Patents

Literature

44 results about "Witherite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Witherite is a barium carbonate mineral, BaCO₃, in the aragonite group. Witherite crystallizes in the orthorhombic system and virtually always is twinned. The mineral is colorless, milky-white, grey, pale-yellow, green, to pale-brown. The specific gravity is 4.3, which is high for a translucent mineral. It fluoresces light blue under both long- and short-wave UV light, and is phosphorescent under short-wave UV light.

SCR denitration catalyst and preparation method thereof

ActiveCN101185886AImprove structural stabilityImprove mechanical stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSilanesAmmonium paratungstate

The invention relates to a preparation method of an SCR denitration catalyst, which comprises the following steps: (1) Al2O3 sol is prepared, which comprises the steps that hot ammonia, the Al2O3 is added in drops into the ammonia and then HCI is added and the mixture is stirred; (2) Al2O3-SiO2-TiO2 composite sol is prepared, which comprises the steps that tetratethoxy-silane, butyl titanate, deionized water are sequentially put into ethanol to be aging and then the sol prepared by step (1) is adding to be stirred and aging; (3) vector is coated, which comprises the steps that cordierite honeycomb immersed into the sol of step (2) and the raffinate in a channel is cleaned, dried and roasted after being taken out; (4) active component impregnating solution is prepared, which comprises the steps that lanthanum nitrate, ammonium metavanadate and ammonium paratungstate are dissolved into the deionized water after being mixed together and oxalate acid is added to be aging; (5) the active component is loaded, which comprises the steps that the vector of the step (3) is immersed into the impregnating solution of the step (4) and then the raffinate in the channel is cleaned to be dried and roasted. The invention also relates to the denitration catalyst which is prepared by the method.

Owner:山西蒲洲博奇环保科技有限公司

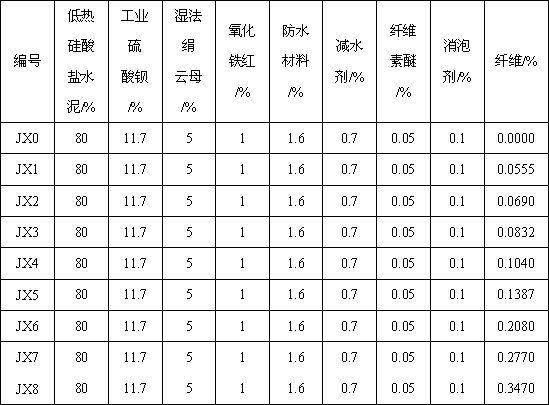

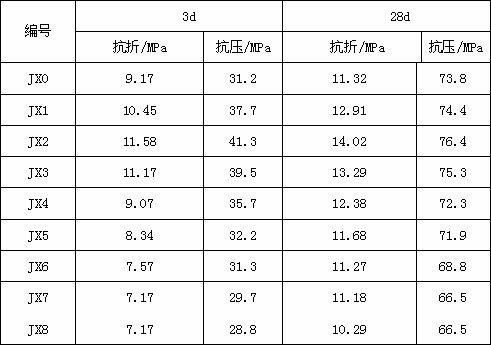

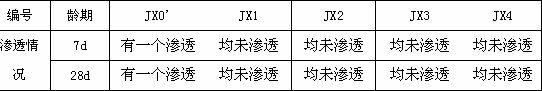

Anti-seepage and anti-crack dry-mixed mortar

The invention discloses anti-seepage and anti-crack dry-mixed mortar which is characterized by comprising the following components in percentage by weight: 20-90% of cement, 2-40% of barium ore, 1-30% of wet sericite powder, 0.05-5% of waterproofing mortar additive, 0-5% of iron oxide red and 0.01-5% of fiber, wherein the barium ore is one of or a mixture of more than two of witherite, industrialbarium carbonate, barite or industrial barium sulfate. In the mortar, the barium ore is used as an element material and has a strong capability of obstructing absorption of ray, the fiber is capable of effectively improving the toughness, ductibility, abrasive resistance, stripping resistance, impact resistance, fatigue resistance, anti-seepage and anti-crack property and freezing and thawing resistance, and the waterproofing material is capable of effectively improving the seepage resistance and the like of concrete. The anti-seepage and anti-crack dry-mixed mortar which is provided by the invention can be widely applied to civil buildings, has the advantages of low cost, wide raw material sources and good anti-seepage and anti-crack property and is easy to construct.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

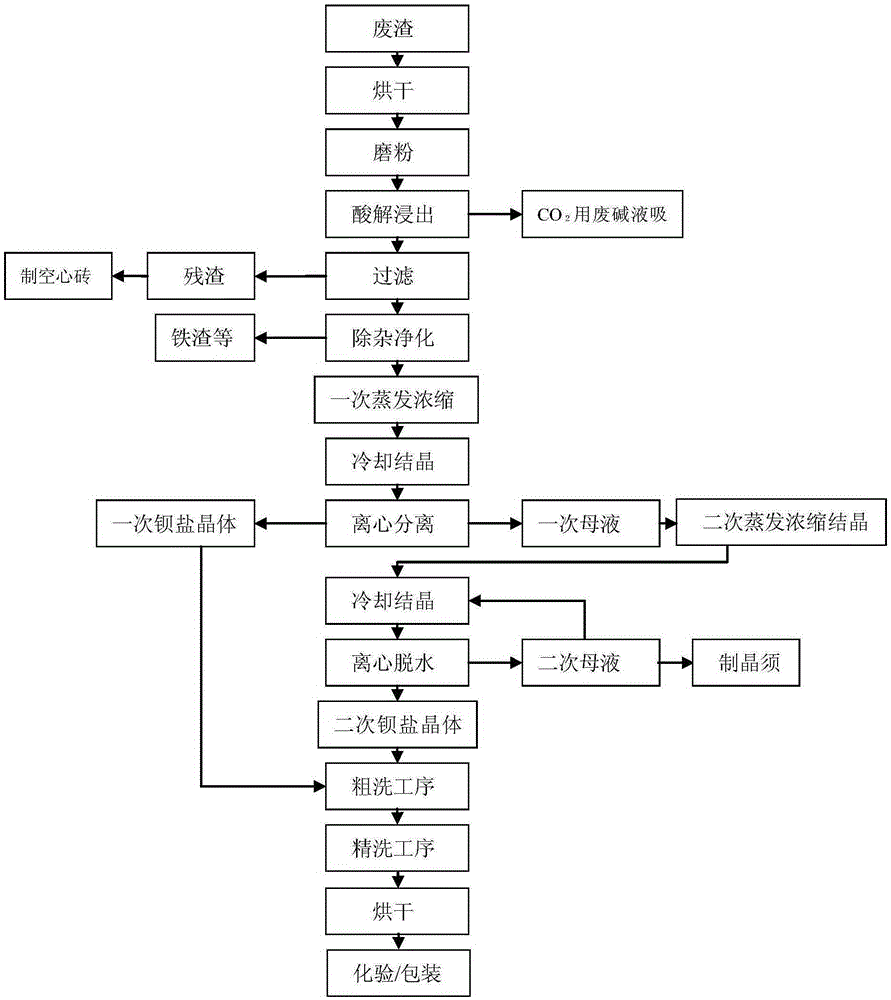

Method for preparing high-purity barium salt by using witherite-barytocalcite industrial waste residues

InactiveCN105271347ARealize deep purificationAchieving a green circular economyCalcium/strontium/barium chloridesSolid waste disposalBarium saltEvaporation

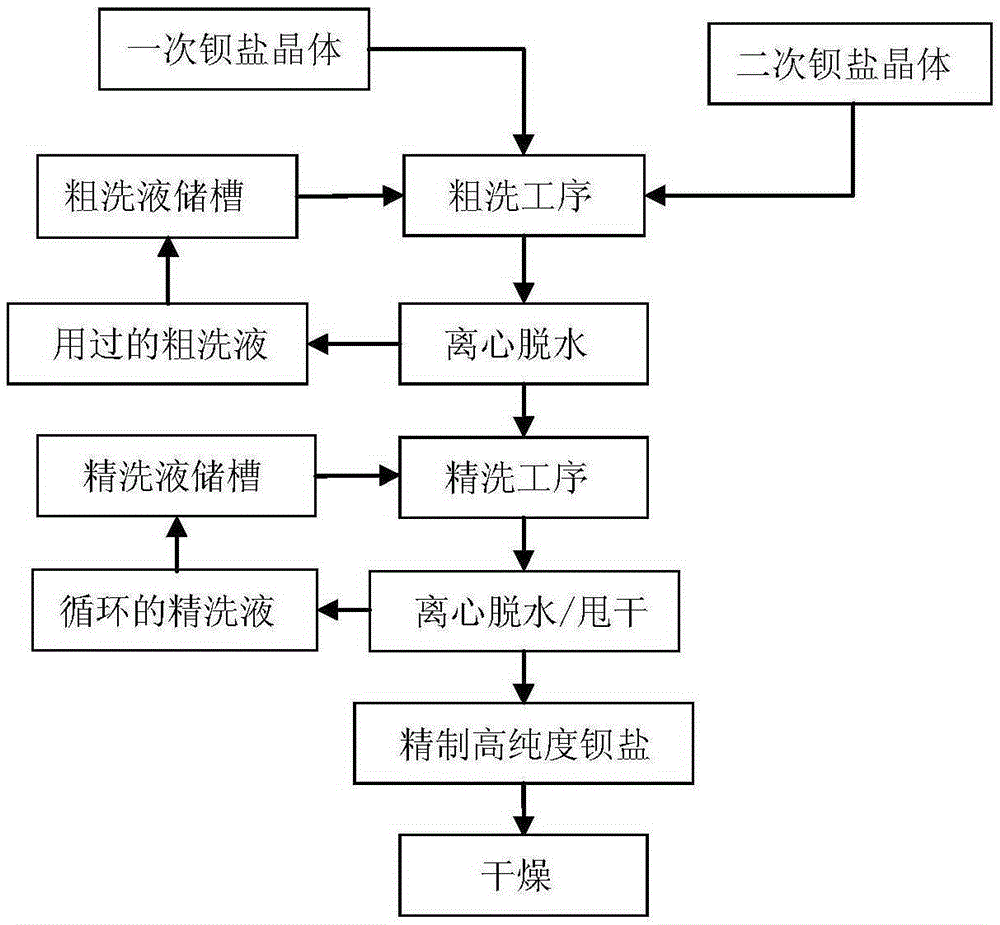

The invention discloses a method for preparing high-purity barium salt by using witherite-barytocalcite industrial waste residues. The method comprises a crushing and grinding procedure, an acid hydrolysis and leaching procedure, an impurity removal and purification procedure, an evaporation, concentration and crystallization procedure, a coarse washing procedure, a fine washing procedure and a drying, testing and packaging procedure. The barium salt with the high product purity and the low impurity content can be prepared with the method, and barium can be recovered efficiently. Meanwhile, high-temperature operation is not required by the whole-wet technology adopted in the method, reaction conditions are mild, the energy consumption is low, three-waste emission is low, thus, clean production and comprehensive utilization in the witherite-barytocalcite industrial waste residue deep-processing field can be further realized, and the economic benefit and the environmental benefit are significant.

