Mechanical hole forming construction method of rectangular slide-resistant pile

A technology of mechanical hole formation and construction method, which is applied in the direction of drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc., which can solve the problems of high construction cost, large ground disturbance, and high labor intensity, and achieve increased construction cost, The effect of fast hole forming speed and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation of the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

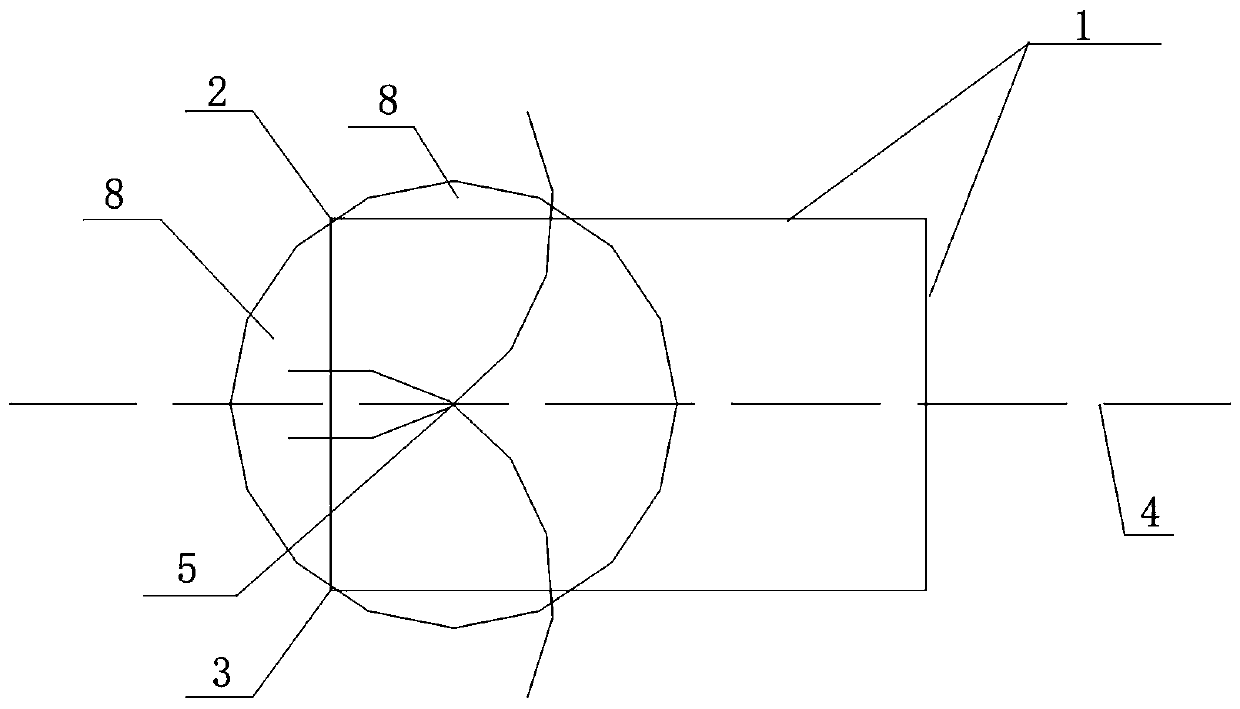

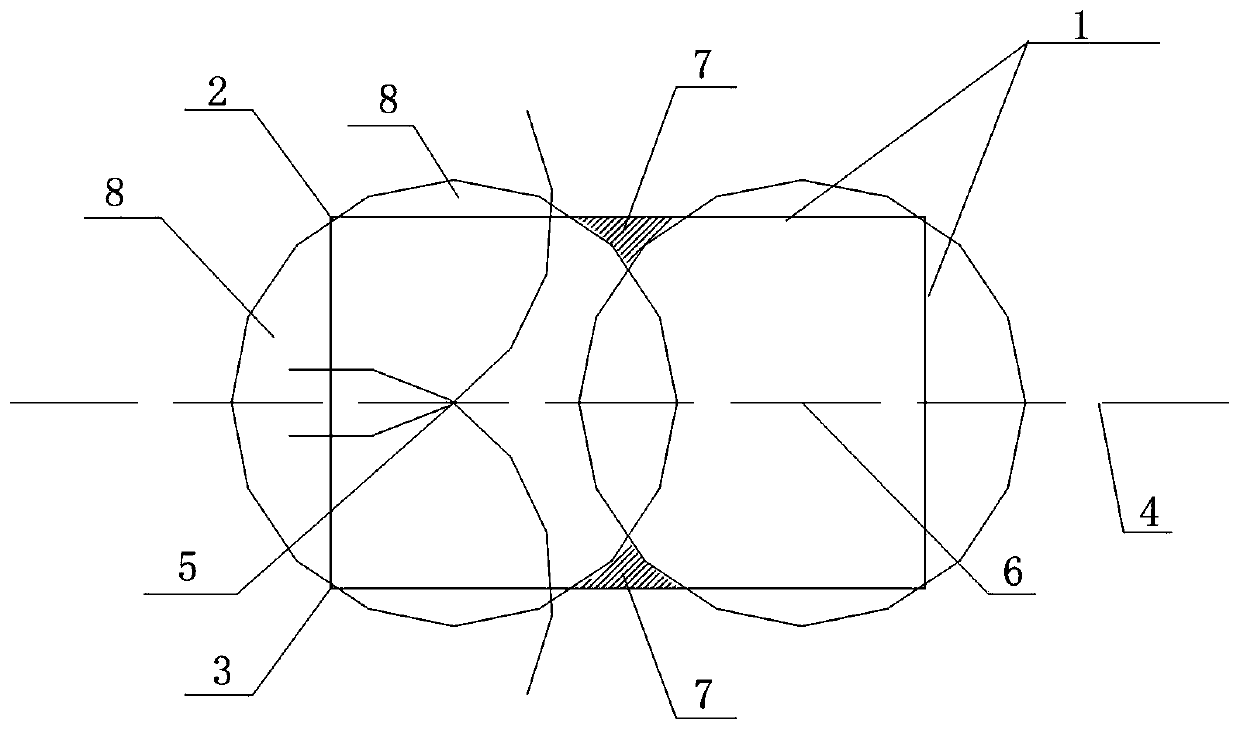

[0046] Taking the landslide prevention and control project as an example, the slope retaining structure is supported by a pile-slab