Large-span welded ball net rack ground assembly integral lifting construction method

It is a technology of overall lifting and ground assembly, which is applied in the direction of architecture and building structure, etc., to achieve the effect of improving installation quality, saving labor and material costs, and ensuring safe construction

Pending Publication Date: 2021-03-26

CHINA MCC 2 GRP CO LTD

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] For this reason, the present invention provides a large-span welded ball grid grou

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Login to View More

Abstract

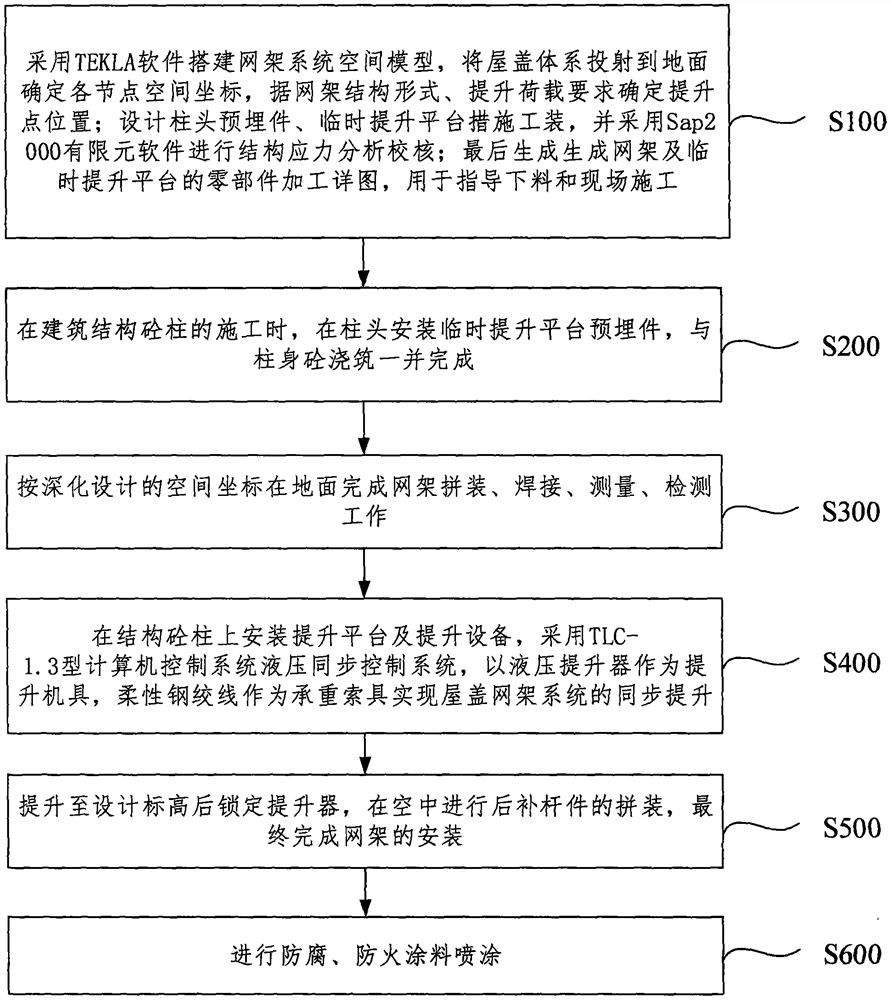

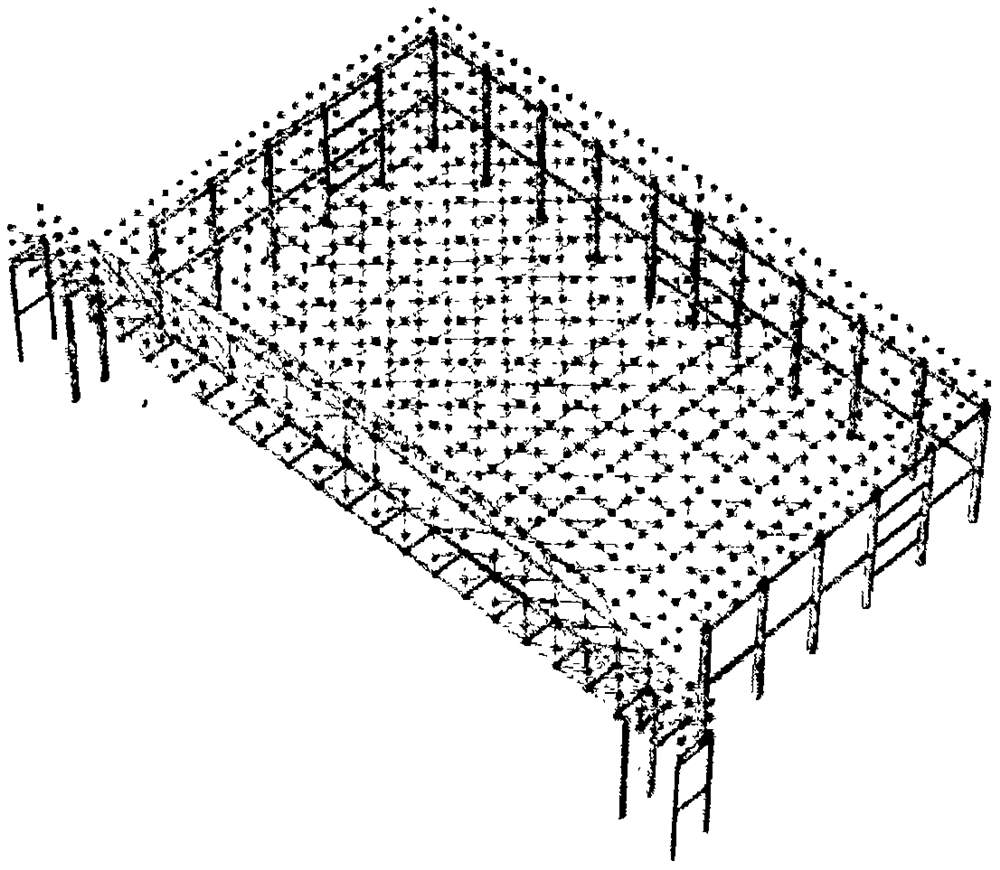

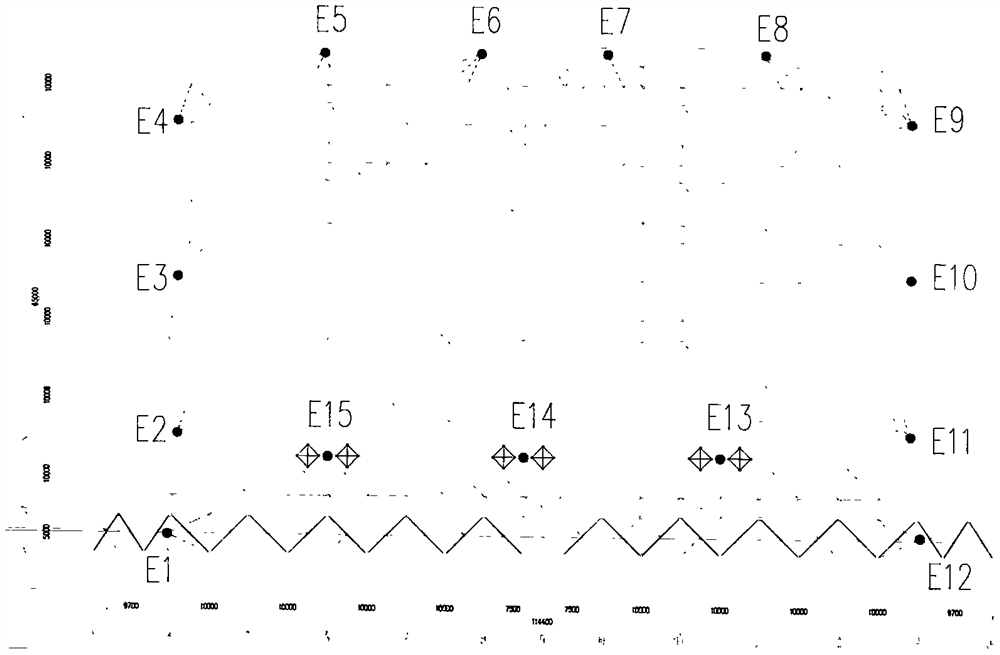

The invention discloses a large-span welded ball net rack ground assembly integral lifting construction method. The large-span welded ball net rack ground assembly integral lifting construction methodcomprises the steps that a roof system is projected to the ground to determine the space coordinates of all joints, and the position of a lifting point is determined according to the net rack structure form and the lifting load requirement; column head embedded parts are designed, and a platform measure tool is temporarily lifted; finally, a part machining detail drawing for generating a net rackand a temporary lifting platform is generated and used for guiding discharging and field construction; during construction of building a structural concrete column, a temporary lifting platform embedded part is installed on a column head, and pouring of the temporary lifting platform embedded part and column body concrete is completed together; net rack assembling, welding, measuring and detecting work