Owner:CHONGQING CHUANYU MINING IND CO LTD

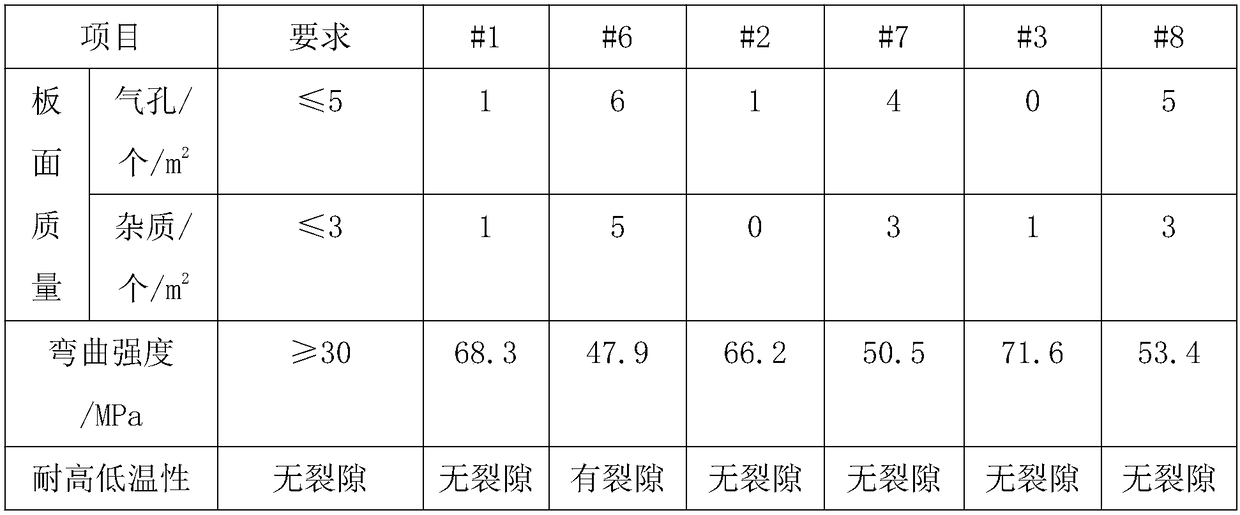

Anti-thermal shock iolite fireproof kiln furniture and preparation method thereof

The invention relates to an anti-thermal shock iolite fireproof kiln furniture and a preparation method thereof. The fireproof kiln furniture comprises the raw materials of 25-37% of a matrix, 50-56% of an aggregate, 4-5% of a sintering agent and 9-14% of a fiber reinforced material, wherein the matrix is composed for 15-25% of kyanite fine powder, 15-25% of kaolin fine powder, 48-69% of and alusite fine powder, and 1-2% of magnesia fine powder, and the aggregate is composed for 60-75% of gangue and 25-40% of high bauxitic clay clinker. In the prepared fireproof material, acicular iolite and cylindrical mullite are interlaced to a net state, the particles are in a free state with uniform size, the matrix and the particles have a certain buffer area, a certain stress is absorbed, and crack dynamic expansion is avoided. An iolite-mullite multiphase is generated in the fireproof product, synchronous increase of flexural intensity and compression strength can be satisfied, and the heat stability of the final product is increased.

Owner:HENAN UNIV OF SCI & TECH

Composite molten steel refining additive

This invention provides a molten steel composite refining additive. The said additive by wt.% includes aluminium ash 10-50% (aluminium content at least being 15% of ash wt.), metallurgical furnace slag 10-60%, carbide 5-65%, limestone 1-10% and witherite 1-10%. This additive is used for the oxidable slag tapping process of steel smelting furnace such as electric furnace, converter, etc. and for refining furnace to make the oxidable molten steel proceed polybasic composite oxygen removal, sulphur removal and quick deoxidated impurity inclusion removal, and at the same time, it enhances quick dissolution of added slagging material and quick slag forming.

Owner:重庆工业高等专科学校

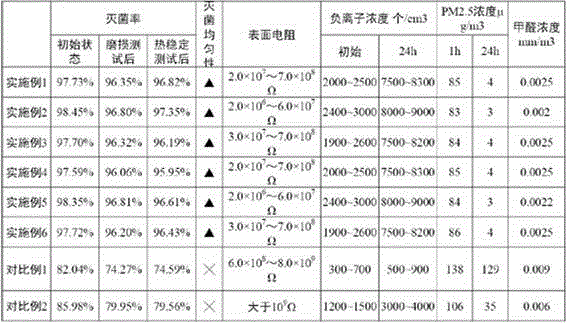

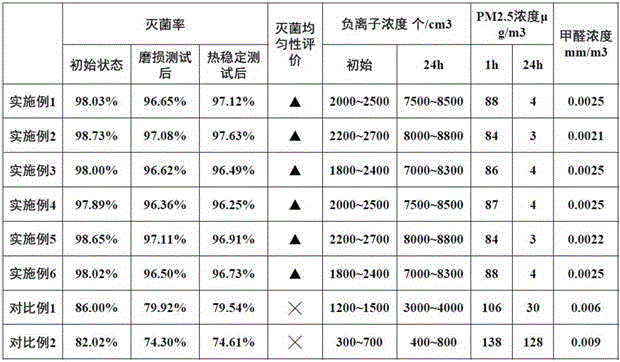

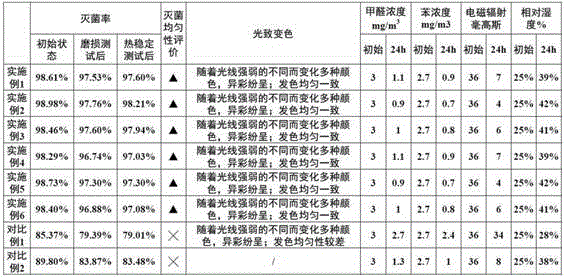

Antistatic health care ceramic and preparation method thereof

The invention discloses an antistatic health care ceramic and a preparation method thereof. The preparation method comprises the steps of: A, preparation of glaze slurry: by mass percentage, mixing 10-15% of zinc oxide, 0.4-0.5% of barium carbonate, 0.3-0.4% of talc powder, 58-65% of borax, 10-12% of silicon oxide, 12-20% of boron oxide, and 2-7% of a functional agent to obtain mixed powder, adding alumina ball-milling balls and distilled water, and performing ball milling; then adding tourmaline and cordierite, further performing ball milling, and controlling the slurry at 300-350 mesh, thus obtaining a glaze slurry, wherein the tourmaline and cordierite respectively account for 3-8% and 1-5% of the mass of the mixed powder; B, glaze slurry impregnation: impregnating ceramic in the glaze slurry, and then performing first firing; and C, glaze slurry spraying: spraying glaze slurry and conducting second firing, thus obtaining health care ceramic. Compared with existing ceramic, the ceramic prepared by the method provided by the invention has the characteristics of scientific compounding, reasonable preparation, and stable performance, does not contain lead, cadmium or other extremely toxic substances, and also has uniform and lasting spectral antimicrobial characteristics, air purification and antistatic functions, thus further broadening the application scope of the ceramic.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Antibacterial negative ion health care ceramic and preparation method thereof

The invention discloses an antibacterial negative ion health care ceramic and a preparation method thereof. The preparation method comprises the steps of: A, preparation of glaze slurry: by mass percentage: mixing 10-15% of zinc oxide, 0.4-0.5% of barium carbonate, 0.3-0.4% of talc powder, 58-65% of borax, 10-12% of silicon oxide, 12-20% of boron oxide and 3-8% of a functional agent to obtain mixed powder, adding alumina ball-milling balls and distilled water, and performing ball milling; then adding tourmaline and cordierite, further conducting ball milling, and controlling the slurry at 300-350mesh to obtain the glaze slurry, wherein, the tourmaline and cordierite respectively account for 3-8% and 1-5% of the mass of the mixed powder; B, glaze slurry impregnation and first firing; and C, glaze slurry spraying and second firing, thus obtaining health care ceramic. Compared with the existing ceramics, the ceramic prepared by the method provided by the invention has the advantages of scientific compounding, reasonable preparation, stable performance, and no lead, cadmium or other extremely toxic substances, and also has uniform and lasting spectral antibacterial properties and air purification function, thus further broadening the application scope of the ceramic.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

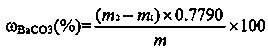

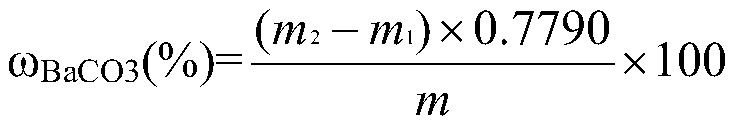

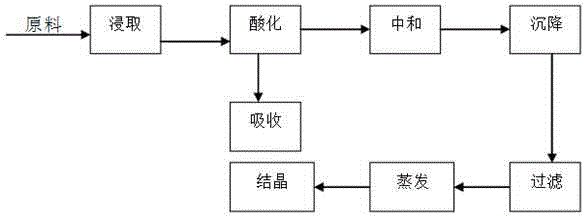

Method for detecting content of barium carbonate in witherite

InactiveCN110095373AEliminate the effects ofImprove stabilityMaterial analysis by observing effect on chemical indicatorMaterial weighingSediment FilterBarium sulfate

The invention discloses a method for detecting the content of barium carbonate in witherite. The method comprises steps of sample preparation, reagent and solution preparation, barium sulfate sedimentremoving, barium chromate sediment generation, barium chromate sediment filtering and drying, and analysis result calculation and the like. The detecting method has a large detection range; influences on the detection result by impurities like barium sulfate, silicate and calcium carbonate can be eliminated effectively; the detection result has high stability, reproducibility and accuracy; and the detecting method is simple and is easy to learn and no high requirement on the analysis staff is needed. The method has the broad application prospects and has the important significance in evaluating the witherite quality grade and omprehensive application.

