Patents

Literature

388results about How to "Guaranteed progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shield synchronous grouting construction method and construction material

ActiveCN104074530AImprove stabilityShort entry into initial setting timeUnderground chambersTunnel liningSlurryMaterials science

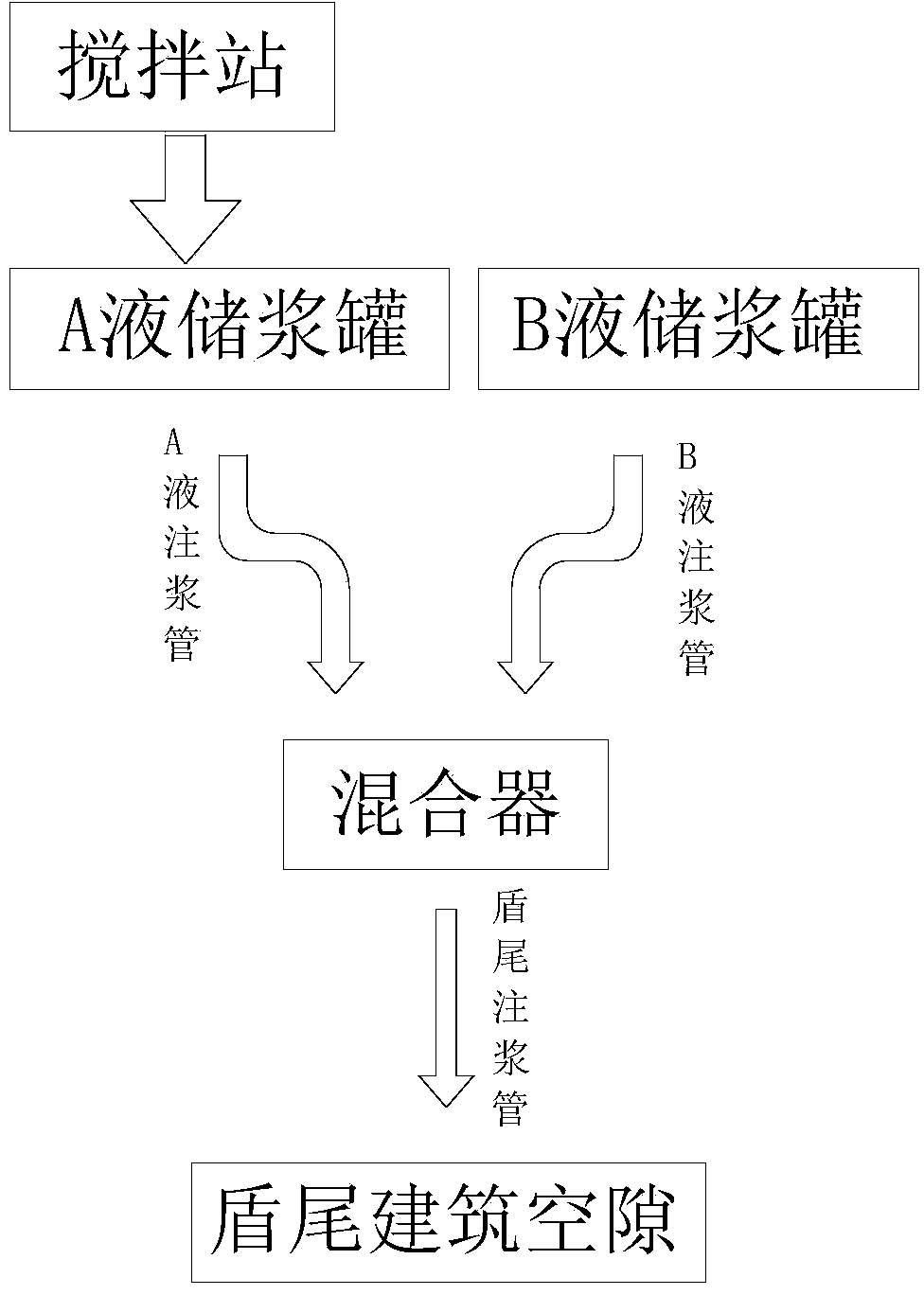

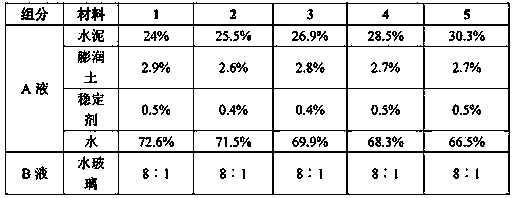

The invention discloses a shield synchronous grouting construction method and a construction material. The construction material comprises liquid A and liquid B, wherein the liquid A comprises 25.5 weight percent of cement, 2.6 weight percent of bentonite, 0.4 weight percent of stabilizing agents and 71.5 weight percent of water; the liquid B is water glass; and the volume ratio of the liquid A to the liquid B is 8:1-15:1. During synchronous grouting construction, the liquid A is prepared in a mixing station, and the liquid A and the liquid B are respectively conveyed into a liquid A slurry storage tank and a liquid B slurry storage tank which are arranged on a shield machine; the liquid A and the liquid B are respectively conveyed into a mixer positioned at the shield tail part of the shield machine through a liquid A slurry injection pipe and a liquid B slurry injection pipe; and the liquid A and / or the liquid B in the mixer are / is synchronously injected into a shield tail building gap through a shield tail slurry injection pipe. The shield synchronous grouting construction method solves various problems in subsequent grouting, synchronous single slurry injection, in-time grouting and secondary grouting in the prior art through utilizing good performance of the liquid A and the liquid B before and after the mixing of the liquid A and the liquid B and combining a primary synchronous grouting process.

Owner:CHINA RAILWAY 15TH CONSTR BUREAU GRP

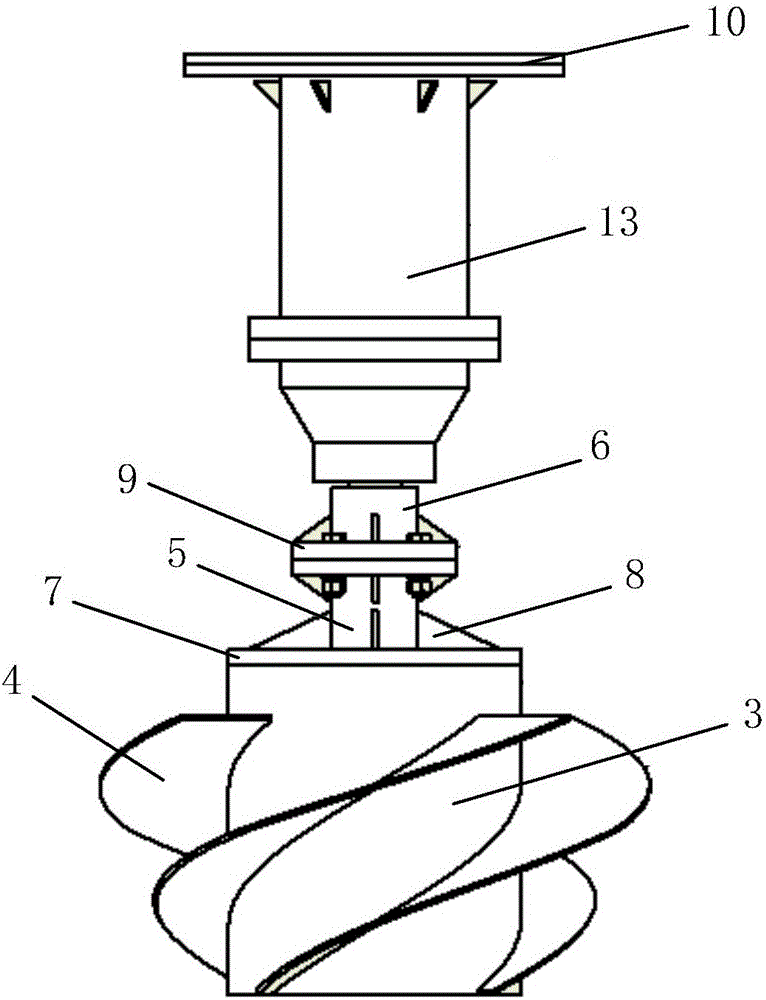

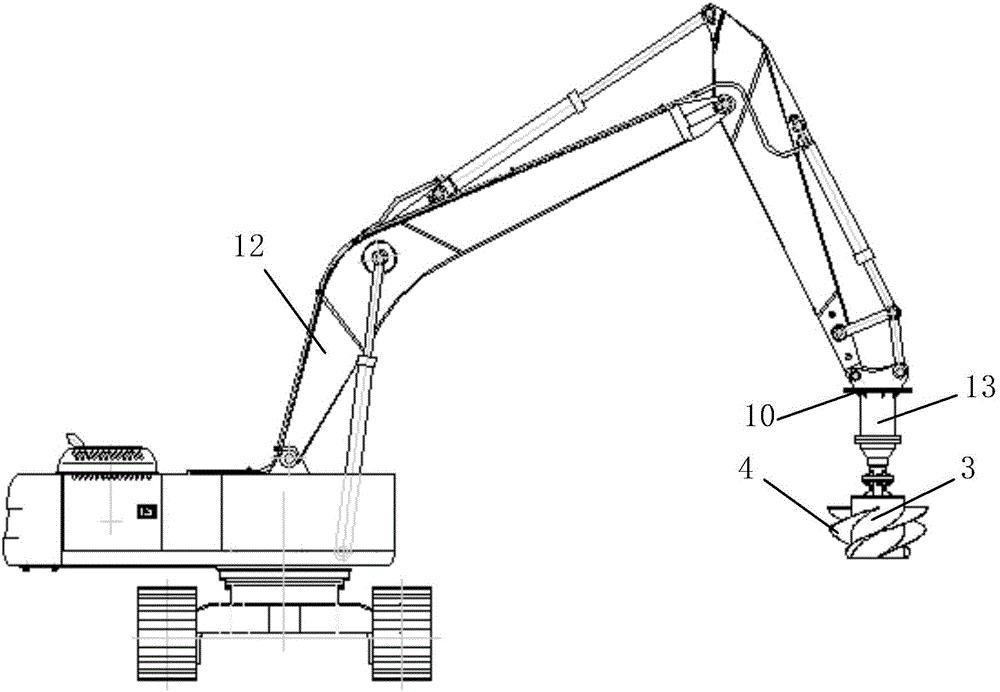

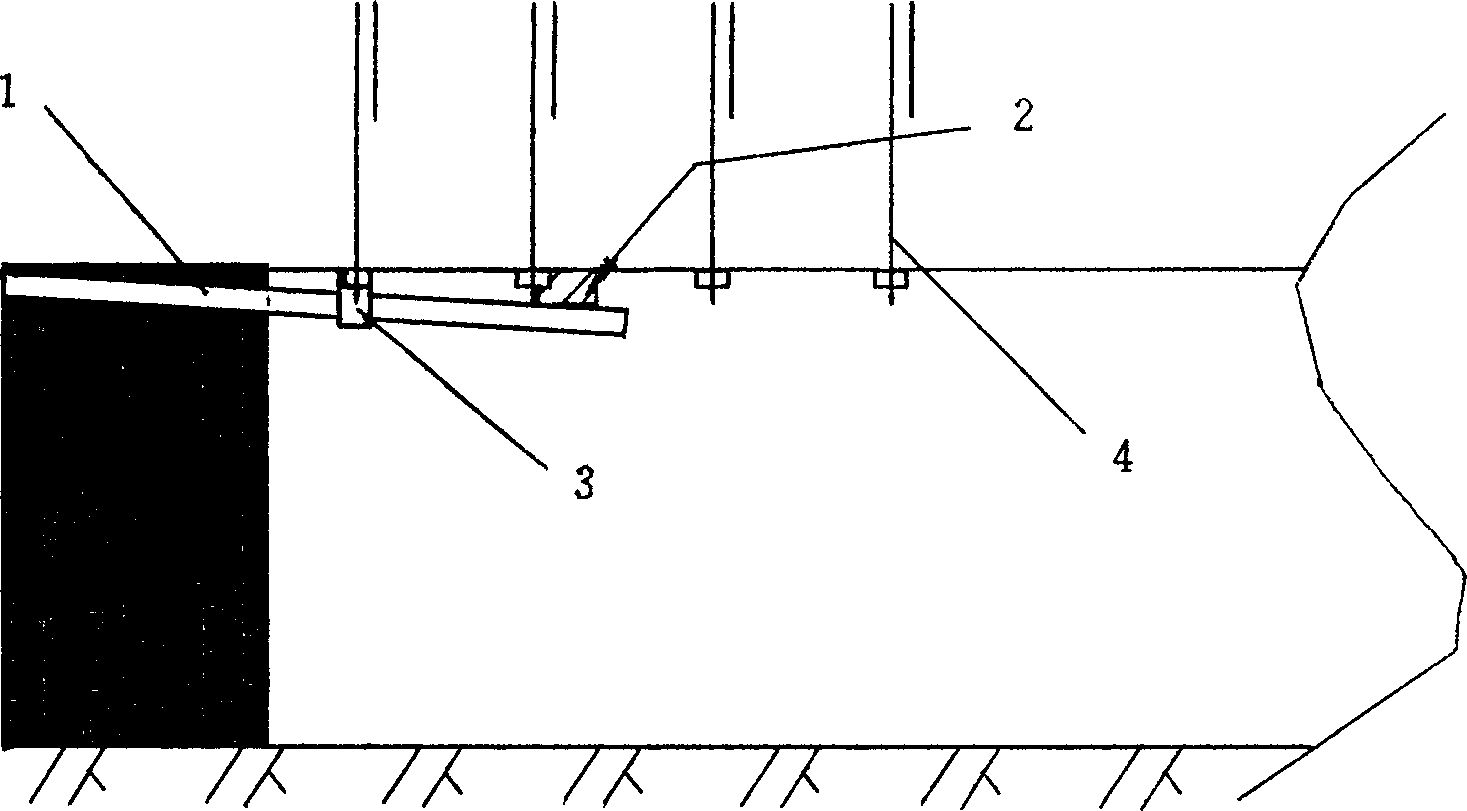

Long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall

ActiveCN106284313AReasonable structural designEasy to operateBulkheads/pilesDrilling machines and methodsUnderwaterHigh pressure

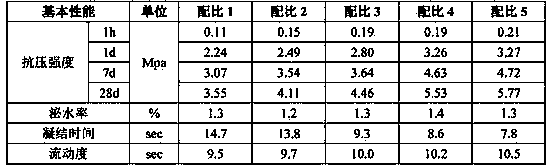

The invention discloses a long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall, comprising the steps of first, burying a protective barrel and setting a slurry circulating system that comprises a slurry storage tank and a slurry pumping device, with the upper portion of the protective barrel provided with an overflow hole; second, drilling to form a borehole; third, lifting a drill pipe, and casting a slurry breast wall under high pressure: lifting up the drill pipe, and continuously casting wall supporting slurry from bottom to top from the borehole bottom through the drill pipe by using the slurry pumping device; fourth, lowering a reinforcement cage; fifth, casting concrete underwater and recycling the wall supporting slurry, and recycling the wall supporting slurry discharged through the overflow hole to the slurry storage tank for backup. The method has simple steps, is easy to implement, has high hole-forming quality and good construction effect, and enables the construction of a long screw extrusion-socketed cast-in-place pile to be finished simply and quickly, and by casting the wall supporting slurry from bottom to top from the borehole bottom in a high-pressure casting manner, it is possible to effectively protect the wall and keep the borehole bottom clean with no deposit; the wall supporting slurry is reusable.

Owner:SHAANXI ZHUANGXIN CONSTR ENG +4

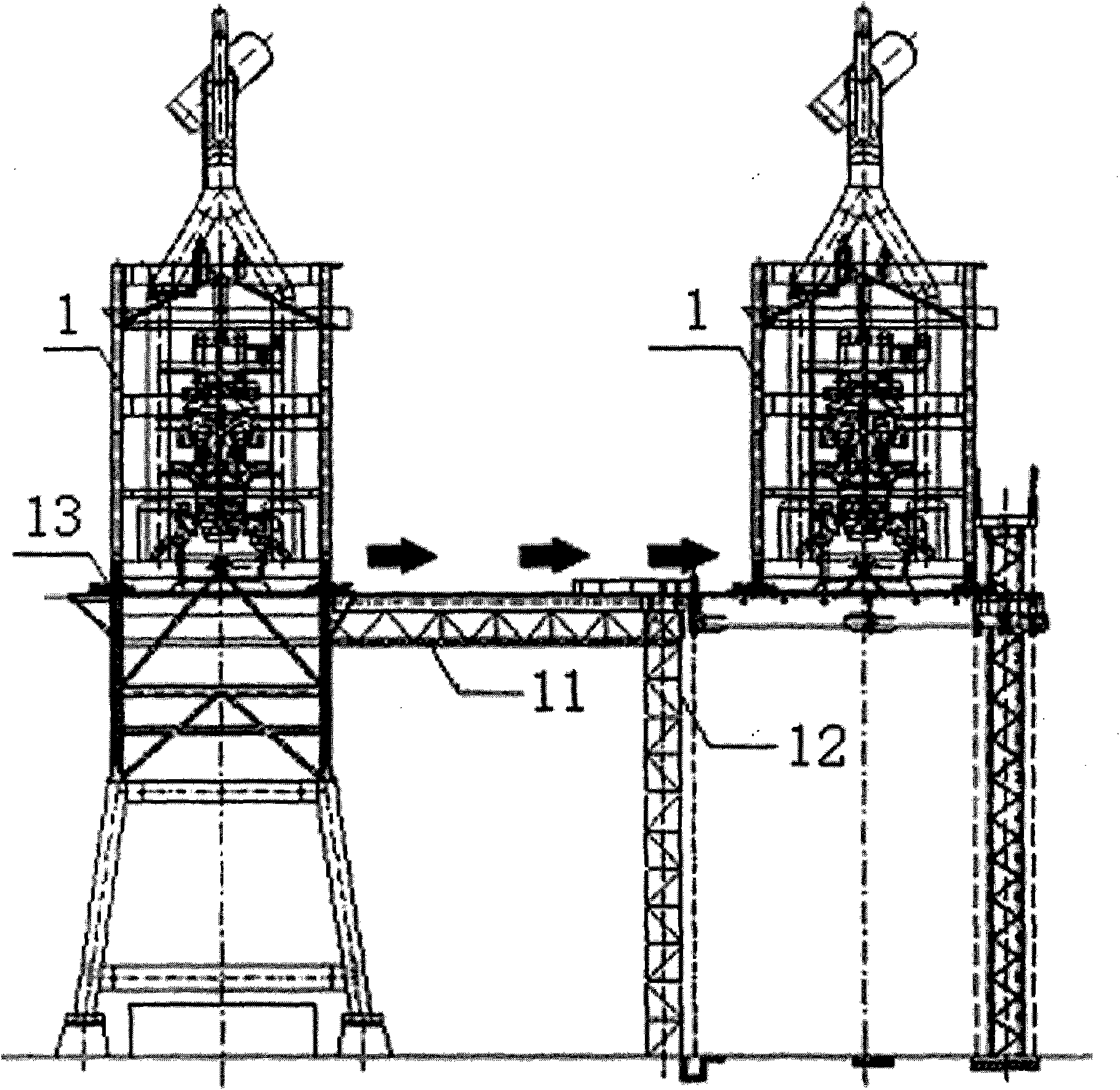

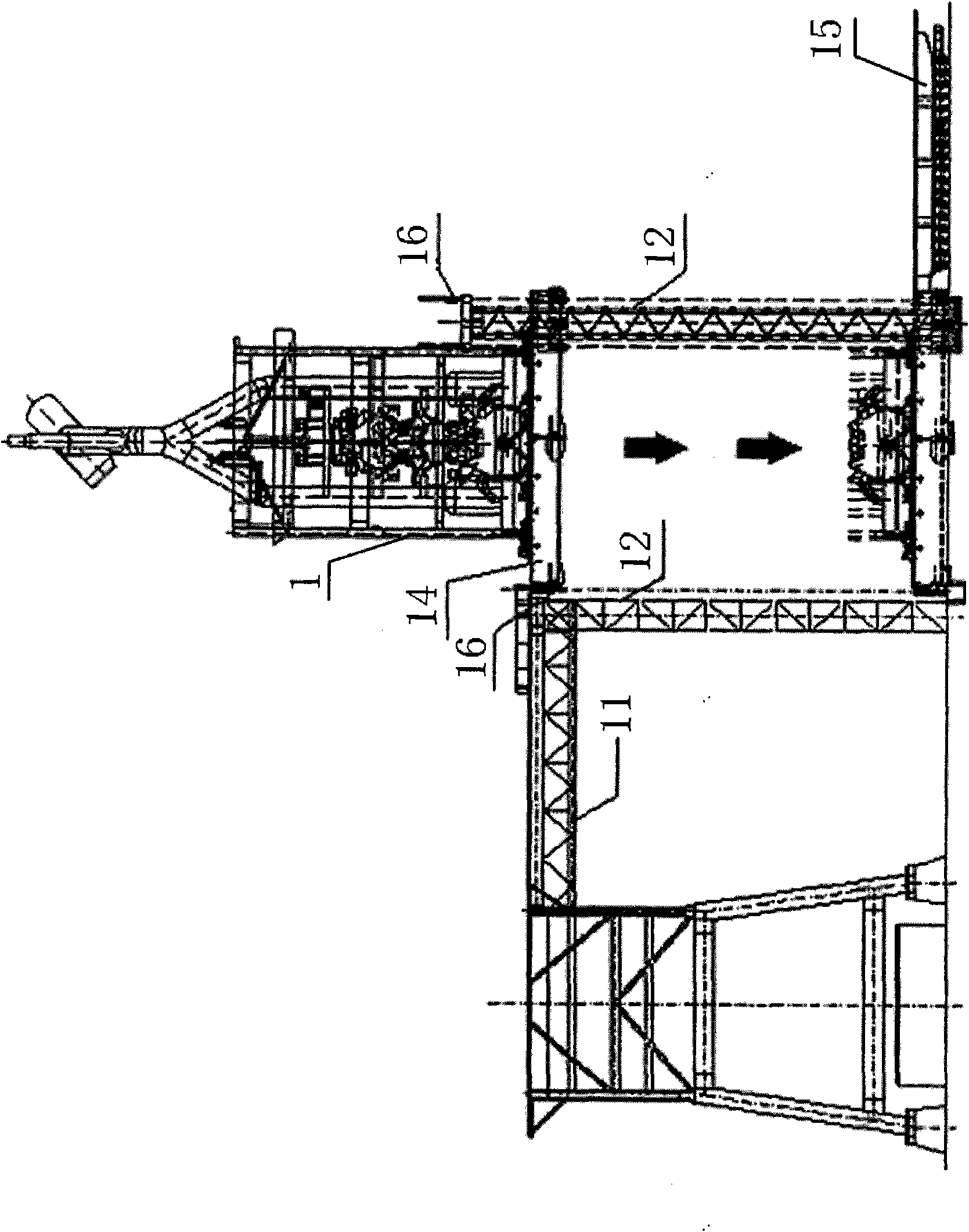

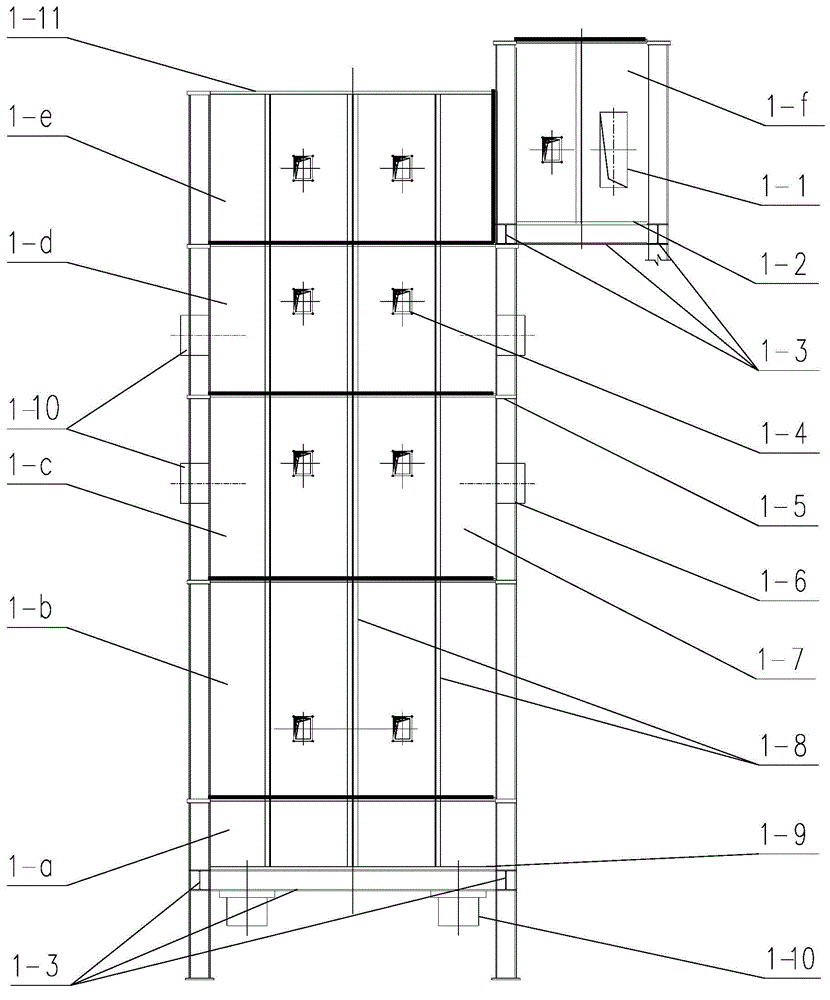

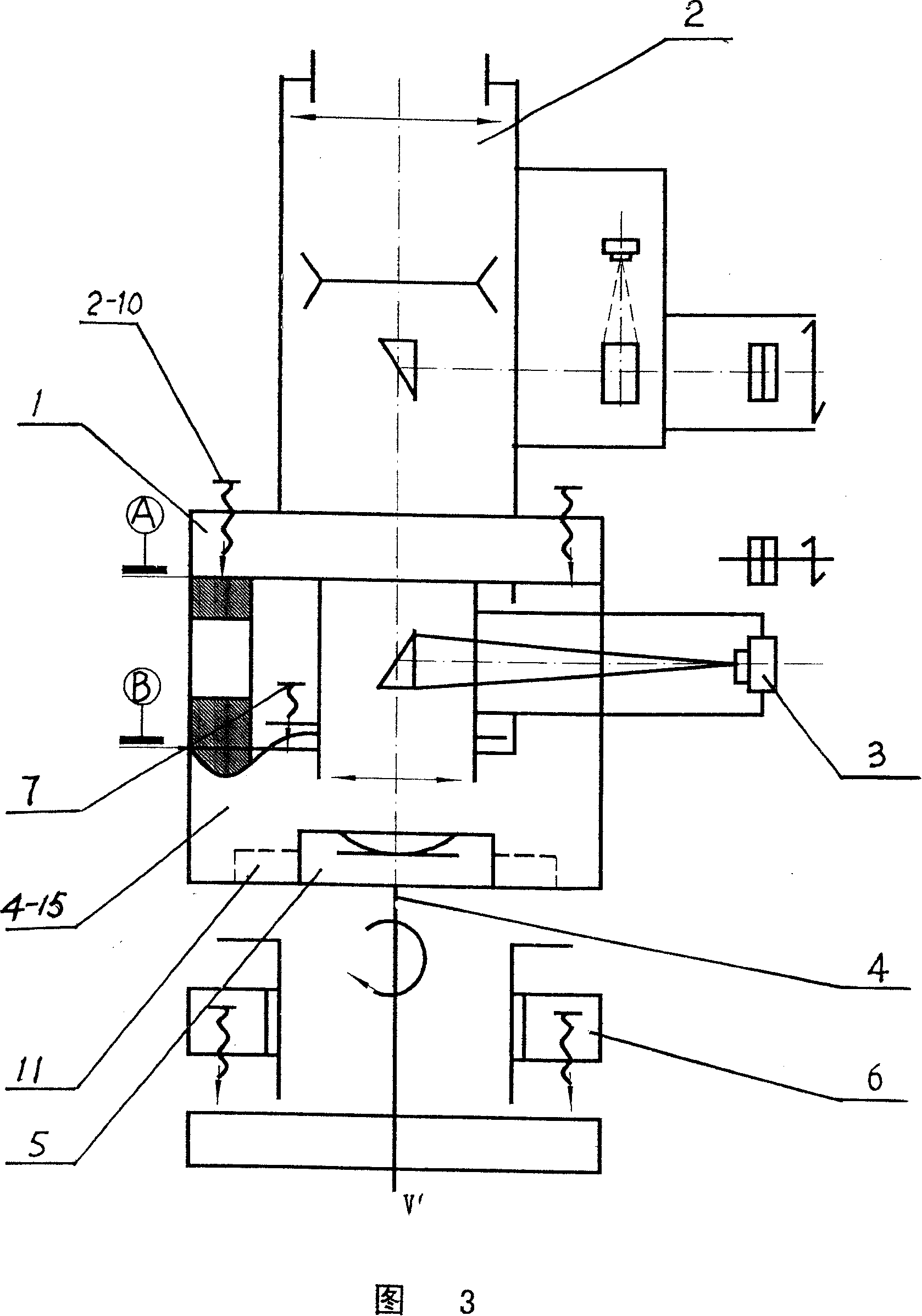

Modularized and integrative disassembling and installing methods for blast furnace

