Goaf gas drainage method of stope working surface of coal mines

A technology of mining face and gas drainage, which is applied in the direction of gas discharge, mining equipment, earthwork drilling, etc., and can solve the problems of poor drainage effect of buried pipes in the upper air duct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

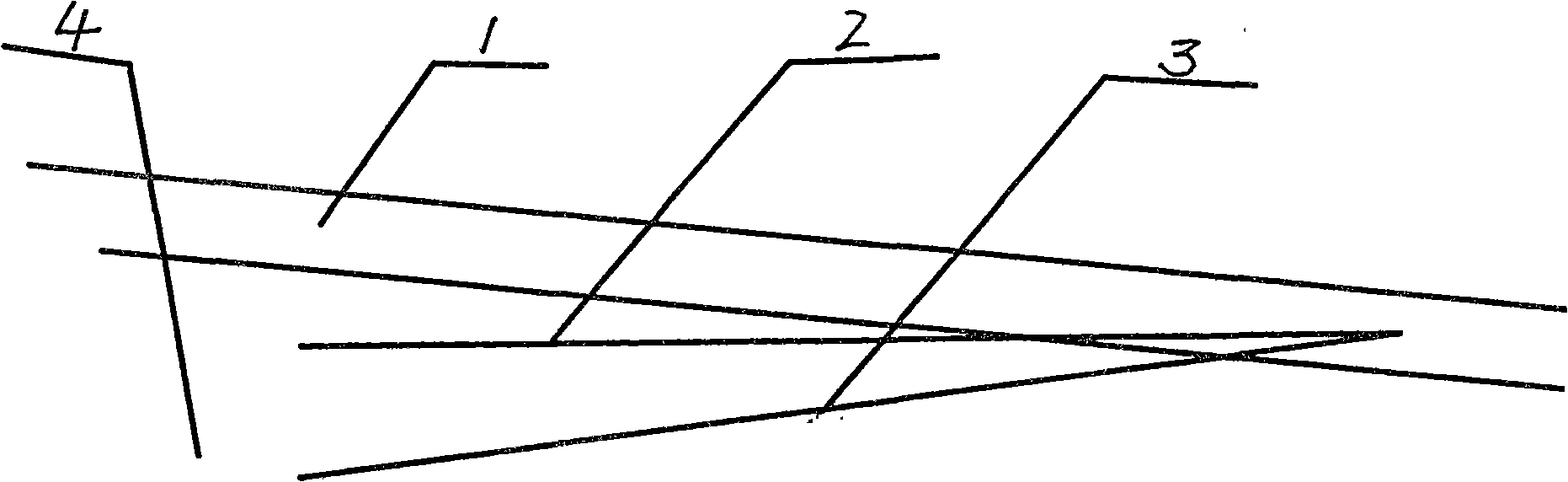

[0013] The method of the present invention is as figure 1 As shown, the specific steps are as follows: the air duct 1 on the mining face is arranged with boreholes 2 and 3 in advance, and the bottom of the borehole is on the coal seam roof 4 of the mining face. Automatic caving, the gas in the goaf moves upwards, and is discharged into the upper air duct through the pre-arranged boreholes. Therefore, the roof gas drainage technology of the mining face is an effective method to control the gas in the goaf.

[0014] Economic Benefit Analysis of the Drainage Technology of the Present Invention

[0015] (1) The use of gas drainage on the roof of the gob in the mining face can reduce the gas concentration in the return air flow of the air duct on the mining face by 0.3%, which can save the air consumption of the mining face by 300m 3 / min, saving more than 103,000 yuan in electricity bills per year.

[0016] (2) It guarantees the safety of the mining face and has huge economic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com