retaining wall, and the pile foundation is a rectangular anti-slide pile with a size of 1.5m×2.4m. Construction method see figure 1 and figure 2 As shown, the following steps are generally included:

[0047] A. Rectangular pile hole positioning

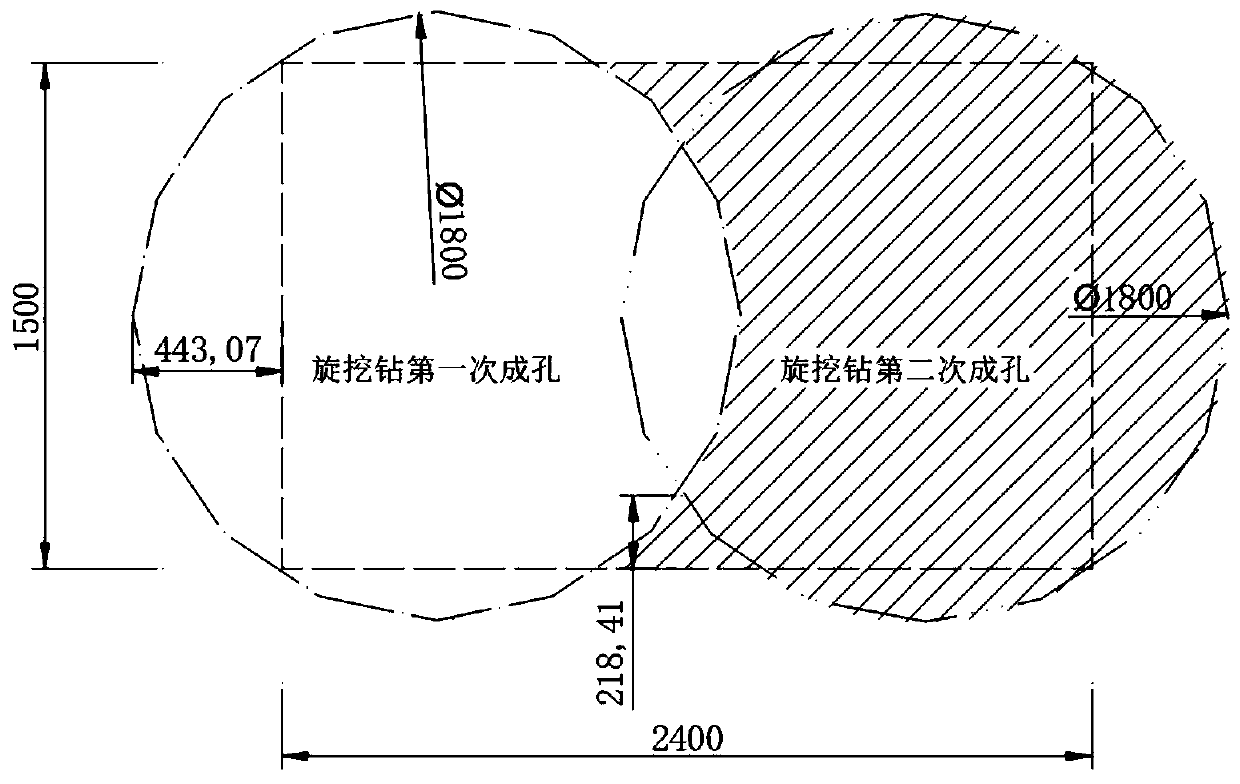

[0048] A.1 Determine the outline of the rectangular pile hole 1.5m×2.4m;

[0049] A.2 According to the length of the short side of the rectangular pile hole contour line is 1.5m, the diameter of the hole formed by medium or large rotary drilling rigs on the market is 0.8~2.5m (Note: if the diameter of the drill bit of the rotary drilling hole is 600mm, the actual The hole is 670mm), and the diameter of the drill bit of the rotary pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com