Buddha ceremonial canopy and manufacturing method thereof

A production method and technology of the Big Buddha, which are applied to building components, arched structures, dome roof structures and other directions, can solve the problems of unguaranteed construction progress, quality and safety, difficult to guarantee positioning accuracy, and high measurement accuracy requirements. Achieve the effect of difficult construction, high measurement accuracy requirements, and large welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

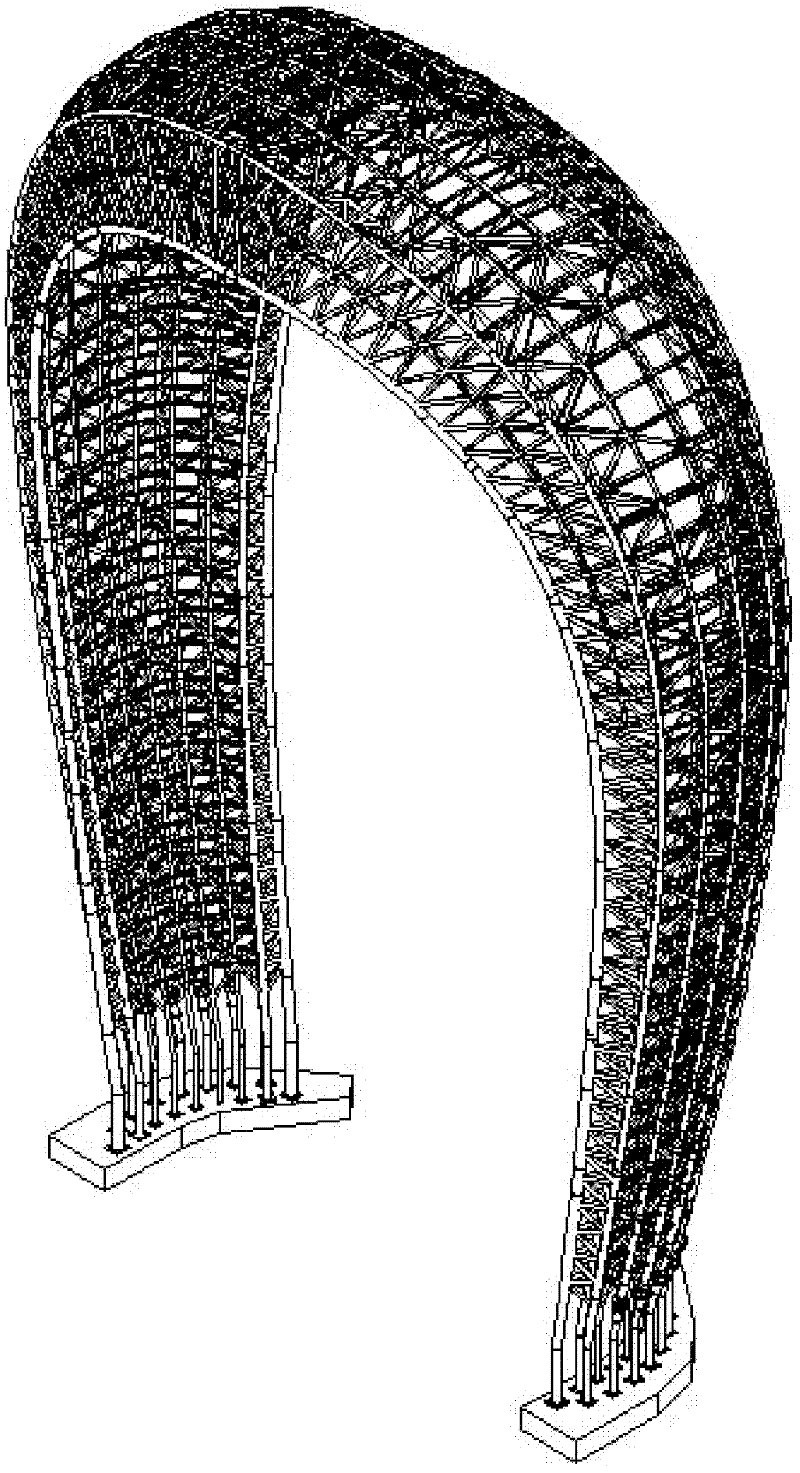

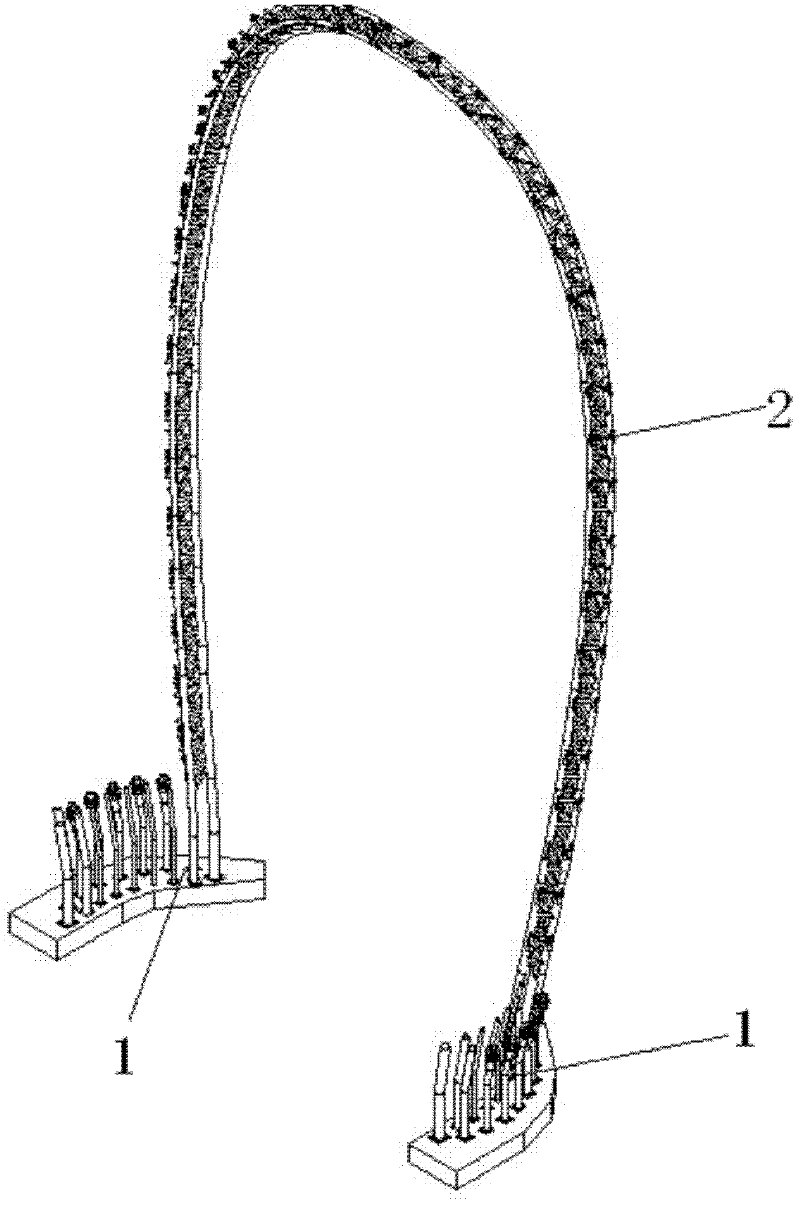

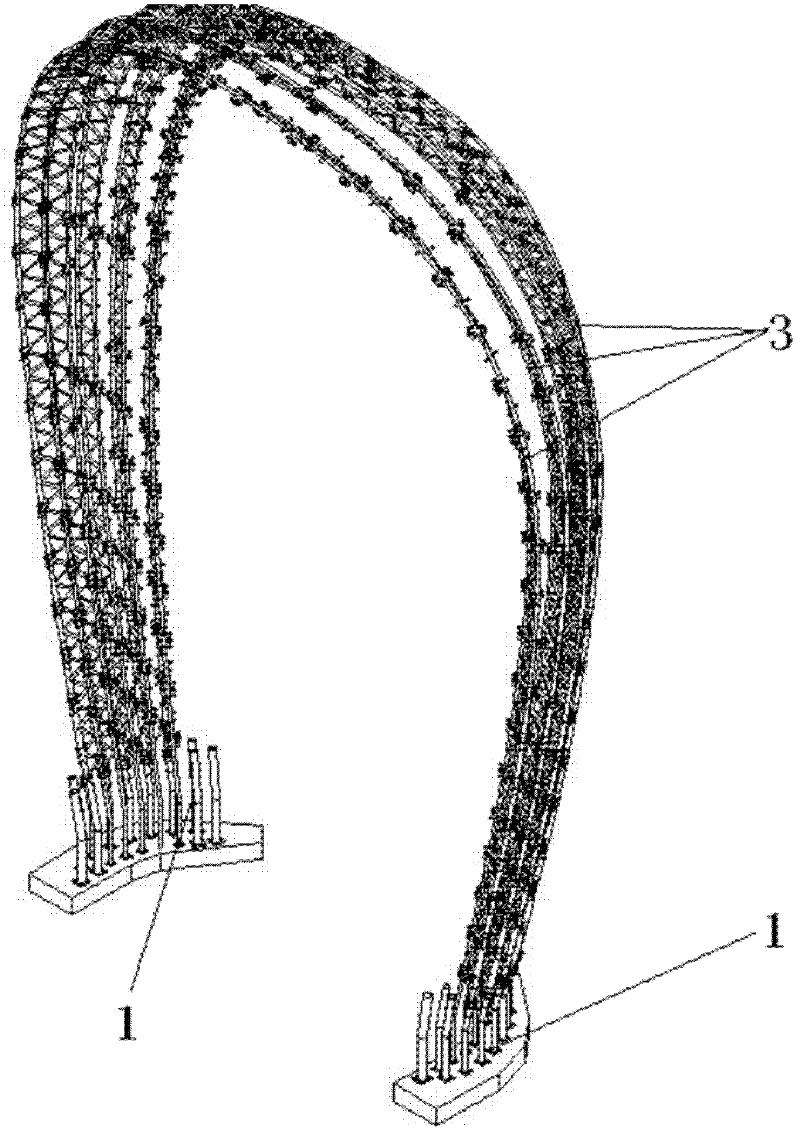

[0045] Such as Figure 1 to Figure 7 As shown, a kind of big Buddha cover, the outer cover of the big Buddha has a net height of 80m, and the top elevation is +86.55m; the cover includes two column feet 1 and a steel structure three-curved arch frame, and the steel structure three-curve arch frame is sequentially arranged from front to back Including the front main arch 2, the middle arch 3 and the rear main arch 4, the front main arch 2 and the rear main arch 4 are double-curved arches, and the middle arch 3 includes 5 vertical double-curved secondary arches The connecting rods are evenly arranged at a horizontal interval of about 2m. There are 81 connecting rods in total. Three-way diagonal rods are installed between two adjacent arches. The two ends of each arch are respectively connected to two column feet. The distance between the inner and outer layers is about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com