Modularized and integrative disassembling and installing methods for blast furnace

A modular, furnace body technology, applied in blast furnaces, blast furnace details, blast furnace parts and other directions, can solve problems such as difficult connection, single structure, limited construction plane, etc., to reduce use and operation time, improve economic benefits, The effect of solving logistics problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Now a blast furnace needs to be dismantled, using a modular and integrated dismantling method for blast furnaces, including dismantling the furnace roof system, dismantling the hot blast surrounding pipe, dismantling the first floor beams, and dismantling the casthouse platform and furnace body. The specific steps are:

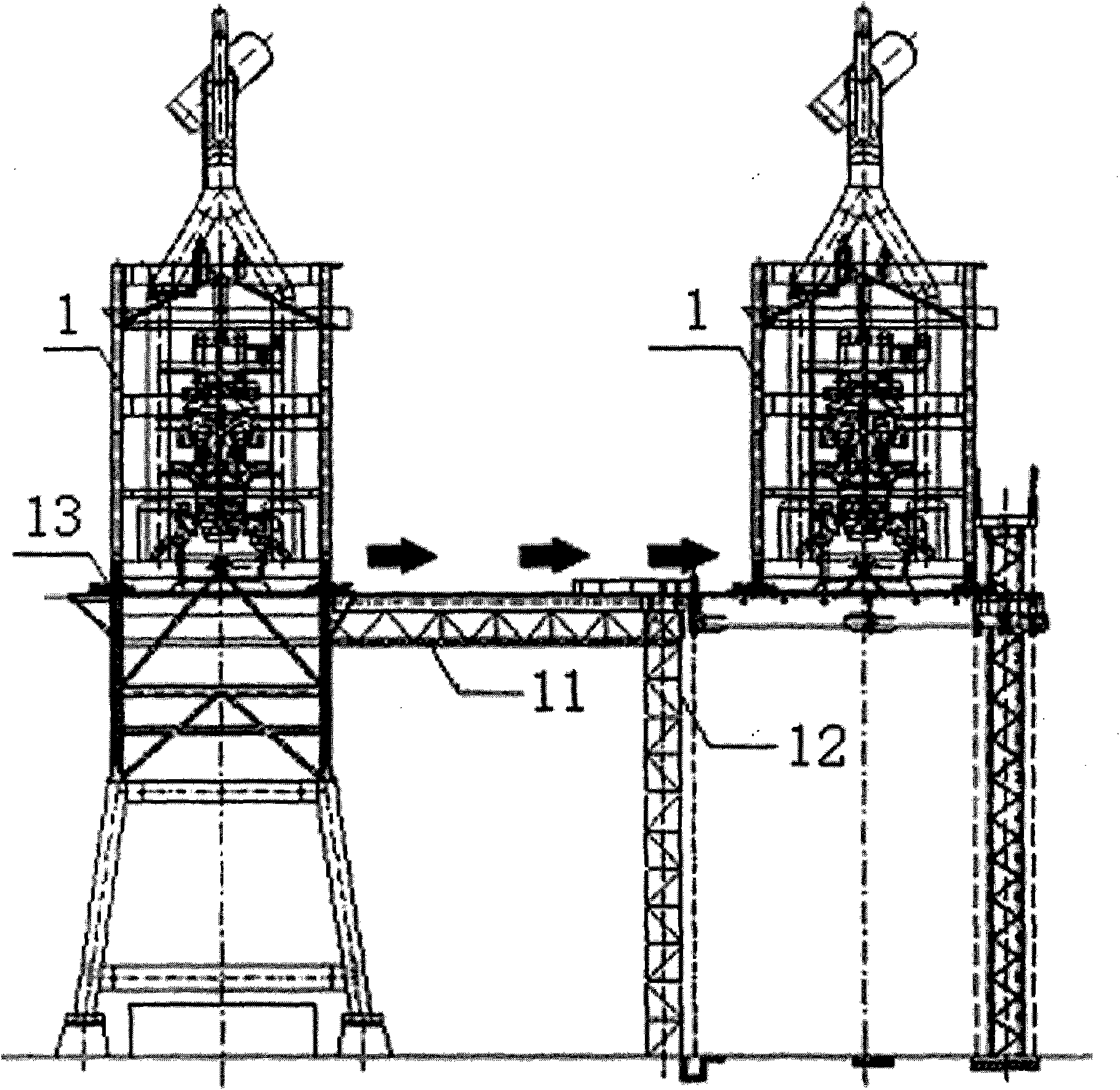

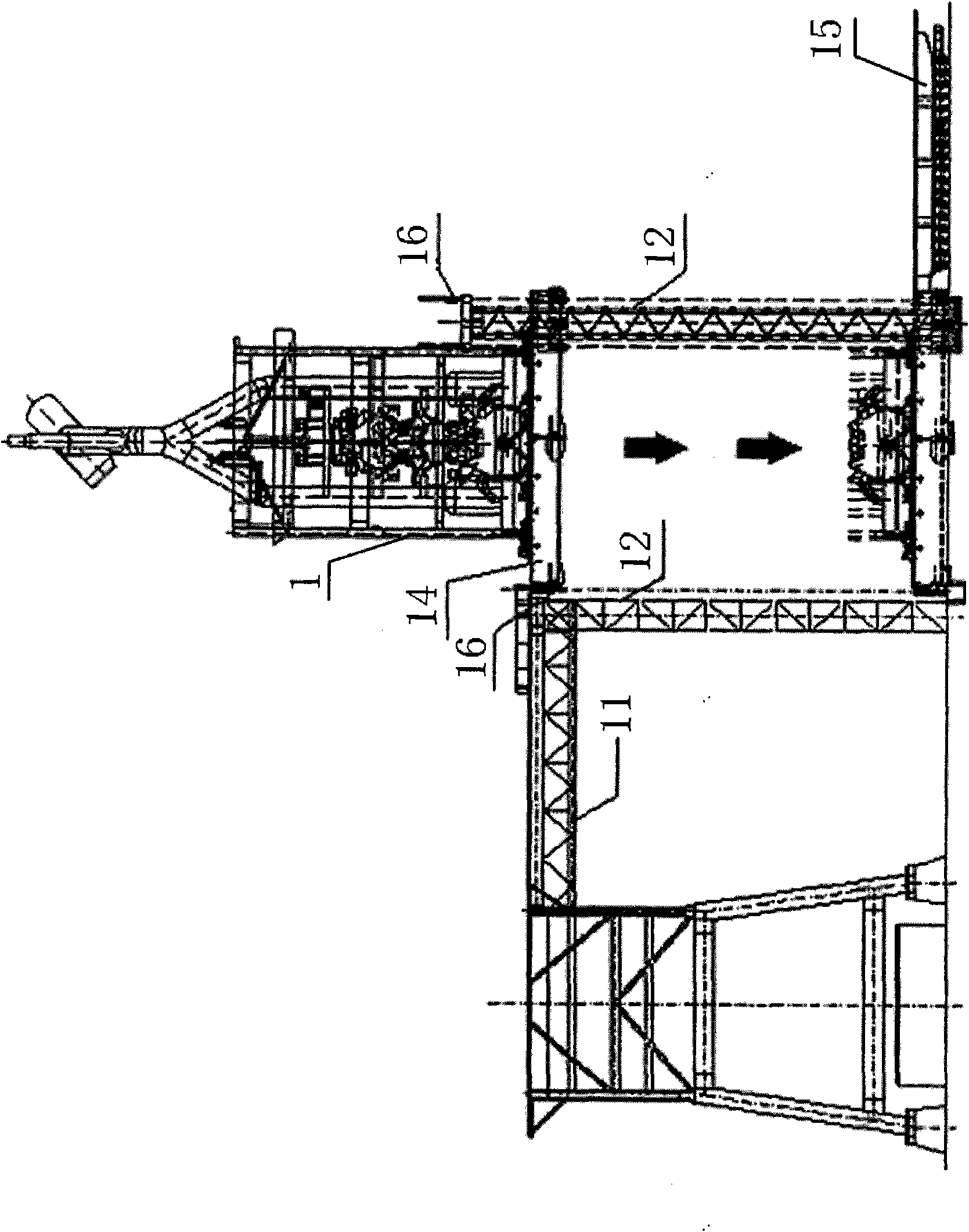