InactiveCN102146488ASatisfy construction safetyMeet construction requirementsBlast furnace componentsBlast furnace detailsCast houseBuilding construction

The invention relates to the installation method field of smelting equipment of iron, in particular relates to modularized and integrative disassembling and installing methods for a blast furnace. The modularized and integrative disassembling method for the blast furnace comprises: disassembling a furnace top system, disassembling a hot wind surrounding pipe, disassembling a layer beam and casting house platform and disassembling a furnace body. The modularized and integrative disassembling method is characterized in that when the furnace top system, the hot wind surrounding pipe, the layer beam and casting house platform and the furnace body are dissembled, the modularized and integrative disassembling method is adopted. The modularized and integrative insulating method for the blast furnace comprises: installing the furnace top system, installing the hot wind surrounding pipe, carrying out furnace body construction, carrying out layer beam and casting house platform construction and carrying out finished product groove construction and is characterized in that when the furnace top system, the hot wind surrounding pipe, the furnace body, the layer beam and casting house platform and the finished product groove are installed, the modularized and integrative installing method is adopted. According to the invention, construction efficiency is high, safety is high, and production cost is reduced.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH

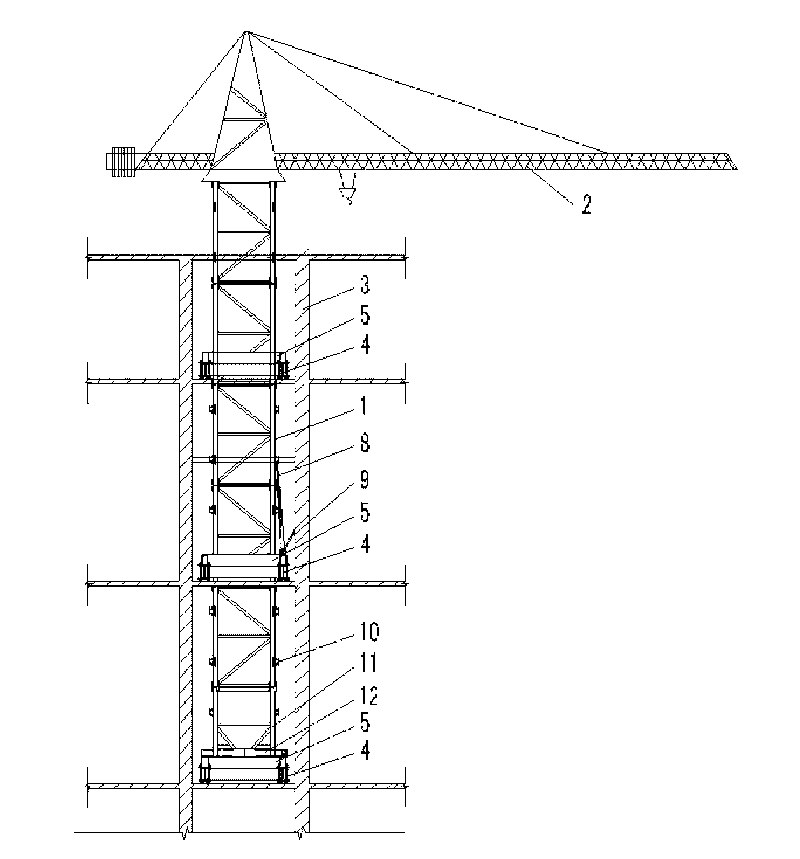

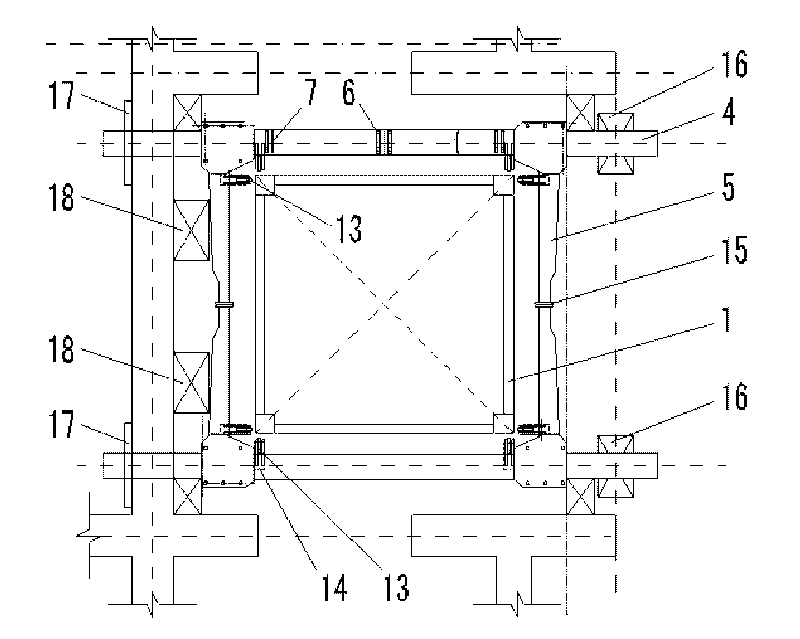

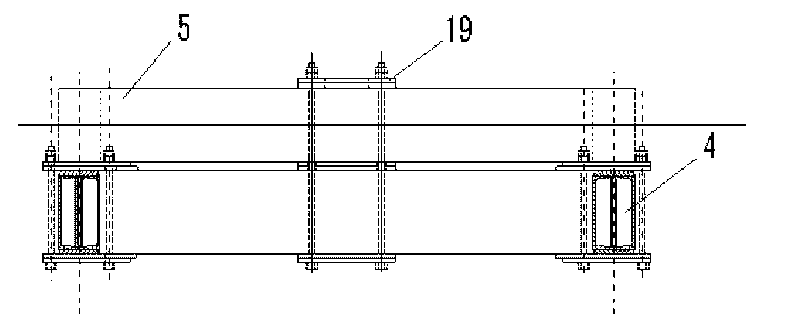

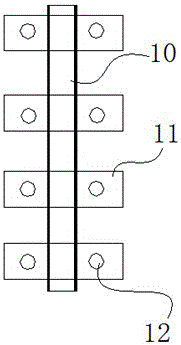

Self-climbing tower crane

InactiveCN101691191AHave vertical transportation requirementsMeet vertical transportation requirementsCranesSocial benefitsTower crane

The invention discloses a self-climbing tower crane, which comprises a tower body (1), a hoisting arm (2) and a climbing mechanism, wherein the climbing mechanism comprises a main stressed supporting steel beam (4) and a steel structure climbing attached frame (5); the steel structure climbing attached frame (5) is fixedly connected on the main stressed supporting steel beam (4) and is provided with a jacking cylinder (8) and a supporting steel beam (9); and a tower body supporting tread (10) is arranged on a tower body (1), and the bottom of the tower body (1) is provided with a climbing base section (11). The self-climbing tower crane can climb upward along a constructed structure by using the constructed building structure as a support, meet the requirements of superhigh-rise and out-of-code tall buildings on vertical transportation at the whole construction height, contribute to construction efficiency, construction period reduction, steel conservation and energy conservation and create obvious economic and social benefits.

Owner:CHINA CONSTR FOURTH ENG DIV

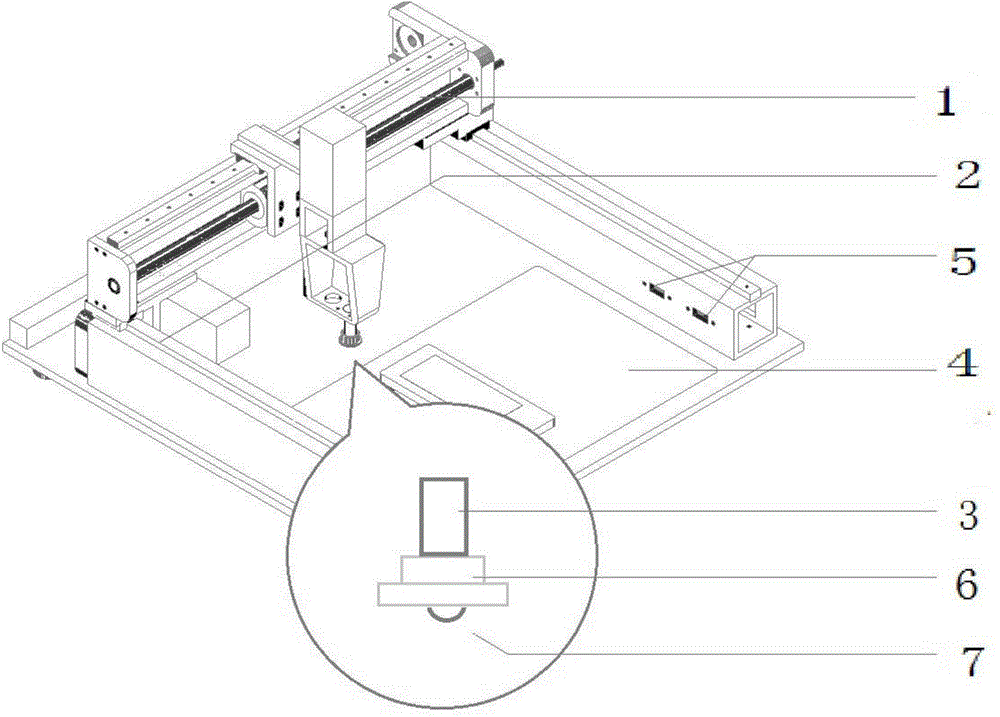

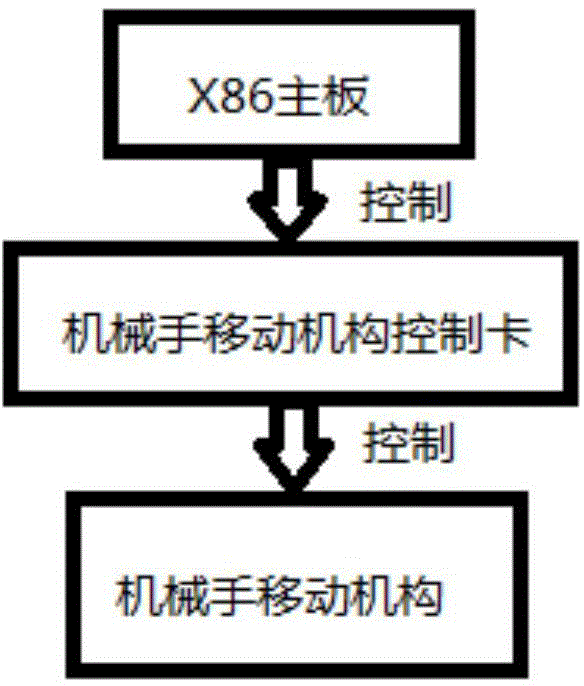

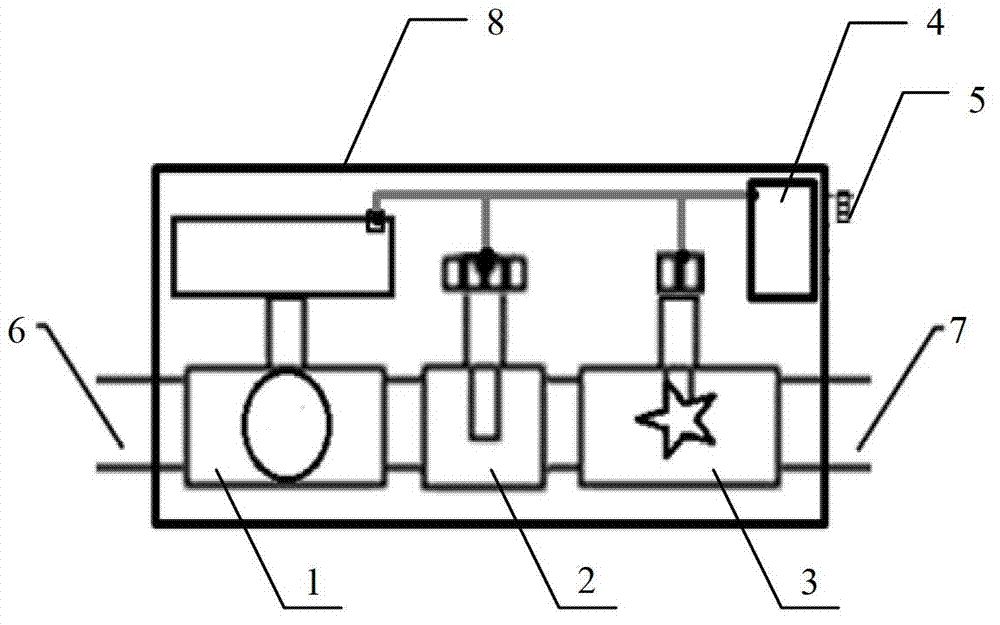

Manipulator device for automatic testing of mobile phone and use method

ActiveCN104608120APrecise movement controlGuaranteed progressProgramme-controlled manipulatorSubstation equipmentThree-dimensional spaceEngineering

The invention provides a manipulator device for automatic testing of a mobile phone. The manipulator device comprises a box, an X86 mainboard, a manipulator moving mechanism control card, a manipulator moving mechanism, a manipulator, a camera and a tray. The X86 mainboard, the manipulator moving mechanism control card, the manipulator moving mechanism, the manipulator, the camera and the tray are located in the box, the X86 mainboard is connected with the manipulator moving mechanism control card, the manipulator moving mechanism control card drives the manipulator moving mechanism, the manipulator is arranged on the manipulator moving mechanism which is of a three-dimensional space moving structure, the camera is connected with the X86 mainboard through a network and located over the tray, and the tray is located below the manipulator. The manipulator device can be used for replacing manual operation, assists in completing automatic testing of the mobile phone and guarantees the schedule and quality of testing work.

Owner:天津市康凯特软件科技有限公司

Method for constructing tower crane foundation

InactiveCN102704504ASimplify the construction processReduce construction costsFoundation engineeringRebarSteel plates

The invention discloses a method for constructing a tower crane foundation. According to the technical scheme, the tower crane foundation is constructed by using a structure raft foundation. The method comprises the following steps of: determining the position of the tower crane foundation, excavating soil, constructing a foundation bed, constructing and plastering brick moulds, performing foundation water prevention, constructing a foundation water prevention protective layer, performing foundation setting-out, bundling foundation base plate lower steel bars, preembedding and assembling tower crane accessories; bundling foundation upper steel bars, assembling steel plate water-stop belts and templates, performing concrete construction on the tower crane foundation, roughening and performing water prevention treatment on concrete surface of the tower crane foundation and a structure raft. By the method, the construction process is simplified, the construction cost is reduced, and the tower crane foundation is integrated with the structure raft and stressed in a relatively balanced and safe mode.

Owner:华新建工集团有限公司 +1

Tube truss manufacture process

The invention provides a tube truss manufacture process which comprises the steps as follows: blanking of steel tubes, positioning of intersecting points of tube fitting, welding of tube fitting, calibrating of members, pre-assembling, and disassembling of the pre-assembled truss, wherein all the manufacturing and processing links are carried out in sequence. The manufacture process has the advantages as follows: the assembly precisions of intersecting ends and intersecting holes are high; the size deviation is small; a truss body can be assembled quickly; the workload of calibration is small; formation of physical appearance is good; workload and time for polishing are greatly reduced; the quality of construction and formation can be guaranteed; smoothness and progression of all manufacture links are guaranteed; total construction period is guaranteed; material cost of manufacturing of the tube truss can be saved; inputs of manpower and goods and materials are saved; and economical effects of production are improved.

Owner:河北二十冶建设有限公司

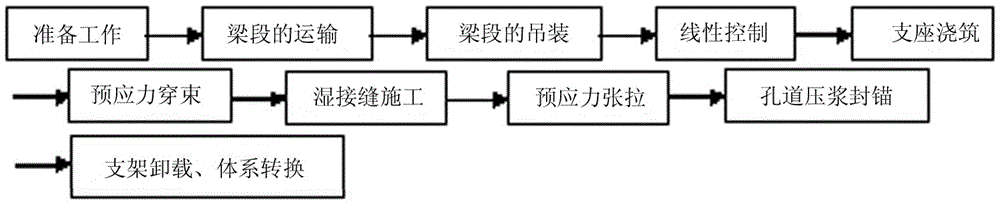

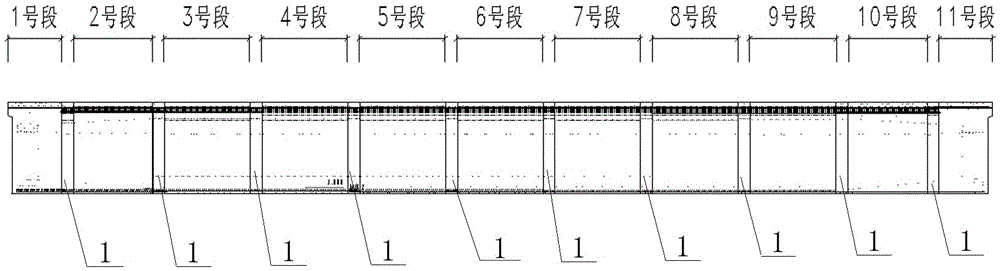

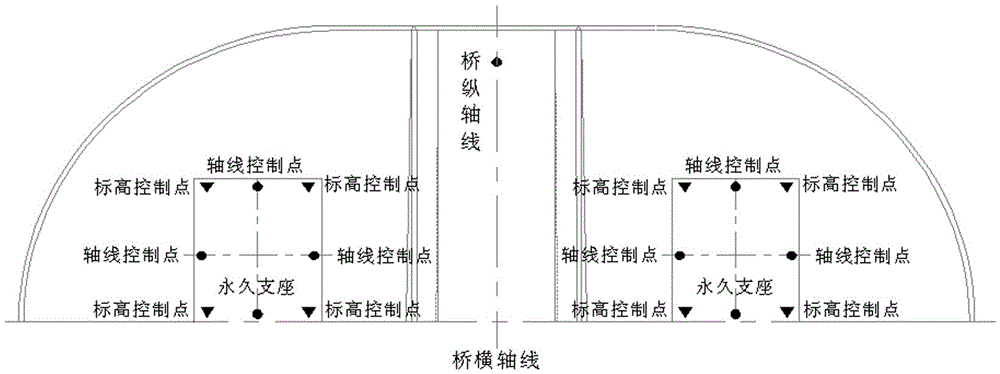

Construction method for 48m sectional beam of passenger railway based on BIM technology

InactiveCN105625188ACollision does not existImprove construction efficiencyBridge erection/assemblyPre stressPre stressing

The invention belongs to the technical field of sectional beam construction of railways, roads, municipal engineering and intercity rail transits. In order to solve the problems such as slow construction progress, high cost, difficulty-to-guarantee construction quality and the like of a large-span beam, the invention provides a construction method for a 48m sectional beam of passenger railway based on a BIM technology. The construction method is characterized being a construction process of dividing a beam body into a plurality of beam sections, and jointing each beam section into a bridge by applying pre-stress; the assembly construction process of the beam sections comprises prefabrication of beam sections, transportation and lifting of the beam sections, strand pulling by pre-stress, wed joint construction, pre-stress tensioning, duct grouting for sealing anchor as well as bracket unloading and system conversion; and each construction process is pre-simulated by adopting the BIM technology. Compared with the conventional construction method, the construction method can effectively guarantee that in a reinforcement binding process, reinforcement does not have collision and can effectively guarantee precision of a corrugated pipe reserved position and the like by utilizing functions such as three-dimensional modeling, visualization and the like of the BIM technology, and has the advantages of high construction efficiency, high construction precision, a short construction period, a high safety coefficient and the like.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

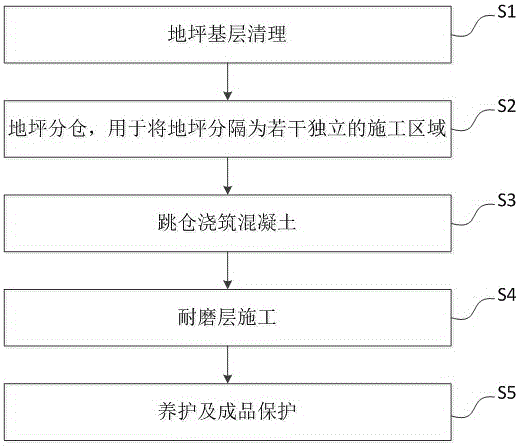

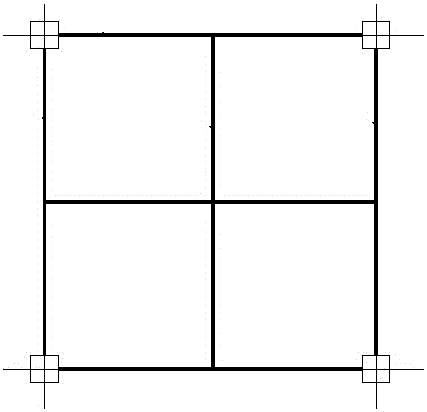

Large-are floor construction method

The invention discloses a large-area floor construction method. The method comprises the steps of floor base course cleaning, floor warehouse division, concrete sequence placement, wear resistant layer construction and maintenance and finished product protection; for the floor warehouse division process, a floor is divided into multiple independent construction areas, concrete ribs divide the floor into multiple independent construction areas, and the floor warehouse division process comprises the following sub-steps of rib making, area dividing, base course drilling, rid fixing, rib horizontal height adjusting, mortar sealing and rib concave groove packing. According to the large-area floor construction method, ribbed concrete sequence placement is adopted, a floor module can be practically and effectively divided according to engineering, the floor surface flatness can be controlled conveniently, cracking and the like, caused by temperature variation or concrete hardening and shrinkage, of the large-area cast-in-place floor can be reduced or avoided, and therefore the construction quality of the wear-resisting floor is practically improved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

