A kind of process of producing barium chloride with witherite as raw material

A technology of barium chloride and witherite, which is applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., which can solve complex process flow, high requirements for raw material witherite, and high energy consumption of barium chloride process problems, to achieve the effect of simple process, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

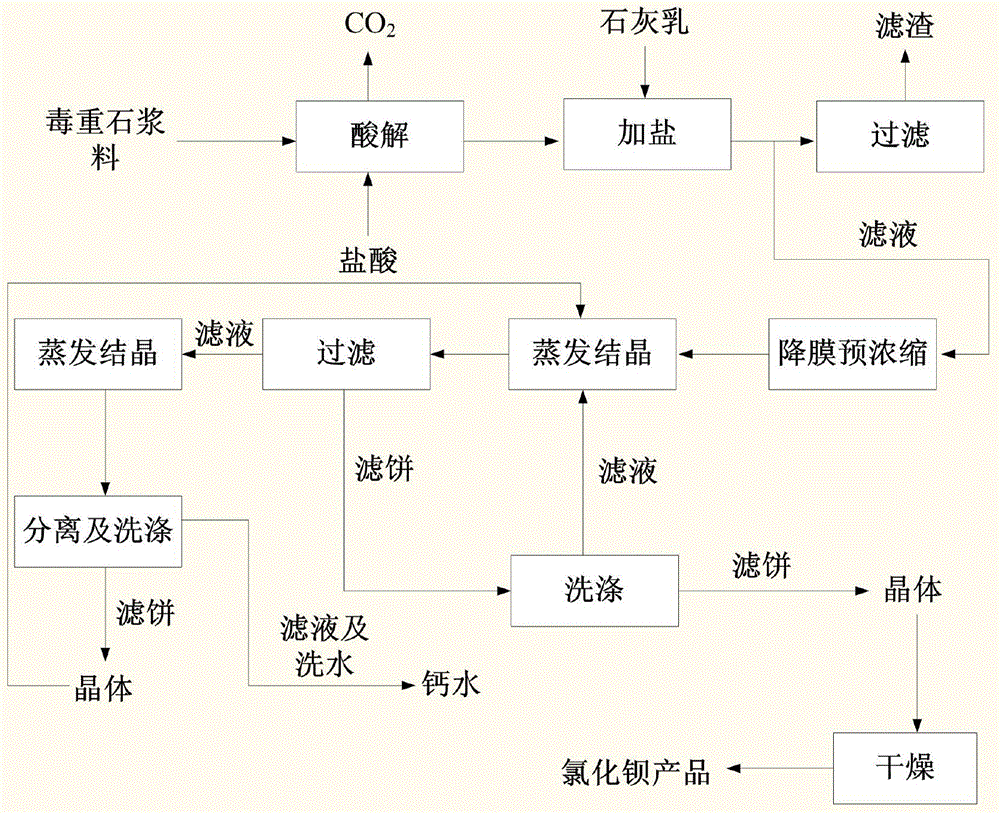

Image

Examples

Embodiment 1

[0040]Step 1: Mix the witherite containing 65% barium carbonate with water, grind it in an ore crusher to obtain ore slurry, wherein the ratio (mass ratio) of the witherite to water is 1:1, and the fineness of the ore powder is 80-100 mesh. The obtained pulp is evenly pumped into the reactor, and 30% hydrochloric acid is added, and the amount of hydrochloric acid is 1.1 times the theoretical acid hydrolysis amount (the pH value of the pulp is about 1.2-2). Heat the solution in the reactor to 65-70°C, react for 0.3-1.5 hours, and recover carbon dioxide gas. After no carbon dioxide is released in the reaction, the released carbon dioxide is purified and used to produce barium carbonate.

[0041] Step 2: Add milk of lime (the mass ratio of lime to water is 1:1) and a saturated sodium chloride solution at a temperature of 50-80°C to the raw material solution obtained in step 1. The amount of milk of lime is to adjust the raw material solution pH value to 8-9, the amount of satura...

Embodiment 2

[0049] Repeat the same steps as described in Example 1. Wherein, the witherite contains 69% by mass of barium carbonate, and finally through recrystallization, the total yield of barium chloride dihydrate crystals can reach more than 92%, and the purity can reach 99.95%.

[0050] The process uses witherite, hydrochloric acid and industrially refined salt as raw materials, and the crystallization method can be used to directly produce liquid low-strontium barium chloride, eliminating the need for high-temperature roasting, evaporation, thermal crystallization and other processes. The mother liquor and wash water are returned as bottom water after treatment, BaCl 2 The yield can be increased to 92.5%, and the mass concentration of strontium is 0.036g / L, that is, the mass fraction of strontium is 0.016%. The process is simple and easy, and compared with other processes, it has low cost and less investment.

[0051] Due to the similar chemical properties of Ba and Sr, it is diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com