Owner:玉溪新兴钢铁有限公司

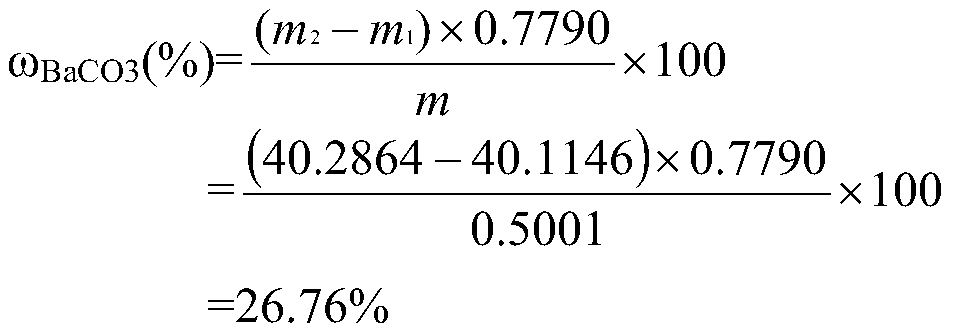

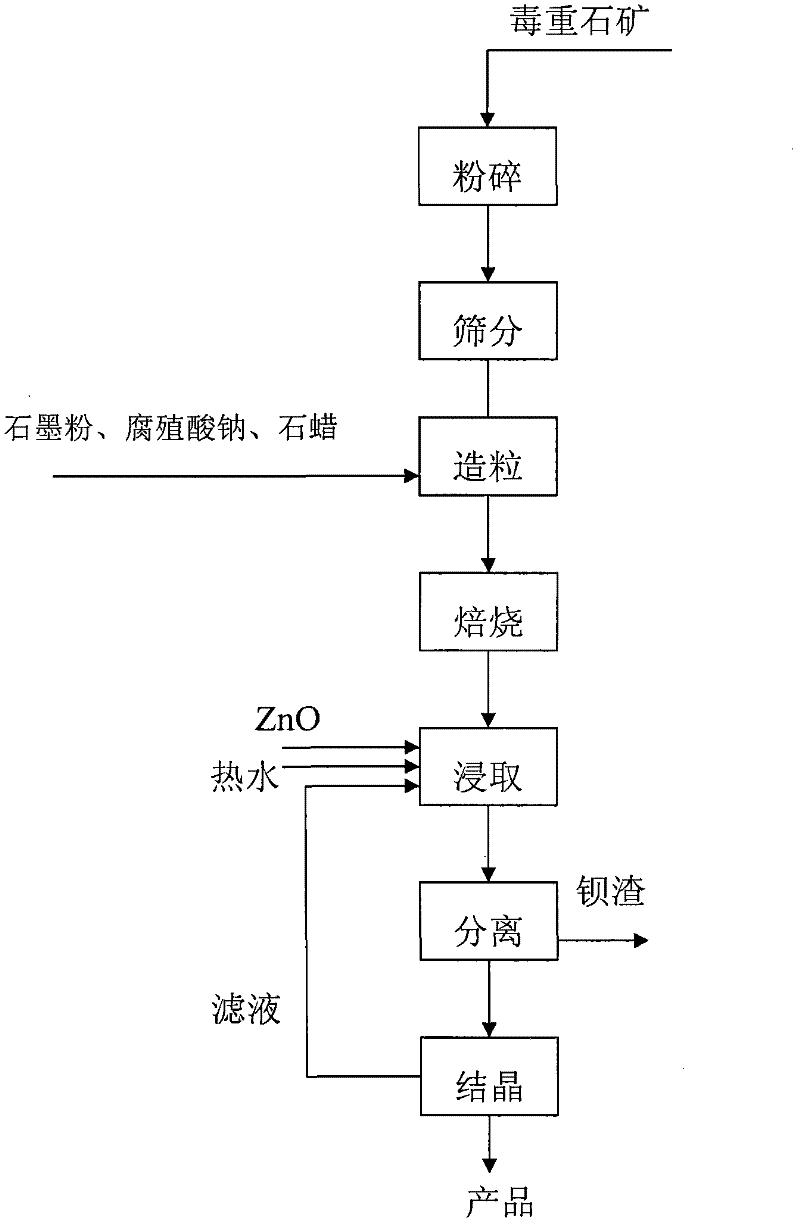

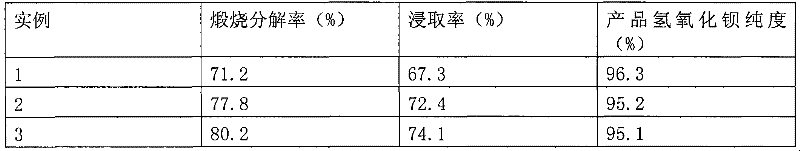

Method utilizing witherite to prepare barium hydroxide octahydrate

InactiveCN102583480AImprove decomposition efficiencyComposition is stable and controllableCalcium/strontium/barium oxides/hydroxidesSlagImpurity

The invention relates to a method utilizing witherite to prepare barium hydroxide octahydrate and belongs to the technical field of fine chemical engineering. The method utilizes witherite to serve as a raw material, witherite slag is sieved after grinding, the grain size is controlled at 120 mesh>50-80%, 8-15% of graphite powder, 1-2% of sodium humate and 2-3% of paraffin are added into the witherite, and pelletizing is performed through a pelletizer. After the grains are dry and hard, the grains are placed in a corundum boat and roasted for 2-3h at 1,000-1,200 DEG C, and the roasted grains are cooled to 500-700 DEG C, placed in hot water at 85-95 DEG C and soaked for 1-2h according to the solid-to-liquid ratio 1:(6-10). After desulfurization, material liquid is concentrated and crystallized so that a barium hydroxide product is obtained, and filtrate returns to a leaching tank to be recycled. Compared with other methods, the method enables thermal decomposition efficiency of witherite to be high, enables water leaching rate to be high, enables the product to be subjected to little influence of impurities in an additive, enables discharged solid residue to be little, and has a certain advantages.

Owner:CHONGQING UNIV OF ARTS & SCI

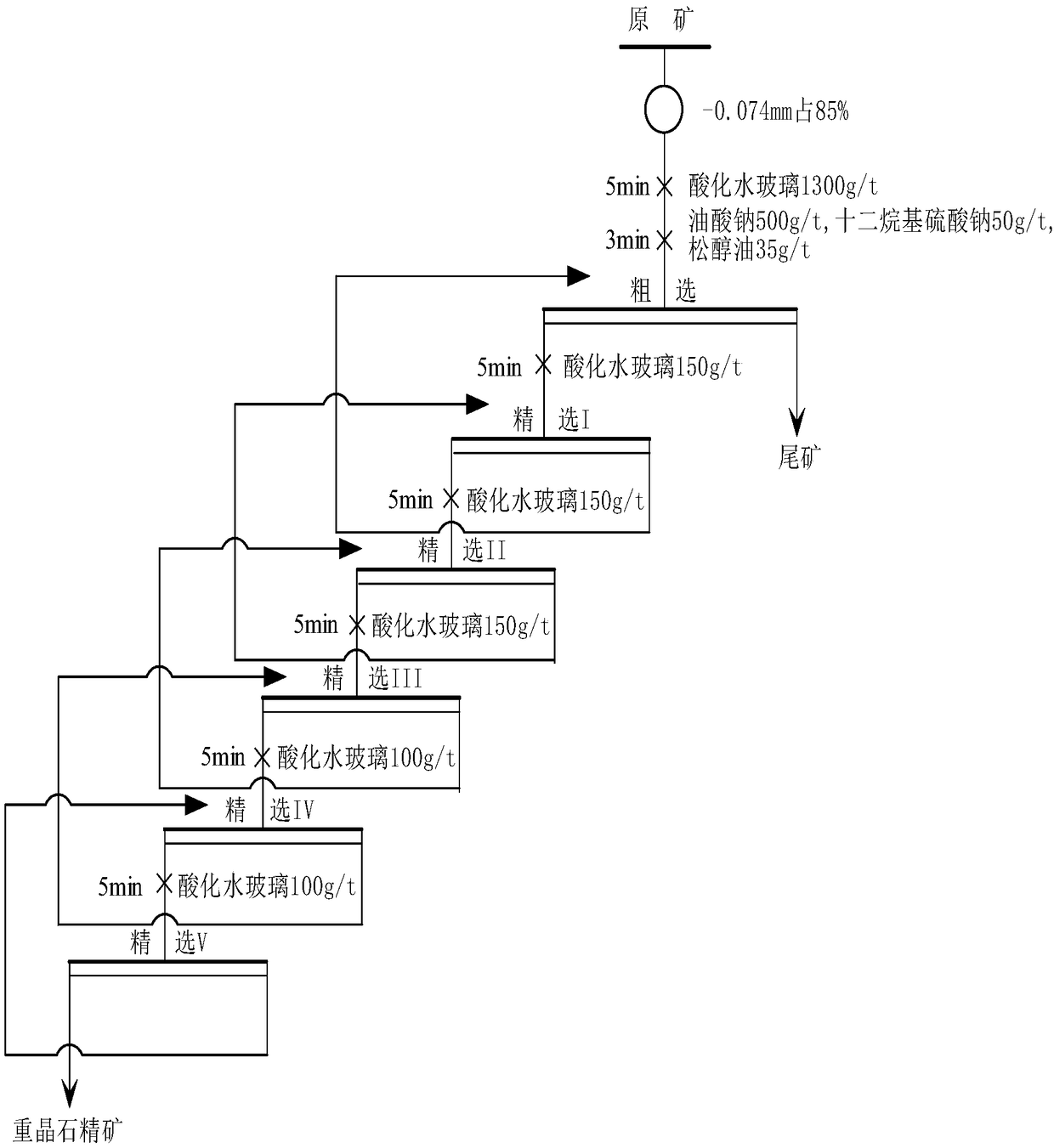

Beneficiation method for barite rich in calcite and witherite

The invention provides a beneficiation method for barite rich in calcite and witherite. According to the beneficiation method, the problem that the quality of flotation concentrate is poor due to thefact that the floatability of gangue minerals such as the calcite and fluorite is similar to that of the barite is solved. The beneficiation method is characterized in that acidified sodium silicate is adopted for inhibition and dispersion so that separation of the barite from the gangue minerals can be well realized; and a combined collecting agent composed of sodium oleate and sodium dodecyl sulfate is selected, so that relatively strong collecting capacity and good selectivity on the barite and the witherite are realized. According to the beneficiation method, barite concentrate with the relatively high recovery rate can be obtained, the quality of the concentrate meets the requirements of national standard first-grade products of drilling grade barite powder, and the barite ores rich in the calcite and the witherite can be developed and utilized.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Method for treating uranium purified radioactive waste water

ActiveCN108182983AFully removedAchieve recyclingRadioactive decontaminationWater dischargeAdditive ingredient

The invention relates to a method for treating radioactive waste water, in particular to a comprehensive method for treating uranium purified radioactive waste water. The method is the standard-achieving discharge processing of high-salt radioactive waste water containing uranium ions generated in the production process of uranium purifying, and the method is particularly suitable for the waste water discharged in the uranium purifying production process of nitric acid dissolving, organic solvent extracting and ammonium carbonate refining. According to the method, the uranium ions are thoroughly condensed and filtered based on special ingredients of witherite and the three-stage purifying technology process, wherein a large number of uranium ions are removed by neutralization and condensation through the witherite in an acid environment in the first stage of purifying, the uranium ions can be condensed under the actions of flocculent settling, ion absorption and like by adding the witherite or industrial barium carbonate in a neutralized environment in the second stage, and at the moment radioactive elements such as the uranium ions and the like are thoroughly removed by adding alkaline sodium carbonate to ensure that the solution is under an alkaline environment in the third stage.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP +1

Preparation method of automobile tail gas purifying catalyst

InactiveCN102941089ALarge specific surface areaImprove conversion rateMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateRare earth

The invention discloses a preparation method of an automobile tail gas purifying catalyst, relating to a preparation method of a catalyst. The method disclosed herein comprises the following steps: adding pseudo-boehmite to decationized water, uniformly stirring at room temperature, then adding diluted hydrochloric acid to adjust the pH value to 5-6, aging for 1h at room temperature, drying at 130 DEG C, and roasting at 650 DEG C for 2h to obtain alumina; saturatedly dipping the alumina in a lanthanum nitrate, cerium nitrate and zirconium oxychloride solution, wherein the molar ratio of CeO2 to ZrO2 is 1:1; drying at 130 DEG C, and roasting at 950 DEG C for 2h to obtain rare earth composite alumina; saturatedly dipping the rare earth composite alumina in a Pt, Rh noble metal solution, drying at 130 DEG C and roasting at 650 DEG C for 2h, then adding decationized water and uniformly stirring for 30min to obtain a catalyst slurry, and coating on a 65 pore / cm<2> iolite cellular carrier. The gamma-Al2O3 prepared by the method has high specific surface area and large pore volume, low ignition temperature, wide air-fuel ratio window and high conversion rate.

