Patents

Literature

81results about How to "Meet the requirements of green chemical industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

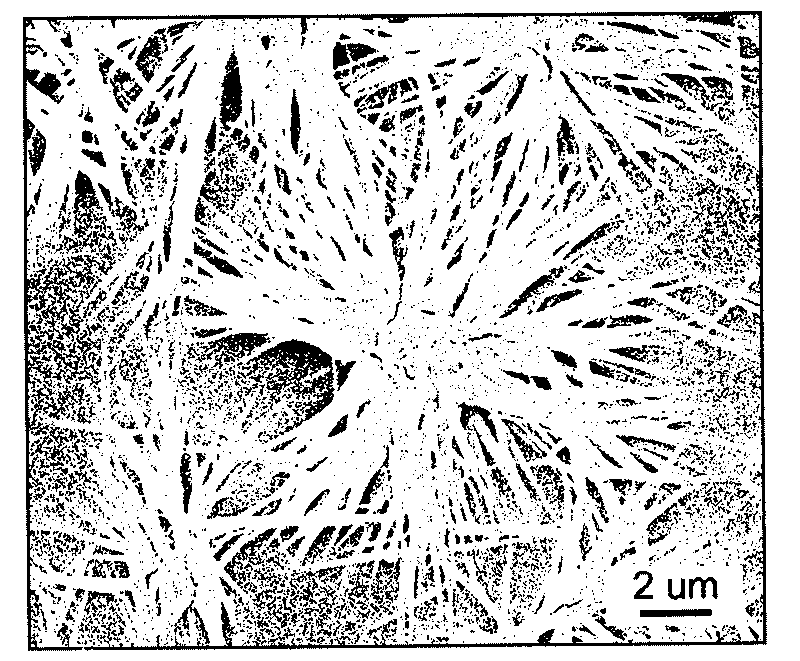

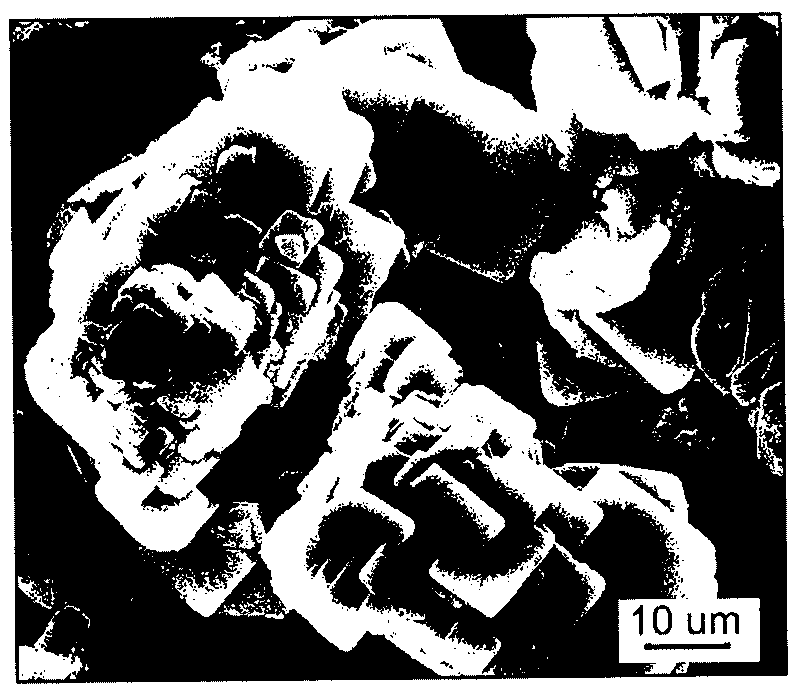

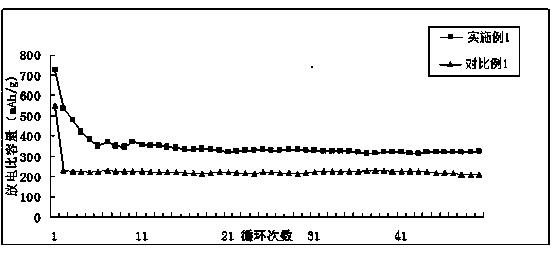

Preparation method of biomass lamella carbon material and application

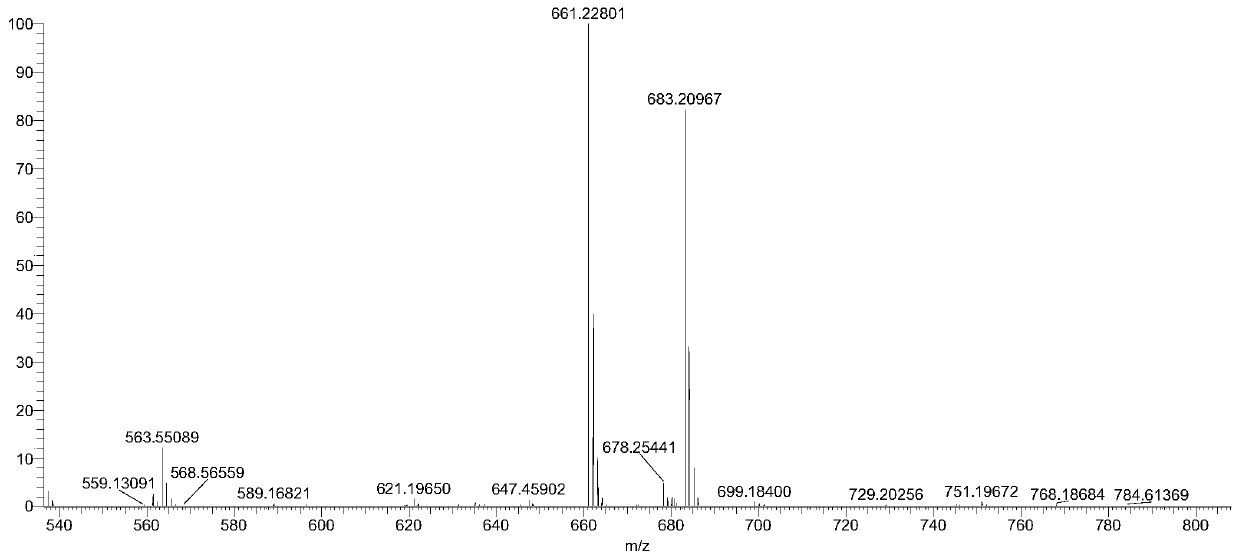

ActiveCN103904328APromote sustainable developmentSave raw materialsFinal product manufactureCell electrodesBetelLithium-ion battery

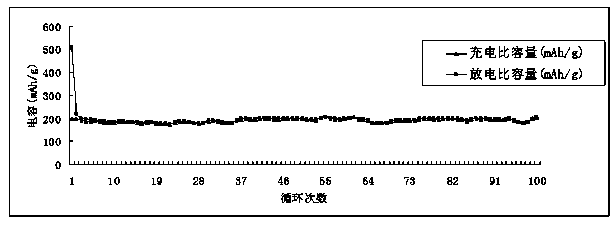

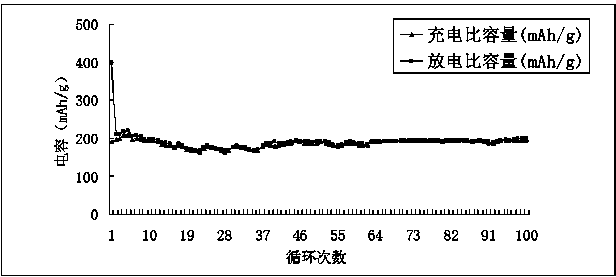

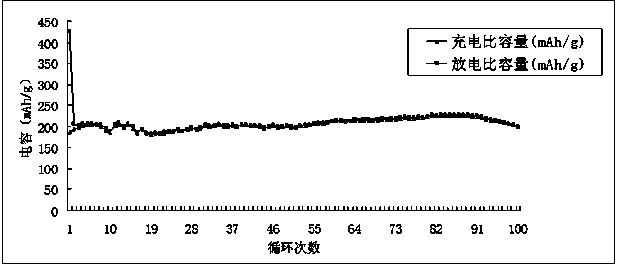

The invention discloses a preparation method of a biomass lamella carbon material and application of the biomass lamella carbon material in a lithium ion battery. The biomass lamella carbon material is prepared by processing betel nut shells through an alkaline solution and an acid solution, carbonizing the betel nut shells and ball milling the betel nut shells and can be used as a battery electrode material. The renewable betel nut shells are selected as a carbon source, the raw material is cheap and wide in source, the preparation process is simple, the cycling stability of the prepared battery is good, and the capacity is large.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Preparation method of hydroxy methionine salt and compound

The invention provides a preparation method of hydroxy methionine salt and a compound, comprising the following steps: a. feeding metal hydroxide or basic metal oxide or amphoteric metal oxide and 2-hydroxy-4-methylthiobutyricacid into a closed and corrosion resistant reaction kettle to react for 0.5-12h according to a stoichiometric ratio, taking the low-boiling polar organic solvent or the mixed solvent thereof with water as the reaction medium, stirring, separating the target product, washing and drying to obtain the products; and b. recycling the reaction medium. The preparation method of the invention has short route, no consumption of acid or alkali reagent, low cost, easily-controllable product quality, environmental friendliness and the like, thus being applicable to large-scale industrial production.

Owner:李宁 +1

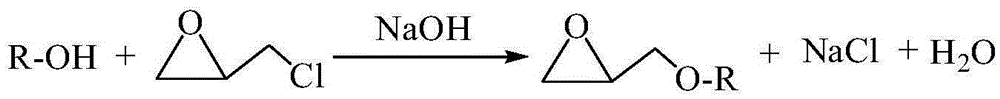

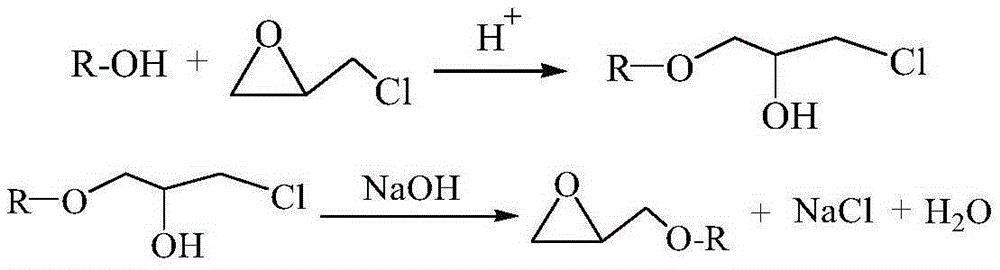

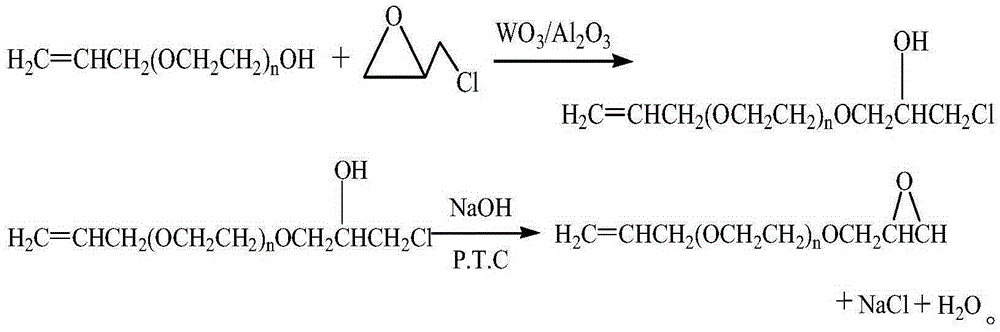

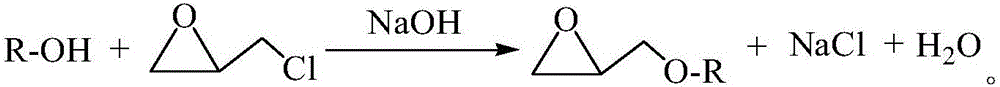

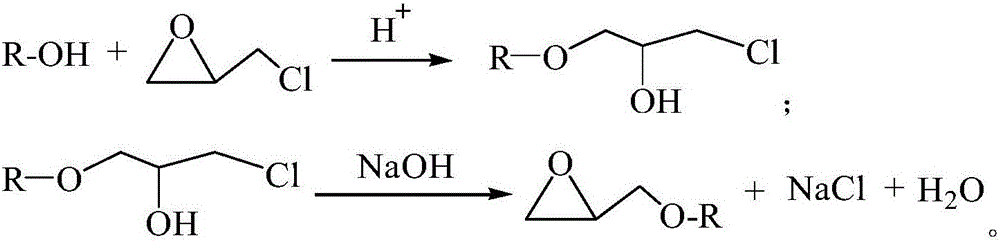

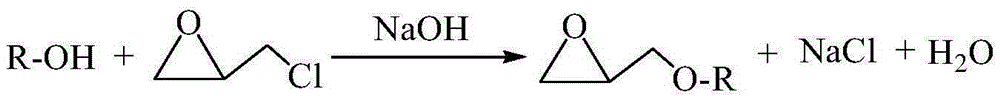

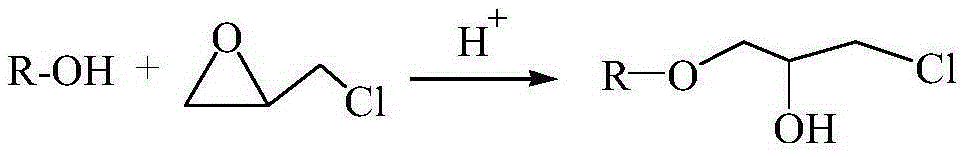

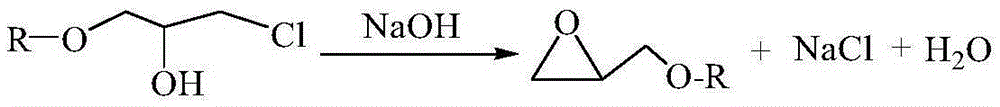

Method for compounding epoxy-terminated allyl alcohol polyoxyethylene ethers

The invention relates to a method for compounding epoxy-terminated allyl alcohol polyoxyethylene ethers, which belongs to the synthesis technology field of organic compounds, and uses allyl alcohol polyoxyethylene ethers and epichlorohydrin as raw materials, adds catalysts into the allyl alcohol polyoxyethylene ethers, is slowly added with epichlorohydrin drop by drop under the protection of nitrogen, filters and recycles the catalysts after finishing a reaction, distills and recycles the epichlorohydrin by reducing pressure, adds solid alkali and quaternary ammonium salt catalyst into a chlorohydrin ether intermediate, reacts for a period of time under the protection of the nitrogen, is added with a neutralizer to neutralize after being filtered to discharge salt, and then is added with an adsorbent to prepare finished products by refining. The method for compounding the epoxy-terminated allyl alcohol polyoxyethylene ethers is applied to compound the epoxy-terminated allyl alcohol polyoxyethylene ethers, effectively recycles the catalysts above 15 times, prevents strongly acidic catalysts from affecting equipment and operation environment, further achieves balance of ending ratio and color, gives high reaction activities for products simultaneously, and also guarantees quality indicators of finished products.

