Red sandstone surface modified polyurethane material smeared in water level variation zone and preparation method thereof

A polyurethane material and surface modification technology, which is applied in the field of materials, can solve problems such as unsuitable reinforcement, water pollution, water quality, and soil environmental pollution, and achieve the effects of improving anti-aging ability, improving water resistance, and inhibiting deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

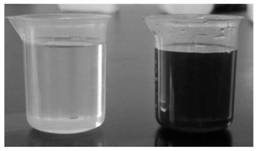

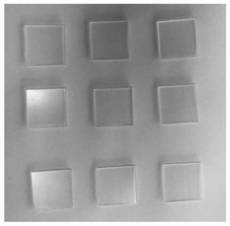

Method used

Image

Examples

Embodiment 1

[0040] A modified polyurethane material for water insulation and reinforcement applied on the surface of red sandstone in the water level amplitude band. The material includes components A and B, and the volume ratio of components A and B is 1:1;

[0041] Part A contains the following components:

[0042] Sodium silicate solution: 40 parts;

[0043] Catalyst: 5 parts;

[0044] Plasticizer: 5 parts;

[0045] Nano titanium dioxide: 10 parts;

[0046] Component B includes the following components:

[0047] Diisocyanate (MDI): 60 parts;

[0048] Polypropylene glycol (PPG): 30 parts;

[0049] Water repellant: 15 parts.

[0050] Preferably, the sodium silicate solution: the Baume degree is 35-50°, and the modulus is 2.0-3.0.

[0051] Preferably, the catalyst is triethylamine or dibutyltin dilaurate or a combination thereof.

[0052] Preferably, the plasticizer is dibutyl phthalate or dioctyl phthalate or triphenyl phosphate or a combination thereof.

[0053] Preferably, the...

Embodiment 2

[0057] A modified polyurethane material for water insulation and reinforcement applied on the surface of red sandstone in the water level amplitude band. The material includes components A and B, and the volume ratio of components A and B is 1:1;

[0058] Part A contains the following components:

[0059] Sodium silicate solution: 50 parts;

[0060] Catalyst: 5 parts;

[0061] Plasticizer: 5 parts;

[0062] Nano titanium dioxide: 20 parts;

[0063] Component B includes the following components:

[0064] Diisocyanate (MDI): 40 parts;

[0065] Polypropylene glycol (PPG): 30 parts;

[0066] Waterproofing agent: 25 parts.

[0067] Preferably, the sodium silicate solution: the Baume degree is 35-50°, and the modulus is 2.0-3.0.

[0068] Preferably, the catalyst is triethylamine or dibutyltin dilaurate or a combination thereof.

[0069] Preferably, the plasticizer is dibutyl phthalate or dioctyl phthalate or triphenyl phosphate or a combination thereof.

[0070] Preferably,...

Embodiment 3

[0074] A modified polyurethane material for water insulation and reinforcement applied on the surface of red sandstone in the water level amplitude band. The material includes components A and B, and the volume ratio of components A and B is 1:1;

[0075] Part A contains the following components:

[0076] Sodium silicate solution: 60 parts;

[0077] Catalyst: 5 parts;

[0078] Plasticizer: 5 parts;

[0079] Nano titanium dioxide: 30 parts;

[0080] Component B includes the following components:

[0081] Diisocyanate (MDI): 40 parts;

[0082] Polypropylene glycol (PPG): 30 parts;

[0083] Waterproofing agent: 25 parts.

[0084] Preferably, the sodium silicate solution: the Baume degree is 35-50°, and the modulus is 2.0-3.0.

[0085] Preferably, the catalyst is triethylamine.

[0086] Preferably, the plasticizer is dibutyl phthalate.

[0087] Preferably, the volume percentage content of the diisocyanate (MDI) (isocyanate group) is 25-29%.

[0088] Preferably, the polyp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com