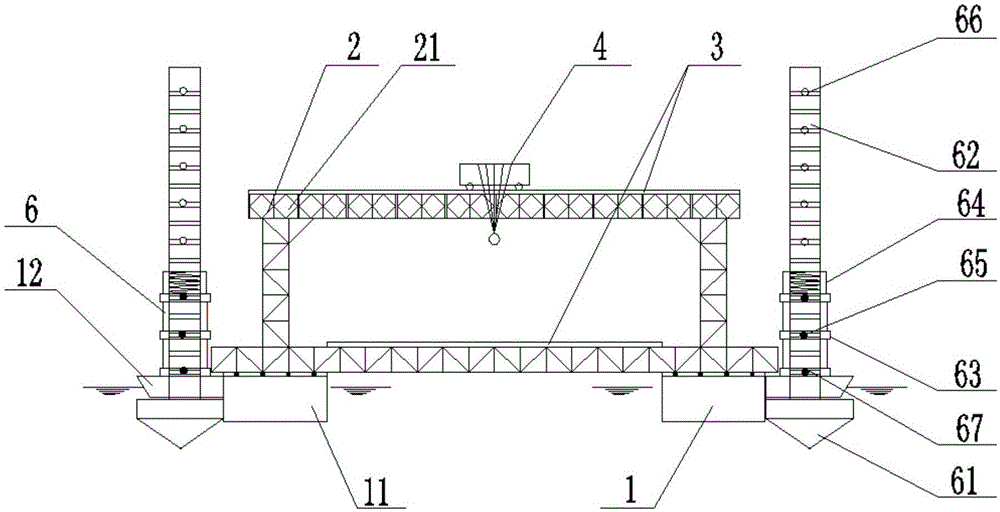

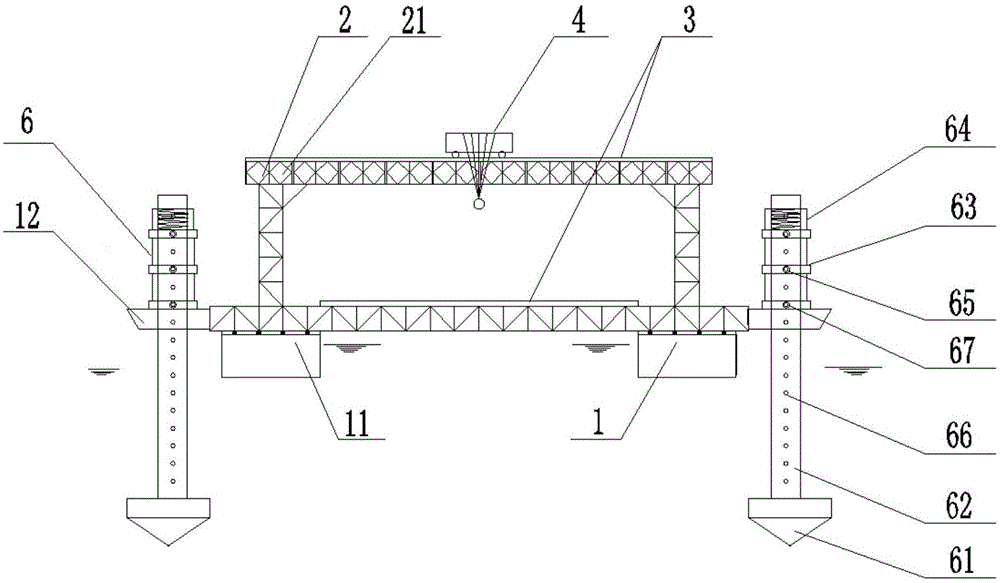

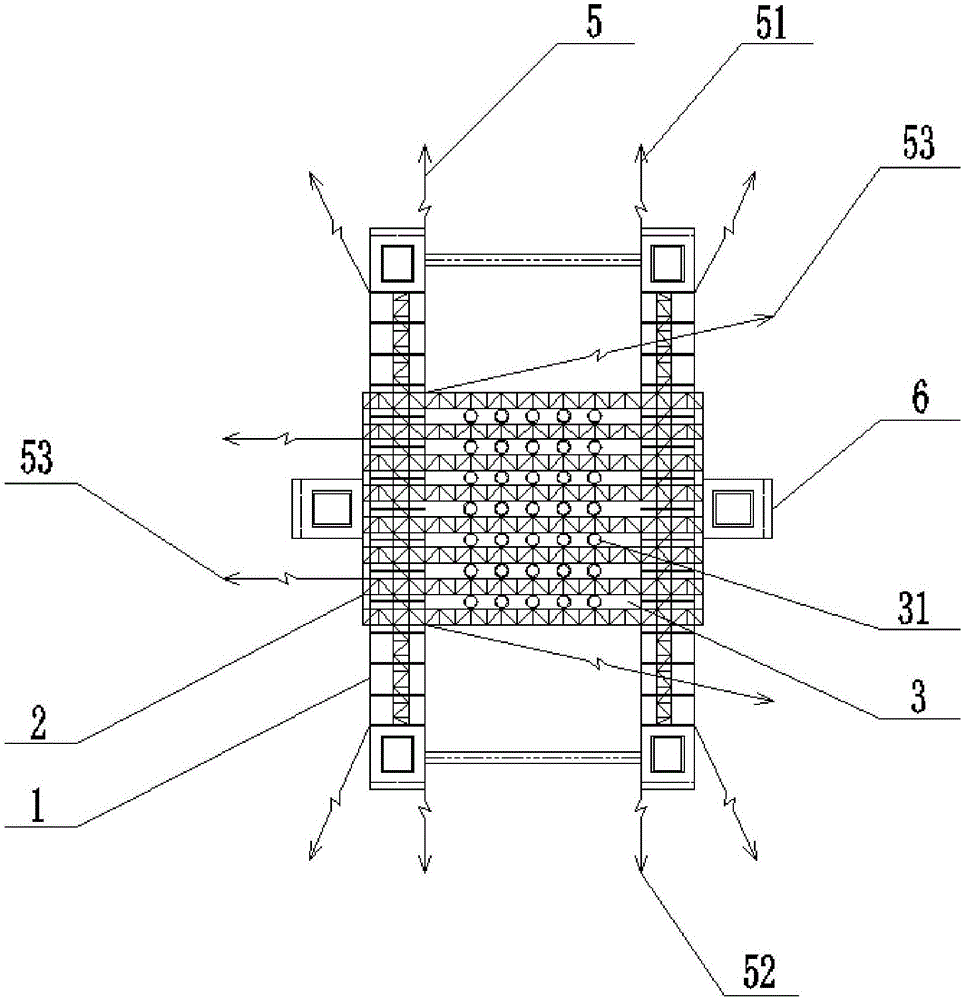

Movable construction platform for bridge foundation building

InactiveCN105088964AEasy to moveAdjustable shiftBridge erection/assemblyBulkheads/pilesBraced frameBody system

The invention provides a movable construction platform for bridge foundation building. The movable construction platform for bridge foundation building comprises floating bodies, horizontal support frameworks, horizontal backing plates, a lifting system, temporary fixing devices and support body systems; the horizontal support frameworks are laid on the upper surfaces of the floating bodies, the horizontal backing plates are laid on the upper surfaces of the horizontal support frameworks, filling pile holes formed according to bridge foundation building are formed in the horizontal backing plates, the lifting system is erected on the horizontal backing plates, and the support body systems are arranged on the peripheries of the floating bodies; each support body system comprises an anchor head, a support leg, support seats, hydraulic lifting equipment and bolt pins, wherein bolt pin holes longitudinally extending in a separated mode are formed in the support leg, through holes correspondingly communicated with the bolt pin holes are formed in the support seats, and the bolt pins are correspondingly inserted into the bolt pin holes and the through holes which are communicated with each other. The movable construction platform for bridge foundation building has the advantages that the platform can be steadily and firmly fixed on the construction water surface, cannot be shaken under the influences of tides or waves when construction is performed and is suitable for arrangement of various filling piles in bridge building; in addition, the size of the platform can be regulated, and construction is easy.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

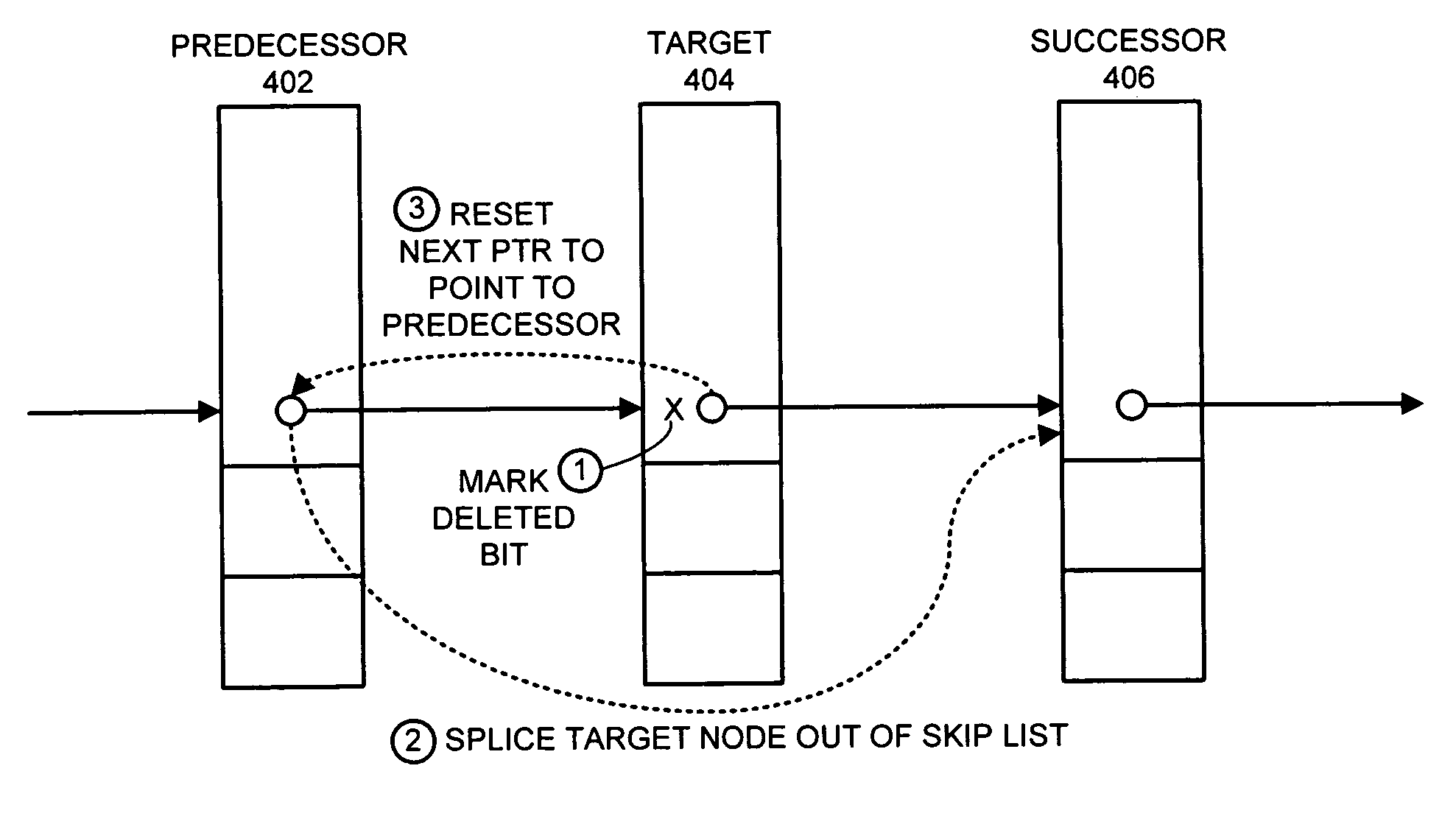

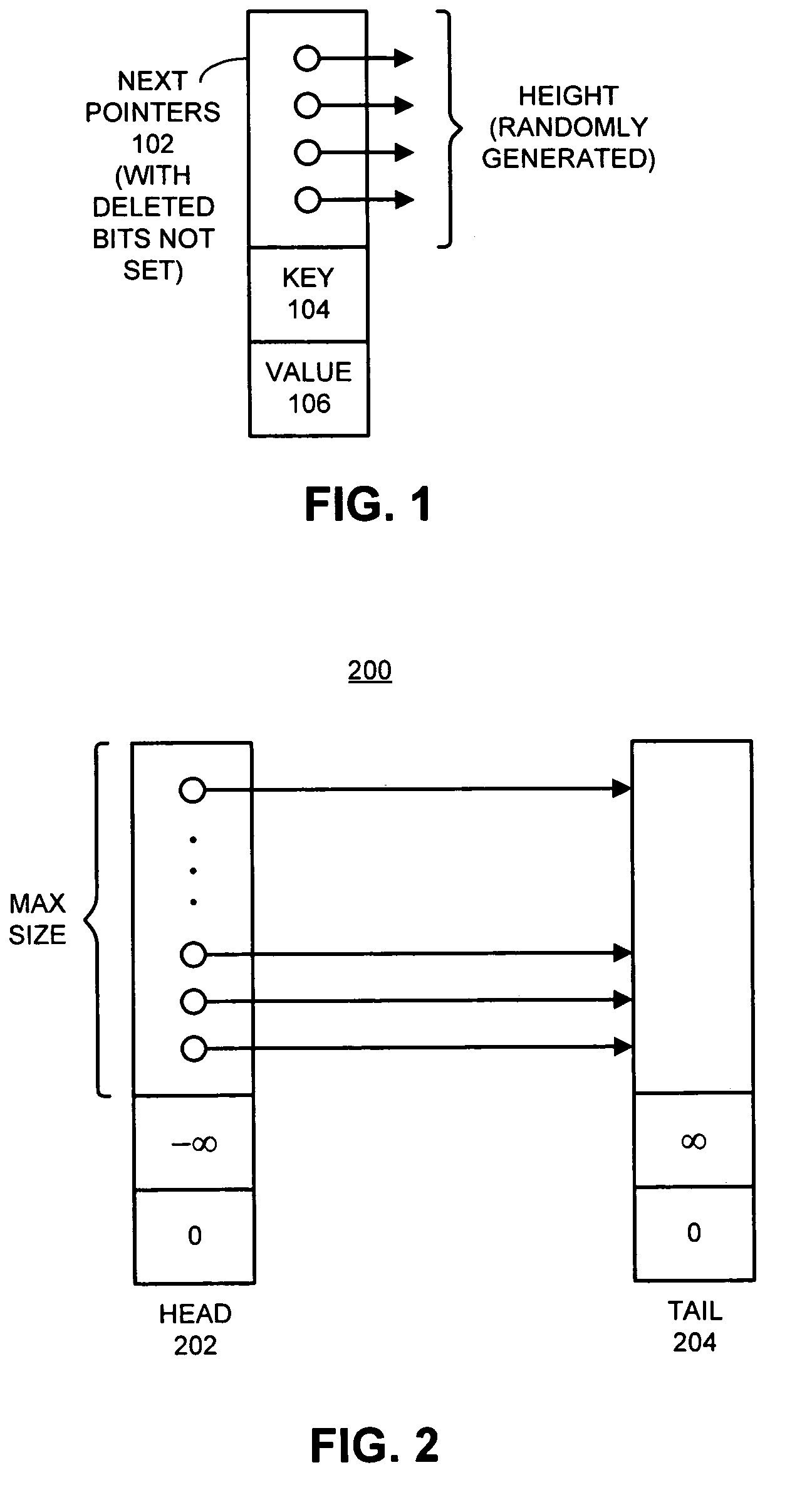

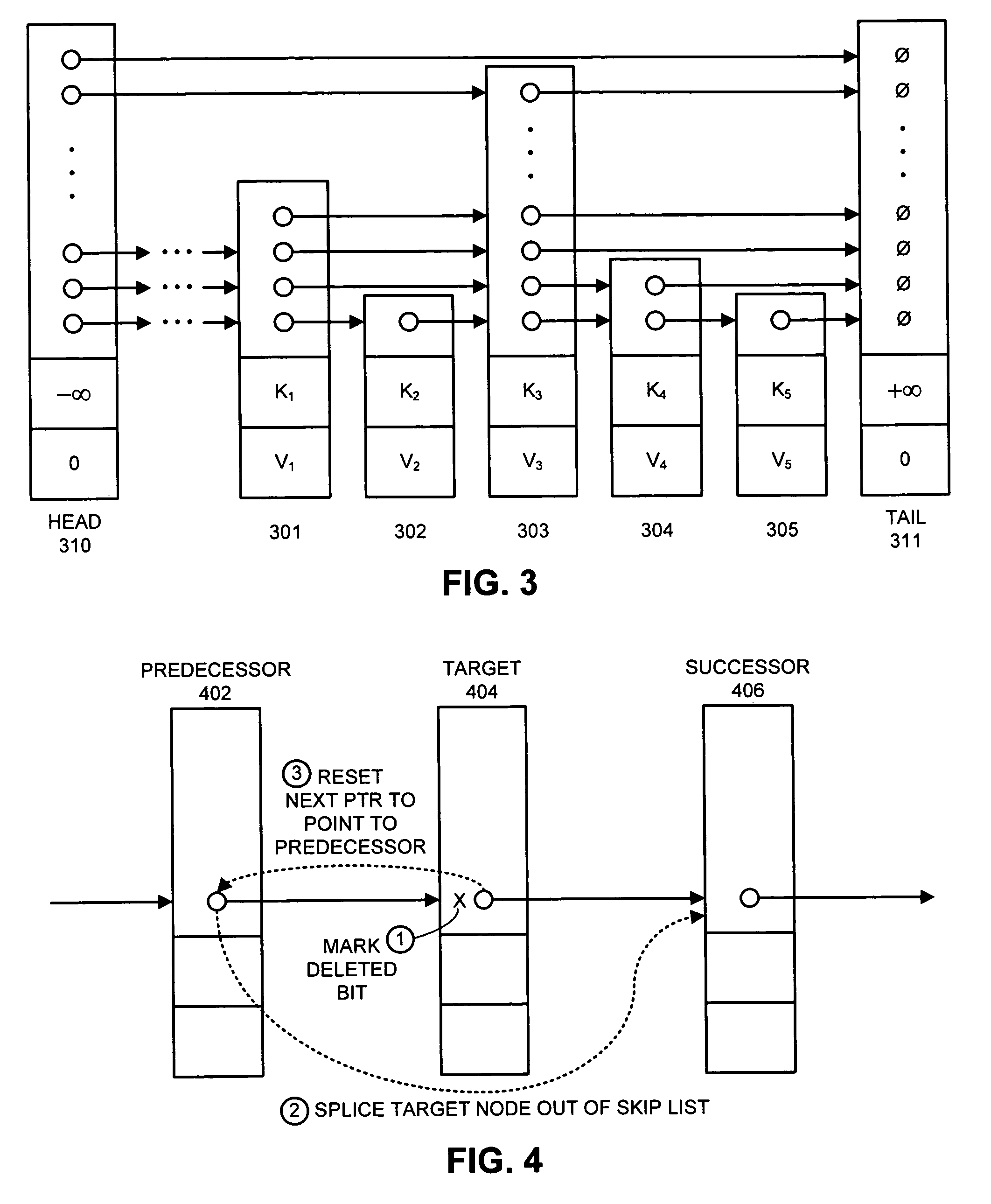

Method and apparatus for implementing a lock-free skip list that supports concurrent accesses

ActiveUS7308448B1Guaranteed progressData processing applicationsProgram synchronisationSkip listComputer science

One embodiment of the present invention provides a system that supports concurrent accesses to a skip list that is lock-free, which means that the skip list can be simultaneously accessed by multiple processes without requiring the processes to perform locking operations. During a node deletion operation, the system receives reference to a target node to be deleted from the skip list. The system marks a next pointer in the target node to indicate that the target node is deleted, wherein next pointer contains the address of an immediately following node in the skip list. This marking operation does not destroy the address of the immediately following node, and furthermore, the marking operation is performed atomically and thereby without interference from other processes. The system then atomically modifies the next pointer of an immediately preceding node in the skip list to point to an immediately following node in the skip list, instead of pointing to the target node, thereby splicing the target node out of the skip list.

Owner:ORACLE INT CORP

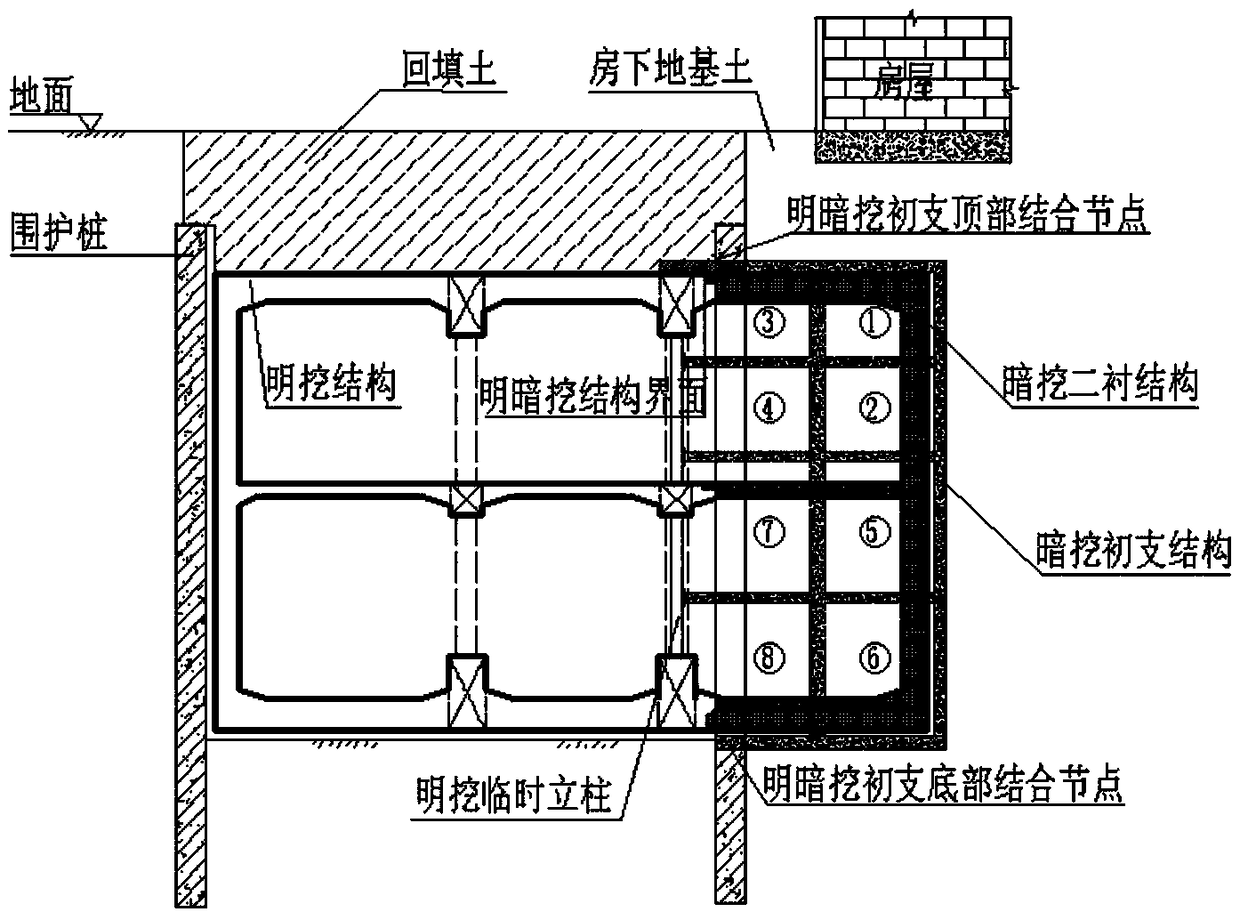

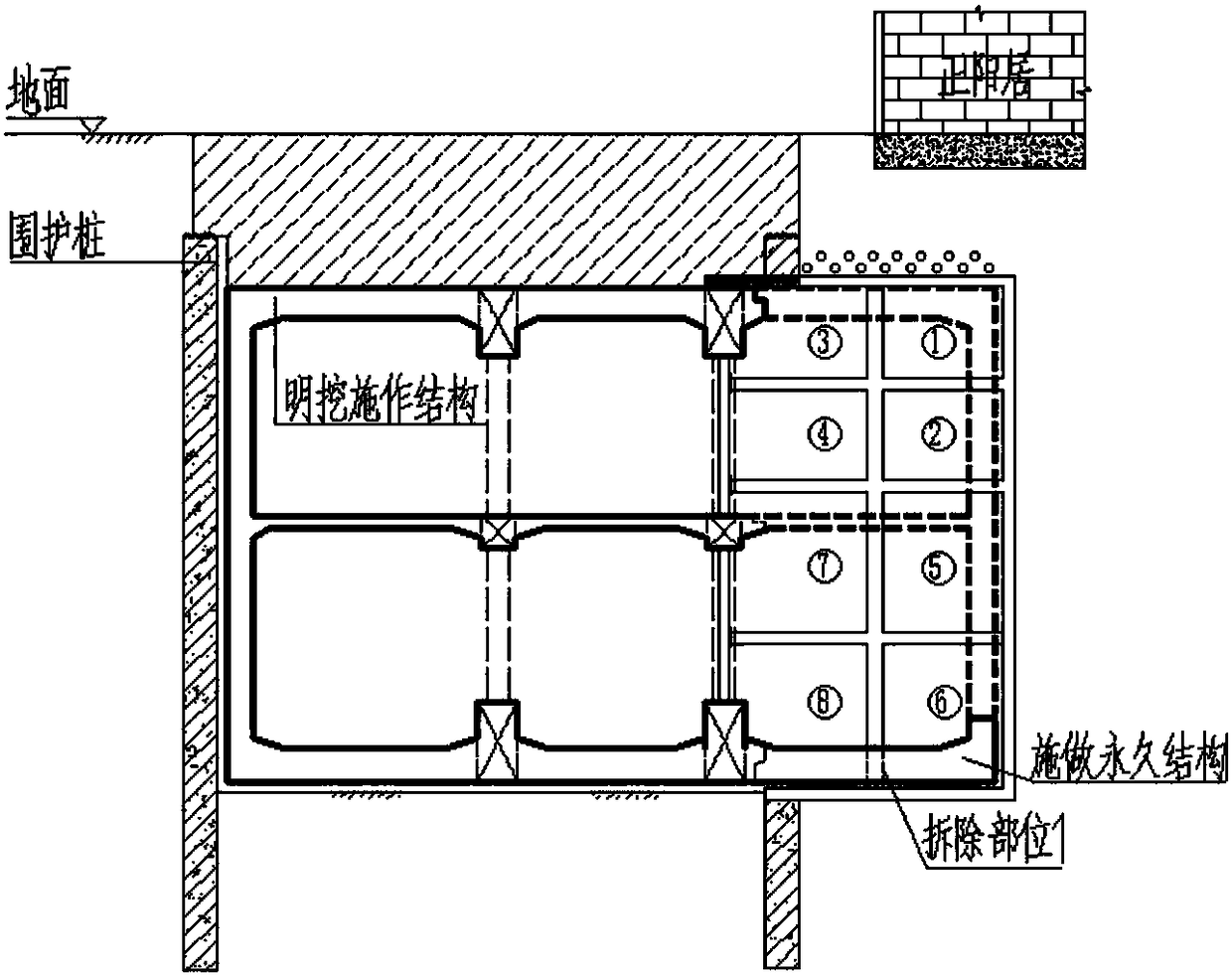

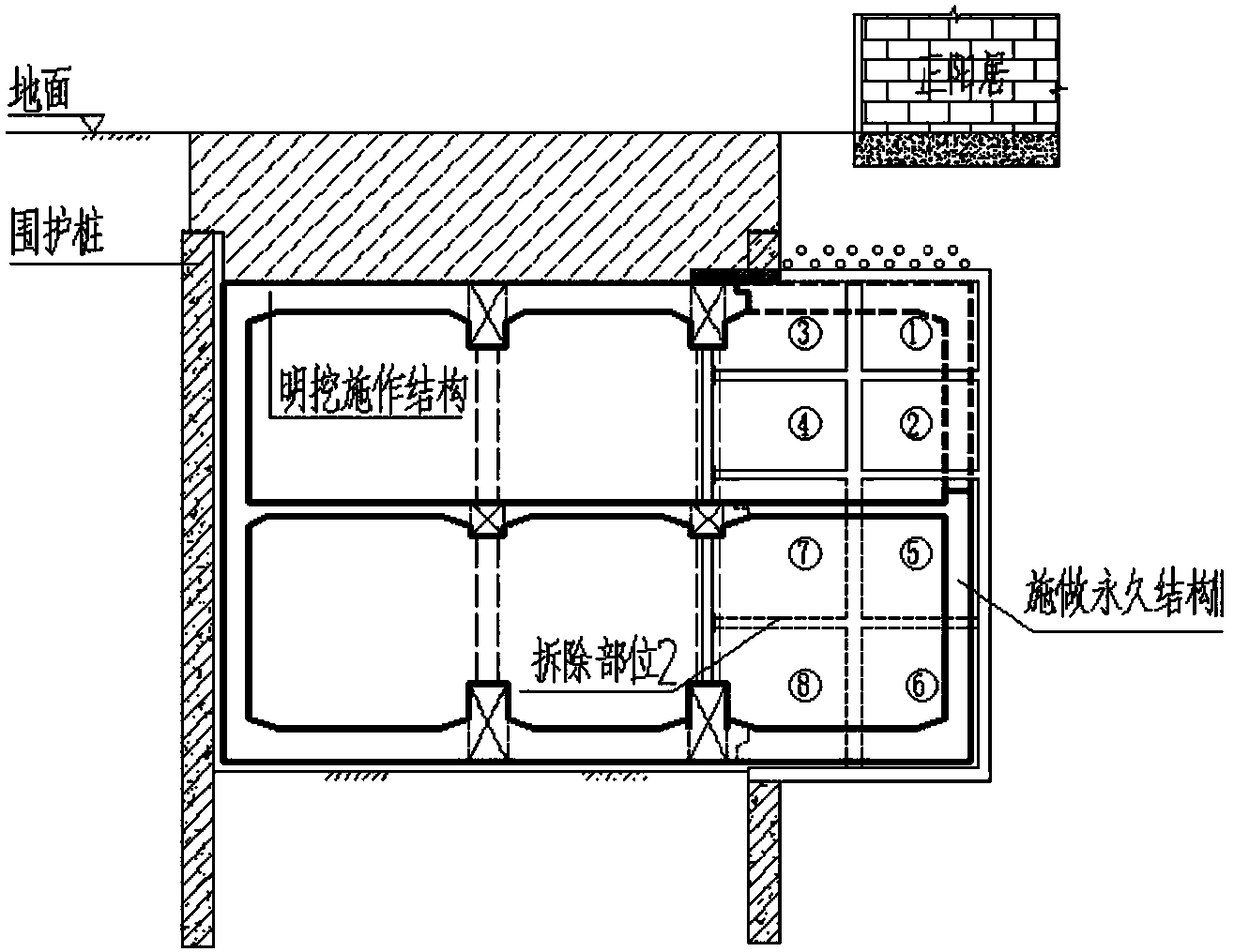

Method for constructing underground structure by combining light-shade excavation with ground matter removal avoidance

InactiveCN108286266AReduce demolitionGuarantee the progress of the projectArtificial islandsUnderwater structuresEnvironmental geologyStructure system

The invention discloses a method for constructing an underground structure by combining light-shade excavation with ground matter removal avoidance. The method comprises the following steps: light-shade excavation construction ranges and boundary points of the underground structure are determined; light excavation is performed; primary support construction and branch excavation are performed on nodes reserved in light excavation; primary supports are removed; and a waterproof system and a secondary lining are constructed. Compared with a full-light excavation method, the method reduces removal, and guarantees the engineering progress; meanwhile, the house removal expense is hundred million Yuan, so that the engineering investment is saved; the underground structure system is kept invariable without influencing ground functions; the removal quantity is reduced; the construction garbage and the resource waste are reduced; and the construction cost is reduced.