Owner:ZHEJIANG HUANGMA TECH

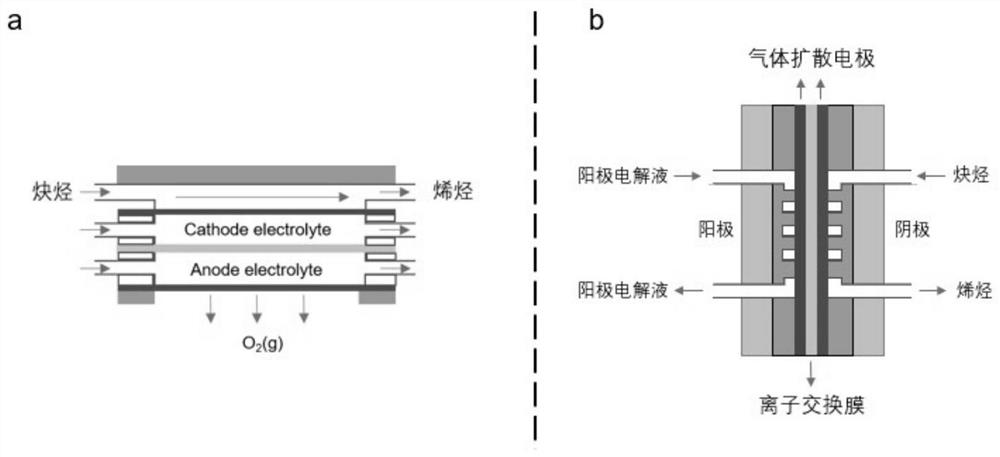

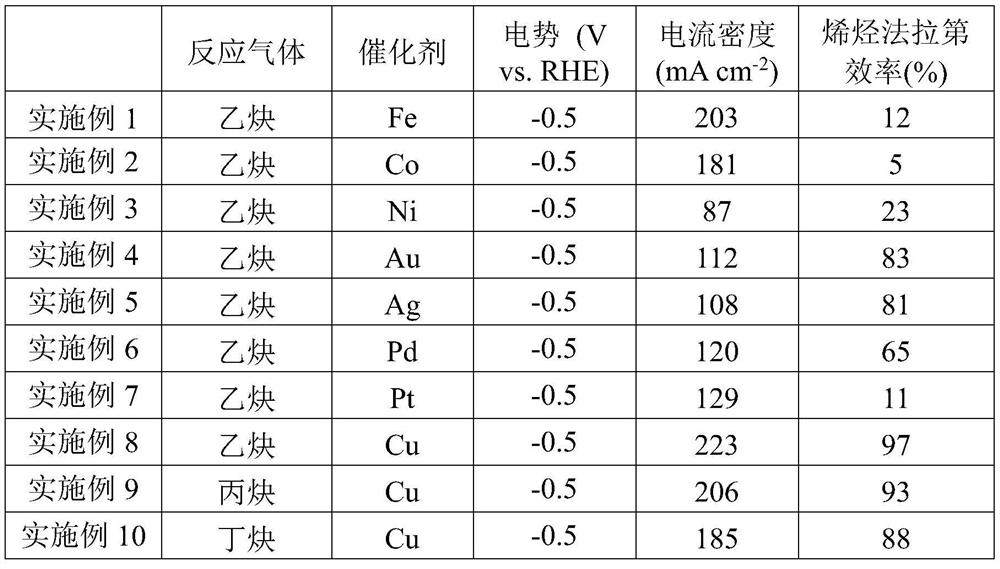

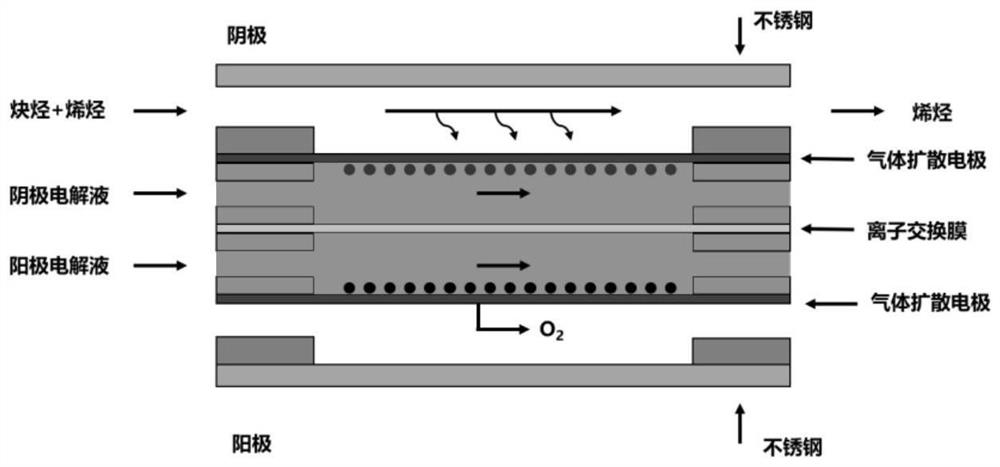

Method for synthesizing olefin by electro-catalyzing semi-hydrogenated gas-phase alkyne

PendingCN112301369AHigh selectivityGood choiceElectrolytic organic productionElectrodesChemical industryPtru catalyst

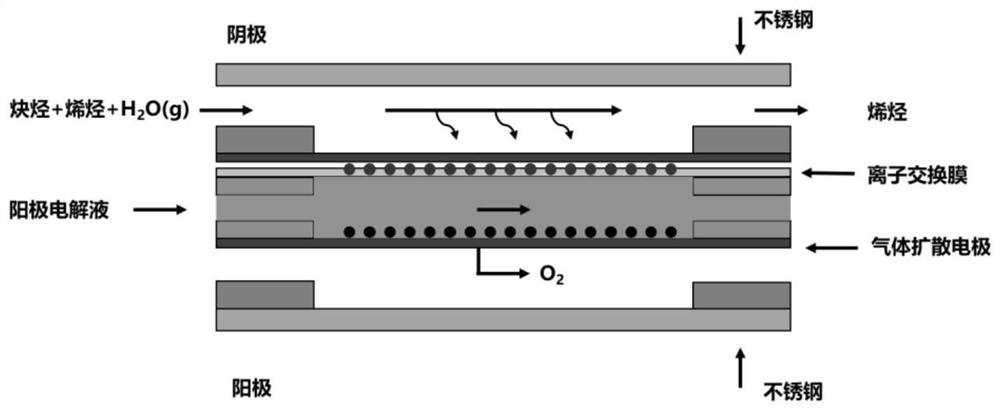

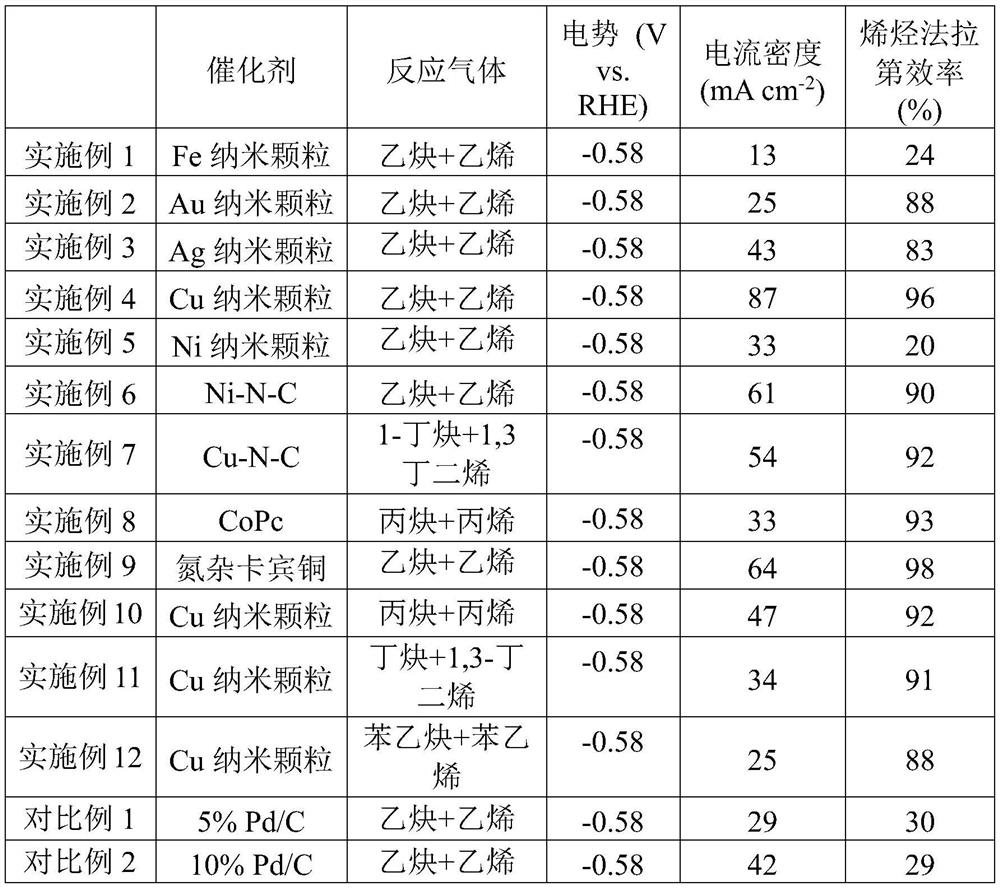

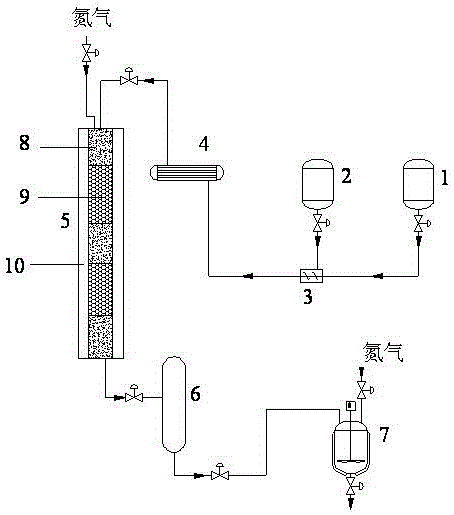

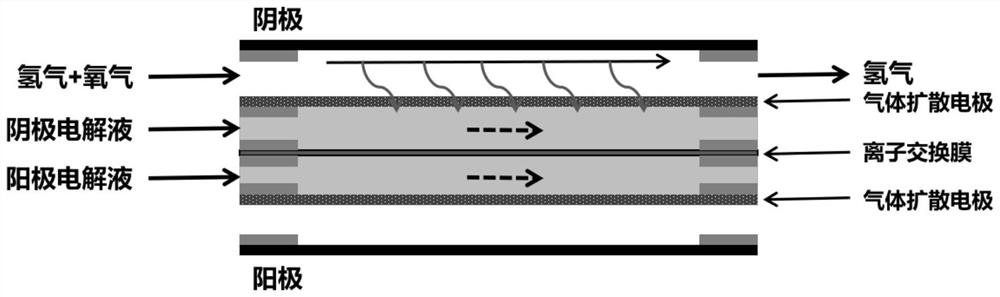

The invention relates to a method for synthesizing olefin by electro-catalyzing semi-hydrogenated gas-phase alkyne. The method comprises the following steps of: spraying a catalyst onto a gas diffusion layer substrate (comprising conductive carbon paper, metal and the like) by using a gas diffusion electrode, isolating a cathode from an anode by using an ion exchange membrane, and adopting a three-electrode or two-electrode system constant-voltage method to carry out electrochemical performance test, wherein the reaction gas is high-purity alkyne. According to the invention, the experimental results show that the method can be used for efficiently and selectively reducing the gas-phase alkyne into the corresponding olefin; compared with an H-type electrolytic tank, after the gas diffusionelectrode is used, the reaction current density is multiplied, the reaction voltage and the reaction current can reach 1 Acm<-2> or above by regulating and controlling the reaction voltage, and the Faraday efficiency of a target olefin product is remarkably improved and reaches 95% or above; and compared with the traditional thermal catalysis technology, the method can selectively reduce the gas-phase alkyne into olefin at normal temperature and normal pressure without hydrogen consumption, can greatly reduce the energy consumption in the process, better meets the requirements of green chemical industry, and has great strategic significance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for electrocatalytically and selectively reducing alkyne impurities in olefin

