Pull rod installing layout method of airplane auxiliary power device

A technology of aircraft auxiliary power and layout method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as optimization and no layout, reduce structural weight, reduce vibration transmission, and meet the needs of layout optimization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

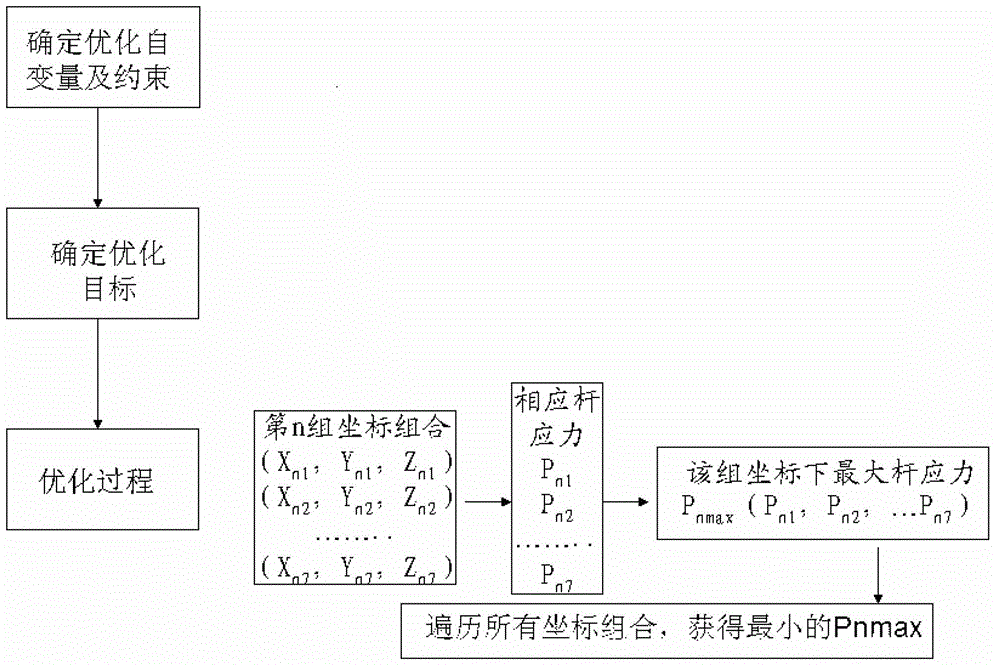

[0022] The present invention will be further explained below through specific embodiments in conjunction with the drawings:

[0023] The tie rod layout method of the aircraft auxiliary power device of the present invention uses engineering design software to carry out the parameterized modeling of the structure, and realizes the data transfer of the parameterized entity structure to the finite element analysis software under the call of the optimized process control program; in the finite element software Mesh the entities and apply conditions such as materials, constraints, and loads to the installation system, calculate the structural force or deformation of the rod system, and determine the optimal installation system based on the optimization goals such as system weight and manufacturability through the optimization process. Excellent structure.

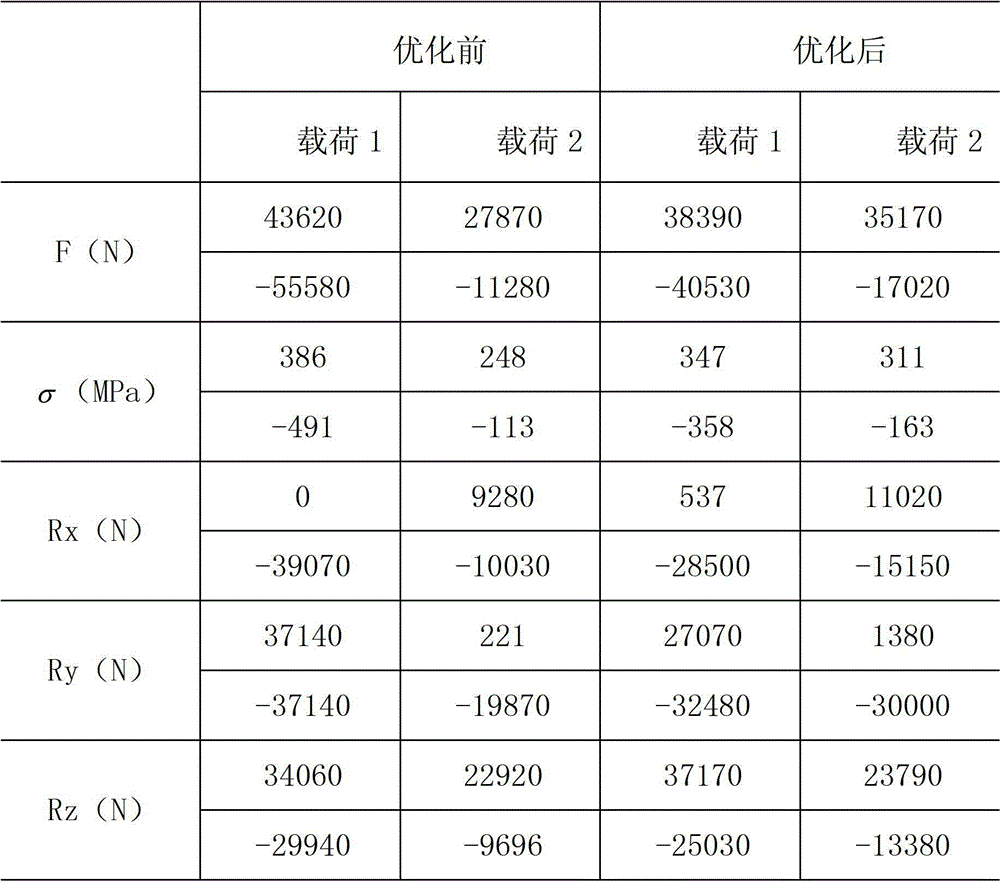

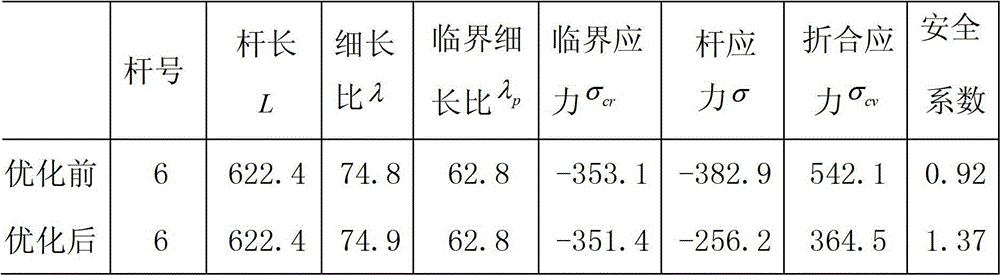

[0024] Now, taking a certain type of aircraft auxiliary power unit (APU) installation system as an example, the method for installin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com