Owner:CHINA RAILWAY FIRST GRP SECOND ENG CO LTD

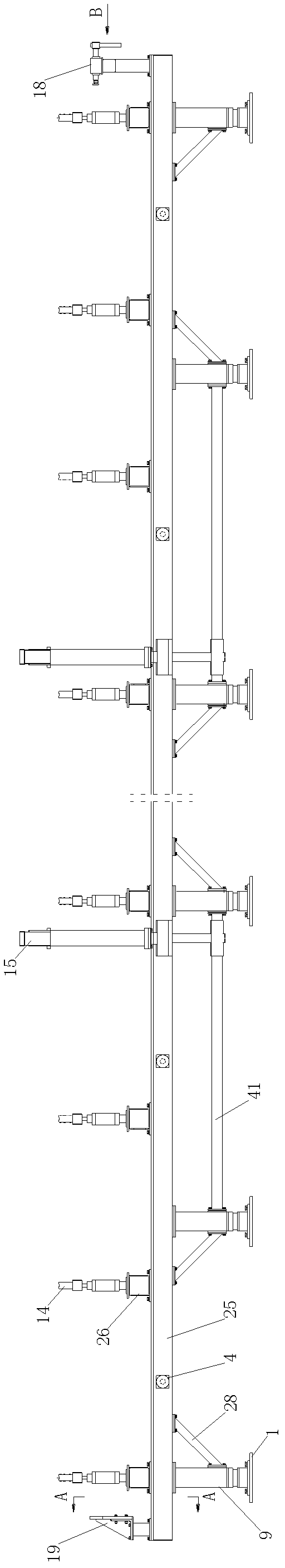

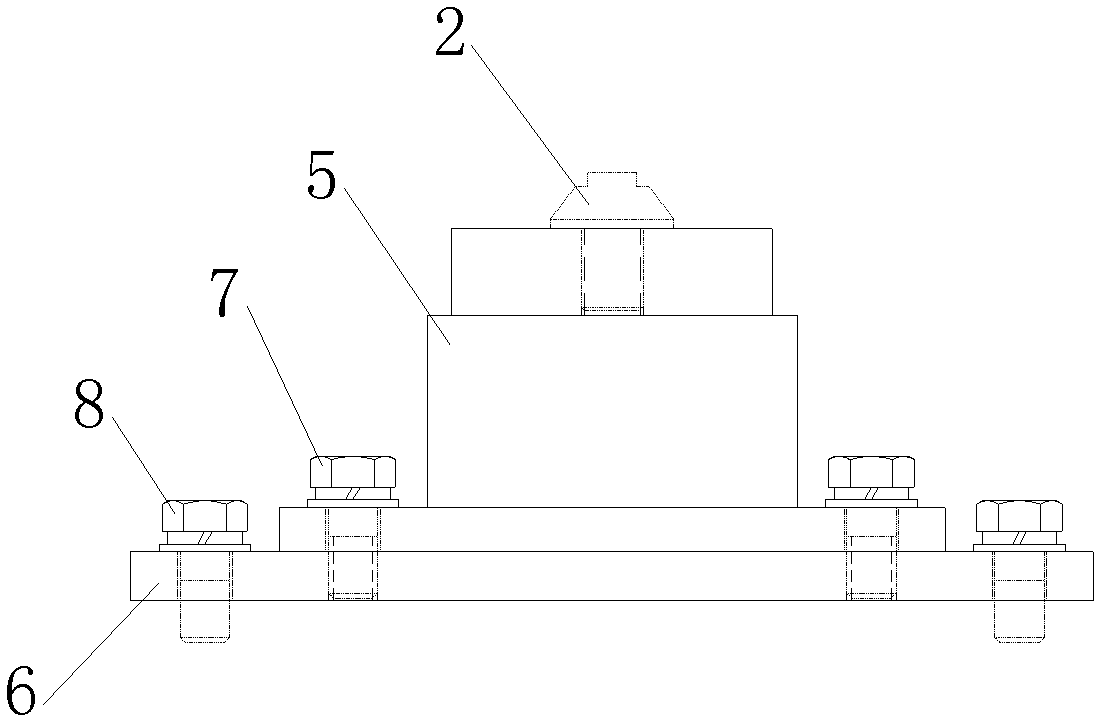

Automatic welding fixture of subway train obverse-reverse side roofs

ActiveCN102626841AGuarantee welding qualityOvercoming Insufficient Process Layout FlexibilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention discloses an automatic welding fixture of subway train obverse-reverse side roofs, comprising a base, an obverse side roof welding fixture body, and a reverse side roof welding fixture body, wherein the base is fixed on the ground and equipped with a connecting tenon on the top portion, the bottoms of the obverse side roof welding fixture body and the reverse side roof welding fixture body are both equipped with a connecting tenon groove which is matched with the connecting tenon, and the obverse side roof welding fixture body and the reverse side roof welding fixture body are both provided with a hoisting structure. A quick switch can be performed between the obverse side roof welding fixture body and the reverse side roof welding fixture body through a crown block, so that an automatic welding operation of the obverse side roof and the reverse side roof can be separately realized on the same automatic welding station and welding quality of roof components can also be ensured, overcoming the problem of insufficient flexibility in layout of the current subway train roof welding process and guaranteeing the project progress of roof welding.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Concrete release paint

InactiveCN110079214AImprove stabilityAvoid condensationAnti-corrosive paintsUltimate tensile strengthDefoaming Agents

The invention discloses concrete release paint. The concrete release paint is prepared from raw materials in parts by weight as follows: 20-40 parts of vegetable oil, 25-35 parts of dilute water, 25-35 parts of an emulsifier, 5-15 parts of a stabilizer, 2-5 parts of a thickening agent, 2-5 parts of a defoaming agent and 2-5 parts of an antirust agent. According to the concrete release paint, the vegetable oil is adopted as the environment-friendly release paint, so that the concrete release paint has the advantages of being reproducible, biodegradable and harmless to a human body; with addition of a coalescing agent and the stabilizer, the coalescing agent can guarantee excellent film-forming property and higher film-forming strength of the concrete release paint, the film-forming time isshort, a formwork is easy to clean after form stripping, construction progress and efficiency can be guaranteed, and the concrete release paint has higher stability and longer storage time by means ofthe stabilizer.

Owner:湖南加美乐素新材料股份有限公司

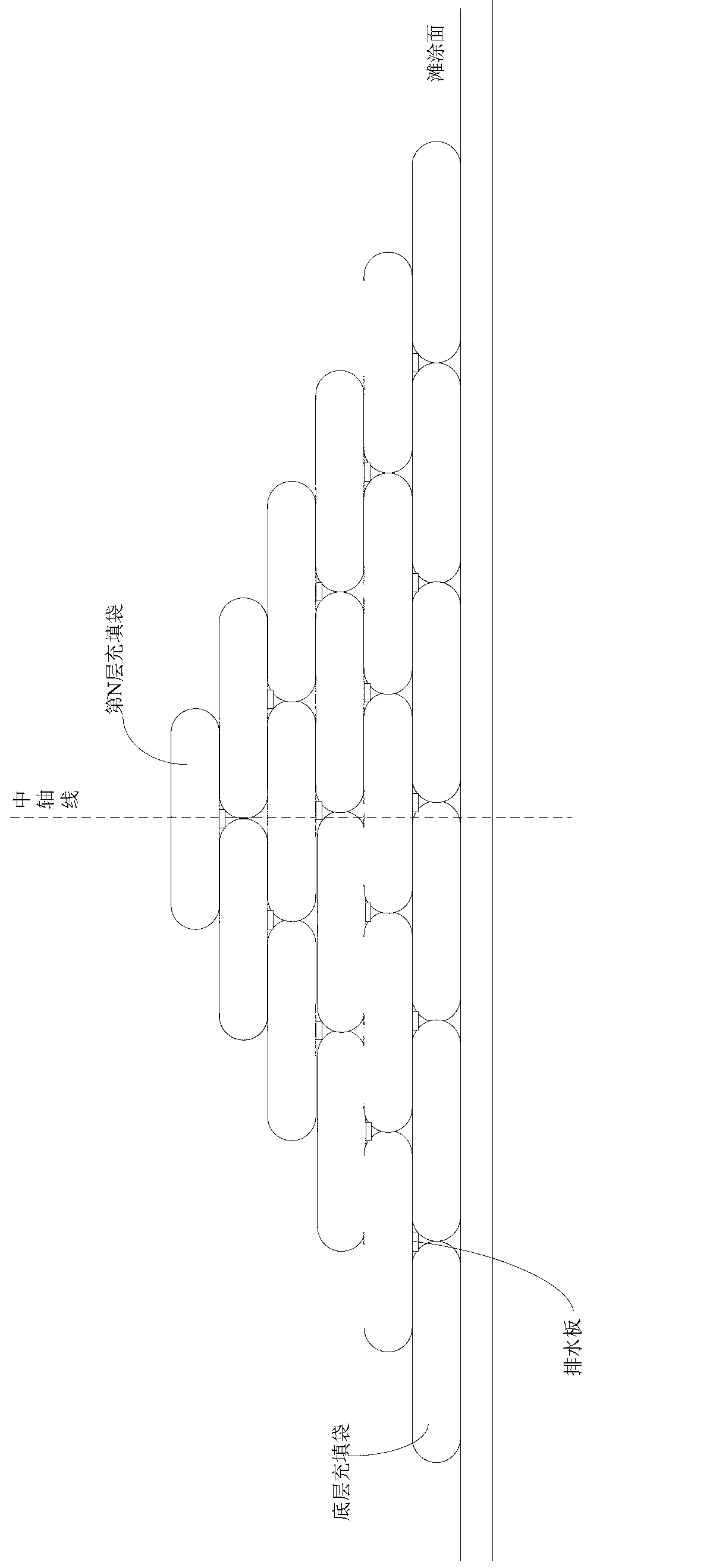

Construction method for embankment by using mucky soil filling bags

ActiveCN102839630ASave resourcesImprove construction efficiencyMarine site engineeringSludgeUltimate tensile strength

The invention relates to a construction method for embankment by using mucky soil filling bags. The construction method is characterized by comprising the following steps of: changing filling building materials to filling sludge or mucky soil from traditional bag body filling sand, paving water drainage plates at the seams of the filling bags, and mutually lapping the seams of the filling bags, so that bag bodies on the upper layer and the lower layer are closer in engagement, thus ensuring the interlayer anti-slide stability of a filled embankment; the embankment is high in overall strength and reliable in structure; and the layers of the filling bags are arrayed by staggering, the bottoms of the bottom bags of the filling bags on the upper layer are partially embedded in the seam channels of the filling bags on the lower layer to form a mutual clamping effect, thus guaranteeing the structural stability during a construction period and a use period, as well as being capable of saving lots of sandstone resources, being economic and environment-friendly, and being high in construction efficiency.

Owner:SDC WATERWAY CONSTR

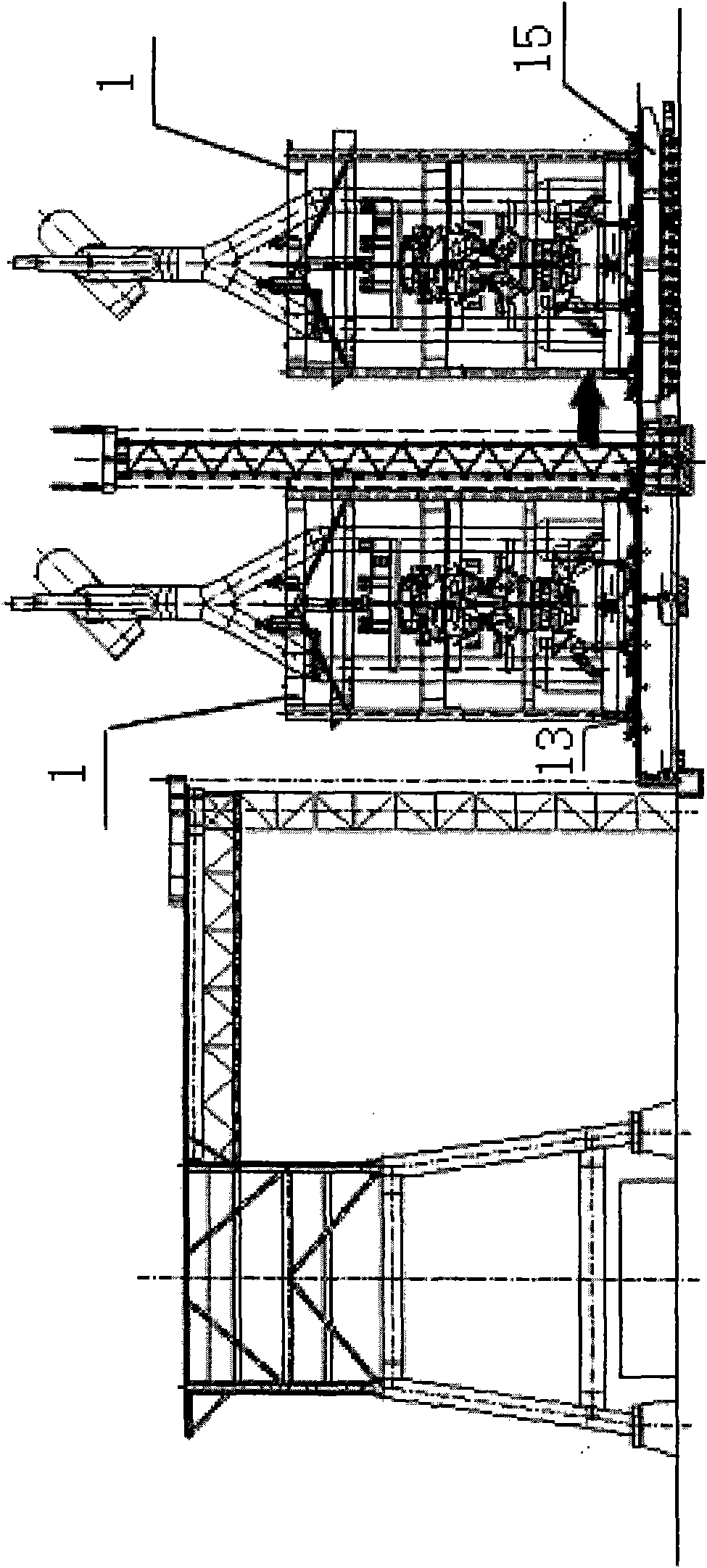

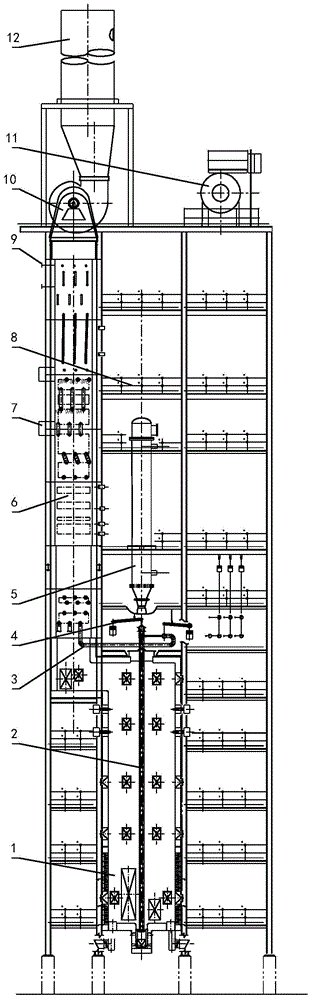

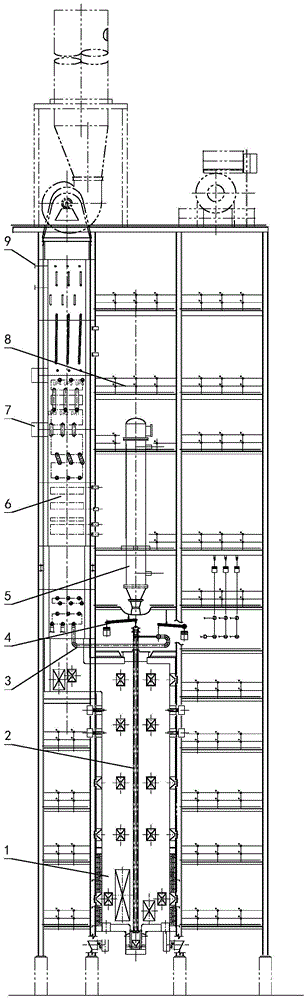

Integral modular structure of industrial furnace and construction method

ActiveCN104976894AShorten the construction periodGuaranteed Build QualityMonolithic liningsModular designModular structure

The invention discloses an integral modular structure of an industrial furnace and a construction method. The integral modular structure comprises a main body part and accessory equipment and accessories. The main body part of the integral modular structure of the industrial furnace comprises a radiation section modular structure, a convection segment, a radiation furnace pipe, a crossing pipe for connecting a convection furnace pipe with the radiation furnace pipe and a supporting hanging system for the radiation furnace pipe and the crossing pipe. The accessory equipment and accessories comprise a chimney, a waste heat boiler, a steam pocket, a draught fan, an ash ejector, parts of platform and ladder, an instrument and a cable of the instrument. The method comprises the steps that the main body part of an integral module of the industrial furnace and the accessory equipment and accessories of the integral module of the industrial furnace are manufactured and assembled in a workshop, integrally transported and integrally mounted to be in place. Integral modular design, workshop modular manufacturing, integral assembly, integral transportation and field integral mounting to be in place are adopted in the industrial furnace; the construction difficulty is reduced, the manufacturing precision and the construction schedule are ensured, the labor cost of site operation is low, the construction period is short, and construction is safe.