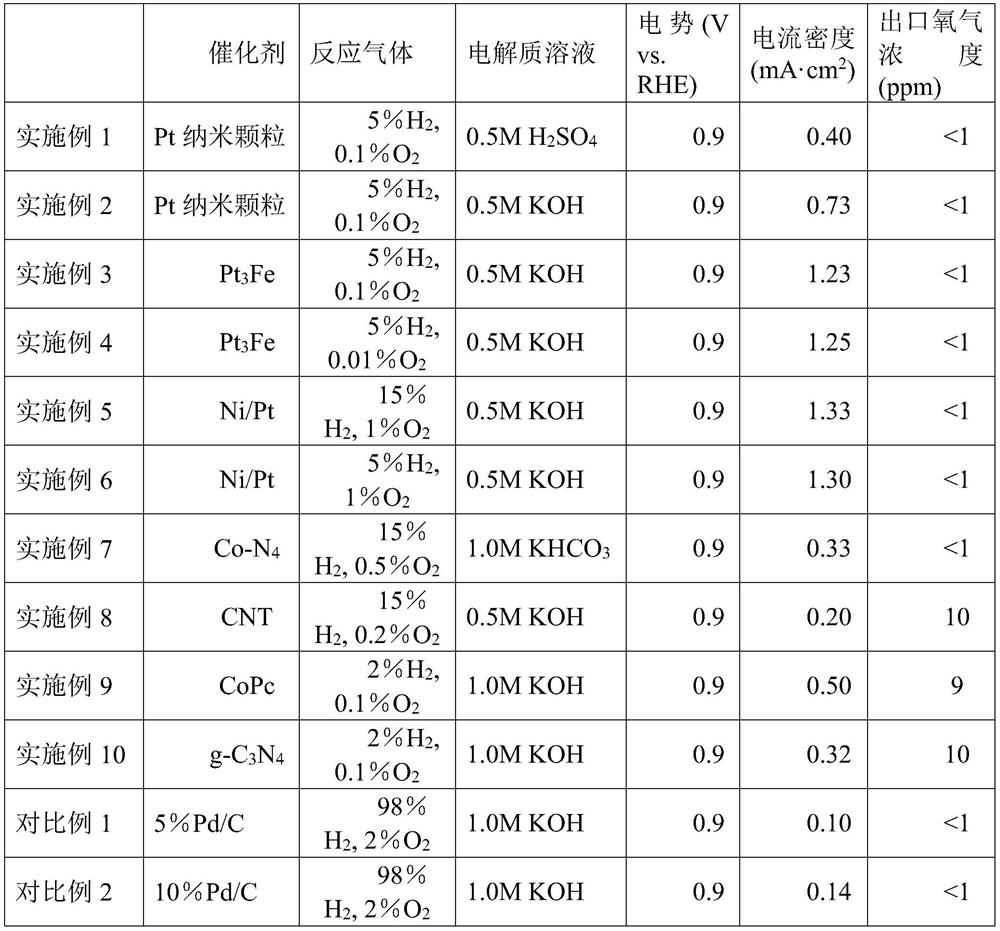

PendingCN112301373AReduced residual concentrationReduce consumptionElectrolytic organic productionElectrodesPtru catalystAlkyne

The invention relates to a method for electrocatalytically and selectively reducing alkyne impurities in olefin, particularly to electrocatalytical and selective hydrogenation of acetylene, propargyl,butyne, phenylacetylene and the like. According to the invention, a gas diffusion electrode electrolytic tank is adopted, a catalyst is sprayed on a gas diffusion layer substrate (including conductive carbon paper and metal) to prepare a gas diffusion electrode, a cathode and an anode are isolated by an ion exchange membrane, and a three-electrode or two-electrode system constant voltage method is adopted to carry out electrochemical performance test, wherein the reaction gas olefin contains 1% of alkyne impurities; experimental results show that the residual concentration of olefin can be reduced to 5 ppm or below by regulating and controlling a proper voltage range; and compared with a traditional thermal catalysis technology, the method of the invention can selectively reduce alkyne impurities in olefin into olefin at normal temperature and normal pressure without hydrogen consumption, can greatly reduce energy consumption and potential risks in the process, better meets the requirements of green chemical engineering, and has great strategic significance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A continuous ring-opening production process for epoxy-terminated polyether

The invention relates to a continuous ring-opening production process for epoxy-terminated polyether and belongs to the technical field of organic polymer compounds. Allyl alcohol polyoxyethylene ether and epichlorohydrin are adopted as raw materials. The process includes mixing the allyl alcohol polyoxyethylene ether and the epichlorohydrin, heating, continuously feeding the mixture to a two-stage fixed bed reactor, performing a ring-opening reaction under catalysis of a solid superacid, adding a product collected by a collecting tank at the lower end of the reactor to a reaction kettle through a metering pump every 2-4 h, adding an alkali and a quaternary ammonium salt catalyst, stirring for 1-4 h while maintaining the temperature, filtering to obtain a crude product, performing vacuum distillation to recover the epichlorohydrin, and purifying to obtain a qualified product. The process is applied for producing the epoxy-terminated polyether, and has advantages of a high equipment utilization rate, a high production efficiency, and the like.

Owner:ZHEJIANG HUANGMA TECH

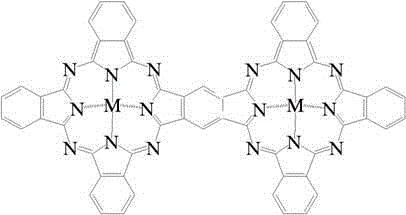

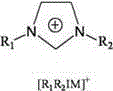

Method for removing dibenzothiophene contained in fuel oil through catalytic oxidation

InactiveCN103555366ALow costAbundant resourcesTreatment with plural serial refining stagesCatalytic oxidationFuel oil

The invention discloses a method for removing dibenzothiophene contained in fuel oil through catalytic oxidation, and belongs to the technical field of chemical engineering. According to the invention, the deep removal of the dibenzothiophene contained in the fuel oil is realized by taking binuclear metal phthalocyanine as a catalyst, ionic liquid as an extracting agent and air as an oxidizing agent and adopting a catalytic oxidation extraction coupling method at the mole ratio of sulfur to a catalyst to an extracting agent to an oxidizing agent of 1:(0.00015-0.0015):(0.45-0.85):(2.067-20.67). The method disclosed by the invention has the advantages of moderate reaction condition, small catalyst usage amount and high catalytic activity. According to the invention, the ionic liquid extracting agent is low in cost, and can realize the automatic layering with a reaction system after the reaction is finished, so that the binuclear metal phthalocyanine catalyst coupling ionic liquid has good recycling. The method disclosed by the invention is an environment-friendly production process and has good industrial application prospect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for improving industrial-grade ammonium vanadate quality

ActiveCN103708553AGood effect of removing impuritiesSimple and efficient operationVanadium compoundsAmmonium sulfateIon

The invention discloses a method for improving industrial-grade ammonium vanadate quality. The method comprises the following steps: by taking industrial-grade ammonium vanadate as a raw material, dissolving in low-concentration ammonium hydroxide; removing impurities by ammonium sulfate; adsorbing collected feed liquid by strongly basic anion exchange resin, and adding ammonium chloride to dissolve; separating out crystal under cooling; filtering, washing and drying, so as to obtain the ammonium vanadate with improved quality. Impurities metal ions can be effectively removed by using ammonium sulfate edulcoration; new impurities metal ions are avoided; the quality of the final product is ensured by absorption of the strongly basic anion exchange resin; the content of the impurity metal ions in the obtained ammonium vanadate is lower than 5ppm; the purity of the ammonium vanadate can be up to 99.5% or more after the quality is improved; the product quality can be up to the standard of the HG / T3445-2003 reagent-grade ammonium vanadate. Therefore, the method is applicable to industrial production.

Owner:SINOPHARM CHEM REAGENT

Method for synthesizing epoxy stop end butanol polyoxyethylene polyoxypropylene ether

The invention relates to a method for synthesizing epoxy stop end butanol polyoxyethylene polyoxypropylene ether and belongs to the technical field of organic compound synthesis. A WO3 / ZrO2 catalyst is added into butanol polyoxyethylene polyoxypropylene ether; under the protection of nitrogen, epichlorohydrin is added dropwise slowly; after the reaction is over, the catalyst is filtered and recycled, epichlorohydrin is recycled through reduced pressure distillation, a chlorhydrin ether intermediate product is obtained; solid alkali and quaternary ammonium salt catalysts are added; under the protection of nitrogen, after the reaction and filtering for desalting, a neutralizer is added for neutralization, an adsorbent is added, and the refining is performed. By applying the method to synthesis of epoxy stop end polyoxyethylene polyoxypropylene ether, the catalyst is effectively recycled and reused 15 times or above, and the influence on devices and the operating environment caused by the strong acid catalyst is avoided; moreover, the balance of the stop end rate and color is achieved, and the condition indexes of finished products are also guaranteed.

Owner:ZHEJIANG HUANGMA TECH

Structured catalyst for preparing 1,3-propanediol by hydrogenation of glycerol water solution, and preparation method of 1,3-propanediol

ActiveCN108636404AImprove stabilityEasy to zoom inCatalyst activation/preparationPreparation by OH group eliminationChemical industryProduction rate

The invention relates to a structured catalyst for preparing 1,3-propanediol by hydrogenation of a glycerol water solution, and a preparation method of 1,3-propanediol. The catalyst comprises a structured ceramic material, and Pt, X and W supported on the structured ceramic material, wherein the X is one or more selected from a group consisting of La, Sm, Ce, Ru, Ag, Pr, Mn, Co, Pd, Cr, Mo and Rh.The structured catalyst provided by the invention has the advantages of high stability, low pressure drop, uniform bed distribution, no catalyst abrasion, simple amplification, flexible operation andthe like, and is suitable for the preparation of 1,3-propanediol by hydrogenation of the glycerol water solution. The 1,3-propanediol is prepared by adopting the method provided by the invention, theraw materials are easy to obtain, the reaction conditions are mild, the reaction temperature is proper, only water is needed as a solvent, the production rate of 1,3-propanediol is high, and the preparation method meets the requirement of green chemical industry and has a great market value and industrial application prospect.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

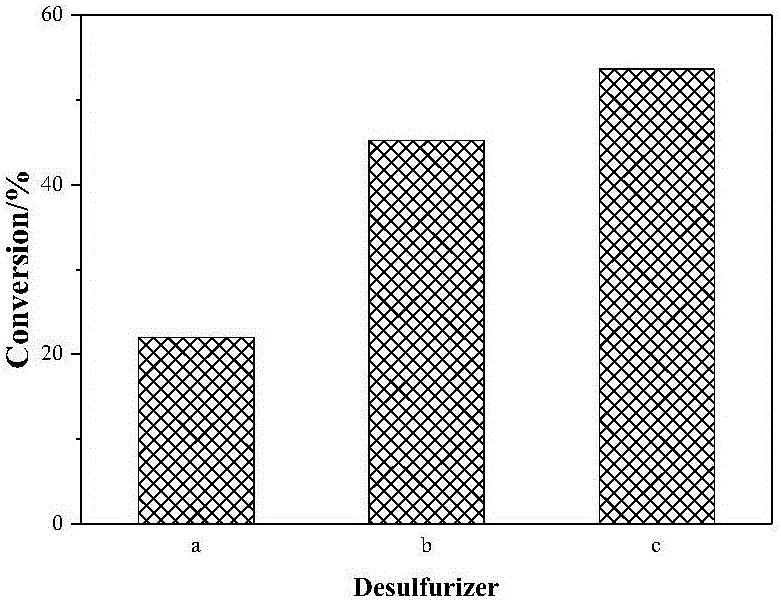

Light-weight oil desulfurizing agent based on supra-molecular inclusion effect and application method thereof

InactiveCN105126768APromote degradationEasy accessOther chemical processesHydrocarbon oils refiningActive componentBeta-Cyclodextrins

The invention discloses a light-weight oil desulfurizing agent based on a supra-molecular inclusion effect. The desulfurizing agent is composed of an active component beta-cyclodextrin or a derivative thereof and a NaOH solution, wherein the beta-cyclodextrin or the derivative thereof has a sustainable biomass source, can be circularly utilized for a plurality of times, can be rapidly degraded under a natural condition, and is environmentally friendly. The invention further discloses a method for taking the beta-cyclodextrin or the beta-cyclodextrin derivative and the NaOH solution as the desulfurizing agent to remove sulfides in light-weight oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