Owner:SHAANXI HI TECH ENERGY DEV

Method for preparing barium ferrite by directly utilizing low-grade witherite as raw material

InactiveCN109485099ASave time and cost of manpower and material resourcesLow costIron compoundsCalcinationWitherite

The invention discloses a method for preparing barium ferrite by directly utilizing low-grade witherite as a raw material. A barium ferrite product is synthesized by taking low-grade witherite as a raw material and adopting technological means such as wet-process mineral leaching, reasonable liquid preparation, chemical coprecipitation synthesis and high-temperature calcination. According to the method, the mass ratio of witherite and hydrochloric acid in a leaching process is 1:1 to 1:5, the solid-to-liquid ratio (g / ml) of witherite to water is 1:2 to 1:9, the leaching temperature is 30-90 DEG C, and the leaching time is 1-6 h; the pH range in a precipitation process is 8-12; the calcination temperature in the calcination process is 700-1400 DEG C, and the calcination time is 1-6 h. The local low-grade witherite is sufficiently utilized while the barium ferrite product with a high additional value is prepared, so that high social and economic benefits are achieved. Compared with an existing technology for preparing barium ferrite, the method has the advantages that not only is the advantage of magnetic property retained, but also various defects are overcome, so that the total preparation cost is relatively low.

Owner:城口县生产力促进中心 +1

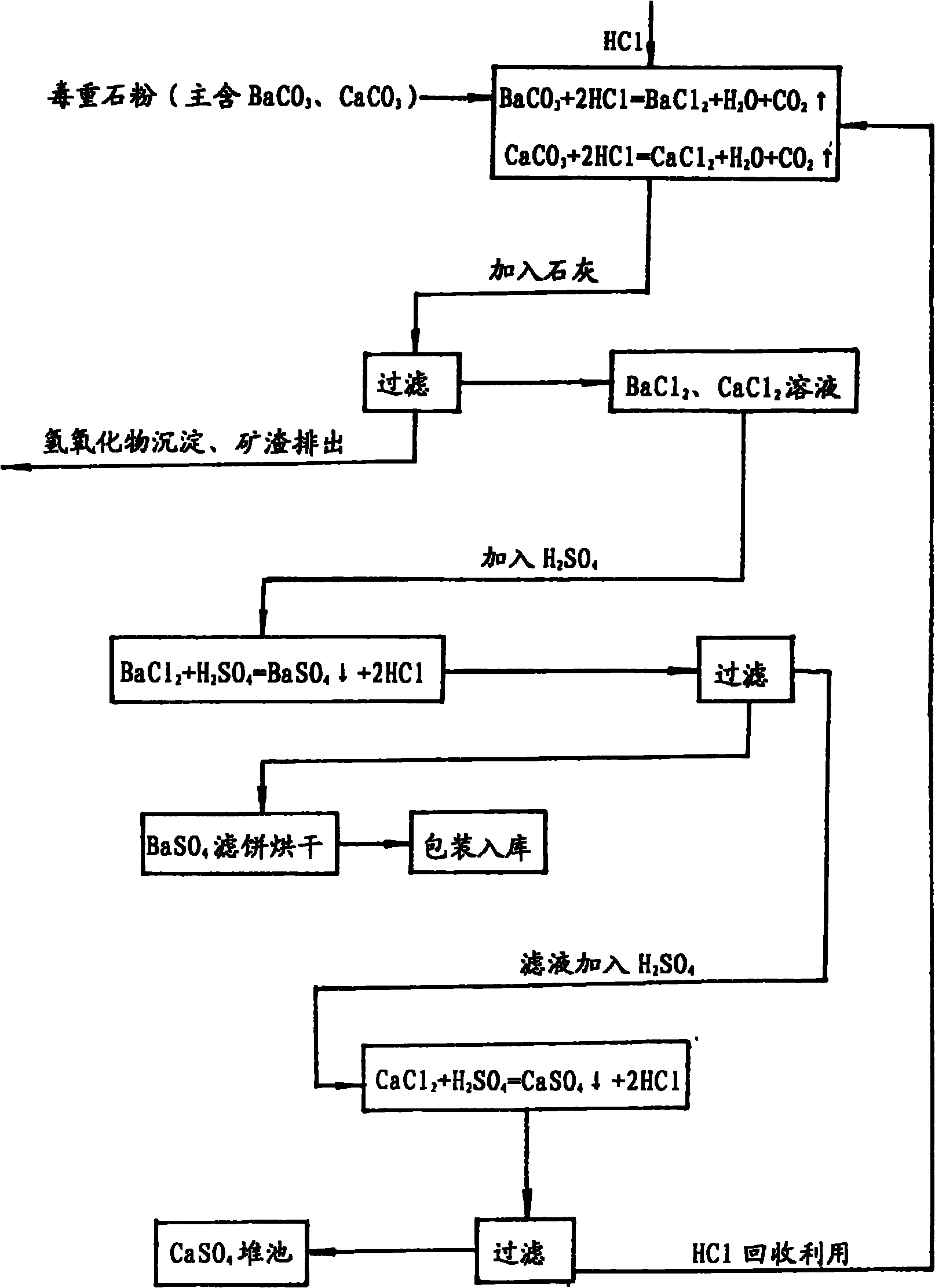

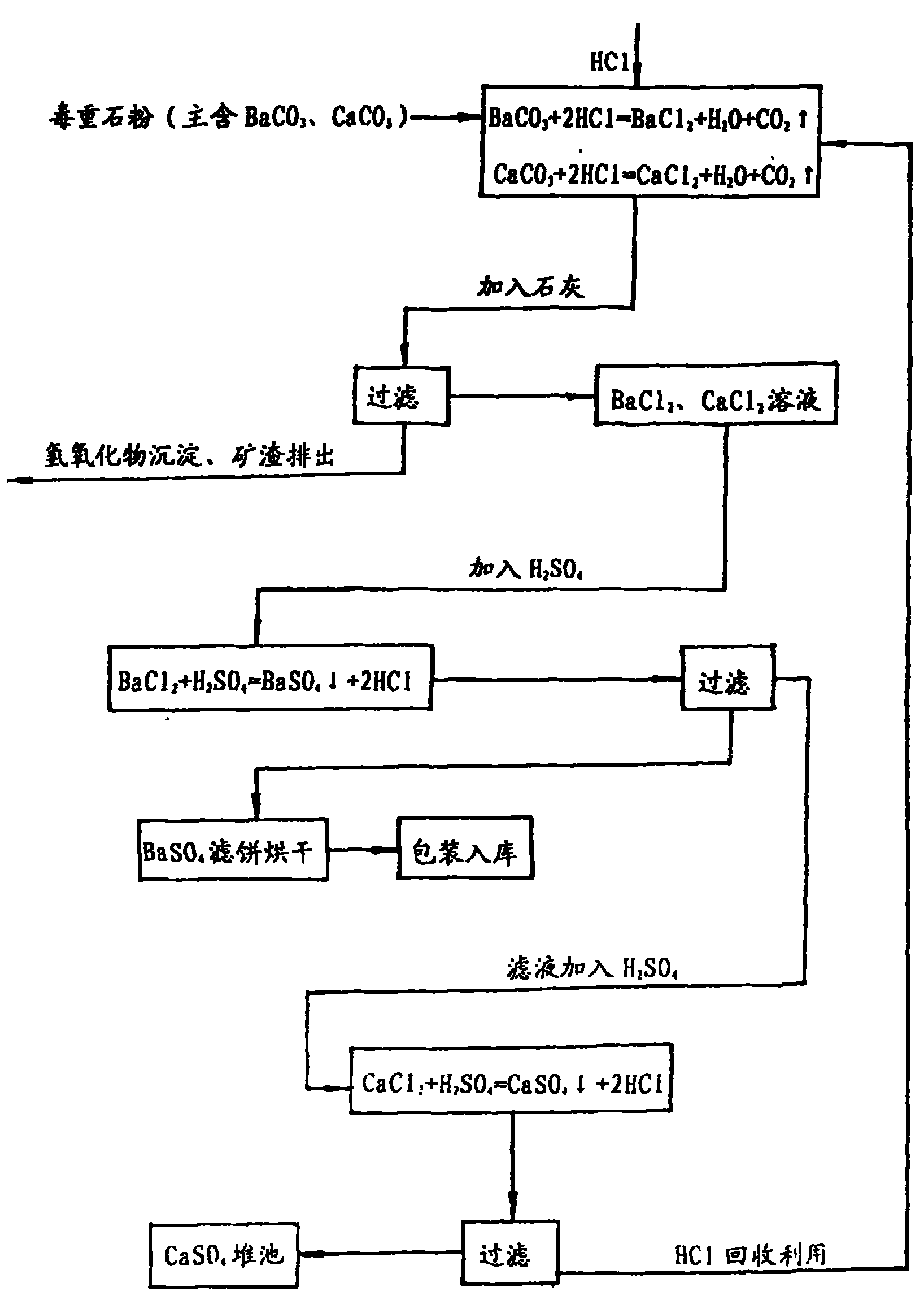

Technology for preparing barium sulfate by witherite

InactiveCN101941729ANo energy consumptionQuality improvementCalcium/strontium/barium sulfatesEconomic benefitsBarium sulfate

The invention relates to a technology for preparing barium sulfate by witherite, which comprises the following steps: mixing the witherite with hydrochloric acid for reaction, adding alkali to cause heavy metal ions in the obtained solution to react with the alkali to generate precipitation of hydroxide, filtering and separating to remove insoluble impurities so as to obtain the solution containing Ba2+ and Ca2+, adding sulfuric acid in accordance with Ba2+ content in the solution to separate out all Ba2+ in the solution, and filtering separation to obtain barium sulfate; adding the sulphuric acid to the filtered liquid to separate out all Ca2+ in the solution, and carrying out filtering separation on the obtained solution and then mixing and reacting the solution with the witherite for applying to the preparation of the barium sulfate. The barium sulfate prepared by the technology has no energy consumption, can improve product quality, does not pollute environment, reduces consumption of the raw materials, and lowers the cost, thereby being capable of generating huge economic benefits.