Owner:SINOPEC ENG +1

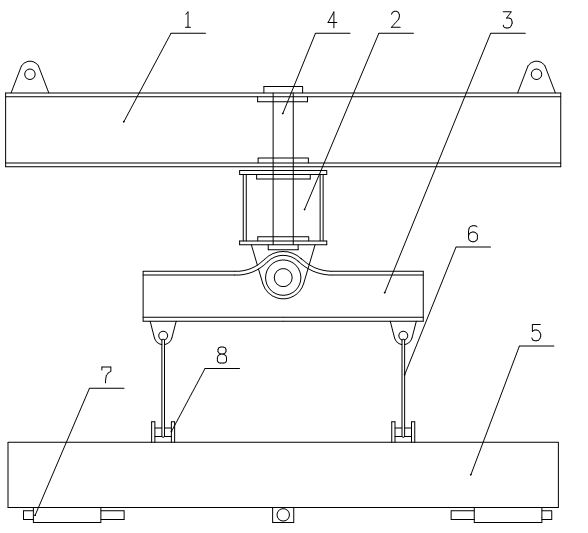

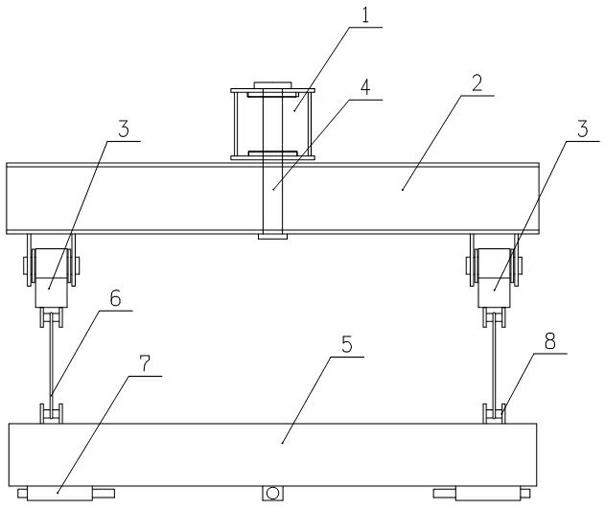

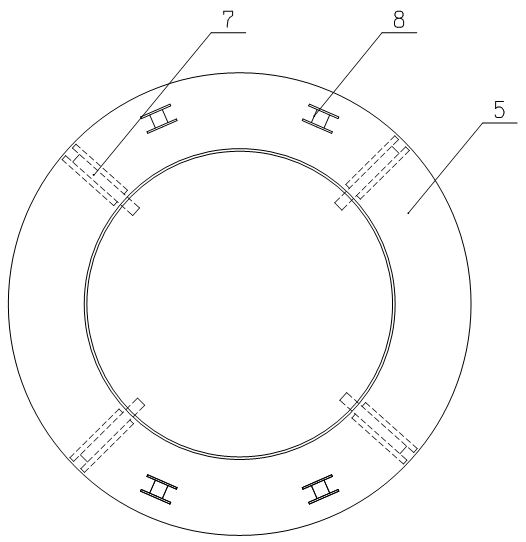

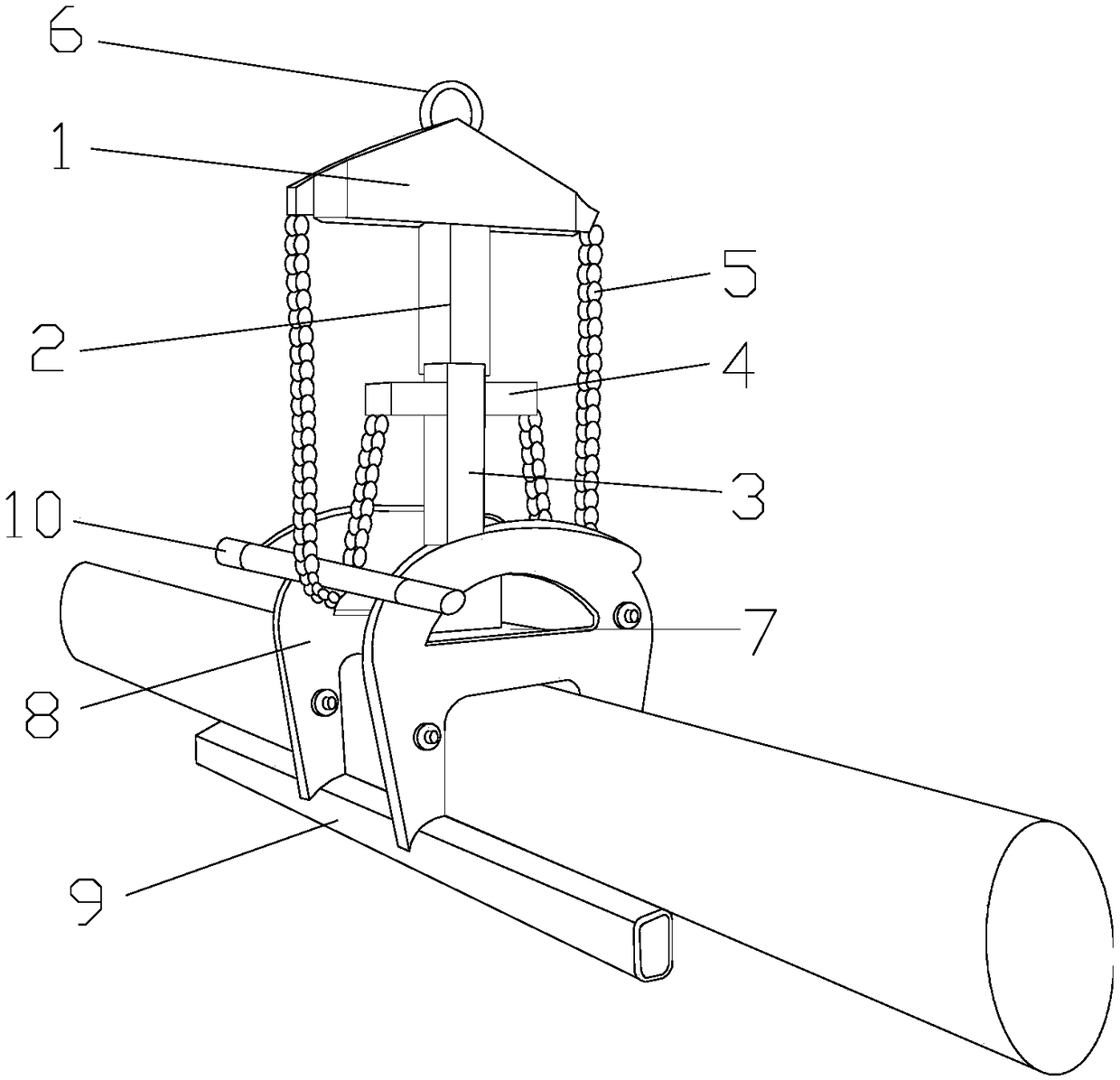

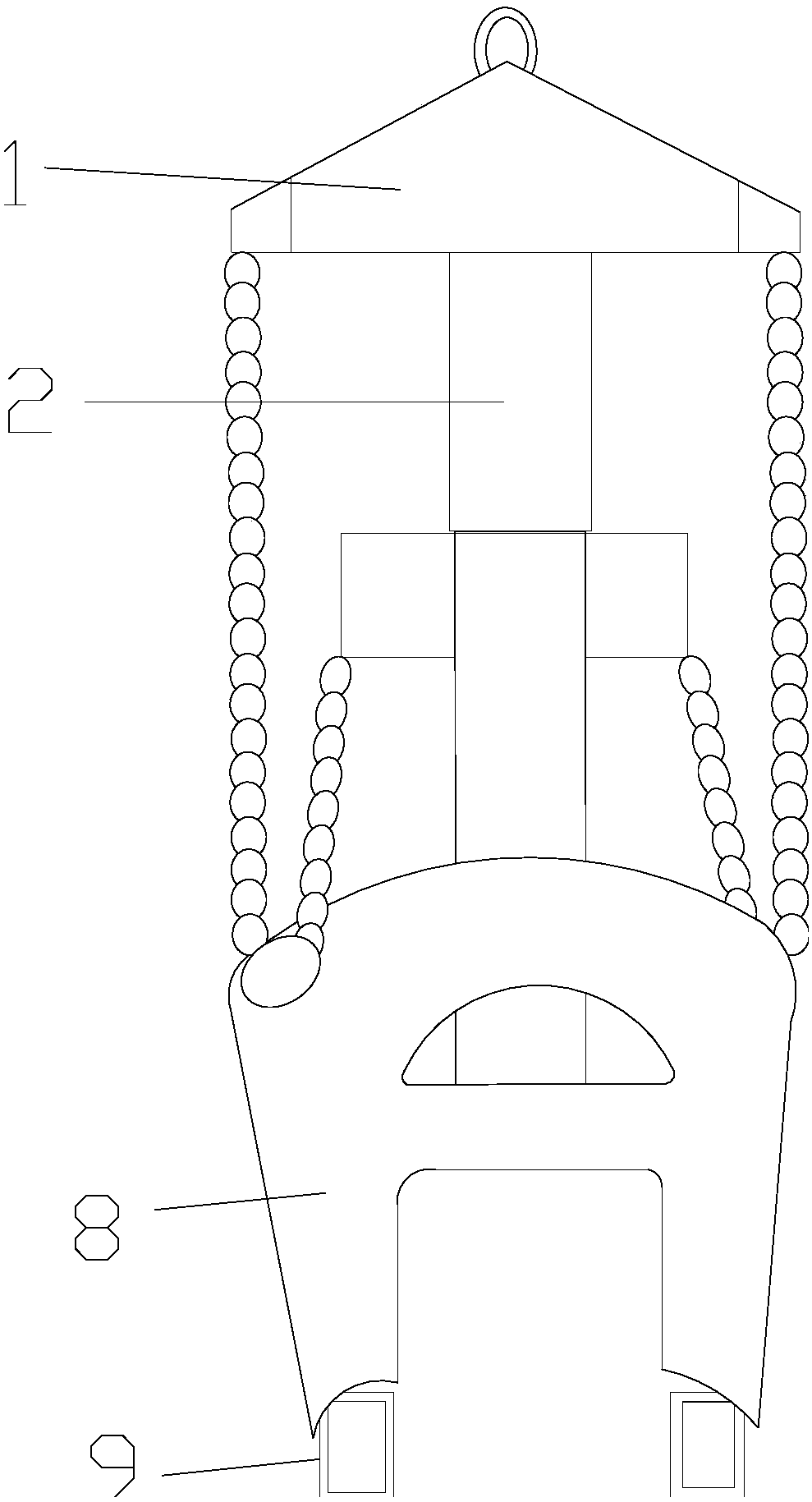

Reinforcement cage lifting device

The invention discloses a reinforcement cage lifting device, which comprises an upper beam, a middle beam, lower beams and an annular beam for connecting a reinforcement cage, wherein the two ends of the upper beam are fixed with a lifting lug for connecting a crane respectively; the middle beam is hinged to the center of the upper beam through a connecting shaft vertically inserted into the middle beam; the lower beams are hinged to the two ends of the middle beam through pin shafts horizontally inserted into the centers of the lower beams respectively; and the annular beam is horizontally suspended on the lower beams by corresponding suspenders. When in use, the reinforcement cage lifting device connects the reinforcement cage to the annular beam in a suspension way, and when the reinforcement cage is jointed, can conveniently drive the reinforcement cage to horizontally rotate, flexibly regulate the vertical angel of the reinforcement cage and ensure the verticality of the reinforcement cage in a jointing process to easily and rapidly finish the jointing of the reinforcement cage, increase the jointing speed of the reinforcement cage and improve the jointing quality of the reinforcement cage by hinging fit among the upper, middle and lower beams, thereby ensuring the progress and quality of pile foundation construction.

Owner:HENAN MINE CRANE

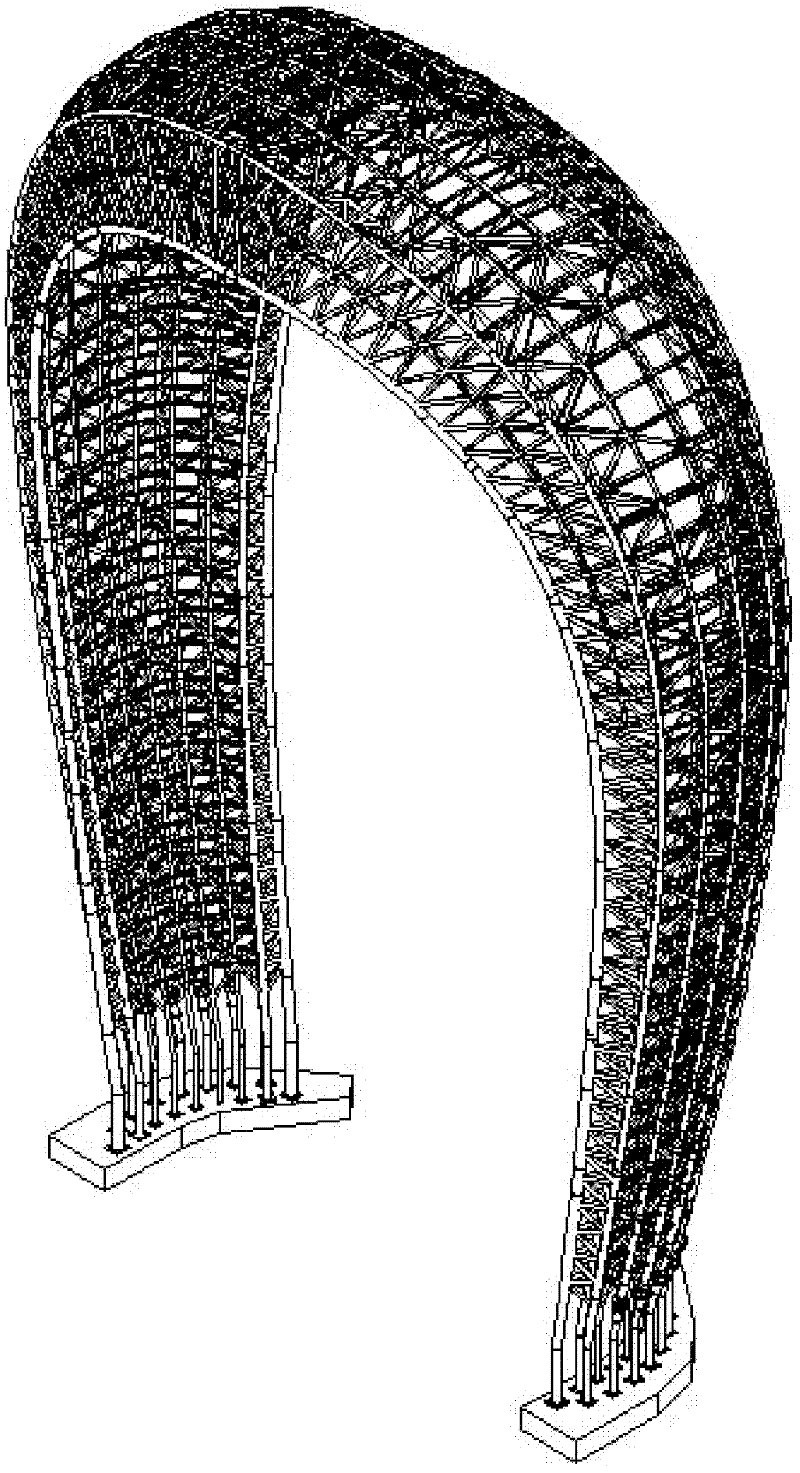

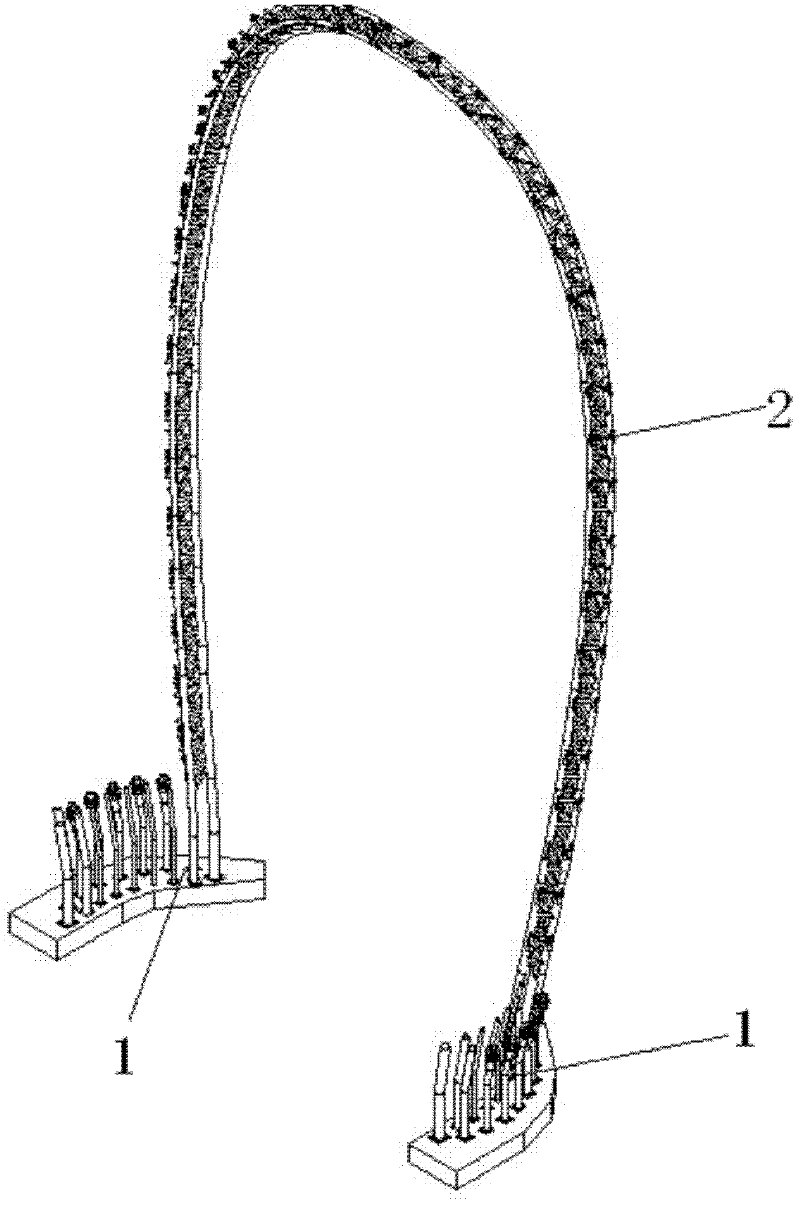

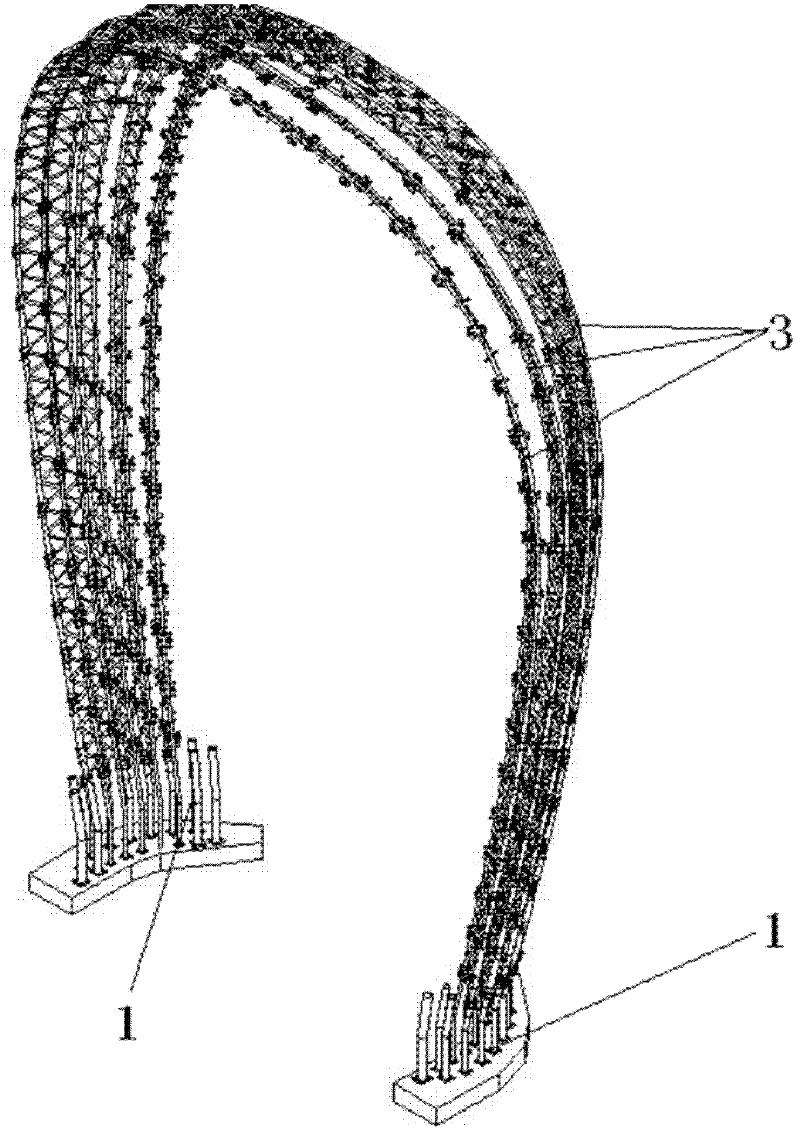

Buddha ceremonial canopy and manufacturing method thereof

ActiveCN102518204AReasonable structureImprove securityArched structuresVaulted structuresTowerQuality management system

The invention discloses a Buddha ceremonial canopy and a manufacturing method thereof. The Buddha ceremonial canopy comprises two column legs and a steel structural triple-bent arch frame. The steel structural triple-bent arch frame successively comprises a front main arch frame, a middle arch frame and a rear main arch frame from front to back, both the front main arch frame and the rear main arch frame are double-bent arch frames, the middle arch frame comprises five vertical double-bent secondary arch frames, three-dimensional diagonal web members are connected between each two adjacent arch frames, and two ends of each arch frame are respectively connected with the two column legs. The manufacturing method of the Buddha ceremonial canopy includes scientifically distributing resources, performing segment processing on members manufacturedby factories, reasonably arranging feeding of components, successively assembling the components in different areas in a field, adopting a mounting scheme of matching of crane tower blocks and high-altitude embedding scattering hanging, and adopting advanced construction technology, technological measures and an improved safety quality management system. The method can effectively resolve problems relevant to construction progress, quality, safety and the like, accurate positioning can be realized, risks during field assembly are reduced, and construction period can be shortened.

Owner:JIANGSU HUNING STEEL MECHANISM

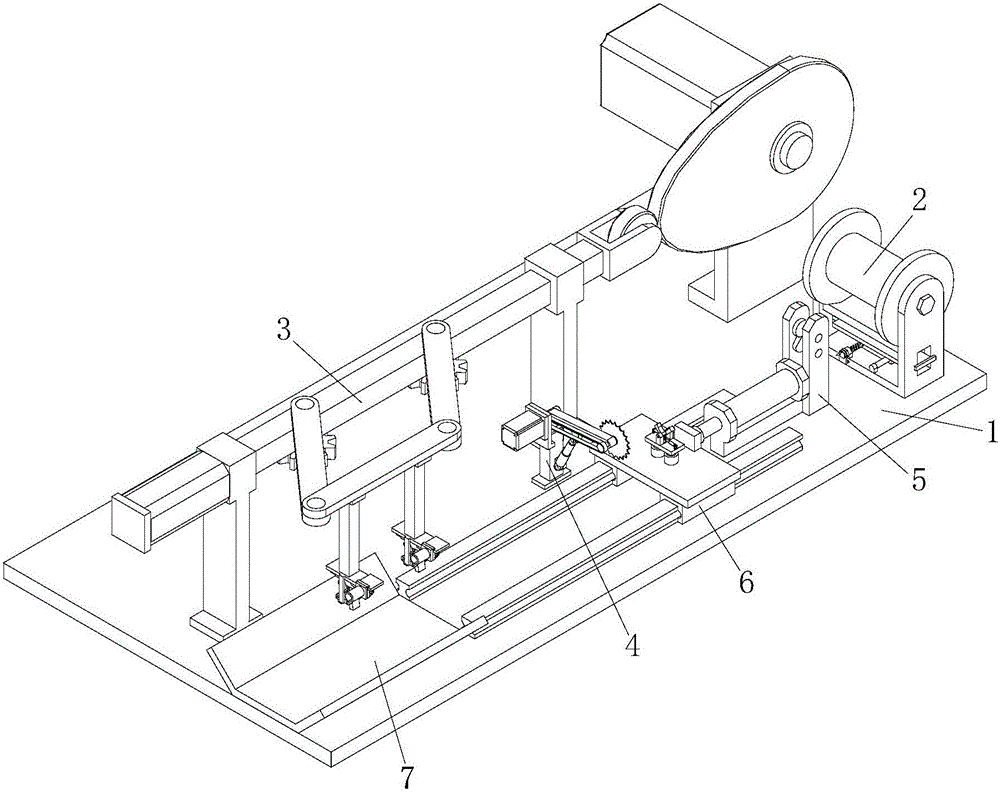

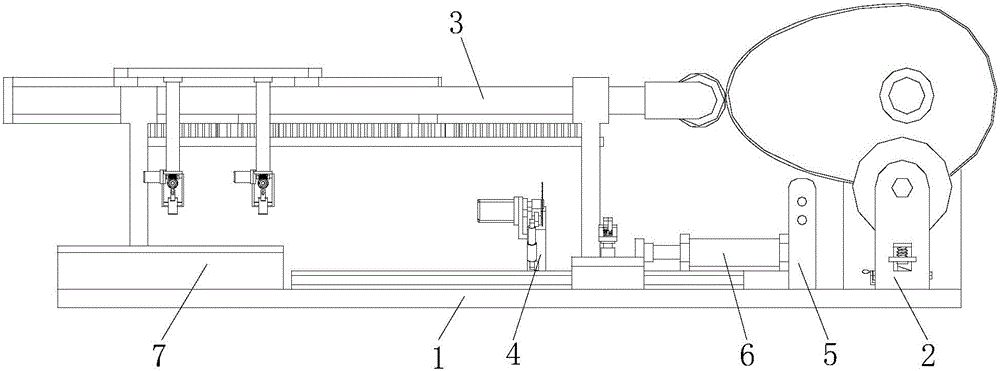

Copper wire cut-off device

InactiveCN105081148ARealize automatic interceptionIncrease productivityCopper wireMaterial resources

The invention discloses a copper wire cut-off device which comprises a bottom plate. A pay-off device is installed at the rear portion of the upper end of the bottom plate. A limiting device is installed in front of the pay-off device. A traction and clamping device is installed in front of the limiting device. A cut-off device body is fixed to the left side of the traction and clamping device. A clamping and displacement device is installed on the left side of the cut-off device body. An unloading tank is arranged in front of the traction and clamping device. The copper wire cut-off device has the advantages of being reasonable in structural design, low in production and manufacturing cost, convenient to use and the like; copper wires can be automatically cut, the cutting procedure is ensured, manual work is replaced, the automation degree is high, the copper wire cutting production efficiency is improved, and manpower and material resources are saved.