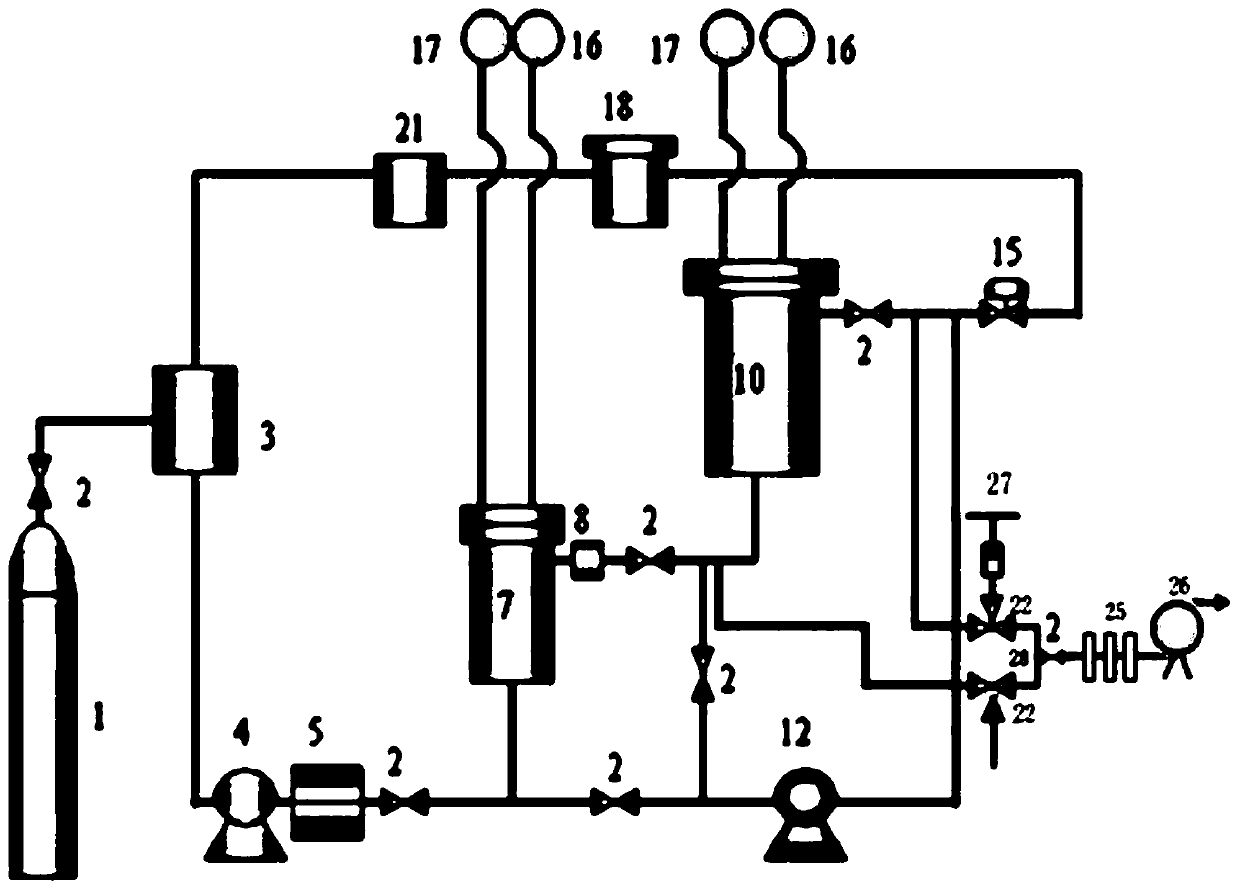

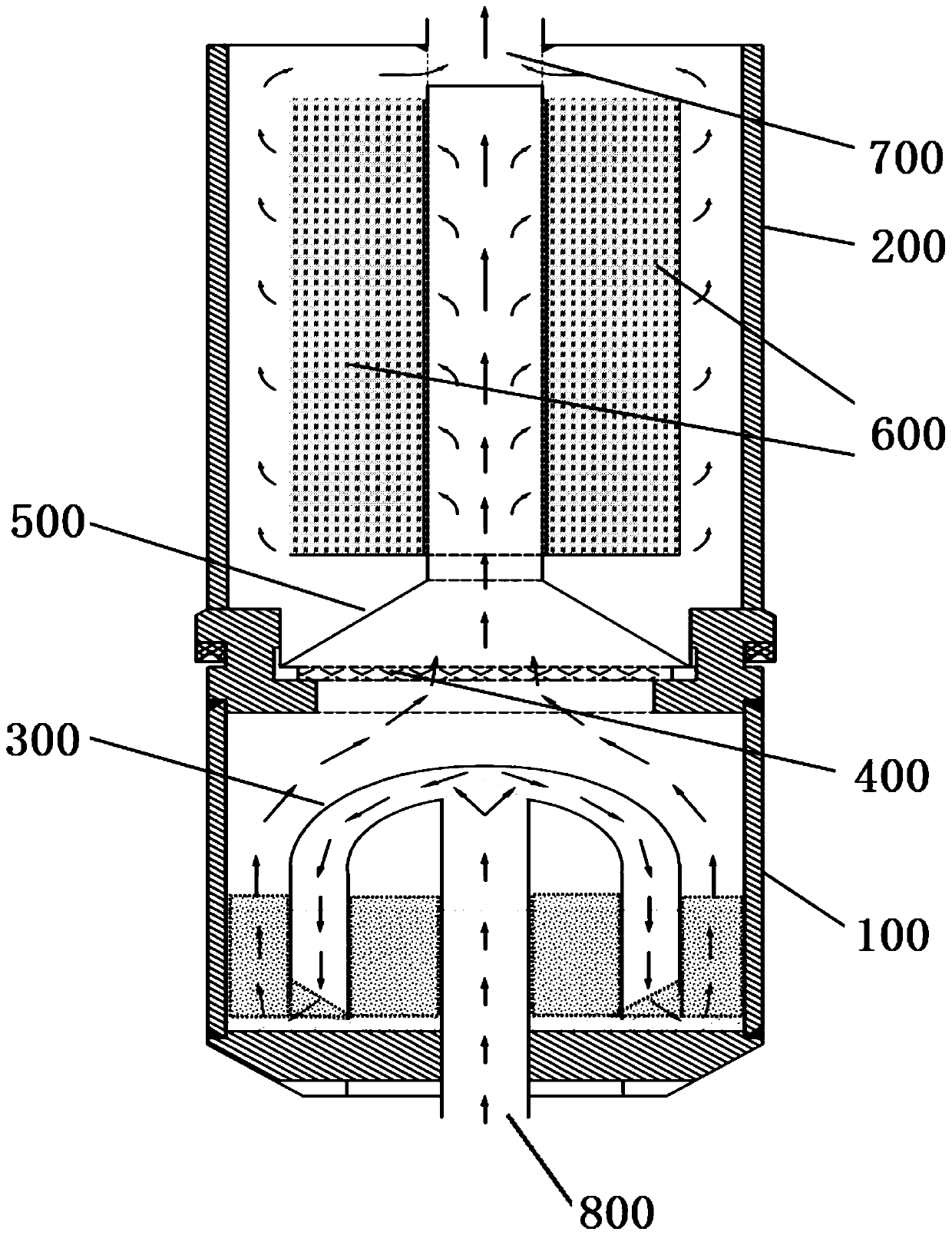

Method for cleaning animal fibers with supercritical fluid

PendingCN110747625AAvoid damageSimple processTextile treatment containersDry-cleaning apparatus for textilesActive agentAnimal fiber

The invention relates to a method for cleaning animal fibers with a supercritical fluid, which comprises the steps: driving a working fluid by a circulating supercritical fluid, and treating animal fibers under closed state with the temperature of 10-130 DEG C, pressure of 6-30 MPa, and dynamic and static circulation time ratio of the fluid being 1:10, wherein the working fluid comprises a surfactant, an enzyme and a solvent. The method provided by the invention has the advantages of good operation convenience, low energy consumption, ecological environment friendliness and zero pollution.

Owner:SUZHOU UNIV

Preparation method and separation method of low polymerization cyclic polymer

ActiveCN110407802AThe synthetic route is simpleShorten the production cycleOrganic chemistryOrganic solventHigh pressure

The invention provides a preparation method of a low polymerization cyclic polymer, and the method comprises the following steps: (1-1) in an organic solvent A, terephthaloyl chloride and 1,4-butanediol undergo esterification reaction under the action of an alkali A to obtain a hydroxyl n-butyl terephthalate mixture (mixture 1), and (1-2) in an organic solvent B, the hydroxyl n-butyl terephthalatemixture (mixture 1) obtained in the step (1-1) and the terephthaloyl chloride undergo cyclization under the action of an alkali B to obtain a low polymerization cyclic polymer mixture (mixture 2). The method has the advantages of simple synthesis route and high atom utilization rate, and four low polymerization cyclic polymers (I) can be prepared by only two steps of reaction, the reaction conditions are mild, high temperature and high pressure steps are not required, and guarantee is provided for safe production.

Owner:GUANGZHOU JOINCARE RESPIRATORY DRUG ENG TECH CO LTD

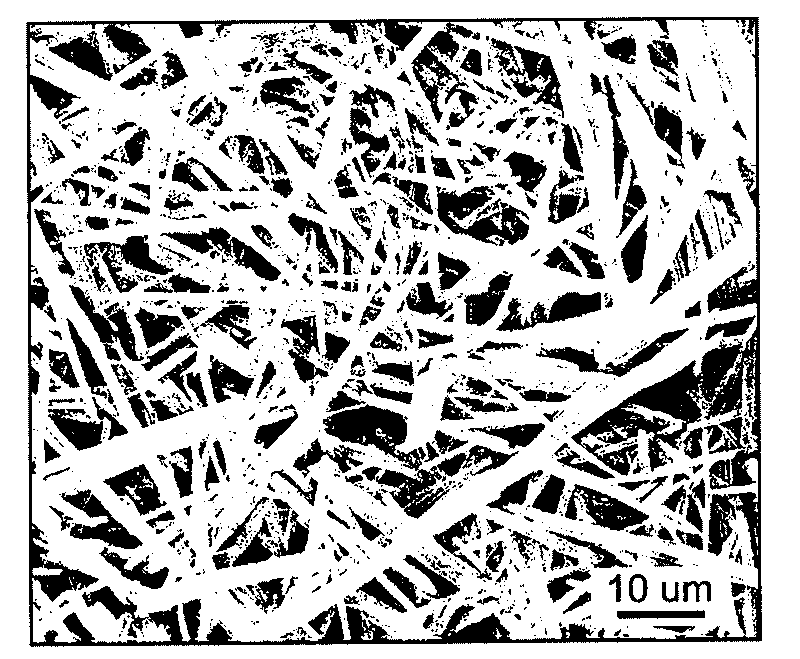

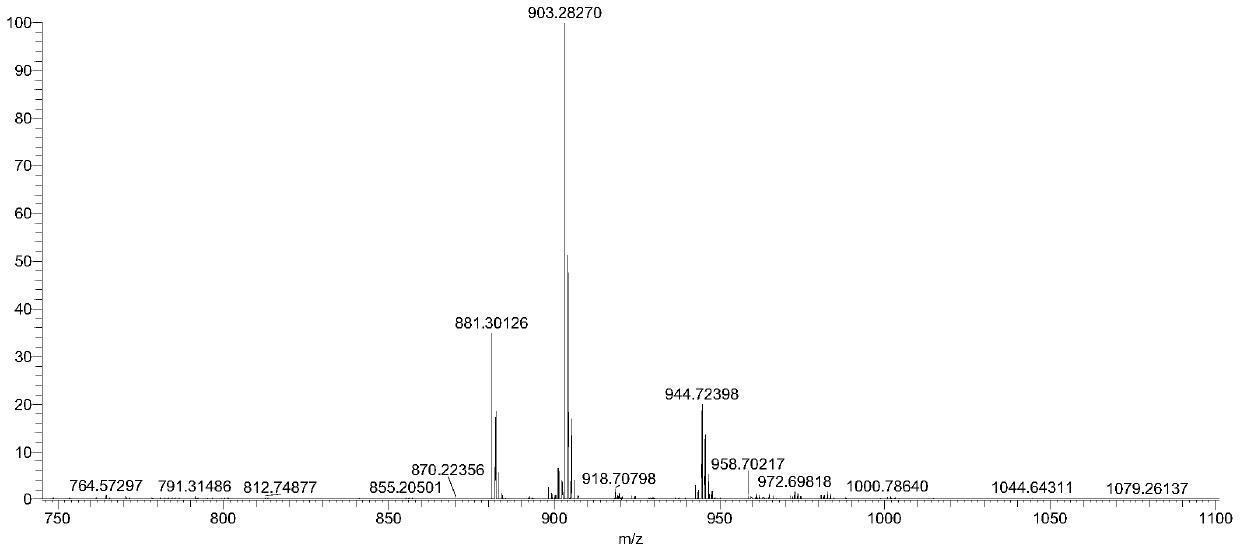

Preparation method of novel carbon silicon composite material

ActiveCN103928662APromote sustainable developmentSave raw materialsCell electrodesSecondary cellsNano siliconGraphite

The invention discloses a preparation method of a novel carbon silicon composite material. The preparation method comprises the following steps: adopting areca nut shells as a carbon source; after carrying out acid and alkali treatment on the areca nut shells, carbonizing into areca nut shell powder, then mixing the areca nut shell powder, nano silicon powder, artificial graphite powder and ethanol at a mass ratio of 1-2: 2-4: 0.5-1.0: 0.2-0.8; slowly adding into a ball mill, mechanically ball-milling for 18-22 hours, and then screening to obtain the carbon silicon composite material. The preparation method disclosed by the invention has the advantages that the cost is low, the preparation is simple, and a lithium battery prepared by utilizing the preparation method has a large capacity.