Owner:付远征

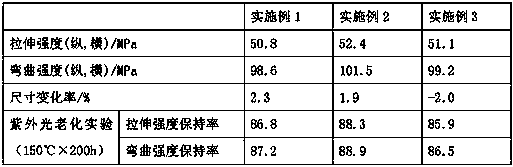

Radiation-resistant plastic flooring and preparation method thereof

InactiveCN107619545AImprove radiation resistanceImprove heat resistancePolyvinyl chlorideLead hydroxide

The invention discloses radiation-resistant plastic flooring and a preparation method thereof. The plastic flooring is made from, by weight part, 46-59 of polyvinyl chloride resin, 31-42 of polyethersulfone, 22-35 of polyisophthaloyl metaphenylene diamine, 22-28 of witherite powder, 16-22 of trioctyl trimellate, 6-11 of ricinoleamide, 18-24 of barite powder, 4-7 of di-n-butyl bis(dodecylthio) tin,14-22 of tritolyl phosphate, 10-15 of high-temperature activated bamboo charcoal powder, and 5-10 of lead hydroxide. Through compounding of polyvinyl chloride resin, polyethersulfone, and polyisophthaloyl metaphenylene diamine, and through addition of raw materials including witherite powder, barite powder, tricresyl phosphate, high-temperature activated bamboo charcoal powder, and lead hydroxide, the plastic flooring is improved in radiation resistance, heat resistance, aging resistance, wear resistance and flame retardance.

Owner:JIANGYIN ZHIYUAN AUTOMOBILE DECORATION PARTS CO LTD

Method of using low-grade witherite to produce high-purity barium chloride

InactiveCN106517289ASolve the problem of washing lossReduce refining costsCalcium/strontium/barium chloridesBarium dichlorideFiltration

The invention belongs to the technical field of fine chemical engineering preparation, and particularly relates to a method of using low-grade witherite to produce high-purity barium chloride. The method comprises the steps of adding the low-grade witherite and hydrochloric acid into an acid corrosion resistant reactor to be subject to acid hydrolysis reaction under a condition of stirring, then conducting alkalization, neutralizing, filtration, neutralizing, evaporative crystallization, filtration washing, size mixing washing and filtration washing, and finally drying the material to obtain a barium chloride product. The purity of barium chloride produced through the method is 99.5wt% or above, Ca is less than 10 PPm, Sr is less than 5 PPm, Na is less than 3 PPm, K is less than 2 PPm, Fe is less than 2 PPm, Mg is less than 2 PPm, S can not be detected, and the quality index of high-purity barium chloride is reached.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +2

Technology for solid barium chloride acidification section

InactiveCN104477963ANo pollution in the processLow costCalcium/strontium/barium chloridesBarium dichlorideFiltration

The invention relates to the field of barium chloride production technologies, in particular to a technology for a solid barium chloride acidification section. The technology comprises steps as follows: witherite is smashed by a smasher, and large-grained barium powder is placed in water for soaking to the pasty state; the well soaked slurry is pumped into an acidification tank by a slurry pump, and a certain amount of hydrochloric acid with the concentration of 31% is added regularly and rapidly stirred for an acidizing reaction; after acidification is completed, a solution is added to a neutralizer, a caustic soda solution with the concentration of 31% is added to the neutralizer for a neutralization reaction, and magnesium ions and iron ions are removed; after neutralization, a neutralizing solution is fed into a settling tank, and large-grained substances are removed; supernatant in the settling tank is fed into a plate and frame filter for filtration, obtained filtrate is sent to an evaporative crystallization section for evaporative crystallization, and a final product is obtained. The technology for the solid barium chloride acidification section has low cost, and H2S pollution cannot be caused.

Owner:ANHUI ZHUCHENG INFORMATION TECH

Method for preparing barium chloride by high-calcium witherite

InactiveCN109336158AHigh purityReduce consumptionCalcium/strontium/barium chloridesHigh concentrationSlag

The invention discloses a method for preparing barium chloride by high-calcium witherite. The method comprises the following raw materials by weight: 100 KG of high-calcium witherite with a barium carbonate content of 40-55 percent and a calcium carbonate content of 25-30 percent, and high-concentration hydrochloric acid with a concentration of 32 percent. The method for preparing the barium chloride by the high-calcium witherite, disclosed by the invention, has the benefits that by utilizing a common-ion effect, the high-concentration hydrochloric acid is adopted for reaction; the high-concentration hydrochloric acid is adopted for reaction with ores, calcium chloride produced by the reaction is fully dissolved in water brought by the hydrochloric acid, only a very small amount of produced barium chloride is dissolved in the water, and most of produced barium chloride exist in barium slag in a solid form; through primary filtration, a filtered liquid is a calcium chloride liquid, thecalcium chloride is removed, and then filter residues enter beating barrel for beating with water; the barium chloride in the barium slag is completely leached out to obtain barium chloride liquid with high purity, and then the barium chloride liquid is used for evaporative crystallization, so that the obtained product is high in purity and high in yield, and the steam consumption and the power consumption per ton of products are low.

Owner:宜昌华昊新材料科技有限公司

Method for preparing lower-radioactivity radiating red mud ceramic material

The invention discloses a method for preparing a lower-radioactivity radiating red mud ceramic material, which comprises the following raw materials in percent by mass: 28-70 percent of red mud, 28-70 percent of red sandstone, 1-20 percent of barium compound or witherite and 1-10 percent of fluxing agent, wherein the fluxing agent is one or more of calcium fluoride, aluminum oxide, magnesium oxide, calcium oxide and silica. The method comprises the steps of: 1, placing the raw materials in a ball-milling device for ball-milling and mixing for 12-48h; 2, drying the raw materials obtained from the step 1 at a temperature of 60-120 DEG C for 6-24h; 3, pressing and forming or plastically forming the raw materials obtained from the step 2 to prepare a blank body; and 4, sintering the blank obtained from the step 3 at a temperature of 900-1300 DEG C for 1-5h, and cooling to the room temperature to prepare a finished product. The invention has the advantages of wide sources of the raw materials and extremely low cost, and is favorable for reducing the red mud radioactivity radiation dose by 30-45 percent to reach the natural radioactivity background level.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

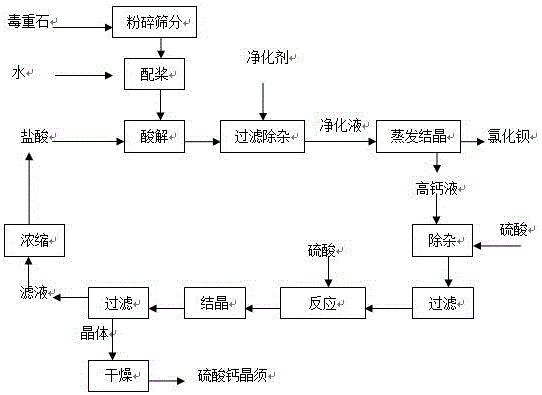

Method for preparing barium chloride and co-producing calcium sulfate whiskers by virtue of acid hydrolysis of witherite

InactiveCN106629804AEmission reductionAchieve recyclingPolycrystalline material growthCalcium/strontium/barium chloridesBarium dichlorideAcid hydrolysis

The invention relates to the technical field of fine chemistry, and particularly discloses a method for preparing barium chloride and co-producing calcium sulfate whiskers by virtue of acid hydrolysis of witherite. According to the method, acid hydrolysis is performed on the witherite to prepare the barium chloride by virtue of a hydrochloric acid, meanwhile, a sulfuric acid is added into a high-calcium solution byproduct to prepare the calcium sulfate whiskers with high added value, and the filtered hydrochloric acid can be finally recycled. Therefore, a calcium water byproduct of a witherite resource is reasonably utilized to turn wastes into wealth, and one of raw materials, namely, the hydrochloric acid, can also be recycled, which is significant for protection and reasonable utilization of the resource, protection of the environment and healthy development of the industry.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +2