Owner:ANHUI YUSHENG HAOHAN ELECTRONICS TECH

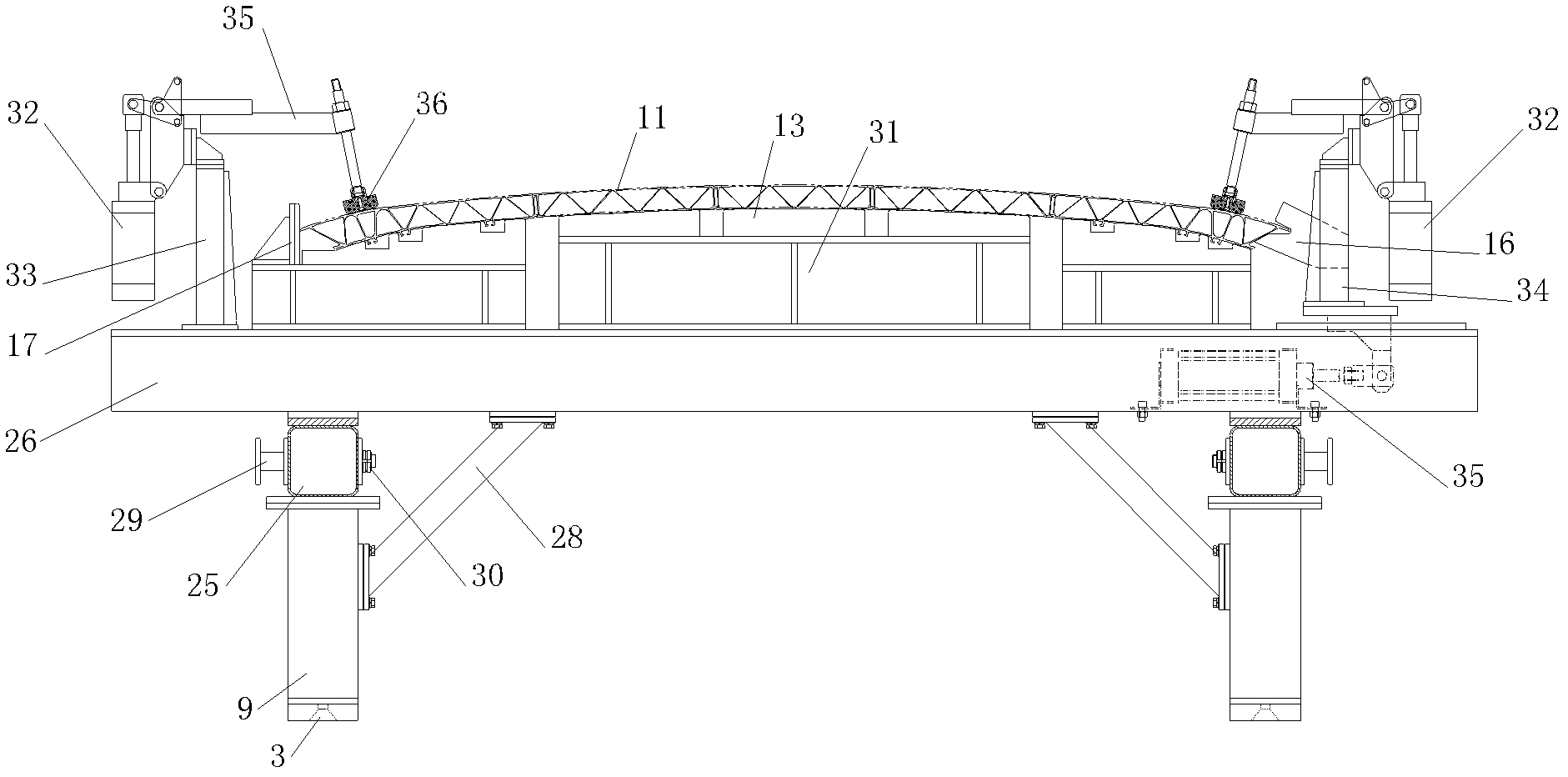

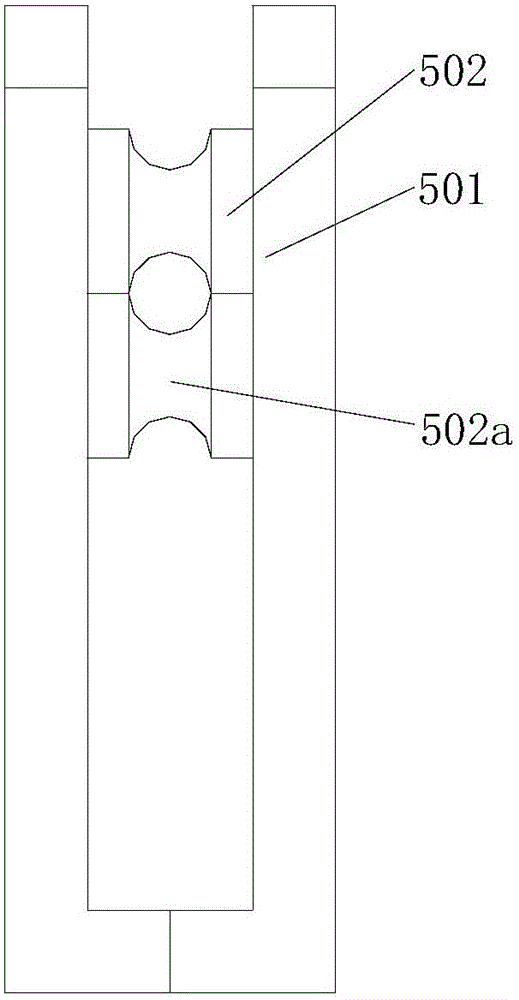

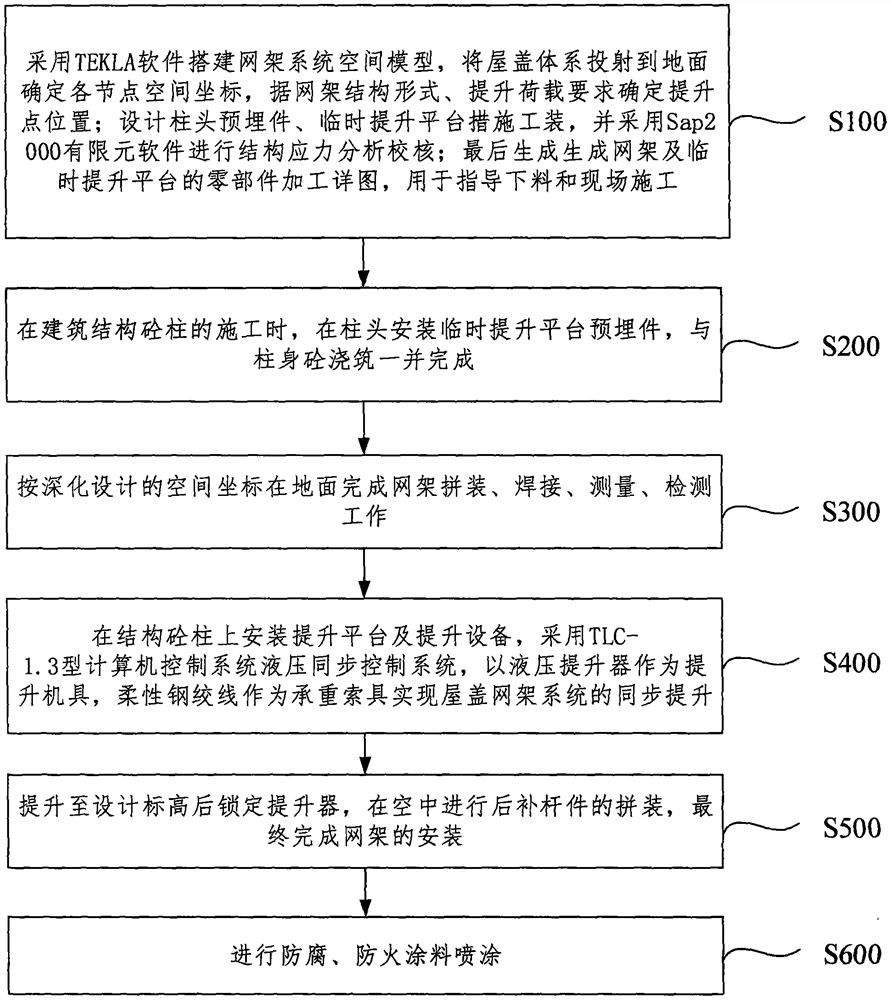

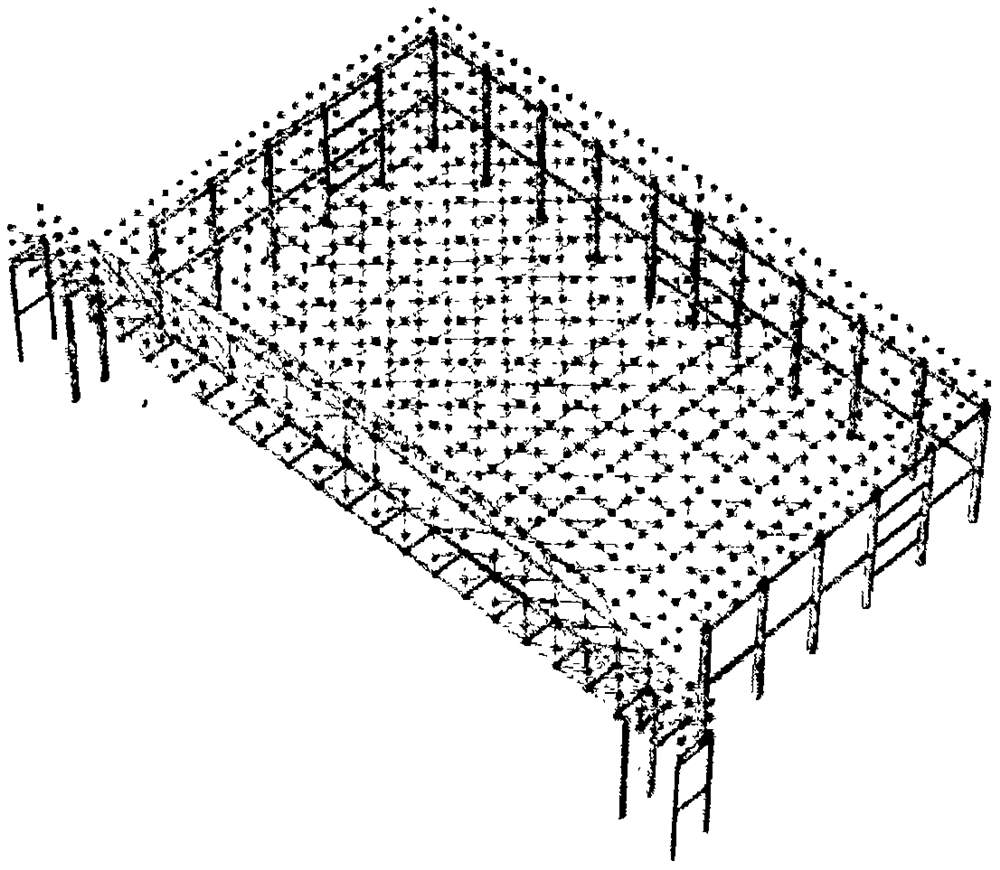

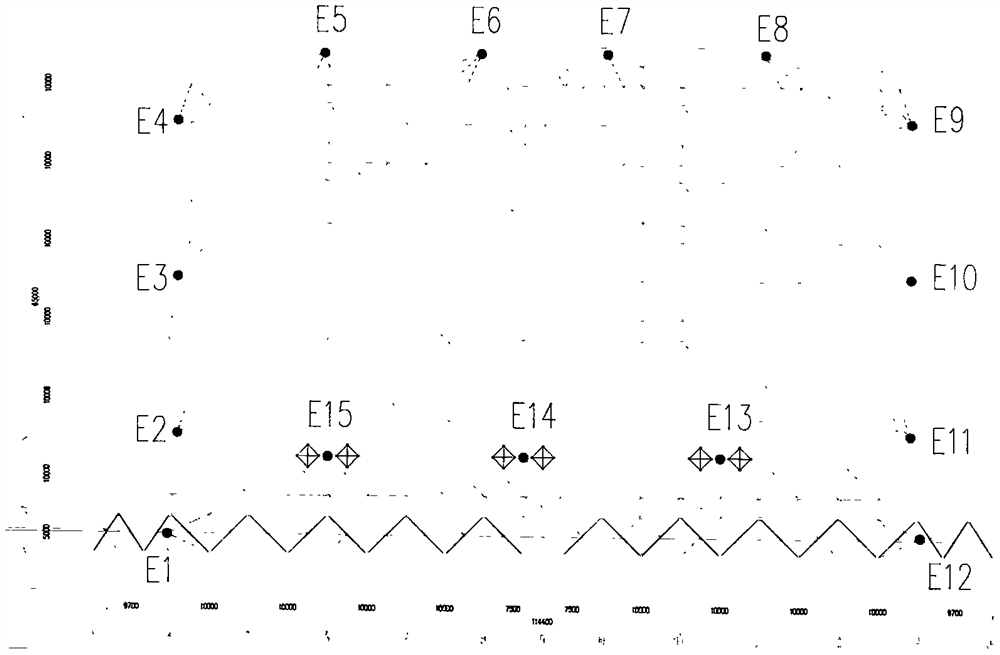

Large-span welded ball net rack ground assembly integral lifting construction method

PendingCN112554345AImprove installation qualityReduce investmentBuilding constructionsEngineeringSpandrel

Owner:CHINA MCC 2 GRP CO LTD

Rock mass tunnel face analysis feedback integrated system based on three-dimensional laser scanning

InactiveCN110260785AGuarantee construction qualityEasy accessUsing optical meansImage generationRock tunnelIntegrated systems

The invention relates to a rock mass tunnel face analysis feedback integrated system based on three-dimensional laser scanning. The system comprises a face three-dimensional laser scanning device which uses a three-dimensional laser scanning technology to record three-dimensional point cloud data and transmits the data out, a background non-continuous numerical value analysis device which carries out three-dimensional reconstruction of the point cloud data and automatic information extraction, establishes and analyzes a three-dimensional non-continuous numerical value model, and feeds back the analysis result to a mobile terminal located at the construction site through a data remote transmission module, and a rock tunnel data remote transmission device which is connected with the face three-dimensional laser scanning device, the mobile terminal and the background non-continuous numerical value analysis device and is used for forwarding data. Compared with the prior art, the system provided by the invention realizes refined and rapid acquisition, analysis and feedback of the information on the face of a rock mass tunnel, and can effectively guarantee the construction quality, safety and progress.

Owner:TONGJI UNIV

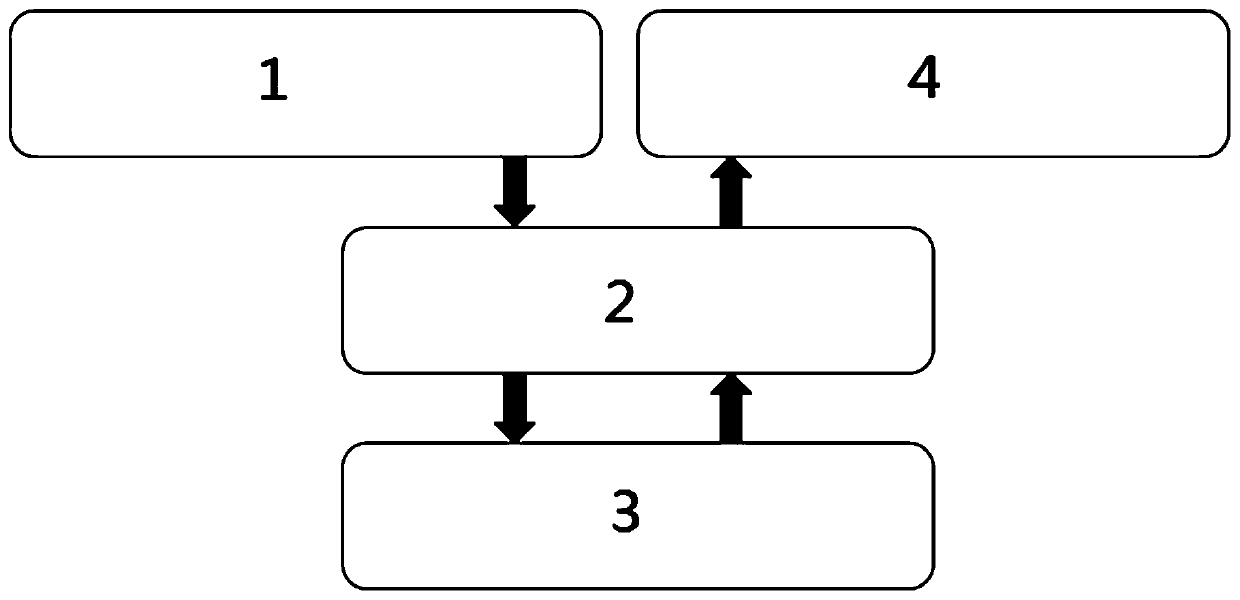

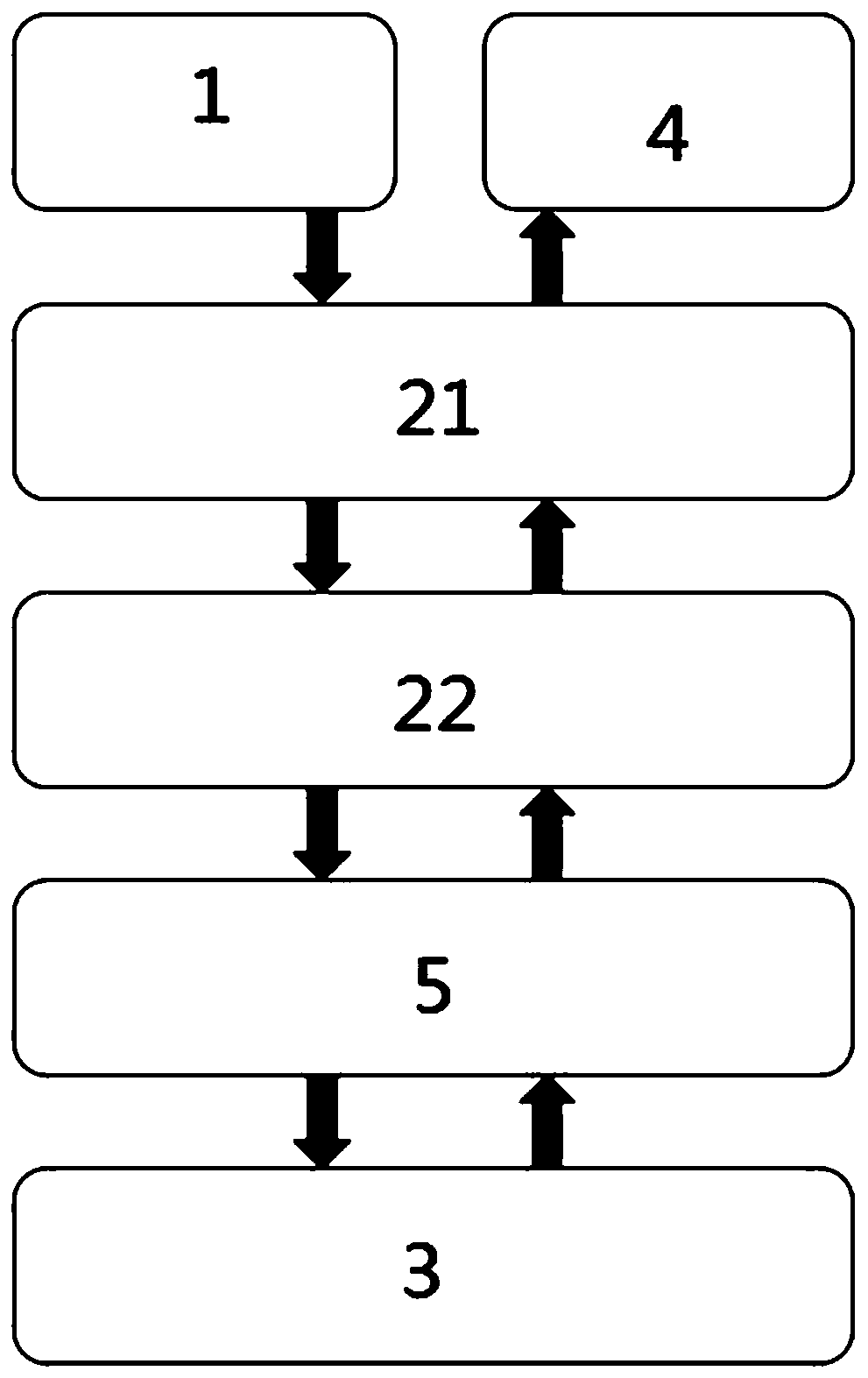

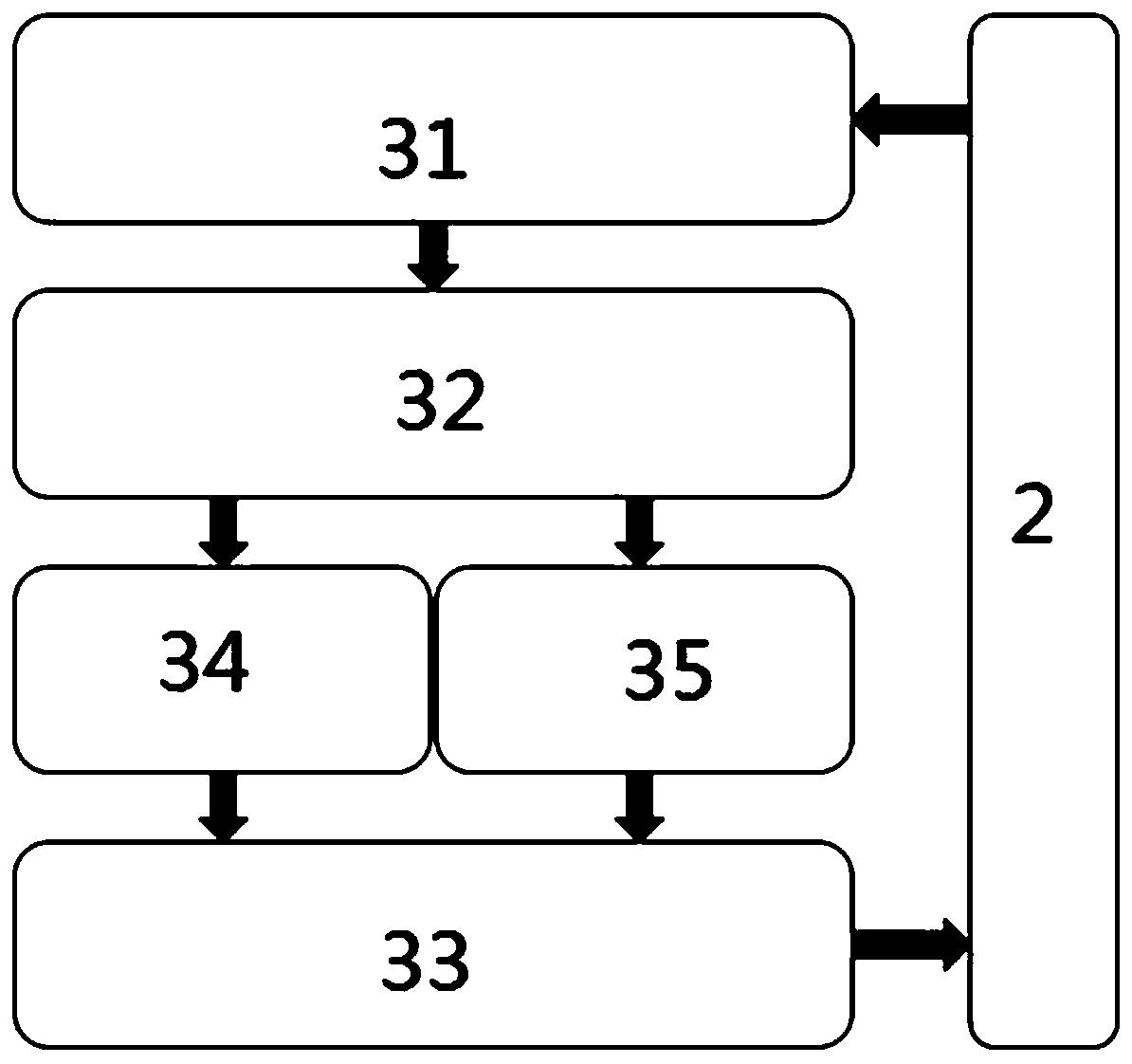

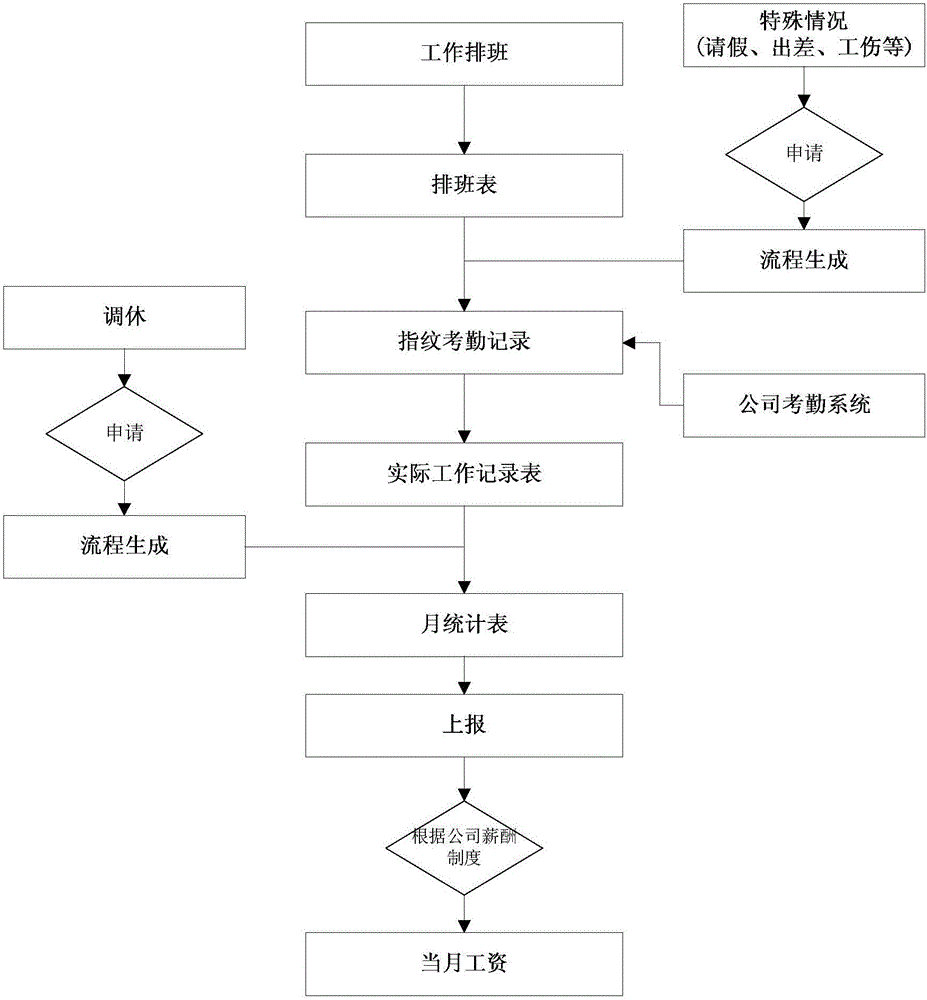

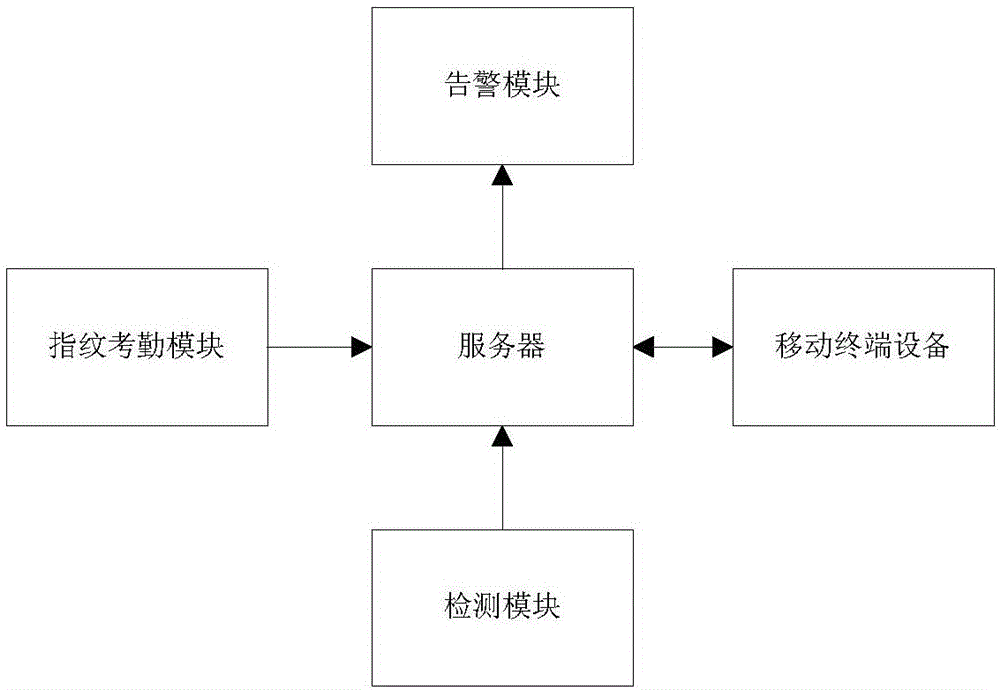

Attendance management method and system

InactiveCN106447156ARealize standardized managementRealize unified managementRegistering/indicating time of eventsResourcesWorkloadComputer science

The present invention provides an attendance management method and system. The method comprises that a. a scheduling table is set, staff attendance information is collected, and the attendance information is uploaded to a server, wherein the attendance information comprises identity information, fingerprint information and scheduling information; b. according to the attendance information, the server collects statistics of the actual work record of staff, and dynamically assigns experimental test tasks through the fingerprint attendance condition of the test staff and the experiment workload; and c. the actual salary of the staff is automatically obtained by matching a pre-established salary system with the actual work record. According to the attendance management method and system provided by the present invention, a digital experiment and digital management platform is established, so that on one hand, assignment of experimental test tasks can be facilitated, efficiency in the experiment process can be improved, and the progress and result of the overall experiment can be ensured, and one the other hand, standardized management to the staff can be facilitated, and the salary system is combined, so that the cost of manual accounting is reduced, and the efficiency of the enterprise is improved.