Owner:GUANGDONG HAOMEI ALUMINUM

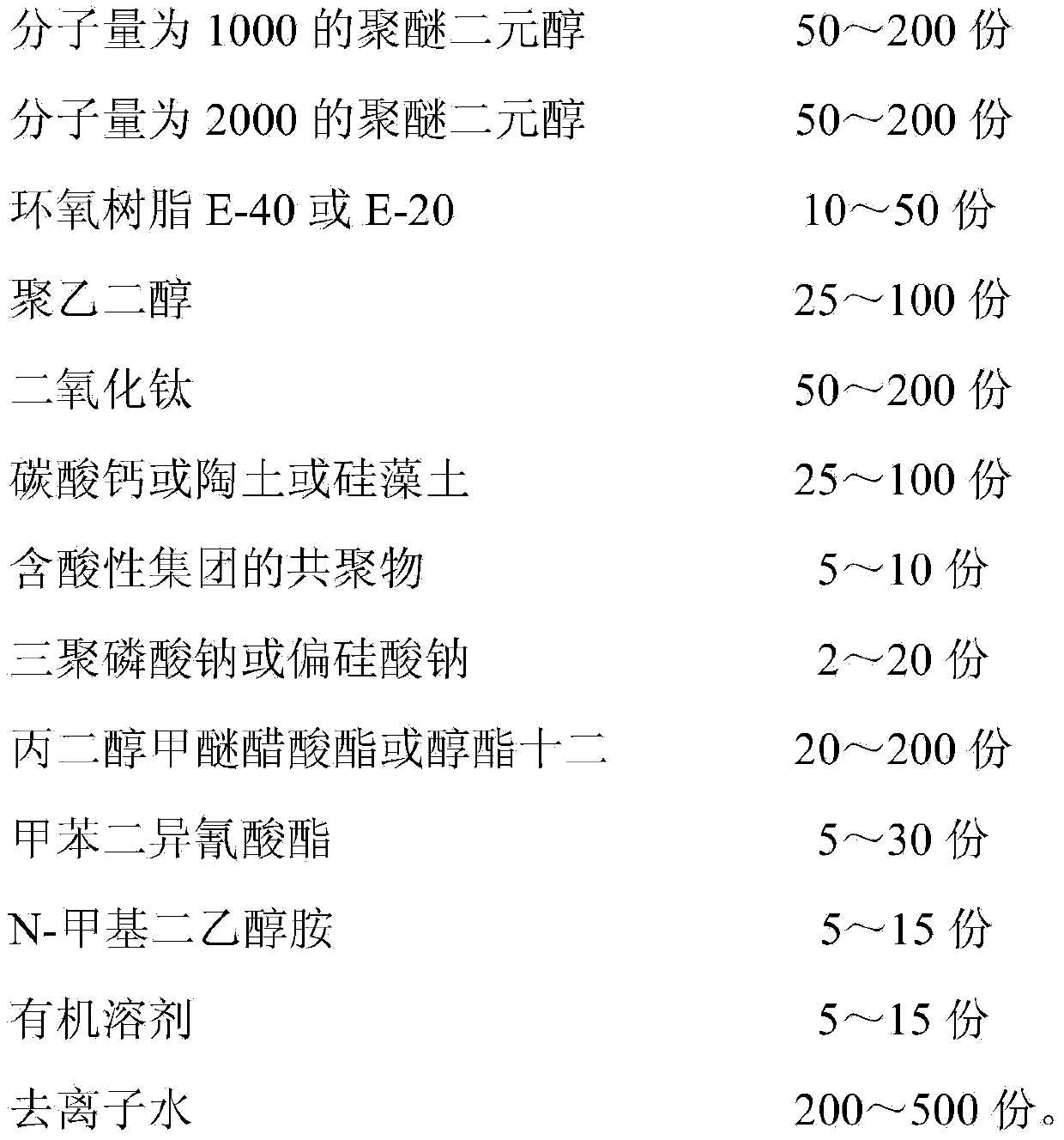

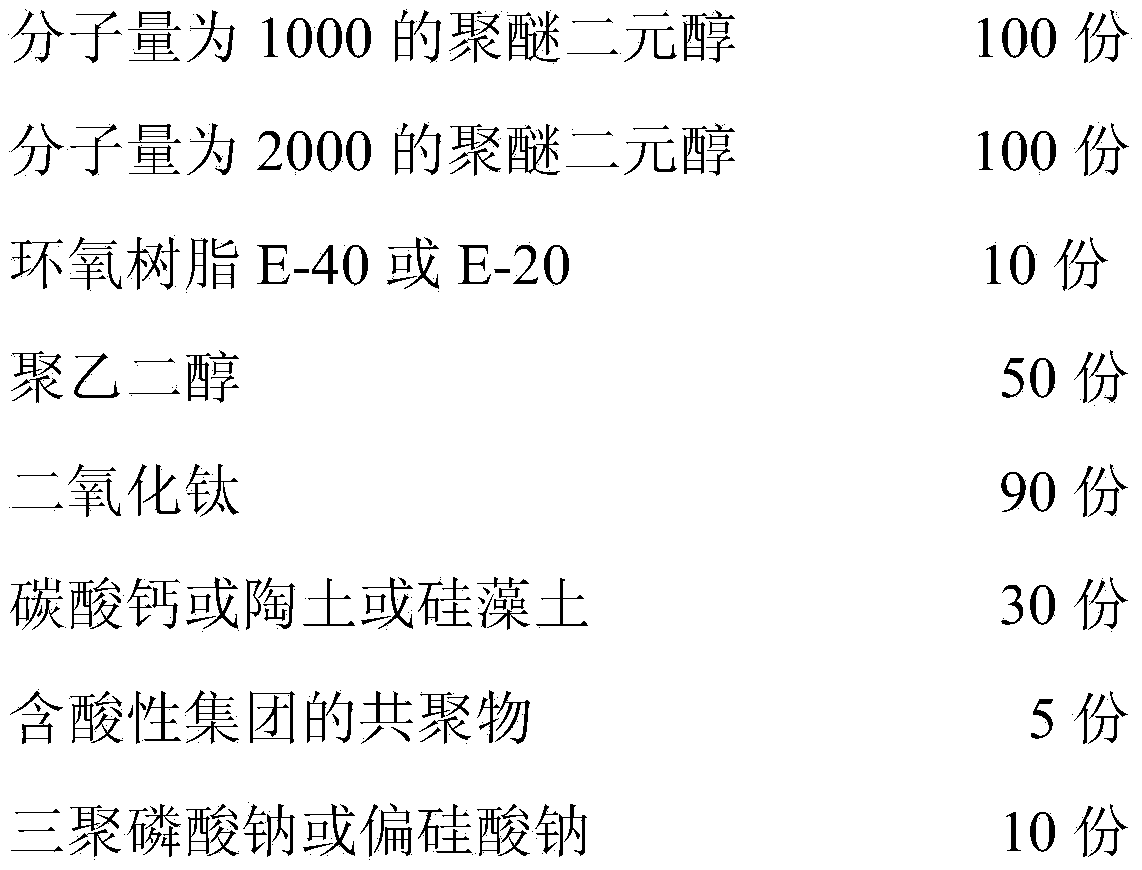

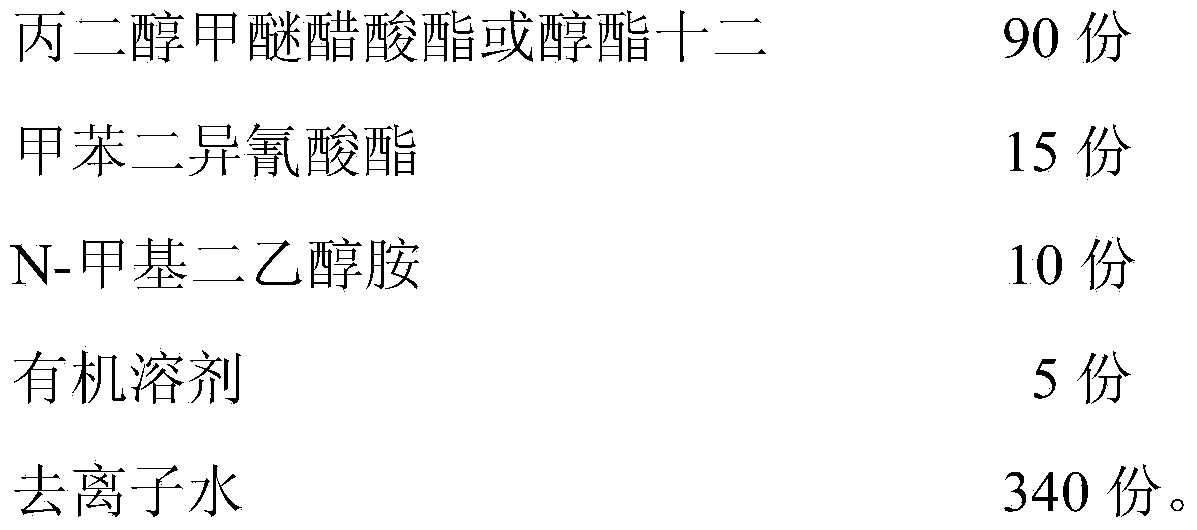

White dust suppressant and preparation method and application thereof

ActiveCN103834364AEasy to manageImprove environmental impactOther chemical processesEpoxySodium metasilicate

The invention belongs to the technical field of prevention and controlling of unorganized emission of dust in storing and transporting processes of coal, and discloses a white dust suppressant and a preparation method and application thereof. The white dust suppressant is prepared by the following raw materials in parts by weight: 50-200 parts of polyether diol with molecular weight of 1000, 50-200 parts of polyether diol with molecular weight of 2000, 10-50 parts of epoxy resin E-40 or E-20, 25-100 parts of polyethylene glycol, 50-200 parts of titanium oxide, 25-100 parts of calcium carbonate or argil or diatomite, 5-10 parts of copolymer containing acid group, 2-20 parts of sodium tripolyphosphate or sodium metasilicate, 20-200 parts of propylene glycol methyl ether acetate or 2,2,4-trimethyl-1,3-amyl glycol monoisobutyrate, 5-30 parts of toluene diisocynate, 5-15 parts of N-methyldiethanolamine, 5-15 parts of organic solvent, and 200-500 parts of deionized water.

Owner:广州普凯热伏微能源科技有限公司

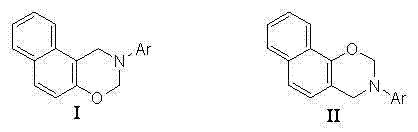

Preparation method of dihydrooxazinyl naphthalene compound

The invention relates to a preparation method of a dihydrooxazinyl naphthalene compound. The method comprises the following steps: adding a catalyst, paraformaldehyde, an arylamine compound and naphthol into water in sequence; fully reacting at the temperature of 20-80 DEG C to obtain reaction liquid; performing extracting, drying, concentrating and column chromatography isolation on the reaction liquid in sequence according to a conventional method to obtain a product I or a product II, wherein the structure formula of the product is shown in the specifications. The method has the advantages of mild conditions, short reaction time, easiness in operation, high yield, environmental friendliness, realization of scale production and good industrial application prospect.

Owner:盐城盐西幸福产业发展有限公司

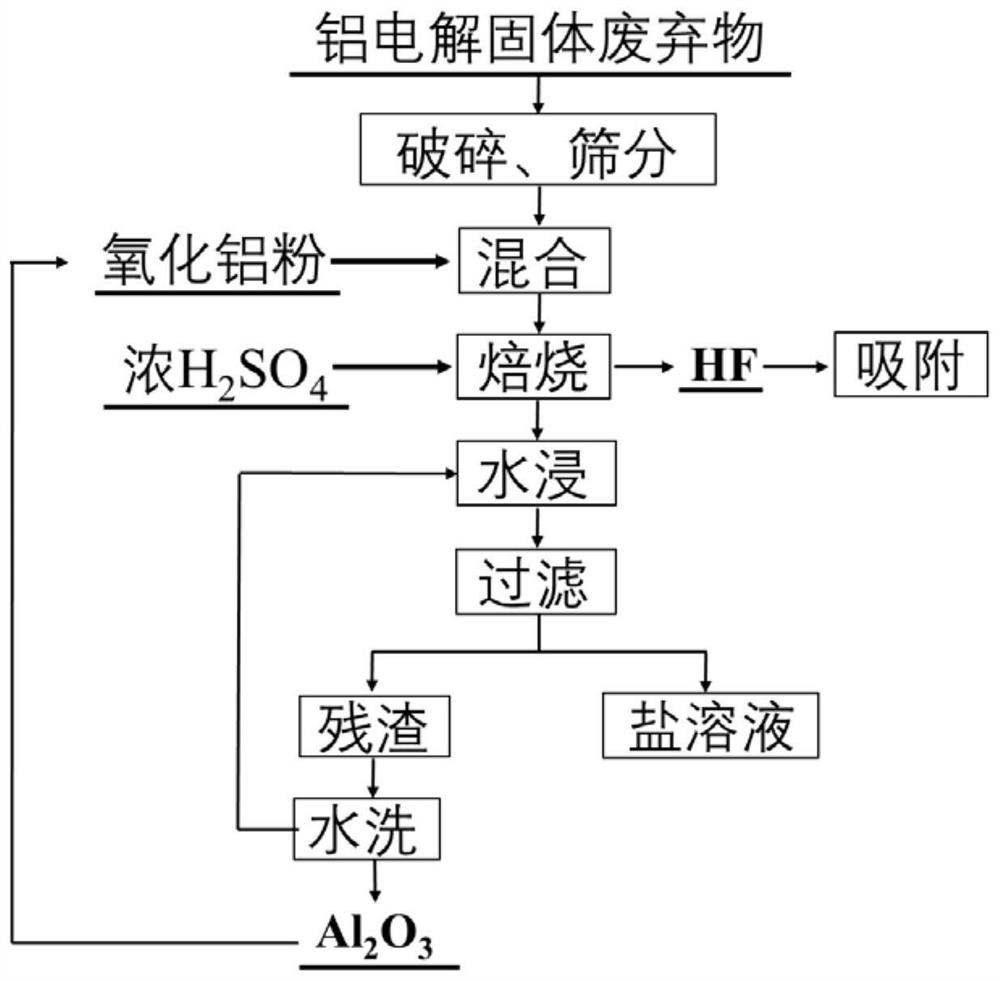

Acidification roasting method for efficiently treating aluminum electrolysis solid waste

ActiveCN114031099AAvoid pollutionSimple processHydrogen fluorideSulfate/bisulfate preparationChemistryProcess engineering

The invention discloses an acidification roasting method for efficiently treating aluminum electrolysis solid waste, and belongs to the technical field of resourceful treatment of the aluminum electrolysis solid waste. The method is characterized in that the specific treatment process comprises the following steps: uniformly mixing the aluminum electrolysis solid waste and aluminum oxide according to a ratio, acidizing and roasting, and finally carrying out wet-process water leaching treatment. According to the method, the aluminum electrolysis solid waste serves as a raw material and is mixed with a certain amount of aluminum oxide, sulfating roasting-water leaching treatment is carried out, finally, valuable elements are sufficiently and efficiently converted into the sulfate solution, and meanwhile the aluminum oxide solid is separated and recycled. According to the method, the aluminum electrolysis solid waste is directly utilized, aluminum oxide is added, so that the fluoride is acidified and roasted more sufficiently, finally, harmlessness is achieved, valuable elements, aluminum oxide, fluorine resources, lithium and potassium resources and the like in the aluminum electrolysis solid waste can be effectively recycled, waste is turned into wealth, the process is simple, and industrial implementation is easy.