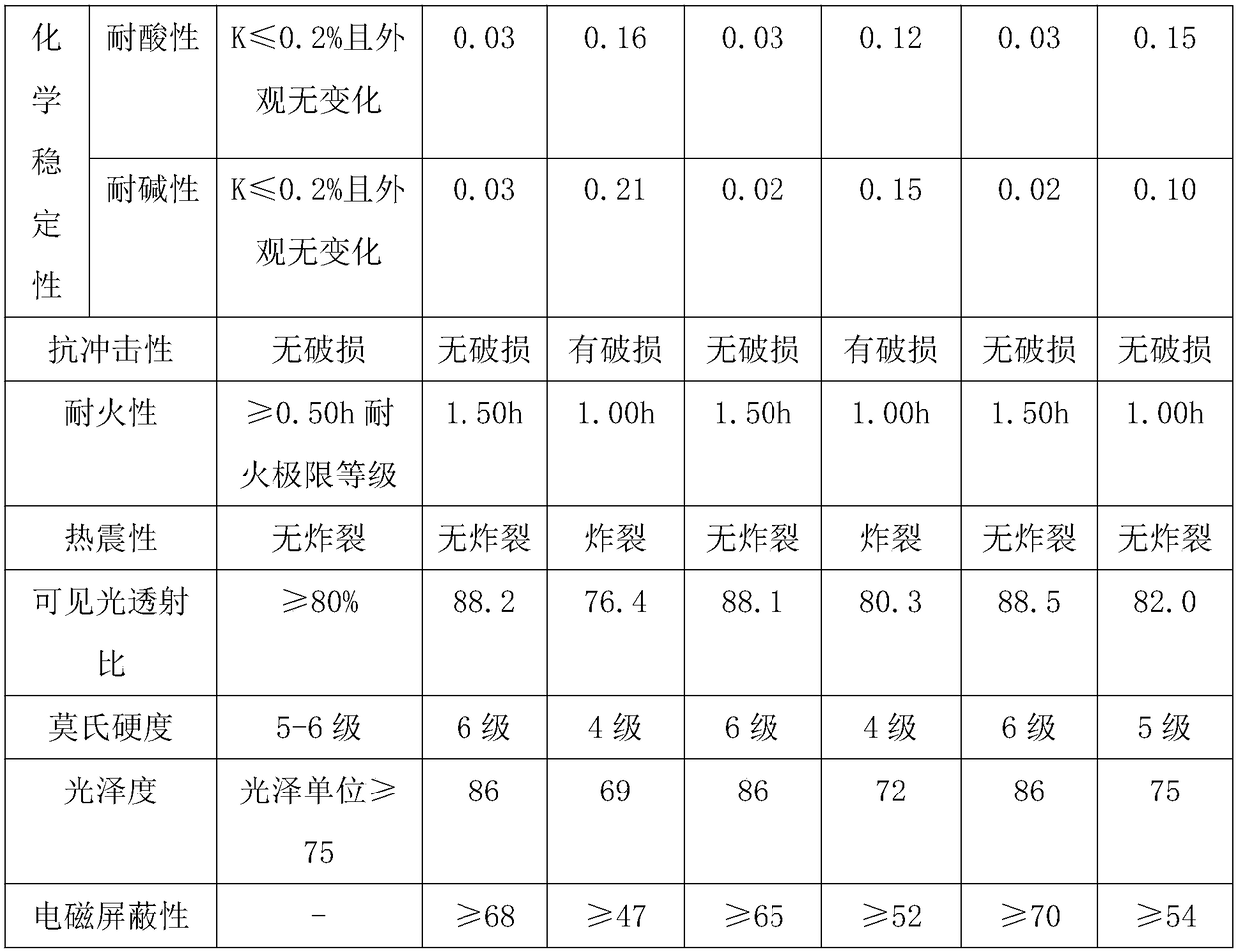

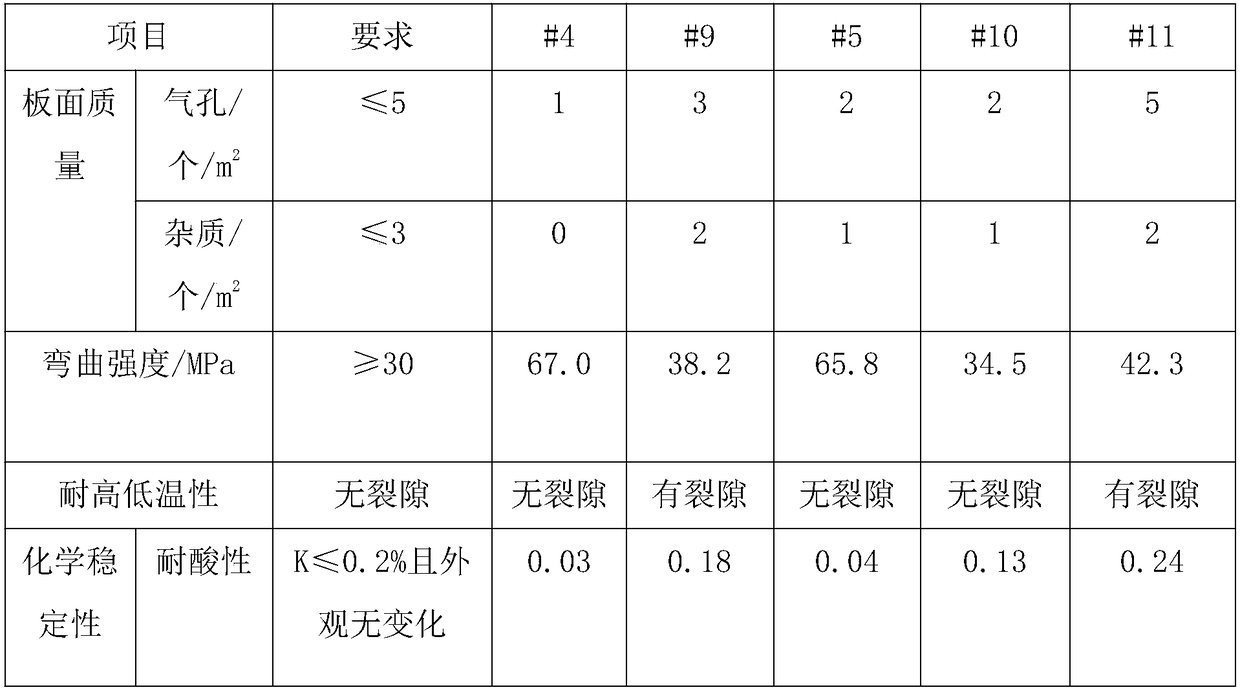

Temperature-resistant and corrosion-resistant building glass ceramic

InactiveCN108585513ACreative improvementImprove appearance qualityTemperature resistanceChemical stability

The invention discloses temperature-resistant and corrosion-resistant building glass ceramic, and relates to the technical field of glass ceramic. The temperature-resistant and corrosion-resistant building glass ceramic comprises siliceous shale, limonite, vanadinite flotation tailing, limestone, witherite, broken glass, Na2CO3 powder, Yb2O3 powder and compound clarifying agents. The temperature-resistant and corrosion-resistant building glass ceramic has the advantages of simplicity and convenience in preparation, excellent temperature resistance, high mechanical strength, good chemical stability, long service life and wide application places and fields.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

Method for measuring sulphur content in witherite

InactiveCN110346320ASolve the problem of no standard sampleMeasure quicklySamplingColor/spectral properties measurementsCombustionQuality control

The invention discloses a method for measuring a sulphur content in witherite. The method is used for measuring the sulfur content by using a high-frequency infrared carbon and sulfur analyzer and a high-frequency induction combustion-infrared absorption method, and specifically comprises the following steps: preparing a reserve part for measurement, measuring a sulphur content blank value, calibrating the high-frequency infrared carbon and sulfur analyzer, sampling, and preparing a sample, preparing a test material, and measuring the sulphur content in a witherite powder sample to be tested.The working conditions of the instrument are as follows: the measurement flow rate is 3+ / -0.5 L / min, the oxygen pressure is 0.2-0.4 MPa, the power barometric pressure is 0.2-0.4 MPa, and the minimum analysis time is 60 s. The method has the advantages of having good reproducibility and accuracy of measurement result, solving the problem of measuring the sulfur content in the witherite, and providing a reliable technical guarantee for steel smelting quality control.

Owner:WUKUN STEEL

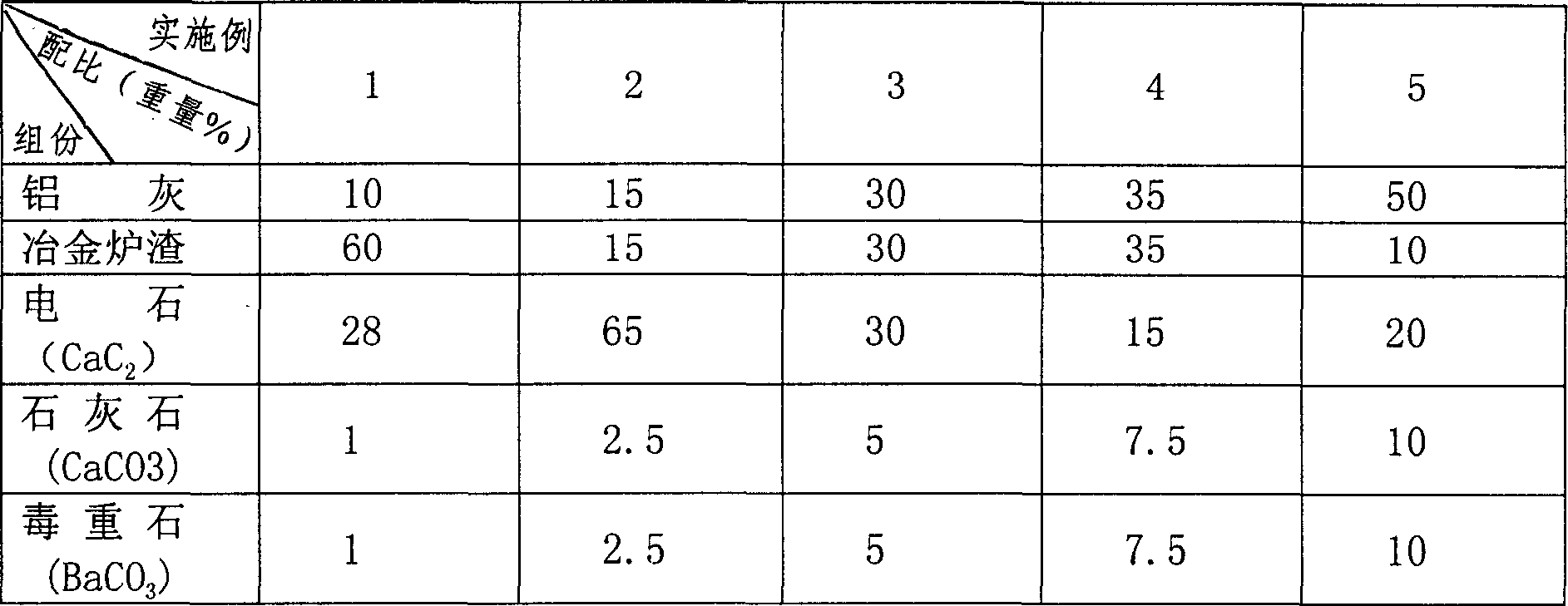

Composite molten steel refining additive

This invention provides a molten steel composite refining additive. The said additive by wt.% includes aluminium ash 10-50% (aluminium content at least being 15% of ash wt.), metallurgical furnace slag 10-60%, carbide 5-65%, limestone 1-10% and witherite 1-10%. This additive is used for the oxidable slag tapping process of steel smelting furnace such as electric furnace, converter, etc. and for refining furnace to make the oxidable molten steel proceed polybasic composite oxygen removal, sulphur removal and quick deoxidated impurity inclusion removal, and at the same time, it enhances quick dissolution of added slagging material and quick slag forming.

