A large-diameter steel pipe construction safety suspension device

A suspension device and large-diameter technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of injury, construction personnel falling, and hidden safety hazards, and achieve high work safety and reliability, convenient steel pipe construction, Use safe and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

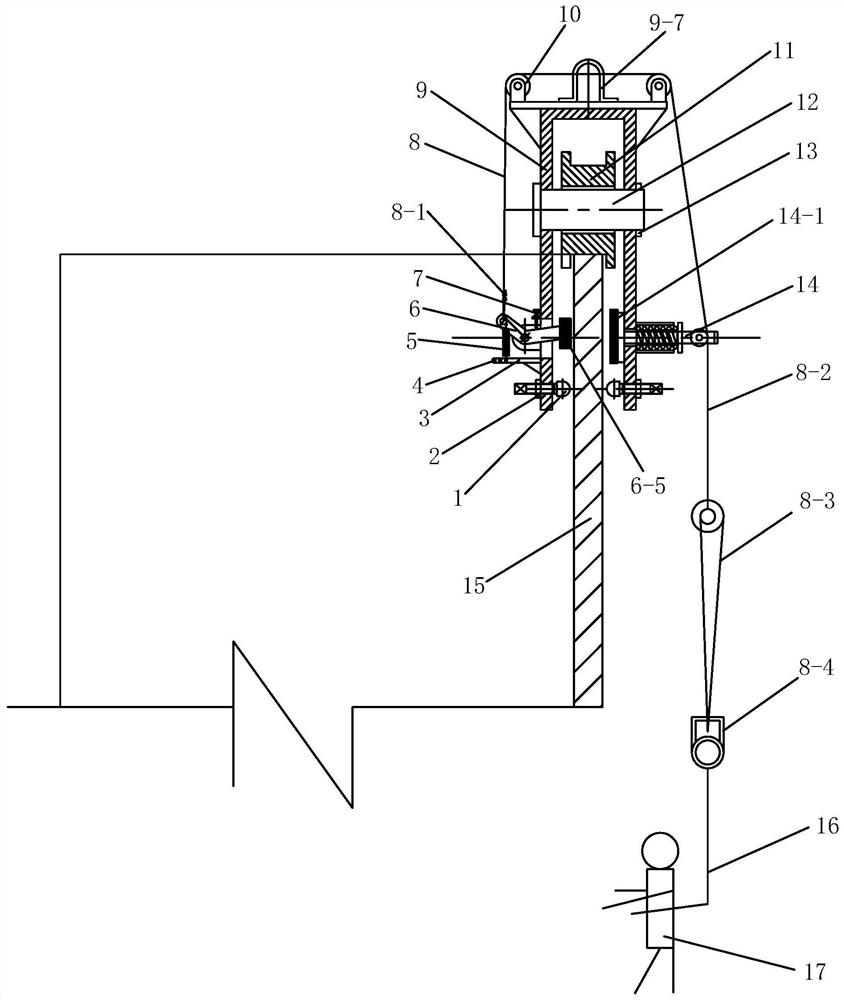

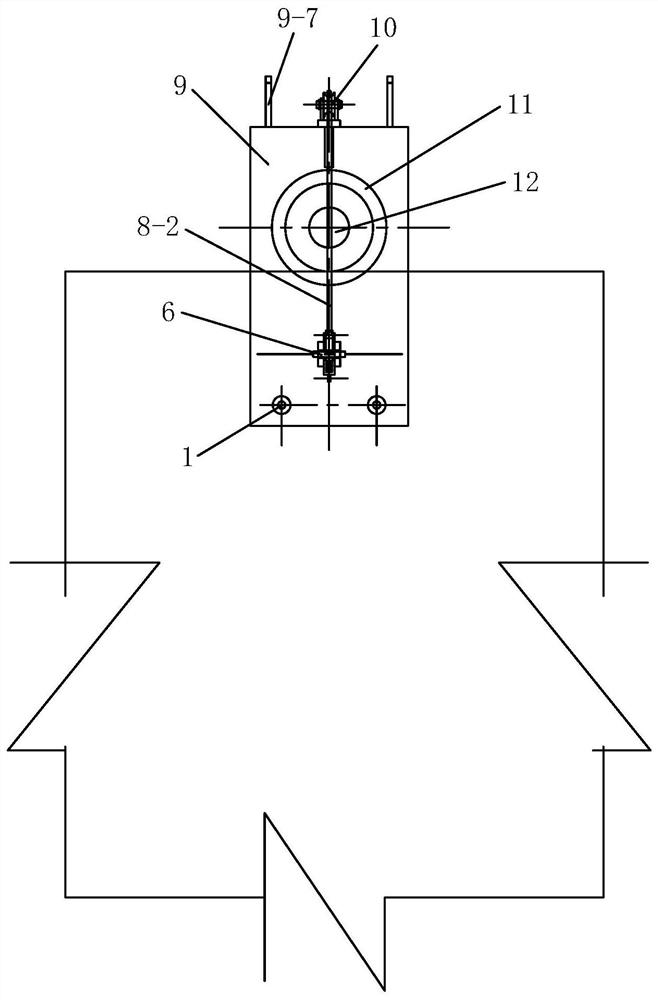

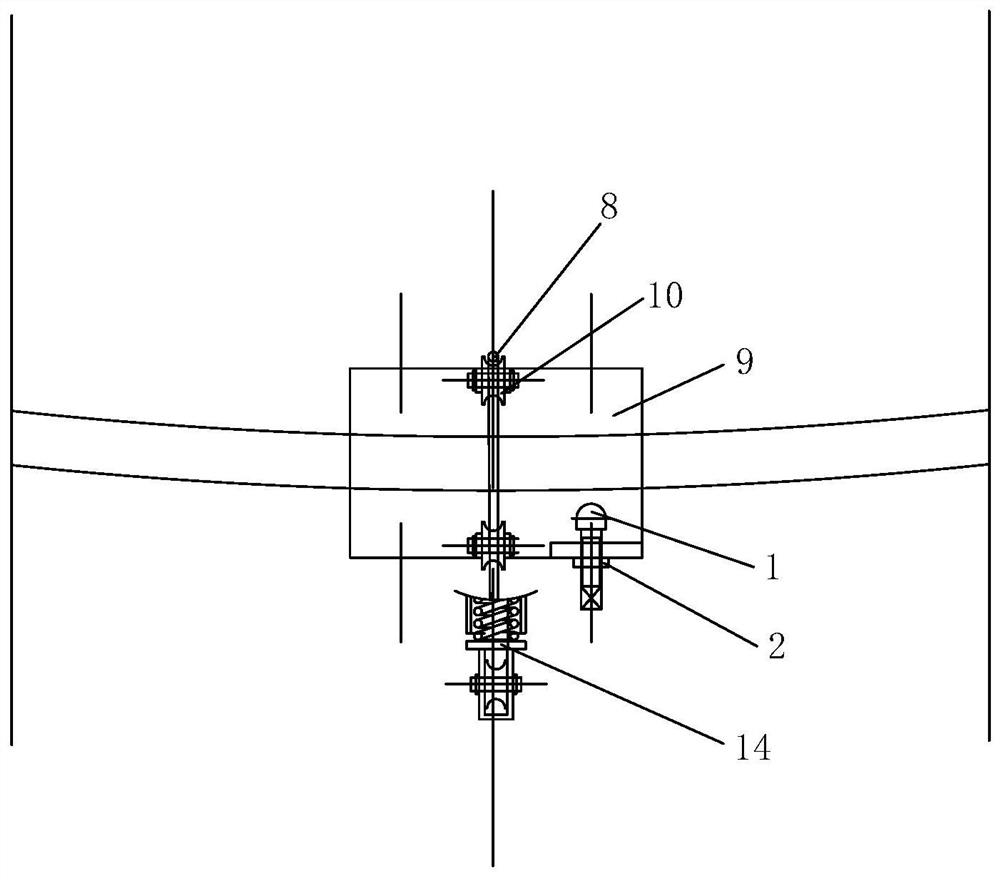

[0055] like Figure 1 to Figure 3 As shown, the present invention includes a frame 9 and a hanging rope system 8, the frame 9 is installed on the upper nozzle of the steel pipe 15, the top of the frame 9 is installed with an upper guide wheel 10, and the upper part of the frame 9 A kingpin shaft 12 is installed, and a main travel wheel 11 that can roll around the upper nozzle is installed on the kingpin shaft 12. The main travel wheel 11 is located in the frame 9; The front and rear sides are respectively installed with a front pressing mechanism 6 and a rear pressing mechanism 14 that can be locked when the human body falls. The steel pipe 15 is provided with a limit screw 7 for limiting the position of the front pressing mechanism 6. A tension spring fixing member 3 is fixed on the outer wall of the steel pipe 15, the tension spring fixing member 3 is located below the front pressing mechanism 6, and a tension spring 5 is connected between the tension spring fixing member 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com