Owner:NORTHEASTERN UNIV

Method for deeply removing oxygen in hydrogen through electrocatalysis at normal temperature and pressure to obtain high-purity hydrogen

ActiveCN113460964AEfficient reductive removalLow costCellsGas treatmentChemical industryPtru catalyst

The invention relates to a method for deeply removing oxygen in hydrogen through electrocatalysis at normal temperature and pressure to obtain high-purity hydrogen; a gas diffusion electrode electrolytic tank is adopted, a catalyst is sprayed on a gas diffusion layer substrate (including electrically conductive carbon paper, the catalyst and the like) to prepare a gas diffusion electrode, and a cathode and an anode are isolated by an ion exchange membrane. Reaction gas contains oxygen impurities with a certain concentration, electrochemical performance testing is carried out by adopting a three-electrode or two-electrode system constant voltage method, and the oxygen impurities in impurity-containing hydrogen are continuously and deeply removed. By adopting the method provided by the invention, the residual concentration of oxygen can be reduced to 1 ppm or less and the purity of hydrogen can reach 99.9999% or more by regulating and controlling a proper voltage range. Compared with a traditional technology, the method can efficiently reduce and remove oxygen in hydrogen at normal temperature and normal pressure, has the obvious advantages of greenness, safety, low cost, high efficiency and the like, better meets the requirements of green chemical industry, and has a wide practical application prospect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

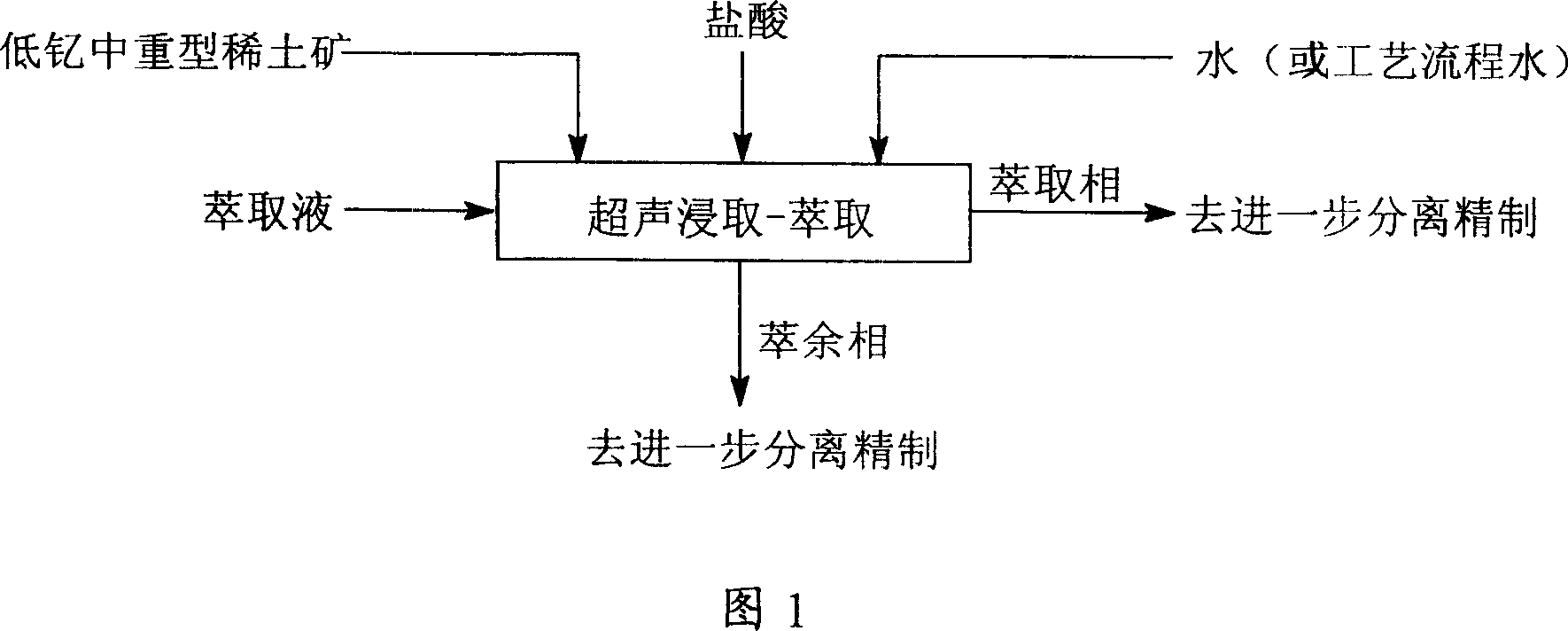

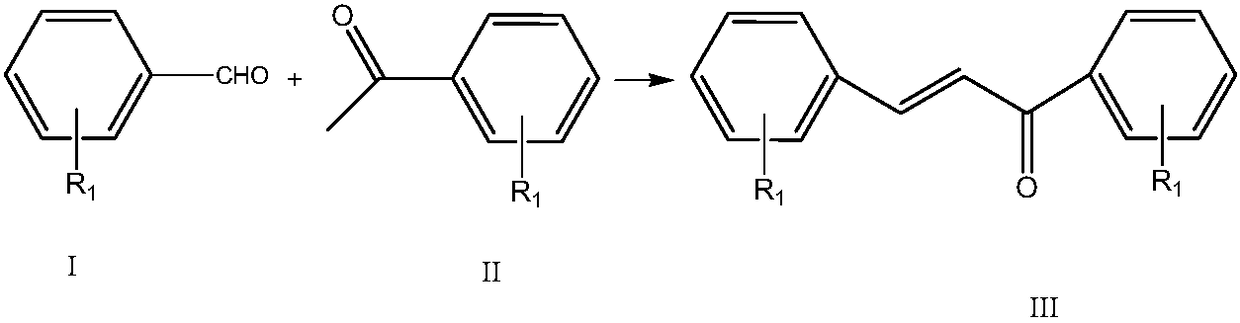

Ultrasonic leaching-extracting separation method for low-yttrium middle-heavy rare earth mine

InactiveCN101012513AIncrease concentrationShort processProcess efficiency improvementRare-earth elementKerosene

The invention discloses an ultrasonic leaching-extracting separating method of low-yttrium middle-heavy typed rare earth ore, which is characterized by the following: adopting low-yttrium middle-heavy typed rare earth ore as raw material and alcaine solution as leaching liquid; blending P507 or P204 and kerosene as extracting liquid; leaching low-yttrium middle-heavy typed rare earth ore to extract and separate at 5-60 deg.c; setting the ultrasonic frequency at 19-80kHz and ultrasonic strength at 0.2-20.0W / cm2; obtaining yttrium rare earth element hydrochlorate enriched material as extracting phase and cerium group rare earth hydrochlorate enriched material as residual phases.

Owner:YANGZHOU UNIV +2

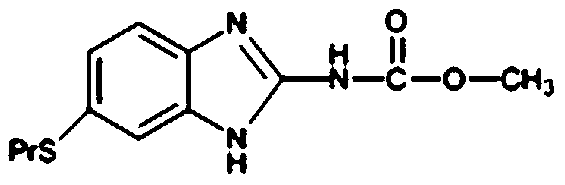

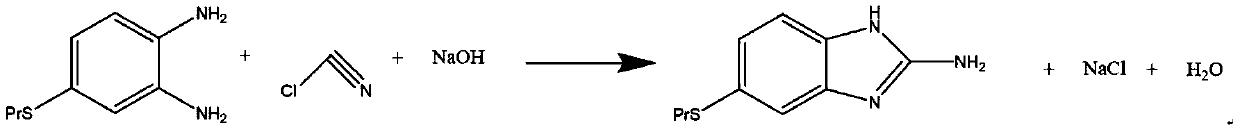

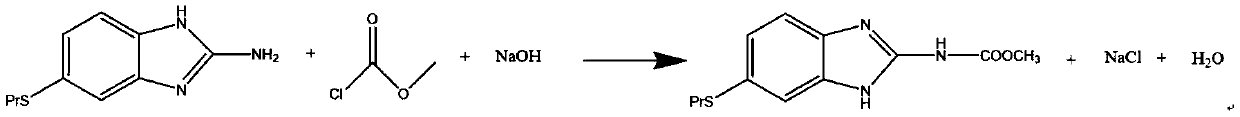

Preparation method of albendazole

The invention discloses a preparation method of albendazole, which comprises the following steps of: dissolving 4-propylthio-o-phenylenediamine in methanol, cooling, keeping the temperature at 0-5 DEGC, slowly dropwise adding cyanogen chloride for reaction under the condition of uniform stirring, and regulating and keeping the pH value at 4-5 in the process; heating to 35-45 DEG C after dropwiseadding is finished, carrying out heat preservation for 1-2 hours, then carrying out atmospheric distillation to recover methanol to obtain a solid-liquid mixed aqueous solution, and carrying out cooling, filtering and drying to obtain 6-propylthio-2-amino-1-hydrogen-benzo [d] imidazole; adding the obtained product into methanol, stirring, cooling, maintaining the temperature at 5-10 DEG C, slowlydropwise adding methyl chloroformate, and adjusting and maintaining the pH value at 6-7; after dropwise adding is finished, heating to 35-45 DEG C, keeping the temperature for 1-2 hours, distilling atnormal pressure to recover methanol, cooling to 15-20 DEG C, and performing filtering and drying to obtain an albendazole product. The method has the advantages of mild process conditions, low cost of used raw materials, water saving, strong reaction activity, good selectivity, high product yield and good product quality.

Owner:SHANDONG GUOBANG PHARMA +1

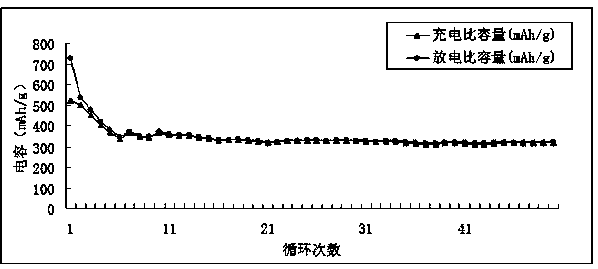

Environment-friendly carbon-silicon composite material

InactiveCN104201329APromote sustainable developmentComposite fullyCell electrodesSecondary cellsCarbon monofluorideChemical industry

The invention discloses an environment-friendly carbon-silicon composite material. The environment-friendly carbon-silicon composite material comprises the following substances in parts by weight: 55-64 parts of betelnut shell powder, 35-42 parts of nano-silicon powder, 10-12 parts of isobutyl methacrylate, 5-9 parts of nano-calcium sulfate, 11-14 parts of organic montmorillonite, 13-20 parts of stearic acid, 3-7 parts of polycarbodiimide, 5-9 parts of liquid paraffin, 10-14 parts of N-N'-diphenyl-p-phenylenediamine, 3.5-6.4 parts of aluminum acetylacetonate and 10-14 parts of carbon monofluoride. The environment-friendly carbon-silicon composite material has the beneficial effects that raw materials are low in cost, are wide in sources and meet the requirements of green chemical industry; a carbon material is composited with silicon by virtue of a mechanical ball-milling method, so that the preparation process is simple, and the materials are adequately composited together; the initial charge-discharge capacity of the carbon-silicon composite material disclosed by the invention is greatly increased, and the carbon-silicon composite material has good cycling stability.