Owner:LONCIN MOTOR

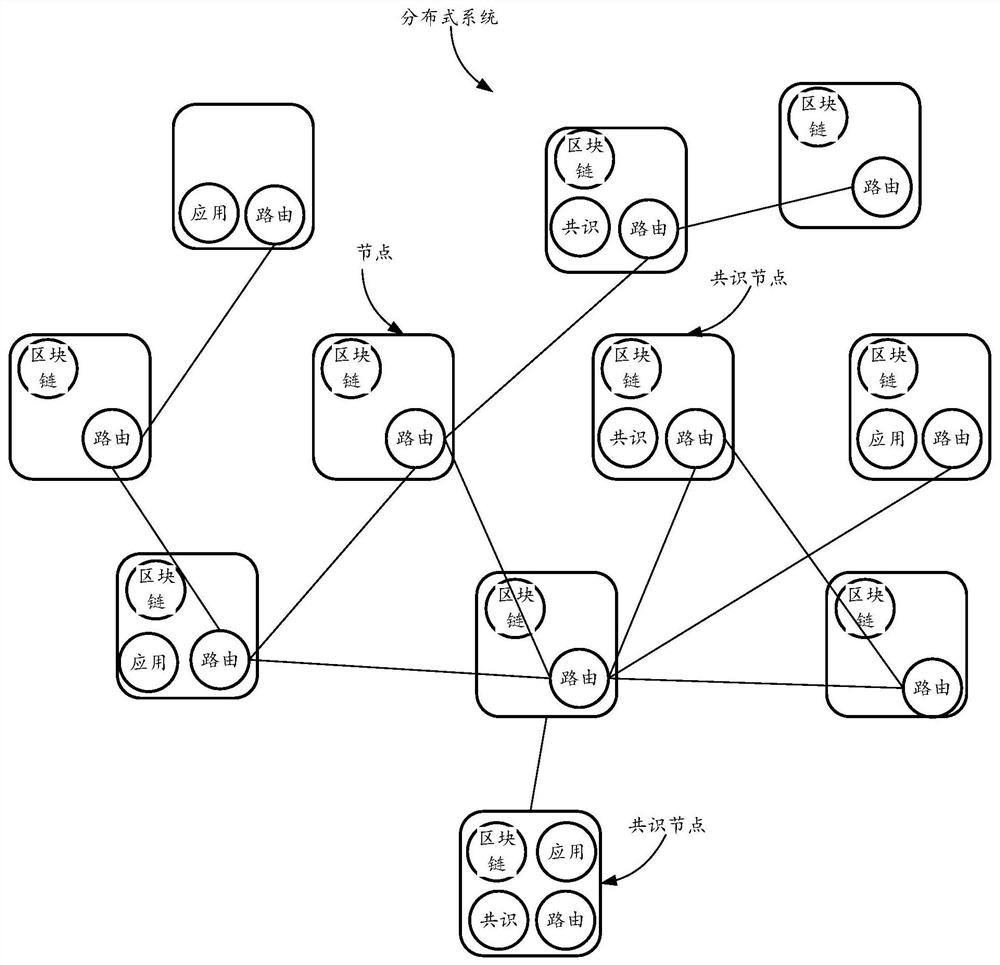

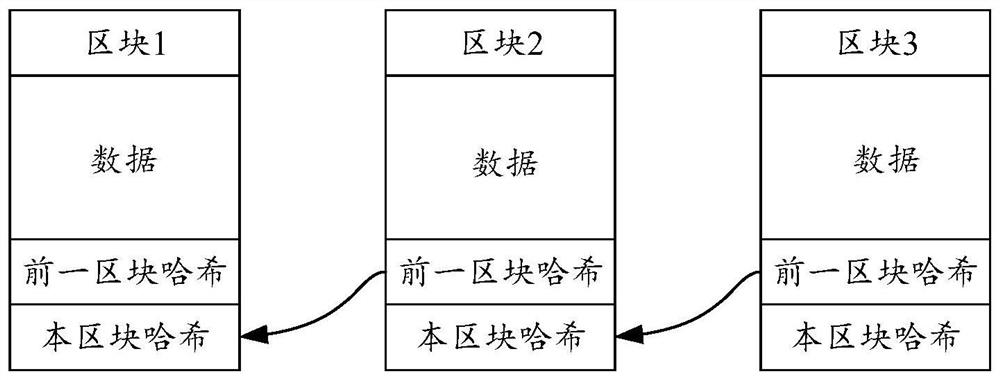

Data processing method and data processing device for block and computer equipment

ActiveCN111698315ASave resourcesImprove processing efficiencySecuring communicationComputer resourcesConsensus

The embodiment of the invention provides a data processing method and device for a block and computer equipment. The method comprises the following steps: if a first consensus node is determined as amain node and a block proposal message about a target block issued by the first consensus node is obtained, obtaining consensus data about the target block from a block chain network; when the consensus data acquired in the first target time meets the master node switching condition, switching the master node to the slave node; and performing exception processing on the target block, determining asecond consensus node from the block chain network, switching the main node from the first consensus node to the second consensus node, and processing a block proposal message about the block issuedby the second consensus node. Through the embodiment of the invention, the block processing progress can be ensured, the time and computer resources are effectively saved, and the service processing efficiency is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Integral flow and temperature control device

ActiveCN102830731AGood control stabilityStable and accurate flowWater cleaningTemperature control using electric meansBall valveEngineering

An integral flow and temperature control device comprises an electric ball valve, an interpolated digital temperature measuring device, a flow measuring device and an integral control circuit board which are fixedly integrated and packaged in a casing. Loose joints with diameter equal to that of external pipes are arranged at two ends of the integral flow and temperature control device, and accordingly the integral flow and temperature control device is flexible, convenient and fast in connection. The integral flow and temperature control device is subjected to data exchange with a main controller and supplied with power through a bus, can complete functions of temperature collection and flow PID(proportion, integration and differentiation) regulation and the like, can complete flow regulation once the main controller outputs a specific flow rate, has excellent stability in control (floating control / proportion control), guarantees stability and accuracy of cooling water flow, and further controls concentrate temperature and stress, and guarantees engineering quality and progress.

Owner:上海高千软件科技有限公司 +1

Advanced supporting and protecting technology for cracked top plate of digging operation face

InactiveCN1580491AImprove support strengthImprove securityMine roof capsEngineeringUltimate tensile strength

An early support and protect technology for a dug-working-face broken-head plate includes the following steps: 1. closing to the head plate to determine the drilling position avoiding normal support, 2. carrying out wet drilling with large diameter cone driller driven by electric coal or wind coal drillers before exposing the head plate, its diameter is greater than the outward diameter of the from beam cross section and hole depth is larger than the cyclic length. 3. plugging the steels making the front beam or hinged bar into the front holes, 4. supporting or fixing the end outside of the hole of the front beam and fastening it with die square wood or wedges, which turns the early support from passive to active and increases the support strength, stability and reliability.

Owner:新汶矿业集团汶南煤矿有限责任公司

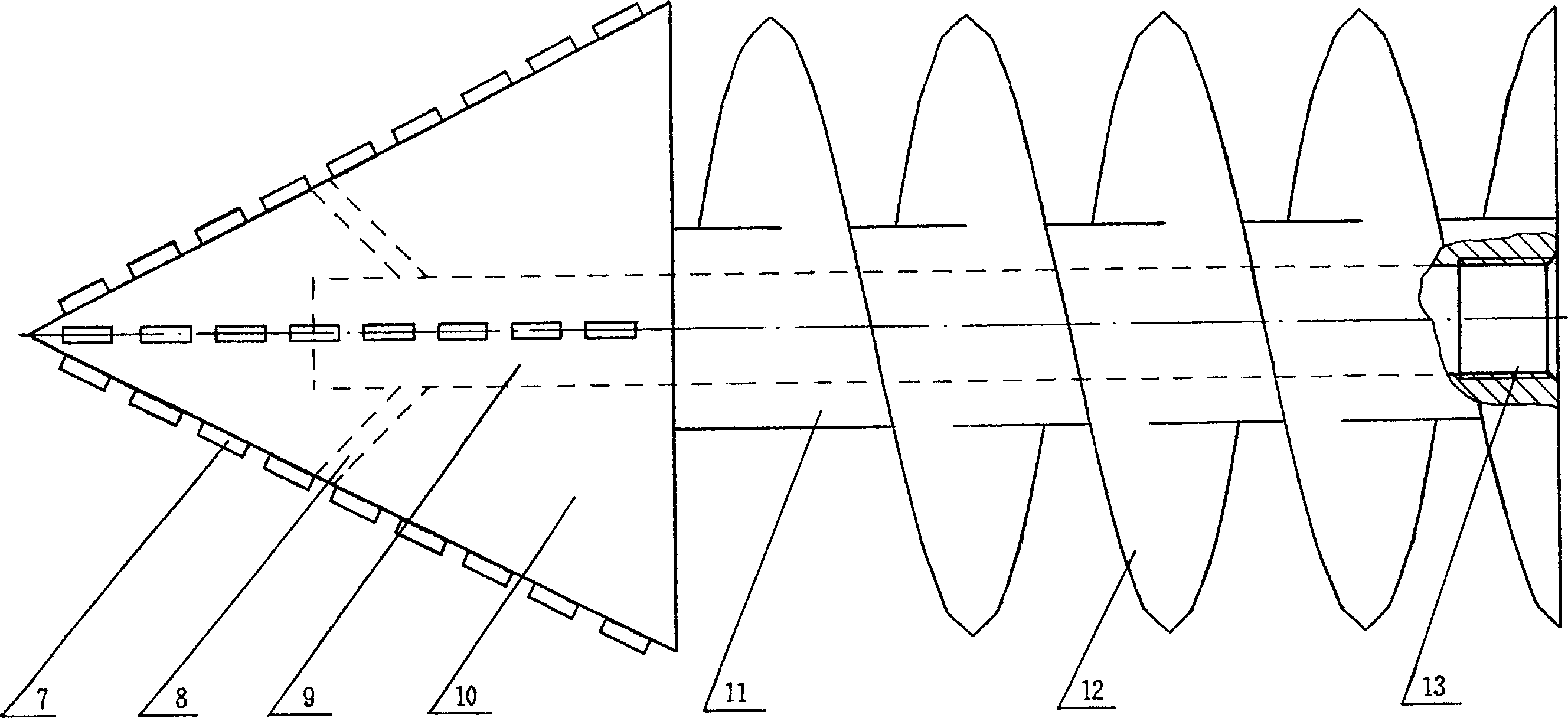

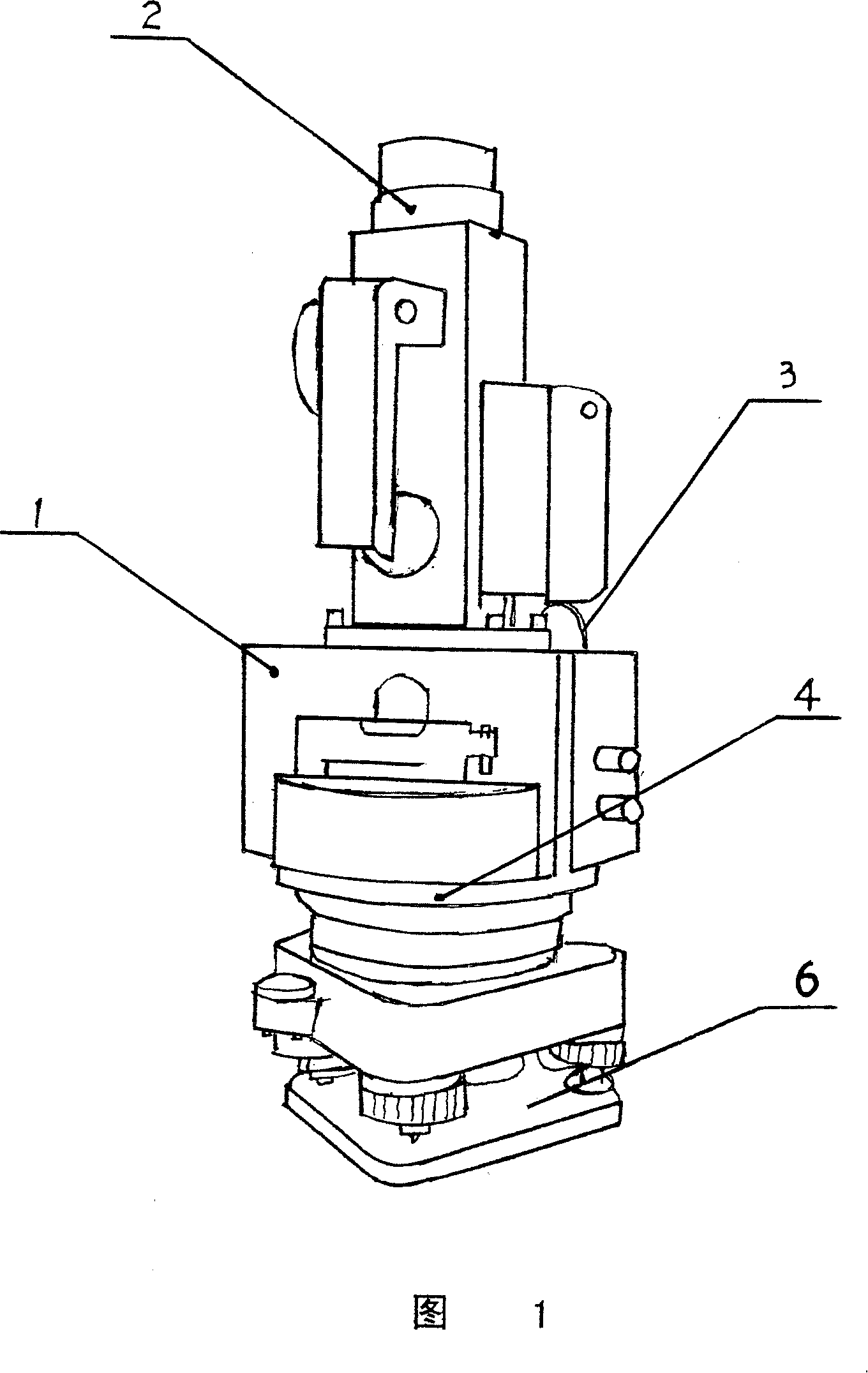

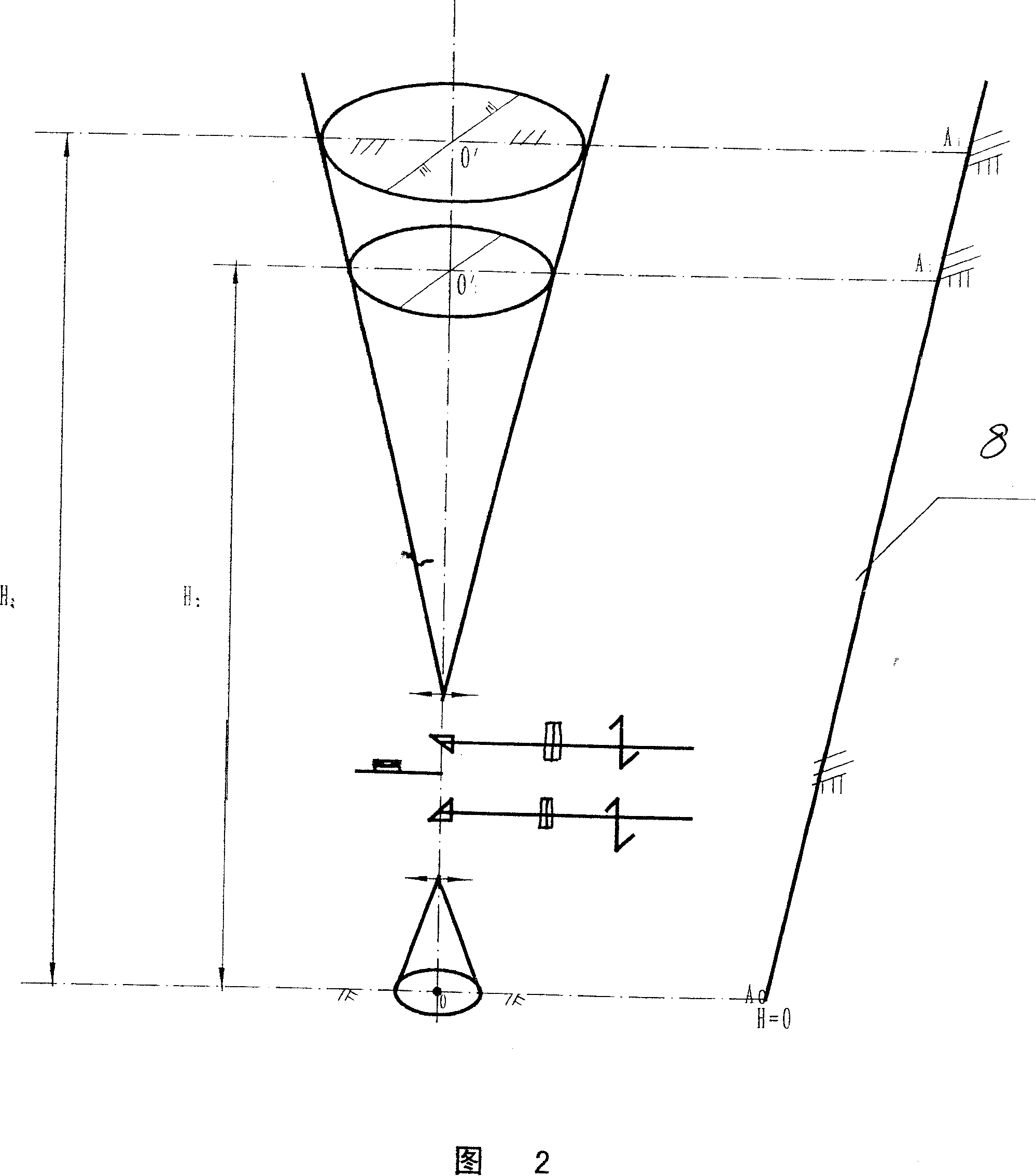

Bidirectional multifunctional laser plumbing apparatus

InactiveCN101149261AImprove vertical measurement accuracyReduce system errorSurveying instrumentsZenith telescopeStructural engineering

A kind of two-way multifunctional laser vertical collimator is made of bracket, zenith telescope module and nadir external laser telescope module, sphere vertical axis module and the triangular base. It is characterized in that: the zenith telescope module and nadir external laser telescope module are set on the A and B plane of main bracket top respectively, which are installed at the bracket or vertical axis center by the socket bolt and the column head bolt respectively. A phi 108 base hole is set below the main bracket, while, the outer of main bracket is set with a V-shape axile bush which is fixed the main bracket on the vertical axis module by a hole adjusting bolt to form a combination shafting which can rotate with the vertical axis; otherwise, a long level tube is installed on the side of main bracket which is used to adjust level and plumb.

Owner:SHANGHAI GUANGZHONG MAPPING INSTR

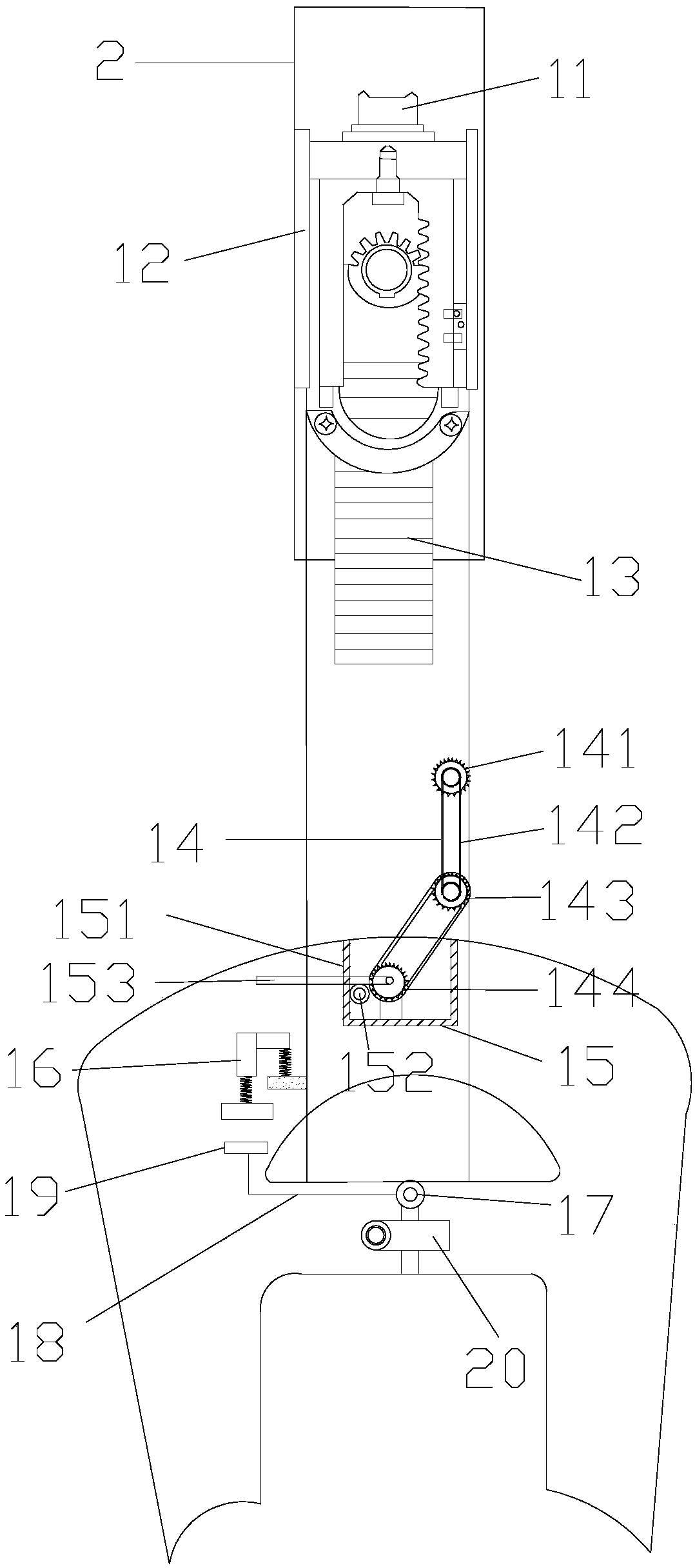

Laying treatment device of water supply and drainage pipelines

PendingCN108178063AReduce workloadGuaranteed progressPipe laying and repairLoad-engaging elementsWater supplyElectrical and Electronics engineering

The invention discloses a laying treatment device of a water supply and drainage pipeline. The device structurally comprises a fixed support plate, an external fixing rod, an external connecting rod,a transverse connecting rod, a hinge structure, a lug, a connecting table, pipeline fixing plates, side clamping frames, a balance connecting rod, a motor, a vertical slide rail structure, an extension rod, a transmission mechanism, a transmission connecting structure, a pressure spring touch structure, an electric switch, a connecting line, a sensing element and an extension connecting frame. According to the device, the vertical slide rail structure, the extension rod and the extension connecting frame are mutually matched; falling time and a position of the pipeline can be controlled freelyand flexibly according to an actual laying situation in a pipeline conveying and distribution process; the operation workload is reduced to a great extent; a progress of the pipeline laying work is ensured; equipment practicability is effectively improved.