Owner:重庆工业高等专科学校

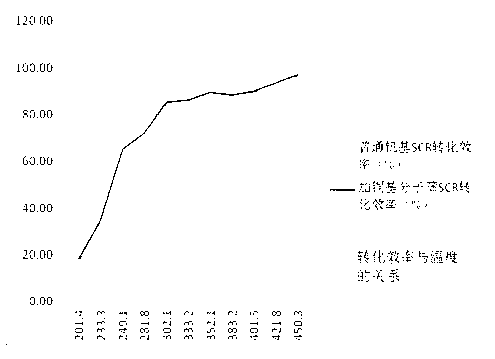

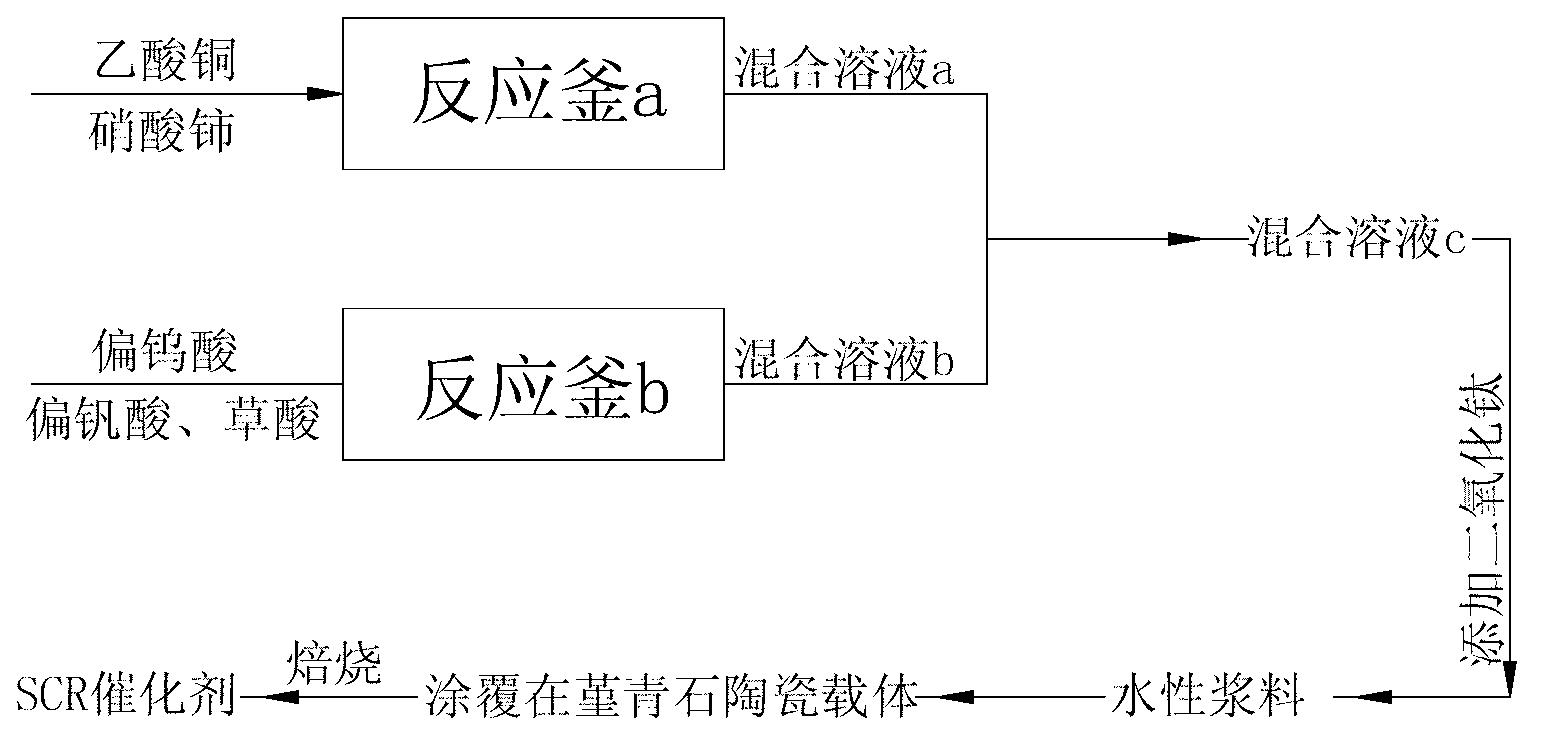

SCR (Semiconductor Control Rectifier) catalyst and preparation method thereof

InactiveCN103316716AGood activity at low temperatureHigh low temperature activityOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationAcetic acidOxalate

The invention discloses an SCR (Semiconductor Control Rectifier) catalyst and a preparation method thereof. The SCR catalyst is characterized by comprising the following ingredients in percentage by weight: 30.30% of cupric acetate, 15.15% of cerous nitrate, 18.9% of metatungstate, 7.57% of metavanadate, 18.9% of oxalic acid and 9.18% of titanium dioxide. SCR catalyst is obtained by mixing cupric acetate to obtain a mixture solution a, mixing the metatungstate, the metavanadate and the oxalic acid to obtain a mixture solution b, subsequently mixing the mixture solution a with the mixture solution b to obtain a mixture solution c, adding titanium dioxide into the mixture solution c to obtain aqueous slurry, and finally coating the aqueous slurry on a cordierite honeycomb ceramic carrier for roasting. The SCR catalyst contains cupric acetate, cerous nitrate, metatungstate, metavanadate, oxalic acid and titanium dioxide, so that the SCR catalyst has the characteristics of excellent low-temperature activity and high high-temperature activity.

Owner:ANHUI ACT BLUE ENVIRONMENTAL PROTECTION CO LTD

Method for preparing barium chloride from calcium-containing witherite ore

InactiveCN109279638AHigh solid purityEasy to operateCalcium/strontium/barium chloridesBarium dichlorideGranularity

The invention relates to the technical field of witherite, and discloses a method for preparing barium chloride from calcium-containing witherite ore. The method comprises the following steps: placing40-to-300-mesh witherite into a reaction vessel with a stirring function, pouring hydrochloric acid with a concentration of 24% to 36% into the reaction vessel, allowing the hydrochloric acid to react with the witherite in a ratio of 3: 1 to 5: 1, continuing heating from 0 DEG C to 80 DEG C in the reaction process of the hydrochloric acid and the witherite, controlling the temperature of the reaction during heating, maintaining the temperature at 30 DEG C to 75 DEG C, carrying out a reaction for 0.5 to 3 hours, and controlling and maintaining the speed of stirring at 0 r.min to 600 r.min at the same time. The method for preparing the barium chloride from the calcium-containing witherite ore provided by the invention has the following advantages: through a plurality of times of tests on the ore size, hydrochloric acid concentration, liquid-solid ratio, heating temperature, reaction time and stirring speed of the witherite, an optimal preparation scheme is selected; a product obtained by using the preparation scheme provided by the invention has high purity and large yield; a large amount of the witherite with high calcium content can be utilized; and production is more environmentally-friendly.

Owner:宜昌华昊新材料科技有限公司

Method for preparing anti-caking high-purity electronic-grade strontium nitrate

InactiveCN105460965AReduced recombinationUniform particle sizeCalcium/strontium/barium nitratesCalcium hydroxideEvaporation

The invention discloses a method for preparing anti-caking high-purity electronic-grade strontium nitrate and belongs to the technical field of strontium nitrate preparation. Strontianite and witherite are crushed and pulped and then nitric acid is added for reaction, and a nitric acid solution is generated; then, a sodium hydroxide solution is added into the nitric acid solution, and calcium hydroxide precipitate is generated through reaction; then, supernate is collected through centrifugal separation, nitric acid is added, and a filtered solution is obtained through reaction, curing and filtering; finally, the obtained filtered solution is subjected to cooling crystallization, impurity removal, filtering, evaporation crystallization and drying, and the anti-caking high-purity electronic-grade strontium nitrate is obtained. Examples show that operation is easy and convenient, and the isomorphous substitution phenomenon can not occur in the preparation process. Besides, the prepared strontium nitrate is high in purity, low in impurity content, not prone to caking, capable of reducing production and use cost of clients and worthy of large-scale production and application.