Owner:QINGDAO HUA CHENG TIAN MACHINERY MFG

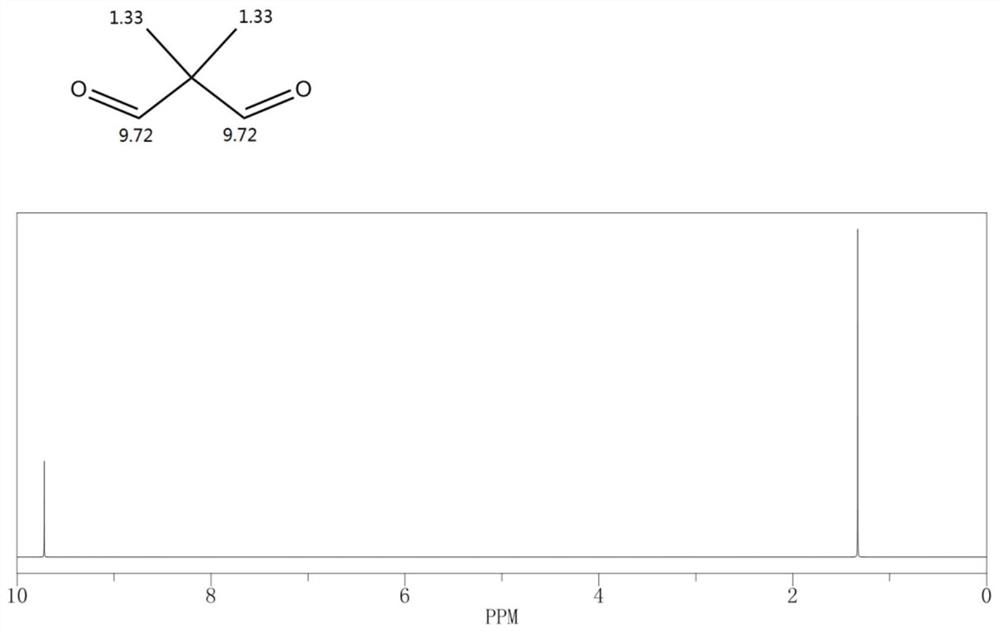

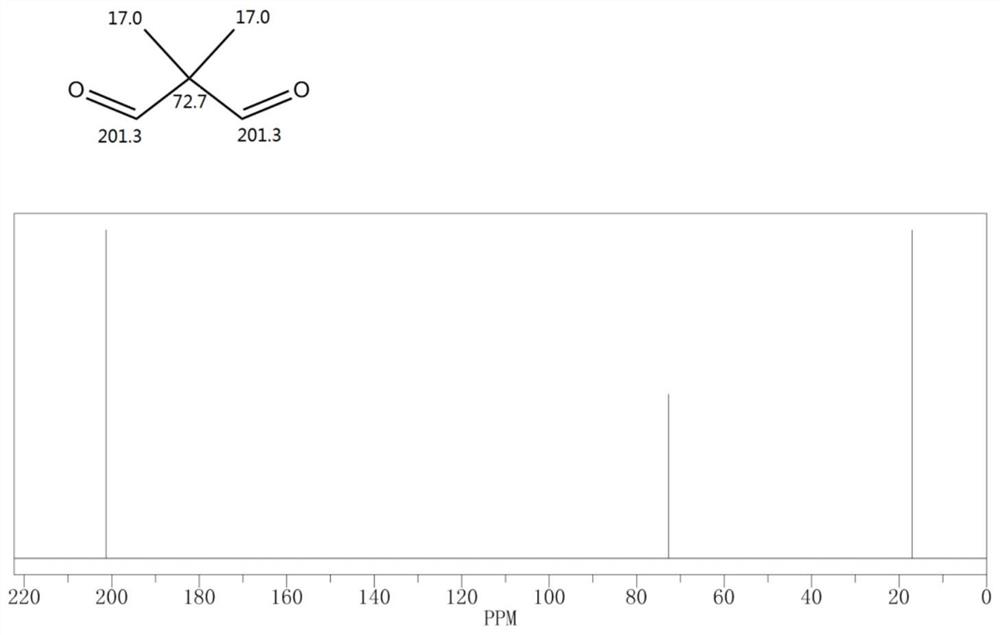

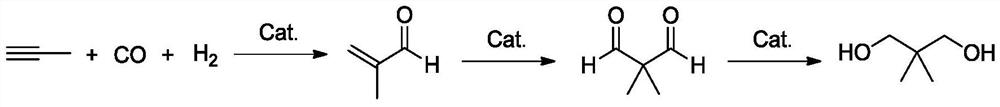

Carbonylation reaction catalyst composition and method for preparing neopentyl glycol

ActiveCN111822050AHigh yieldAtom utilization is highOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCupric bromide

The invention provides a carbonylation reaction catalyst composition and a method for preparing neopentyl glycol. The catalyst composition comprises one or more of a palladium or rhodium-containing compound, diphenylphosphine pyrrole, triphenylphosphine pyrrole, diphenylphosphine-naphthalene sulfonic acid and triphenylphosphine-naphthalene sulfonic acid, and one or more of copper bromide, p-toluenesulfonic acid, boron trifluoride and lanthanum trifluoromethanesulfonate. The method for preparing neopentyl glycol comprises the following steps: (1) carrying out carbonylation on propyne to preparemethylacrolein; (2) under the action of a catalyst composition, methylacrolein is subjected to carbonylation to prepare dimethyl malonaldehyde; and (3) preparing neopentyl glycol by hydrogenation. The catalyst composition can be used for efficiently catalyzing the carbonylation reaction of the alpha, beta-unsaturated carbonyl compound. The method for preparing neopentyl glycol is good in atom economy, low in raw material cost, free of wastewater generation and relatively good in yield.

Owner:WANHUA CHEM GRP CO LTD

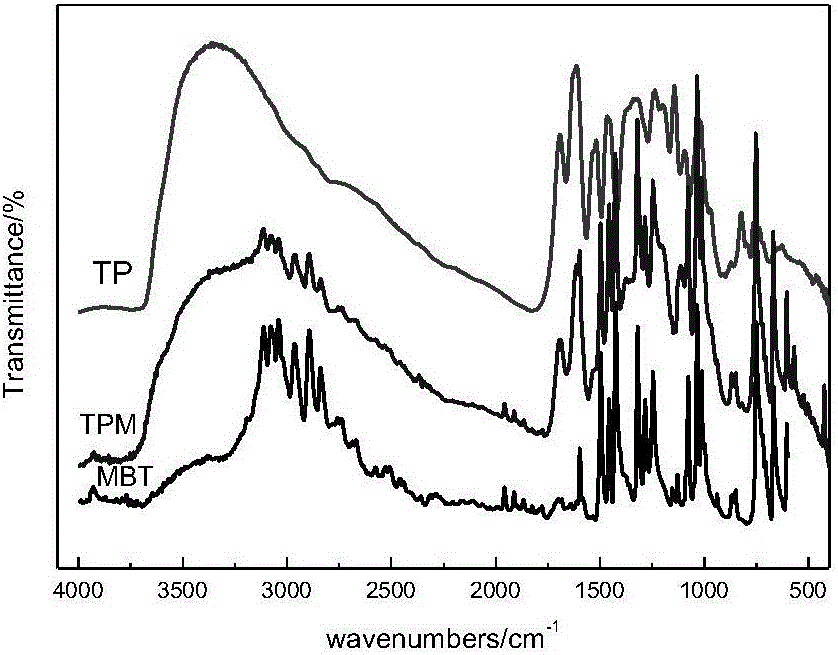

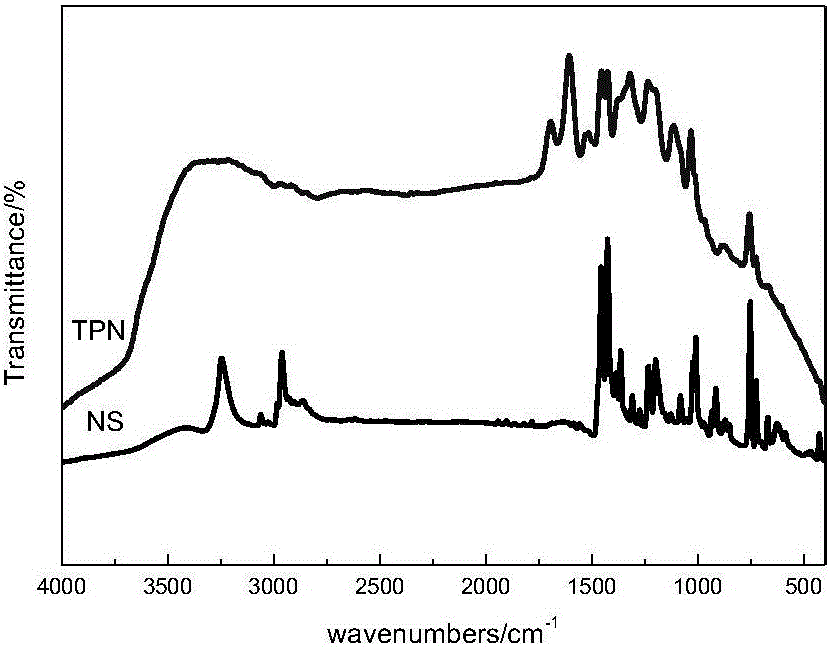

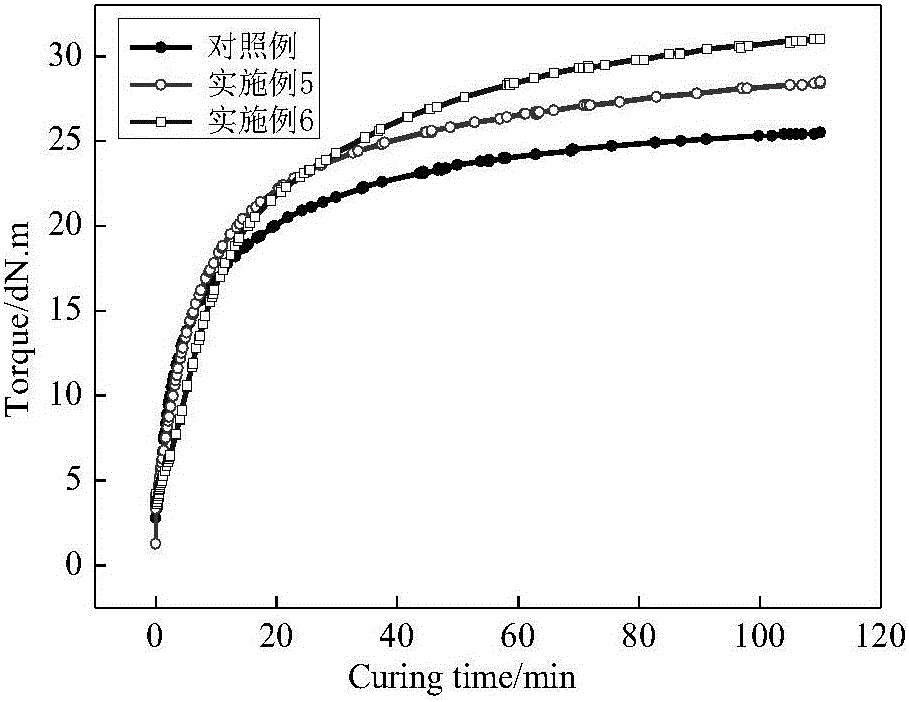

Preparation method and application of plant polyphenol based rubber accelerator

The invention discloses a preparation method and application of a plant polyphenol based rubber accelerator. The preparation method comprises the following steps: (1) dissolving secondary amine containing a rubber accelerator into a formaldehyde absolute ethyl alcohol solution and stirring; (2) reflowing and stirring in an acid adjusting water bath; (3) adding plant polyphenol into absolute ethyl alcohol, carrying out acid adjustment and ultrasonic oscillation, and continually reacting; (4) standing a reaction product at low temperature and filtering; (5) adding distilled water into filtrate and separating out the plant polyphenol based multifunctional accelerator; washing with water, filtering and drying to obtain a final product. The plant polyphenol based rubber accelerator integrates a plurality of functions of rubber vulcanization, white carbon black surface modification, ageing prevention and the like and is a multi-functional rubber accelerator, and has the characteristic of environment friendliness; the multifunctional auxiliary agent has moderate preparation conditions; a few of reaction byproducts are generated, the yield is high and the cost is low; the requirements of green chemical are met; the plant polyphenol based rubber accelerator is applied to white carbon black rubber and the strength and elongation properties and dynamic mechanical properties of the rubber can be effectively improved; the plant polyphenol based rubber accelerator can be applied to green tire tread rubber.

Owner:肇庆市联力化工有限公司

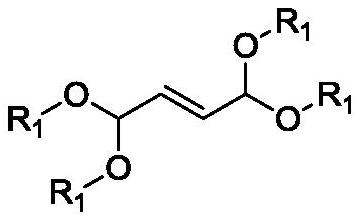

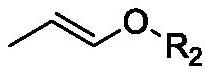

Method for preparing 1, 8-dialkoxy-1, 3, 6, 8-tetraalkoxy-2, 7-dimethyl-4-octylene

ActiveCN113604824AReduce pollutionMild reaction conditionsElectrolysis componentsElectrolytic organic productionPtru catalystOctene

The invention discloses a method for preparing 1, 8-dialkoxy-1, 3, 6, 8-tetraalkoxy-2, 7-dimethyl-4-octylene. The method comprises the following steps of: adding iodized salt, electrolyte, 1, 1, 4, 4-tetraalkoxy-2-butene, allyl alkyl ether and a solvent into a reaction container; and performing reaction under the condition of electrification to obtain the 1, 8-dialkoxy-1, 3, 6, 8-tetraalkoxy-2, 7-dimethyl-4-octylene. The method has the advantages of high efficiency, no use of a metal catalyst in the reaction, environmental protection and mild reaction conditions, and overcomes the defects of serious transition metal catalytic pollution, complex process, tedious post-treatment and the like in the prior art.

