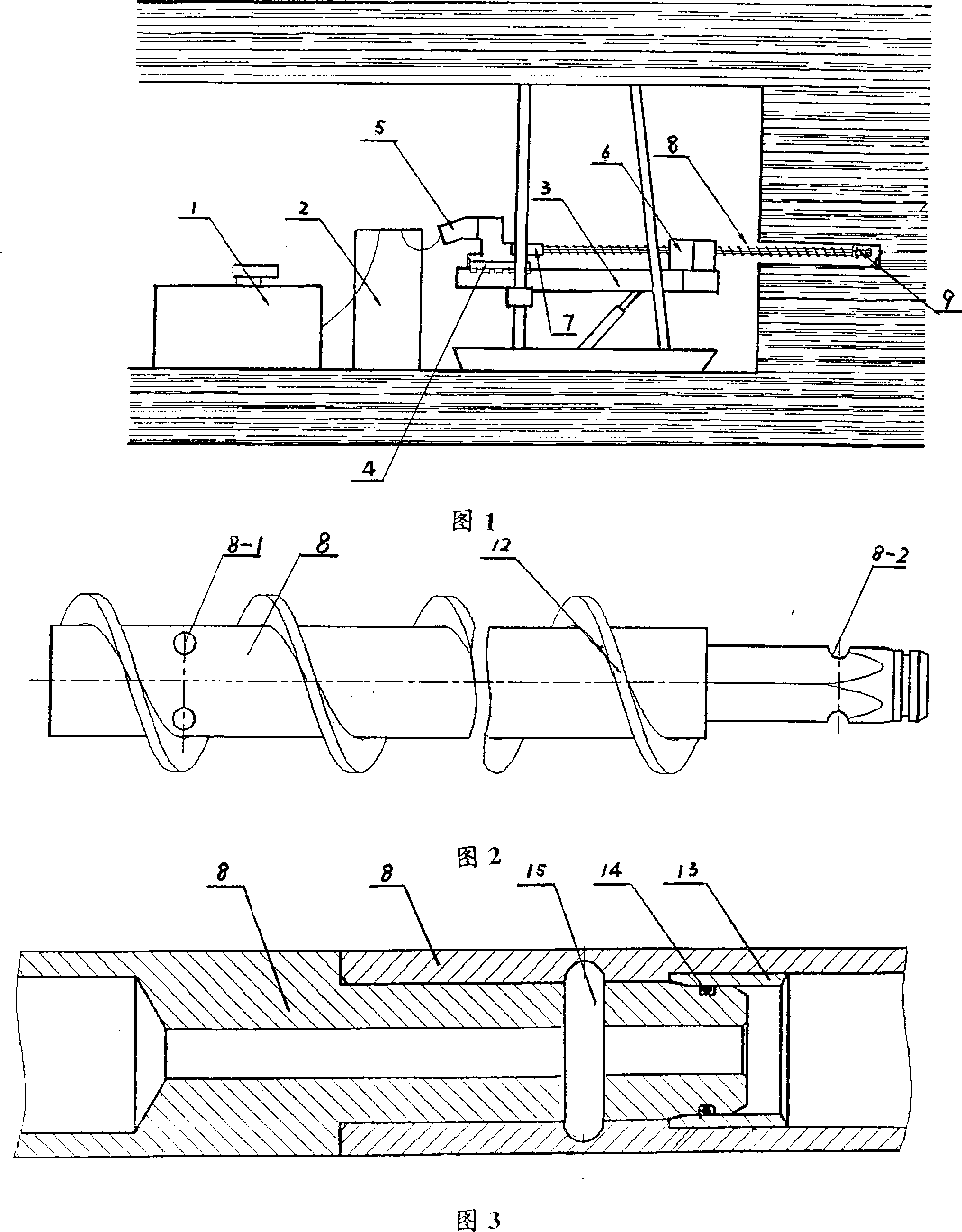

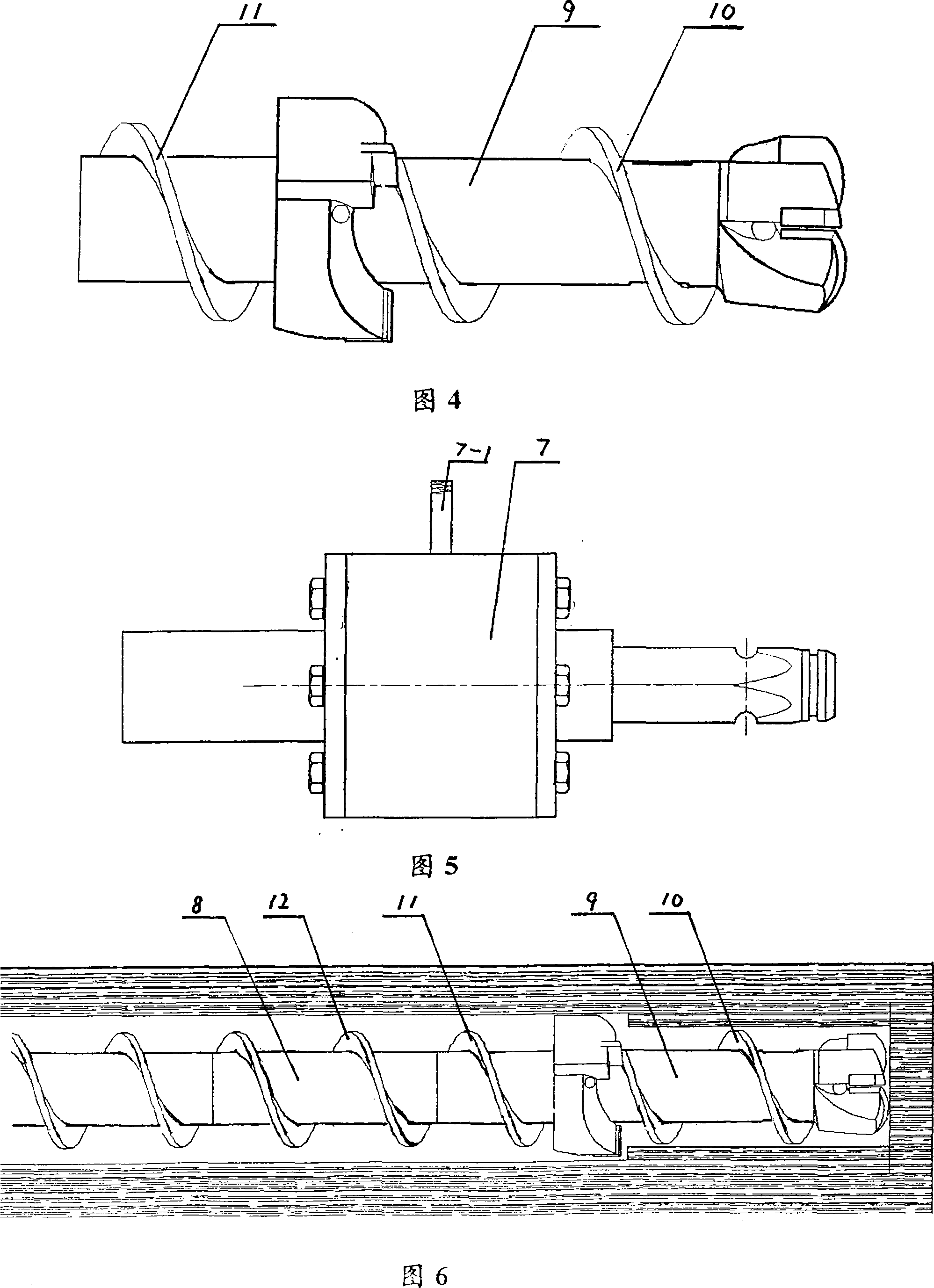

[0025] The present invention will be further described in detail below in conjunction with the drawings.

[0026] Referring to Figure 1, Figure 5 and Figure 6, the underground coal bed air spiral drilling machine of the present invention includes a pump station 1, an operating table 2, a frame 3, a moving device 4 arranged on one end of the frame rail, and a device The power head 5 on the mobile device, the clamper 6 arranged on the other end of the frame, the clamper 6, the power head 5 and the mobile device 4 are respectively connected to the pumping station through the operating platform through the oil pipe;

[0027] One end of the air supply switching device 7 is connected to the power head 5, and its compressed air input port 7-1 is connected to the mine air pressure system; one end of the hollow spiral drill rod 8 is connected to the other end of the air supply switching device 7, and the other end It extends through the holder 6 and is connected to the two-stage combined d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com