Owner:CHANGZHOU JUNCHENG MACHINERY

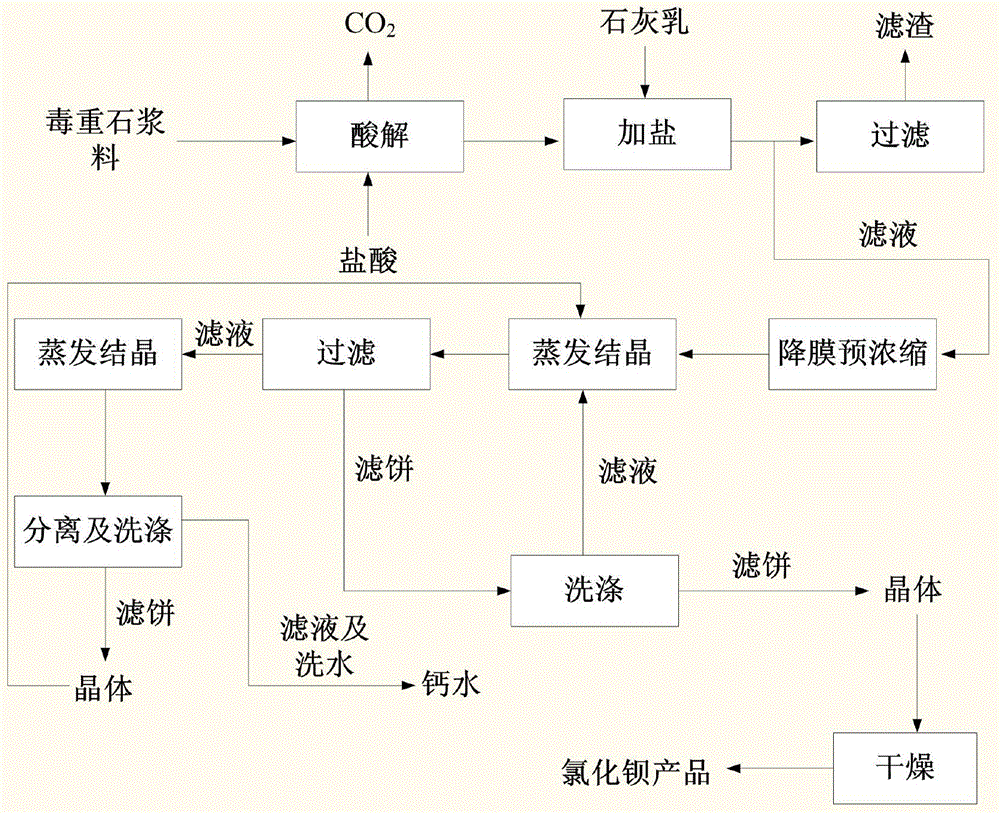

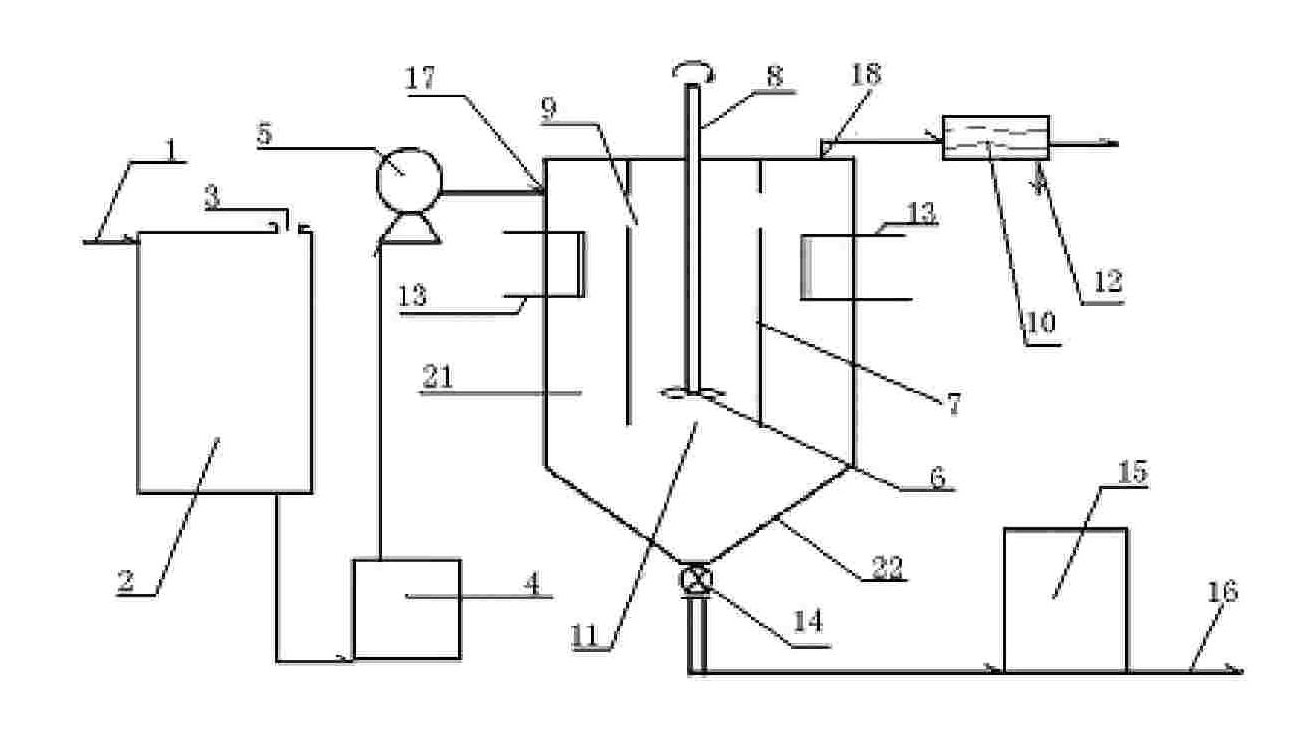

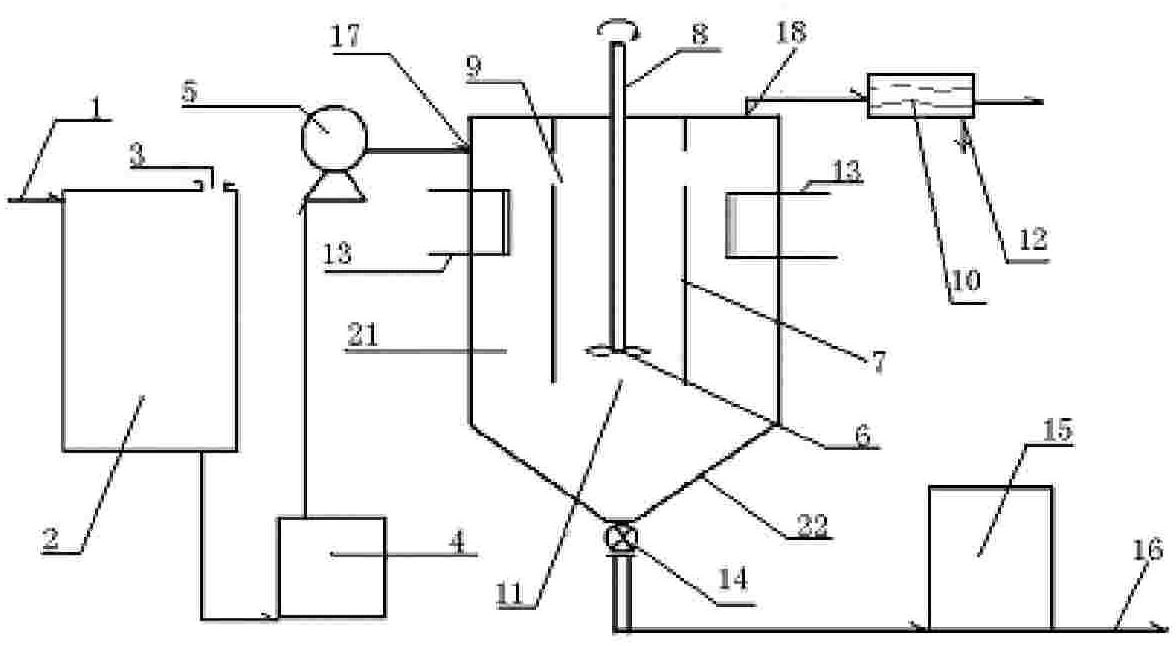

A kind of process of producing barium chloride with witherite as raw material

InactiveCN104891549BEase of mass productionSimple processCalcium/strontium/barium chloridesLiquid wasteBarium dichloride

The invention belongs to the technical field of chemistry, and concretely discloses a technology for producing barium chloride by taking witherite as a raw material. The technology comprises the following steps: mixing witherite and water, grinding and adding acid for acidolysis, adding salt and lime milk for removing impurity, falling film and pre-concentrating, evaporating and crystallizing to obtain barium chloride dehydrate crystals; cooling the crystal slurry and recrystallizing, recovering the barium chloride dehydrate crystals in a hot solution; merging the barium chloride dehydrate crystals and washing by saturated salt solution, recrystallizing and purifying, and drying to obtain the product barium chloride. The method has no restriction on witherite types, and raw material requirement is reduced, impurities removal step during the production process in a traditional mode is not required, flow is simple, operation is easy, no exhaust gas, waste residue and waste liquid is discharged during a whole process, and the technology accords with green chemical requirement, and the prepared barium chloride crystal has the advantages of high yield, high purity and low cost, and is suitable for large scale industrial production requirement.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Photochromic health care ceramic and preparation method thereof

The invention discloses a photochromic health care ceramic and a preparation method thereof. The preparation method comprises the steps of: A, glaze slurry preparation: by mass percentage: mixing 10-15% of zinc oxide, 0.4-0.5% of barium carbonate, 0.3-0.4% of talc powder, 58-65% of borax, 10-12% of silicon oxide, 12-20% of boron oxide and 5-8% of a functional agent to obtain mixed powder, then adding alumina ball-milling balls and distilled water to conduct ball milling; then adding tourmaline and cordierite to further perform ball milling, and controlling the slurry at 300-350mesh, thus obtaining the glaze slurry, wherein the tourmaline and cordierite respectively account for 3-8% and 1-5% of the mass of the mixed powder; step B, glaze slurry impregnation: conducting impregnation of the glaze slurry and then performing first firing; and C, glaze slurry spraying: spraying the glaze slurry and then conducting second firing so as to obtain health care ceramic. Compared with the existing ceramics, the ceramic prepared by the method provided by the invention has the characteristics of scientific compounding, reasonable preparation, stable performance, no lead, cadmium or other extremely toxic substances, and also has uniform and lasting spectral antibacterial properties, photochromic and anti-radiation functions, thus further broadening the application scope of ceramics.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

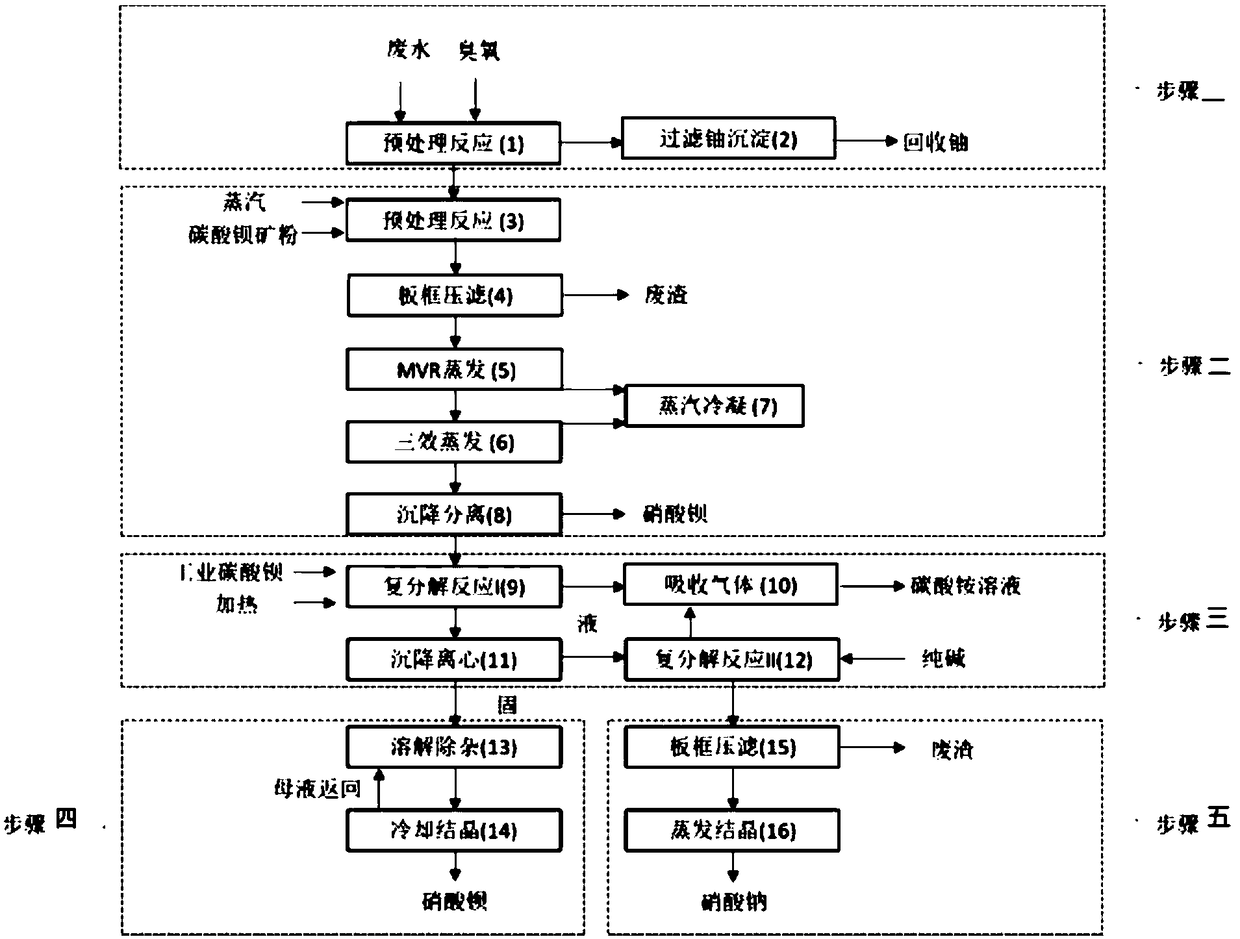

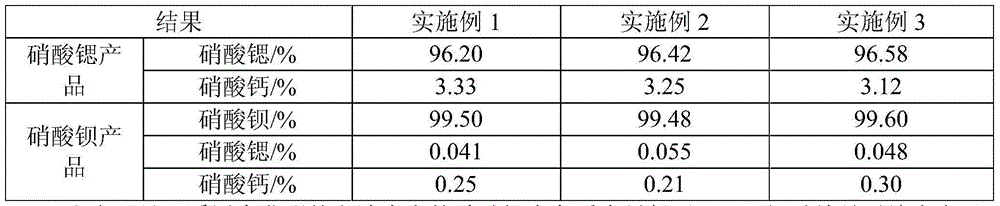

Method for joint production of strontium nitrate and barium nitrate from high-calcium strontianite and witherite

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Barium chloride production technology

InactiveCN101654274BReduce in quantityReduce wasteCalcium/strontium/barium chloridesAxial-flow pumpBarium salt

The invention discloses a technology for producing barium chloride by the witherite containing barium carbonate, which mainly comprises steps as follows: sulfur iron impurities are decomposed and oxidated to remove and the hydrated barium salt raw material liquid is prepared; the raw material liquid is electrically heated and concentrated in vacuum, which is driven by an axial flow pump, the solute is thermally crystallized to form the hydrated barium chloride dihydrate saturated crystalline; the crystallized hydrate is cooled to produce the serial barium salt products, wherein the vacuum heating condensation crystallization is a continuous production process; the whole technological process is implemented in the closed state; the by-products could be recycled; the crystallisation processis completed at one time and the production process is continuous. The products manufactured in the technological process has low impurity content, saves energy, is adaptive to the large-scale industrialization production and reduces the pollution and resource waste to a large extent.

Owner:重庆洋铭化工产品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com