Owner:朱恩惠

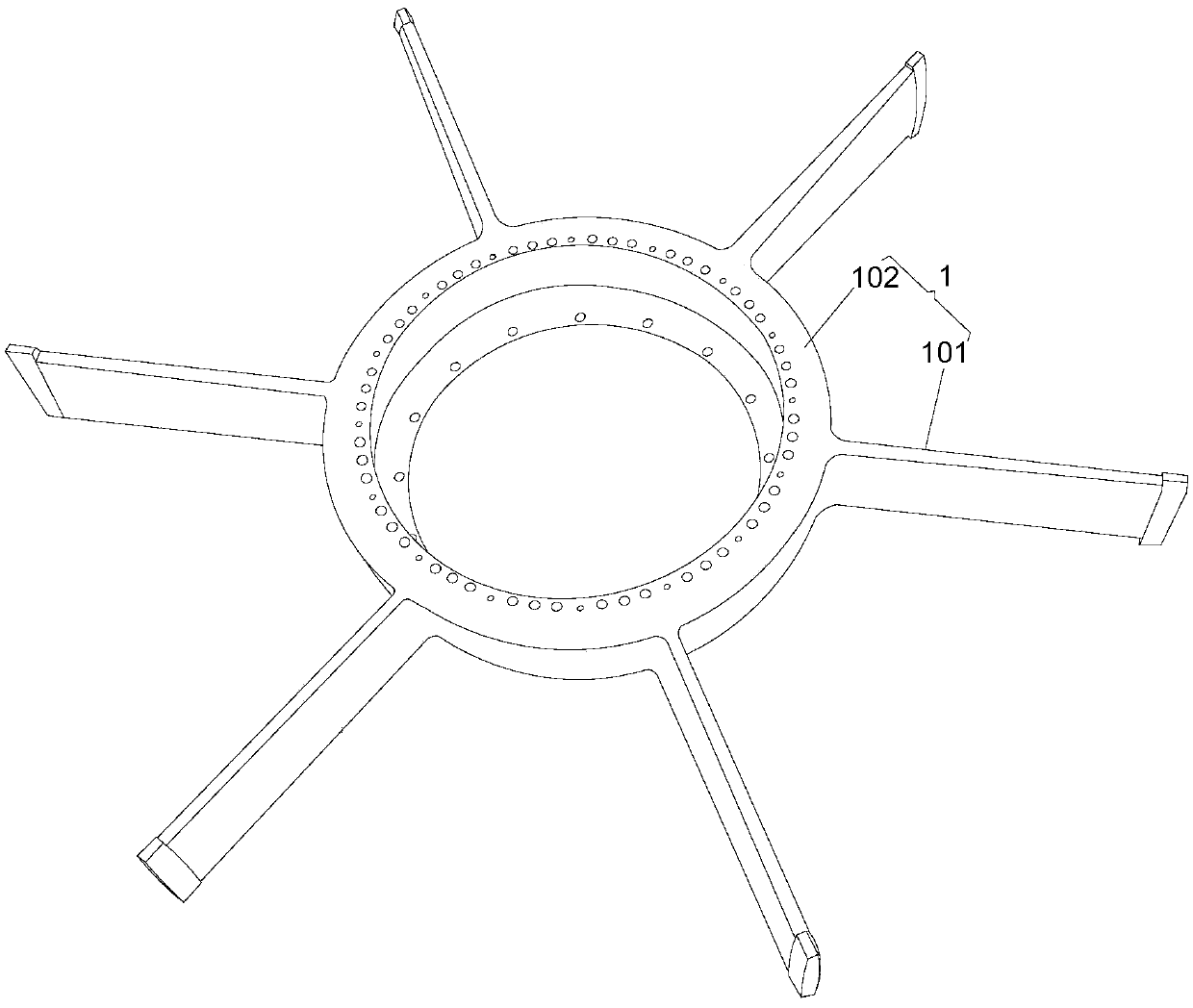

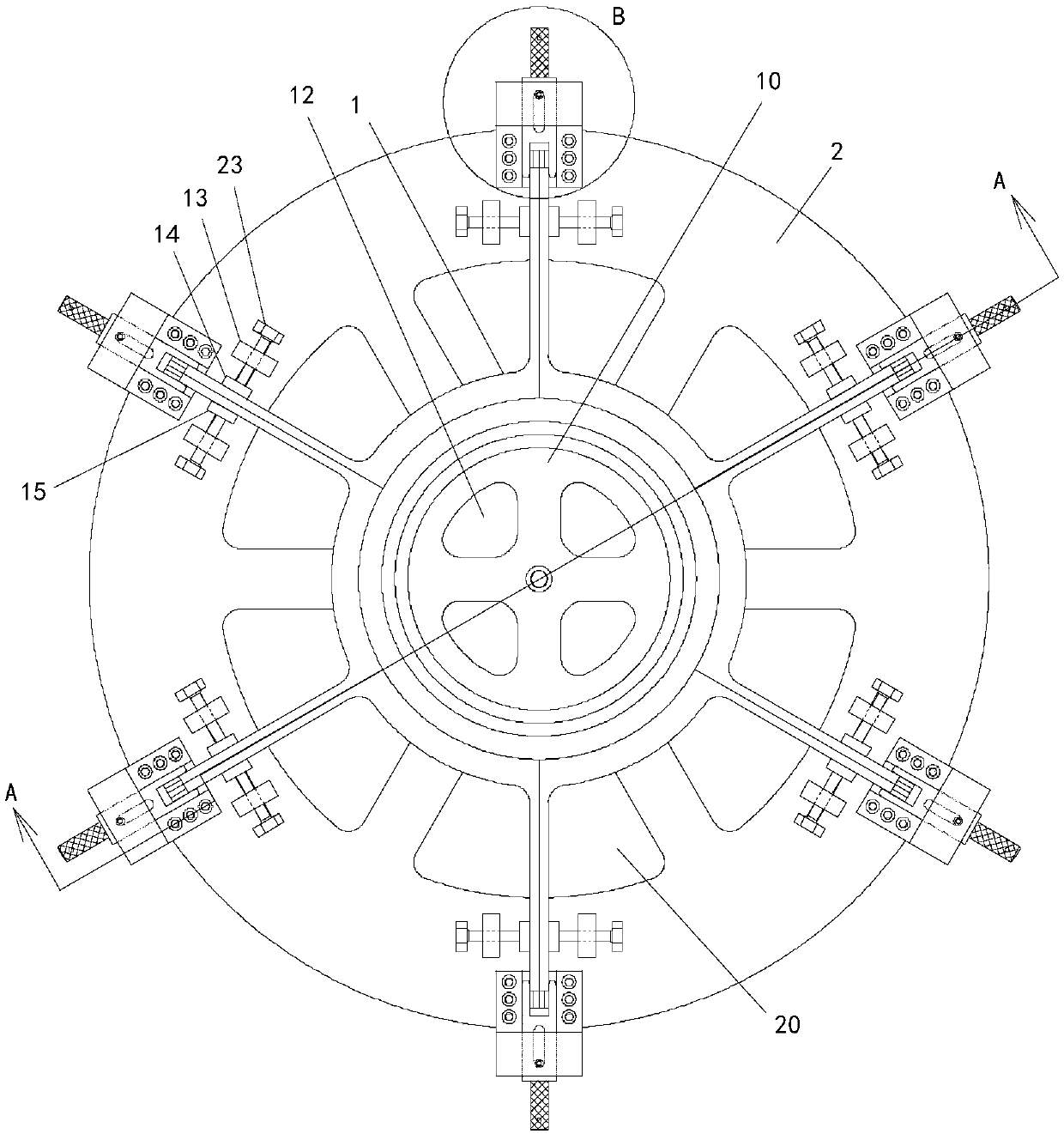

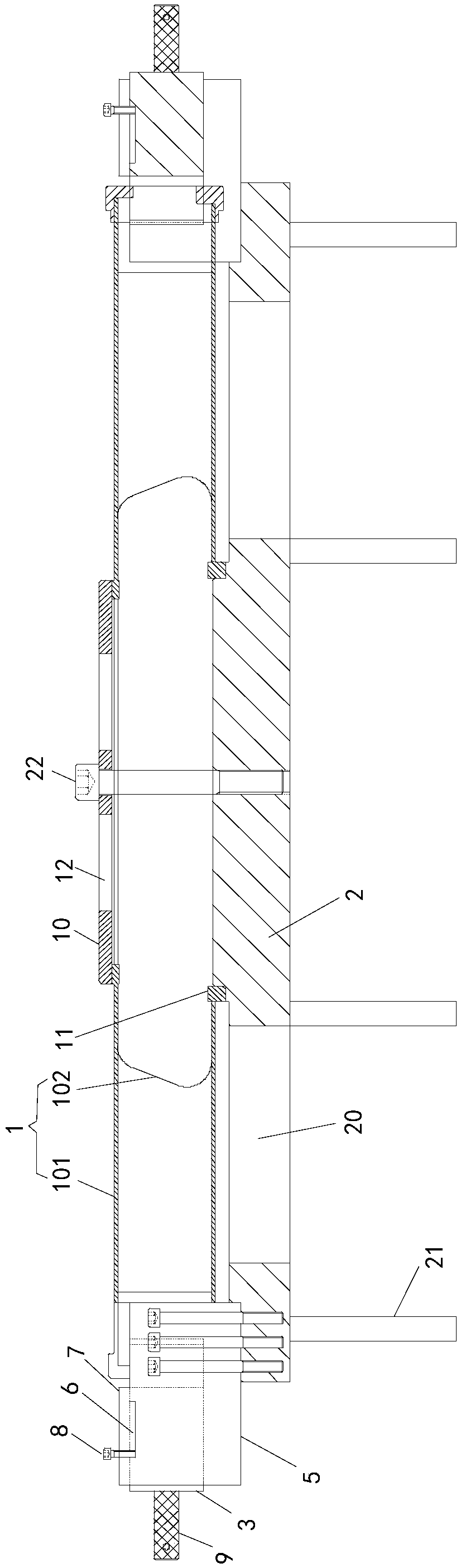

Integrated device for angular alignment and detection of turbine supporting casing support plates

ActiveCN109520400AImprove stabilityImprove pass rateMechanical solid deformation measurementsManufacturing technologyEngineering

The invention provides an integrated device for angular alignment and detection of turbine supporting casing support plates, and relates to the technical field of manufacturing of aeroengine turbine supporting casing assemblies. The technical problems of difficult angular size control, size tolerance, unstable part processing and low qualification rate of six support plates of a turbine supportingcasing rear housing support in the prior art are solved. The problem that product delivery is seriously restricted is solved. The problem that the progress of model development is affected is solved.The device comprises a base, support plate correction devices, support plate detection devices, and a fixing device which is used for fixing the turbine supporting casing rear housing support on thebase. The support plate correction devices and the support plate detection devices are arranged on the base. A set of support plate correction device and support plate detection device are correspondingly arranged on each end, which is corresponding to the turbine supporting casing rear housing support, of six support plates. The device provided by the invention is used for angular alignment and detection of the turbine supporting casing support plates.

Owner:AECC AERO SCI & TECH CO LTD

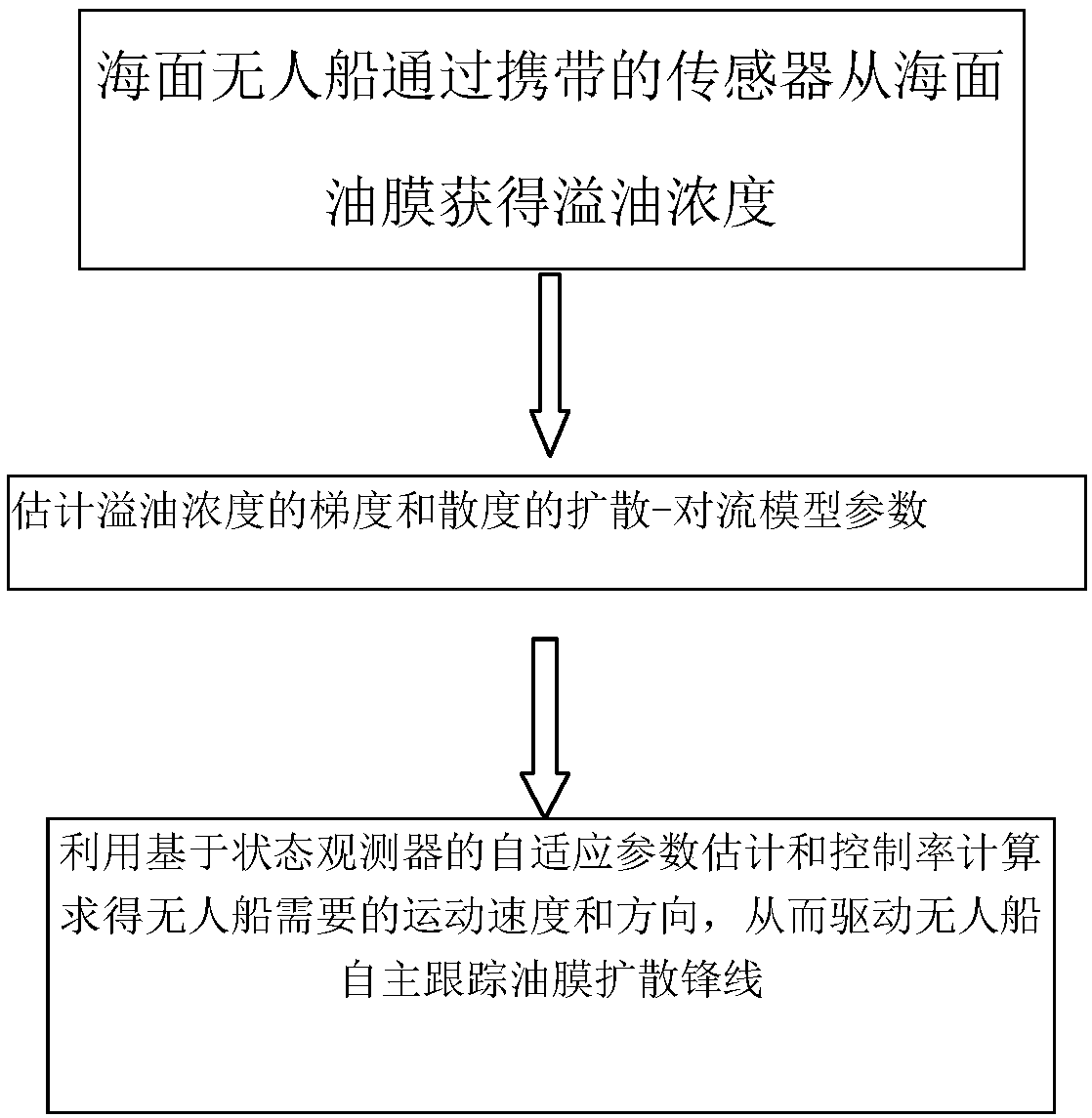

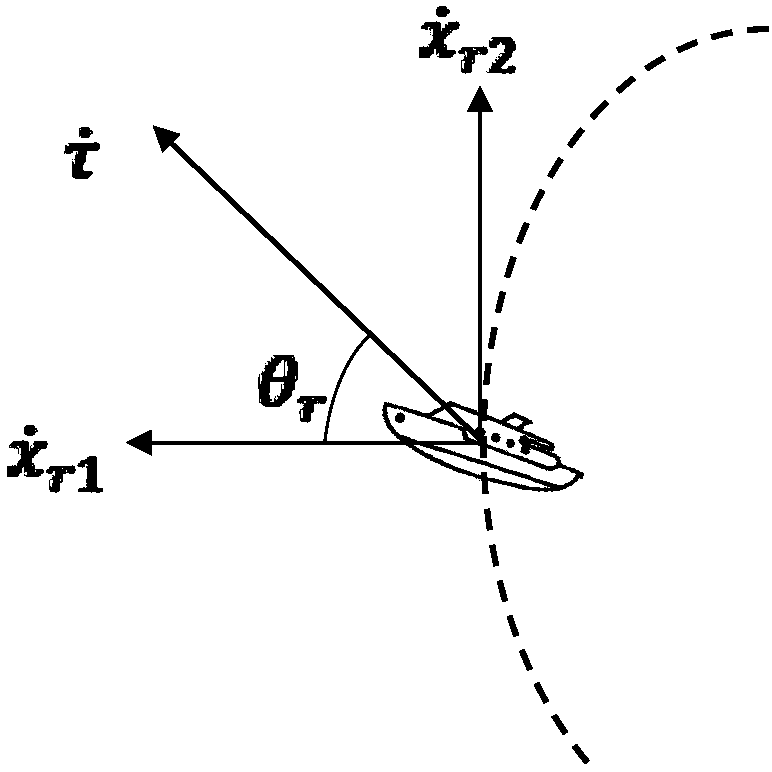

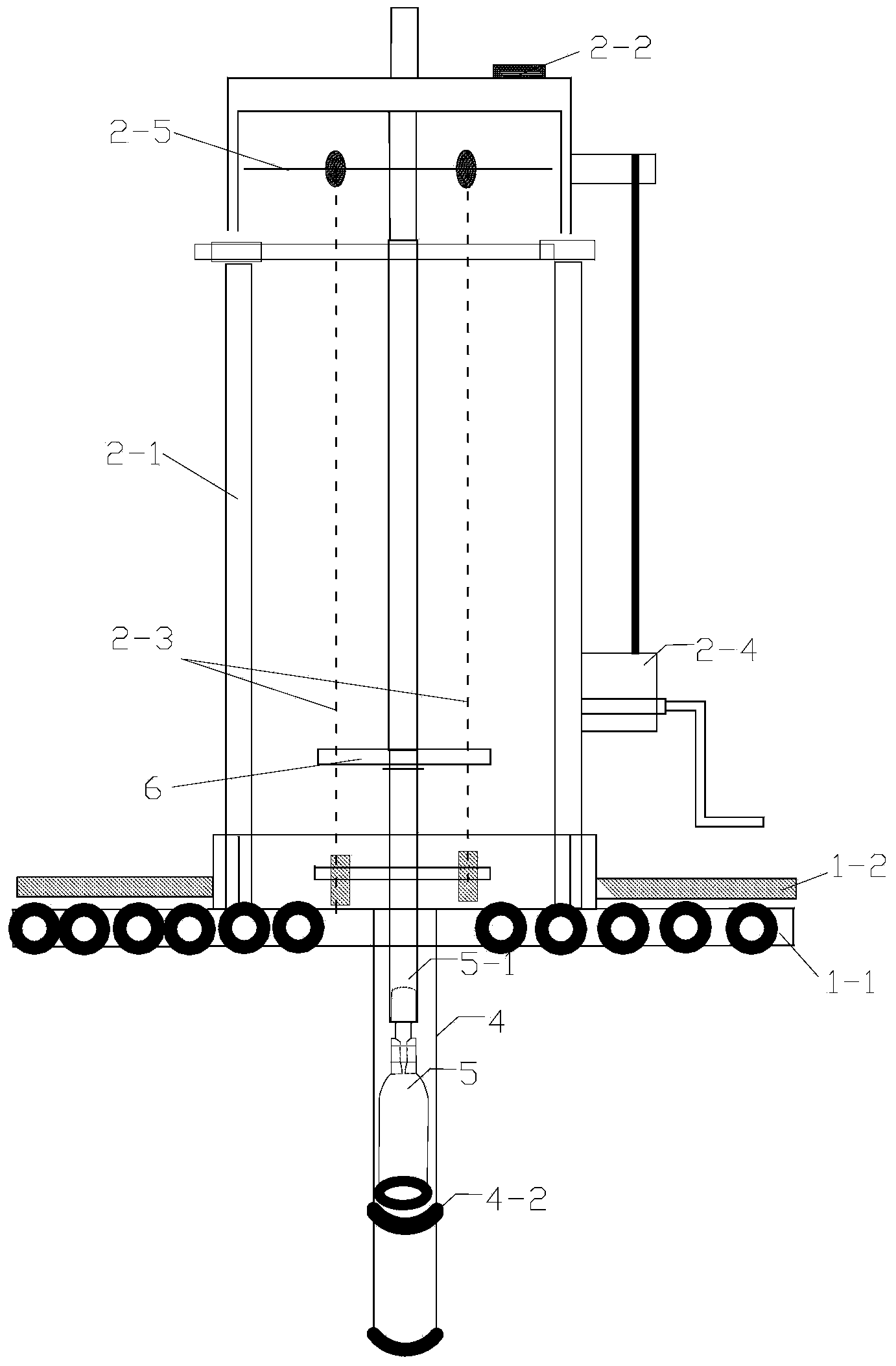

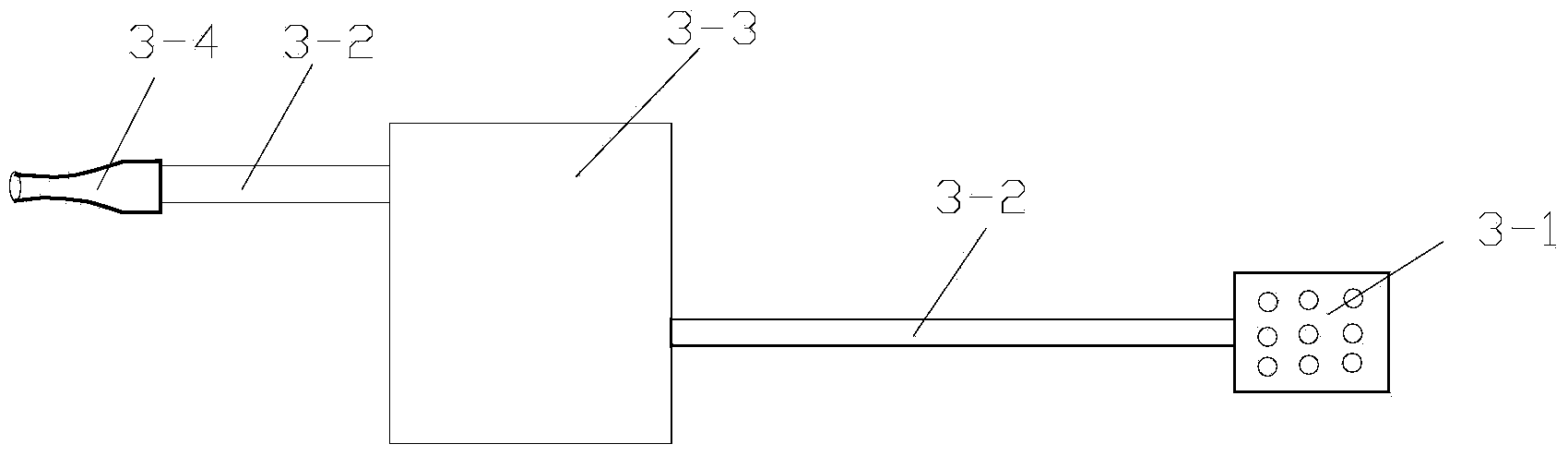

Littoral spilled oil adaptive tracking and controlling method and system

InactiveCN107807069AReal-timeGuaranteed real-timeSurface/boundary effectTarget-seeking controlState observerMarine engineering

The invention provides a littoral spilled oil adaptive tracking and controlling method and system, and relates to the field of control of unmanned ships. The method comprises the following steps: (1)carrying a sensor by an unmanned ship to obtain the concentration of spilled oil of oil slick; (2) calculating to obtain the model parameters of spilled oil concentration; and (3) utilizing adaptive parameter estimation of a state observer and adaptive control rate to calculate the moving speed and direction of the unmanned ship so as to drive the unmanned ship to automatically trace the forward line of oil slick. The method has a real time property, an adaptive property, and robustness, and can trace the forward line of spilled oil by using an unmanned ship without using parameters of an oilslick diffusion-convection model.

Owner:SHANDONG UNIV

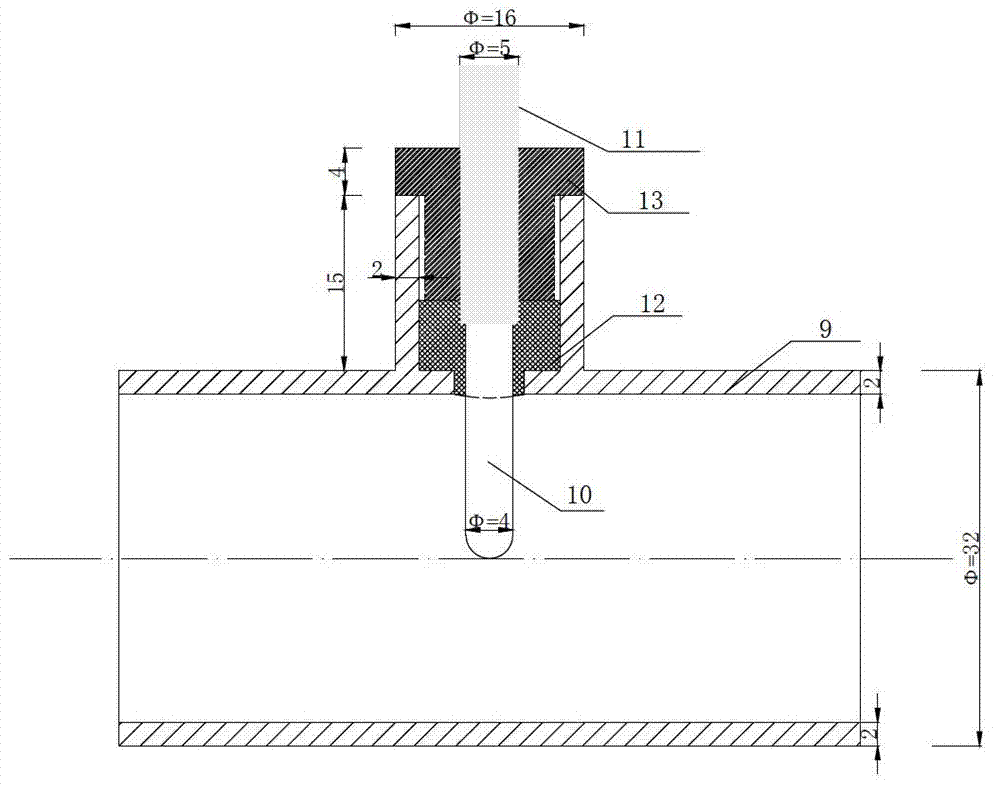

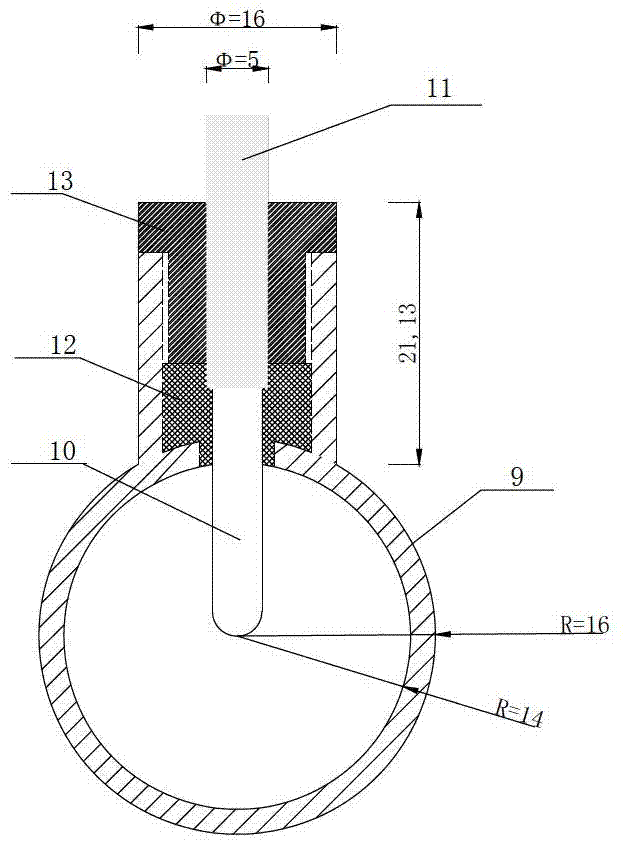

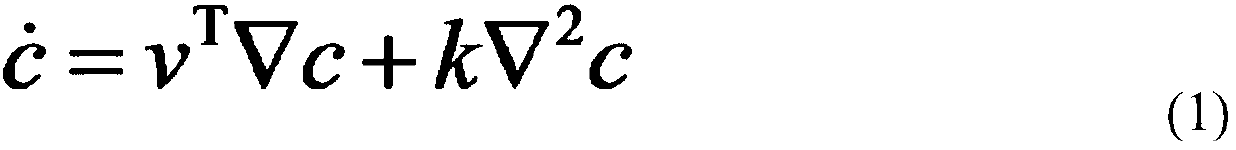

Equipment and method for reconnoitering and field sampling in soft soil region

InactiveCN103643669ASolve different difficultiesQuality improvementIn situ soil foundationEngineeringHigh water content

The invention discloses equipment for reconnoitering and field sampling in a soft soil region. The equipment comprises a bearing platform, a sampling power system, a sampling device, a hole-forming device, a hole-protecting device, a power generator and a transport device, wherein the transport device is used for transporting the bearing platform to a work place; the hole-forming device is used for forming a sampling hole in the bearing platform; the hole-protecting device is arranged in the hole formed by the hole-forming device; the sampling device is used for obtaining a soil sample in a position with the distance of 15-80 cm from the lower part of the bottom elevation of the sampling hole. The invention further discloses a method for sampling by the equipment for reconnoitering and field sampling in the soft soil region. According to the equipment and the method, the reconnoitering and sampling operations can be carried out in the soft soil region with very high water content and very low bearing capacity, and the high-grade undisturbed soil sample can be obtained.

Owner:TIANJIN SURVEY & DESIGN INST OF WATER TRANSPORT ENG +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com