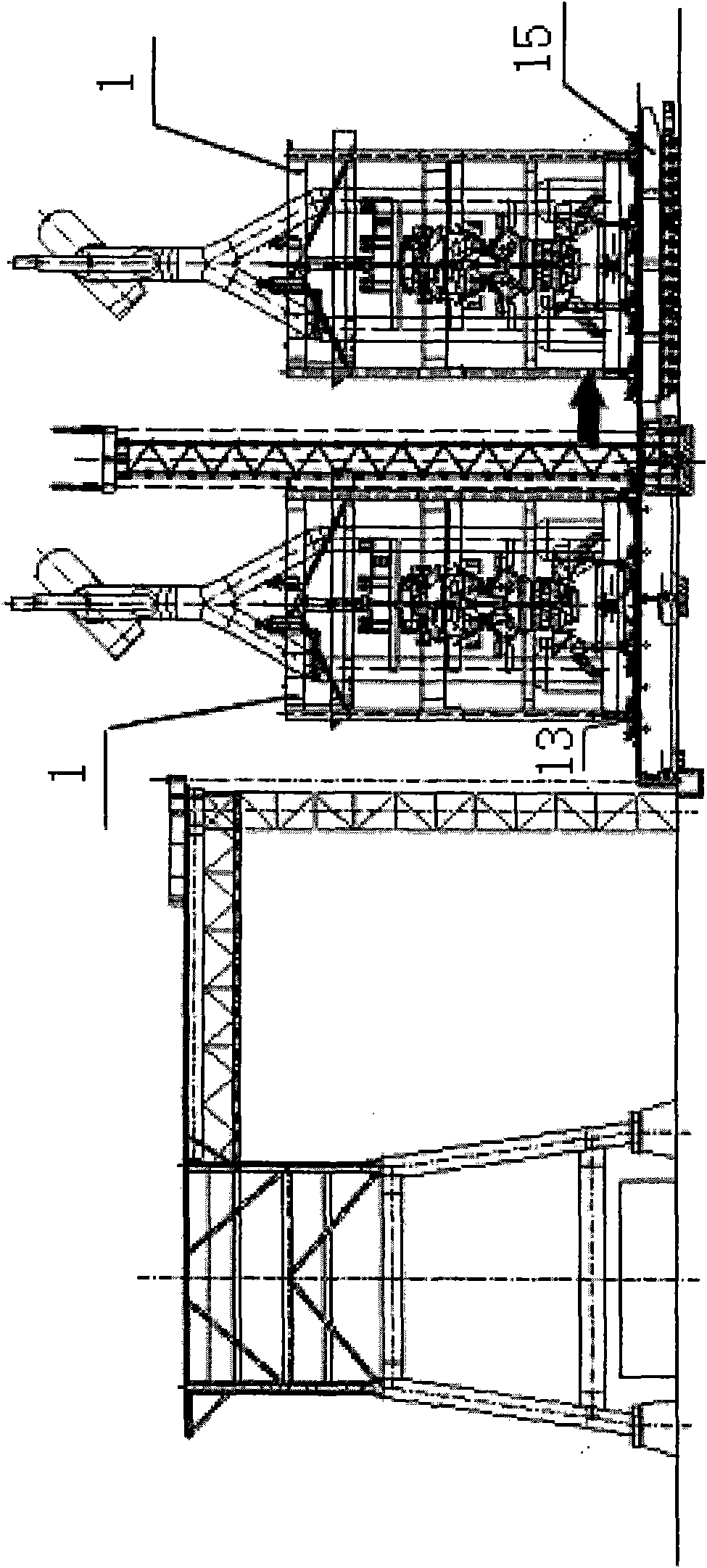

[0063] When dismantling the furnace roof system, a modular and integrated dismantling method is adopted. The furnace roof system 1 is located above an elevation of 40m, including the old seven-story platform and above structures and equipment, and weighs about 2600t. figure 1 As shown, through the sliding truss 11 and supporting system 12 erected on the 180° side of the blast furnace, the entire furnace roof system 1 is slid from a high altitude to a lowered position with the sliding equipment 13, and the arrow in the figure indicates the sliding direction. like figure 2 As shown, the furnace roof system 1 is lowered to the ground as a whole with the h...

Embodiment 2

[0071] A blast furnace needs to be installed now, using a modular and integrated installation method for blast furnaces, including installation of the furnace roof system, installation of hot air surrounding pipes, installation and construction of the furnace body, construction of the first floor beam and platform in the casting yard, and construction of the finished product tank , the specific steps are:

[0072] The installation of the furnace roof system adopts a modular and integrated installation method, and the frame, gas riser pipe and ball joints, furnace roof equipment above the material tank, electrical instruments, furnace top small piping and hydraulic piping are assembled offline and reinforced into a whole furnace roof System 1, such as Figure 15As shown, the entire roof system 1 is slid onto the transport vehicle 15 with the sliding equipment 13, and the furnace roof system 1 is transported to the ground on the 180° side of the blast furnace with the transport ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com