is completed on the ground according to the space coordinates of the deepening design; a lifting platform and lifting equipment are installed on the structural concrete column, a hydraulic lifter serves as a lifting machine tool, and a flexible steel strand serves as a bearing rigging to achieve synchronous lifting of the roof net rack system; a lifter is locked after being lifted to the designed elevation, the rear supplementary rod pieces are assembled in the air, and finally installation of the net rack is completed; and an anti-corrosion and fireproof coating is sprayed.

Description

technical field [0001] The invention relates to the technical field of building construction, in particular to an overall lifting method for ground assembly of a large-span welded ball net frame. Background technique [0002] The large-span welded spherical grid structure is widely used in the roof load bearing of airports, gymnasiums, exhibition centers, etc. in recent years due to its novel and beautiful appearance, strong regularity of rods, good integrity, large space rigidity, and good seismic performance. structure; it is a new type of roof load-bearing structure, which belongs to the multi-time hyperstatic space structure system, which changes the stress state of the flat roof truss structure and can bear loads from all sides; due to various grid structure shapes, The installation methods are different for different spans; the traditional grid installation methods include the high-altitude bulk method of erecting a full house scaffolding, the overall hoisting method, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04B1/35

CPCE04B1/3511E04B2001/3577

Inventor 张宝平陈克温旭

Owner CHINA MCC 2 GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com