Integral modular structure of industrial furnace and construction method

A modular and industrial furnace technology, applied in the direction of overall lining, furnace, furnace components, etc., can solve the problems of difficulty in ensuring construction continuity, high cost of safety measures, and long-term personnel stationing, so as to improve installation accuracy and overall construction level, The effect of reducing follow-up maintenance costs and manpower expenditure, reducing work intensity and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

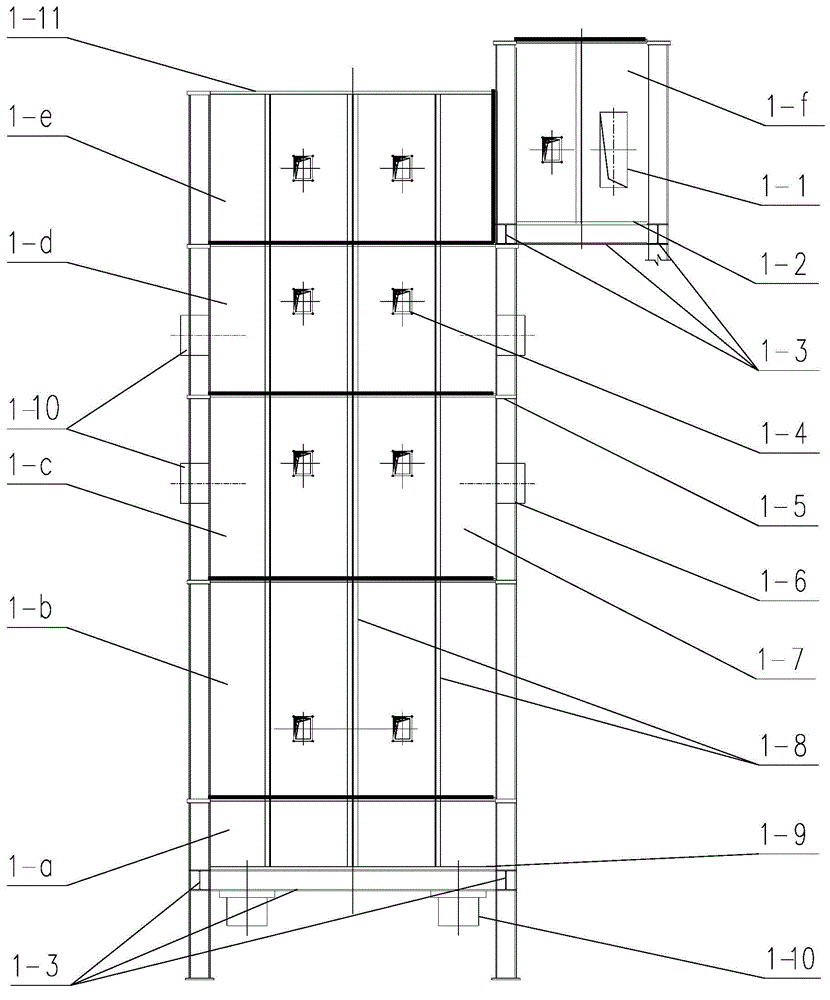

[0070] Radiation segment modular structure such as figure 1 As shown, along the horizontal and vertical directions of the radiation section, the radiation section is divided into six modules: module a, module b, module c, module d, module e, and module f.

[0071] Module a consists of four façade walls and a horizontal radiant section furnace bottom 1-9 consisting of five sides in total. Its steel structure consists of ten load-bearing columns 1-6, four load-bearing beams 1-3, connecting channel steel at the interface of the upper module, furnace wall plates 1-7 and furnace wall plate reinforced steel 1-8. The structure of the facade wall and the bottom lining of the horizontal radiant section are: heat insulation backing + heat insulation refractory bricks. The thermal insulation backing is a ceramic fiber product. The heat-insulating refractory brick is fixed to the furnace wall plate 1-7 by the anchor, and the anchor is welded on the furnace wall plate 1-7. Burners are i...

Embodiment 2

[0087] The modular structure of the radiation section is the same as that in Embodiment 1.

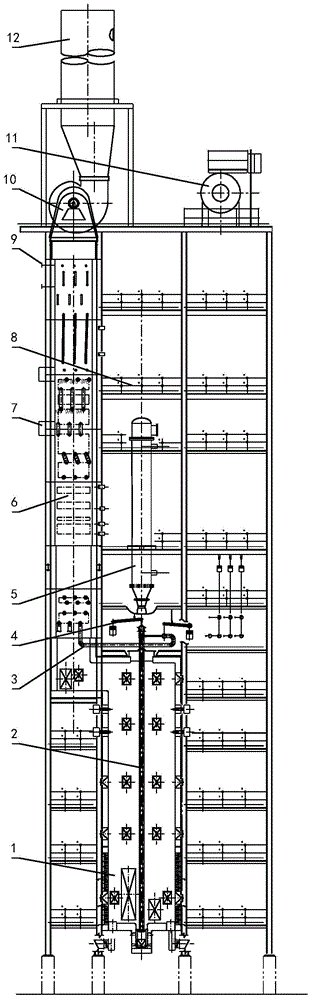

[0088] Such as image 3 As shown, limited by site construction conditions and transportation conditions, the height of the overall module of the industrial furnace is limited. The main part of the overall module of a single industrial furnace includes: radiant section 1, radiant furnace tube 2, spanning tube 3, radiant furnace tube And the support and suspension system 4 across the pipe, the convection section 6; the structure of the radiation section 1 is the same as that mentioned above, and the convection section 6 includes: steel structure, lining and its anchors, convection furnace tube, inspection door; the main part is in the workshop Complete fabrication and assembly.

[0089]Both ends of the steel structure load-bearing columns 1-6 on the surface of each module are provided with suitable column joints 1-5 that meet the load requirements. During on-site installation, the load-...

Embodiment 3

[0096] The modular structure of the radiation section is the same as that in Embodiment 1.

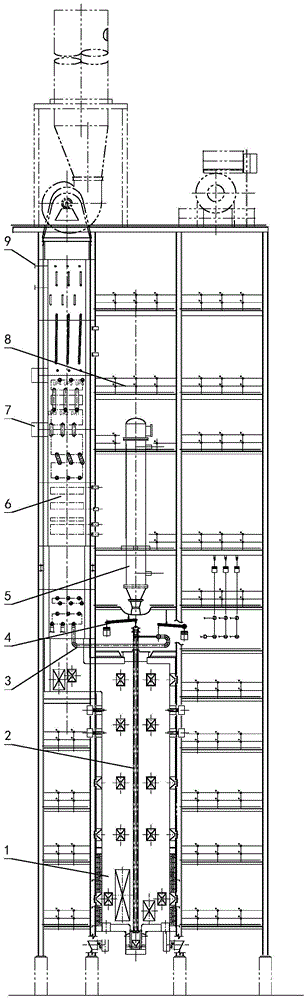

[0097] Such as Figure 4 As shown, considering the stability of the overall module of the industrial furnace, when transportation, installation and other conditions permit, two symmetrically arranged industrial furnaces are connected with a set of section steel to form an overall industrial furnace in the form of "pairing furnaces". module. The main parts of the two industrial furnaces include: radiant section 1, radiant furnace tube 2, spanning tube 3, support and hanging system 4 for radiant furnace tube and spanning tube, convection section 6 (including steel structure, lining and its anchors , convection furnace tube, inspection door), ancillary equipment and accessories include: waste heat boiler 5, soot blower 7, platform ladder 8, instrument and its cable 9, fan 10, steam drum 11, chimney 12 are all manufactured and processed in the workshop Assemble.

[0098] Both ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com