Owner:WANHUA CHEM GRP CO LTD

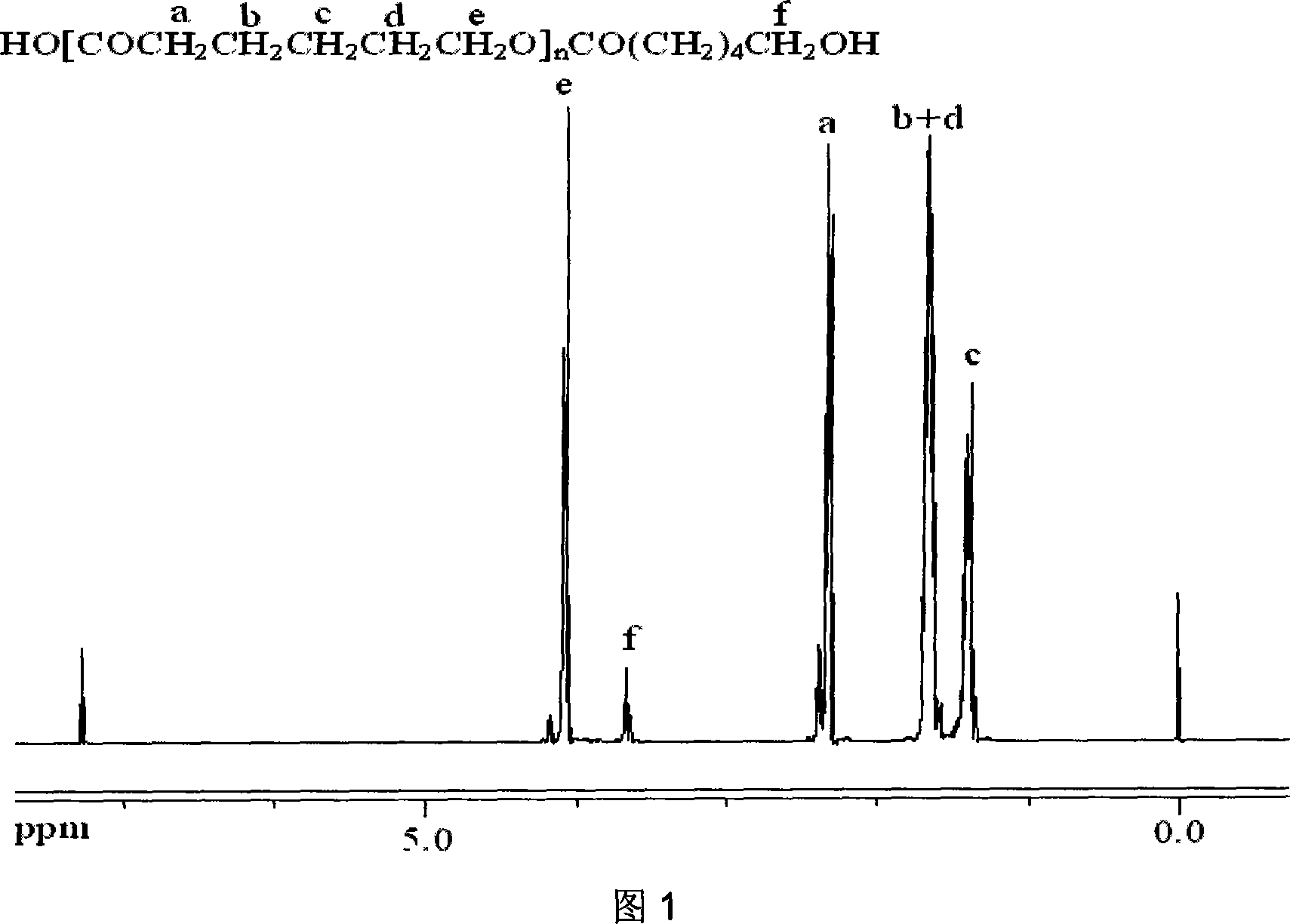

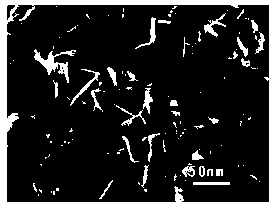

New-type super thermophilic esterase catalyzed prepn of poly-epsilon-caprolactone

InactiveCN101020740AReduce manufacturing costIncrease reaction rateHydrolasesFermentationDichloromethaneArchaeoglobus fulgidus

The present invention is super thermophilic esterase catalyzed poly-epsilon-caprolactone synthesizing process, and belongs to the field of polymer chemistry and biotechnology. At normal pressure, monomer epsilon-caprolactone is mixed with organic solvent enzyme catalyst is added to react at 60-100 deg.c for 24-120 hr; and after reaction, dichloromethane is added into the reacted system, enzyme is filtered out, the filtrate is vacuum concentrated to eliminate organic solvent, the concentrate is added with ice cooled methanol for low temperature depositing and centrifuged, and the precipitate is vacuum dried to obtain the polymer product. The enzyme catalyst is super thermophilic esterase AFEST of Archaeoglobus fulgidus. The present invention has the features of simple production process, high safety, low power consumption and high yield.

Owner:JILIN UNIV

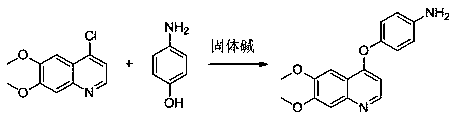

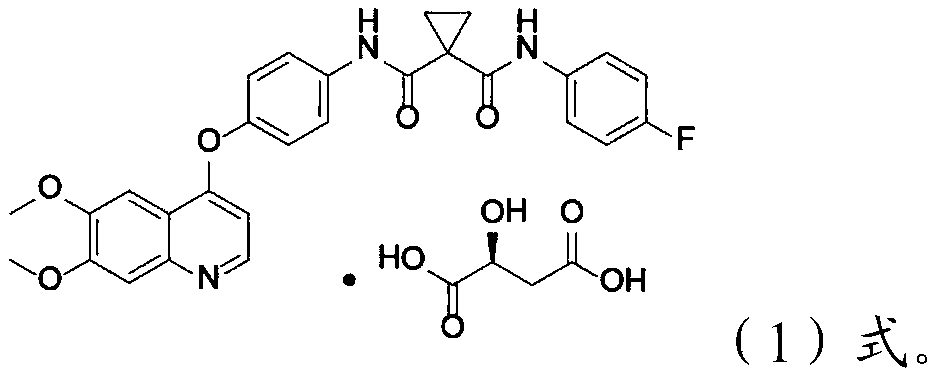

Method for preparing antitumor drug cabozantinib intermediate by solid base catalysis

InactiveCN108658856AAvoid it happening againNo pollution in the processOrganic chemistryPhysical/chemical process catalystsChemical industryM-aminophenol

The invention belongs to the technical field of catalytic materials, and in particular relates to a method for preparing an antitumor drug cabozantinib intermediate by solid base catalysis. Accordingto the method provided by the invention, Zr is used as a third metal element to modify Mg / Al bimetal, a Zr-doped Mg / Al composite metal hydroxide is prepared by a co-precipitation method, then ion exchange is carried out through potassium carbonate, high-temperature calcination is carried out, and finally reforming is carried out in water to finally prepare a Zr-doped Mg / Al composite metal oxide solid base with a three-dimensional structure. The solid base prepared by the method provided by the invention can replace sodium hydroxide to catalyze the preparation of 4-chloro-6,7-dimethoxyquinolinewhich is condensed with 4-aminophenol to prepare 4-(4-aminophenoxy)-6,7-dimethoxyquinoline, an antitumor drug cabozantinib intermediate. The catalytic system provided by the invention is green and pollution-free, avoids the generation of alkaline waste water and has a high yield and meets the requirements of green chemical industry.

Owner:张淑华

Preparation method of tetraimidazole hydrochloride

The invention provides a preparation method of tetraimidazole hydrochloride, which comprises the following steps: preparing tetraimidazole; the preparation method comprises the following step: reacting tetraimidazole, 1, 2-dibromoethyl benzene and 2-aminothiazoline hydrochloride to generate tetraimidazole. The synthetic route is shorter, the comprehensive yield is higher than that of other processroutes, styrene is used as an initiator, tetra-imidazole free alkali is used as a final product, the yield of the hydroxysalt process route is about 65%, the yield of the N (2chloroethyl) alpha (chloromethyl) benzylamine hydrochloride process route is about 72%, and the yield can reach 85% or above when the patent route is used. Meanwhile, the problem of large amount of waste water and waste saltgenerated by multi-step reactions such as chlorination, hydrolysis and cyclization is avoided, the investment of reaction equipment such as an autoclave is avoided, the green chemical engineering requirement is met, the economic benefit is remarkable, and the industrial prospect is good.

Owner:SHANDONG GUOBANG PHARMA +1

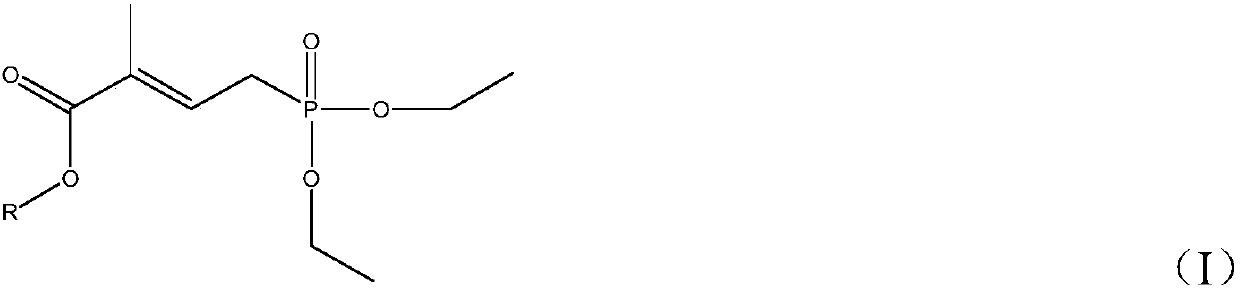

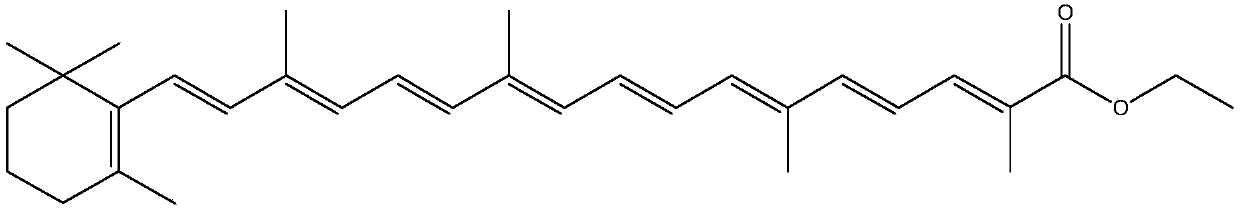

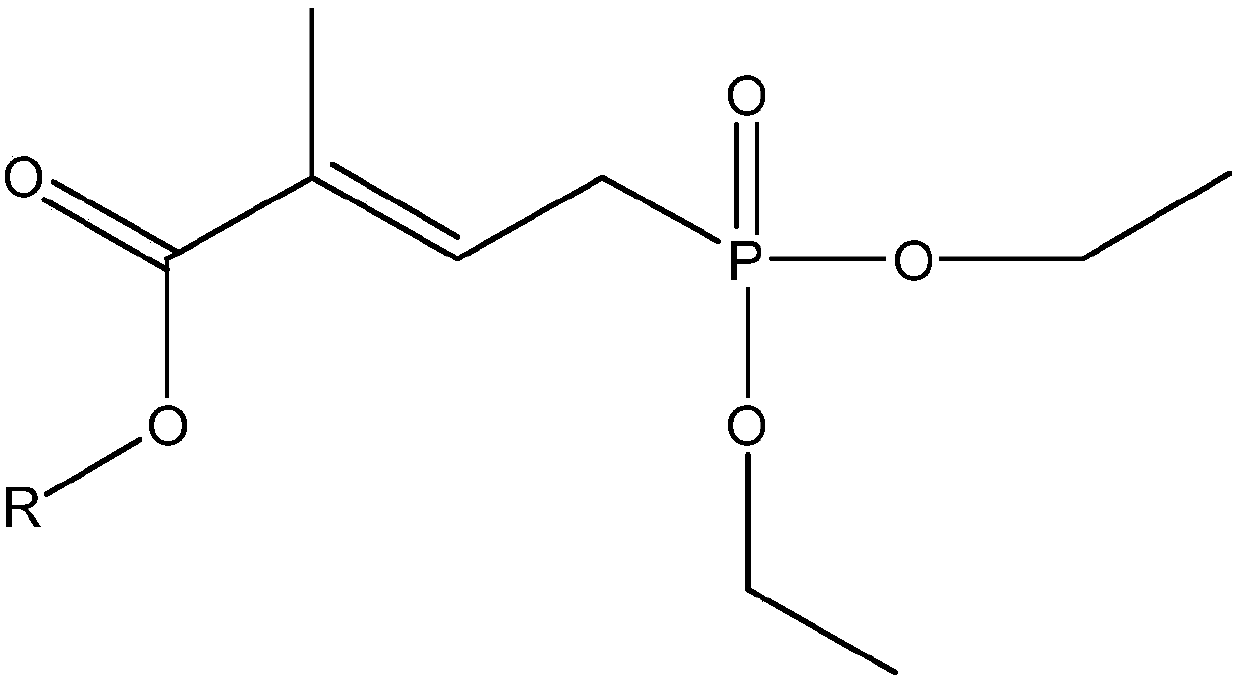

4-(diethoxy-phosphoryl)-2-methyl-but-2-enoate preparation method

ActiveCN110655533AHigh yieldEasy to operateGroup 5/15 element organic compoundsAlcoholPyruvate lactate

The invention discloses a 4-(diethoxy-phosphoryl)-2-methyl-but-2-enoate preparation method, which comprises: (a) carrying out an oxidation reaction on a pyruvic aldehyde aqueous solution to obtain a pyruvic acid / pyruvate aqueous solution; and (b) carrying out a reaction on the pyruvic acid / pyruvate aqueous solution and tetraethyl ethylene diphosphate, and performing an esterification reaction withan alcohol to obtain 4-(diethoxy-phosphoryl)-2-methyl-but-2-enoate. The method of the invention has advantages of cheap and easily available raw materials, simple operation of each step, high yield of the whole route, and high industrial application value.

Owner:SHANGYU NHU BIOCHEM IND +1

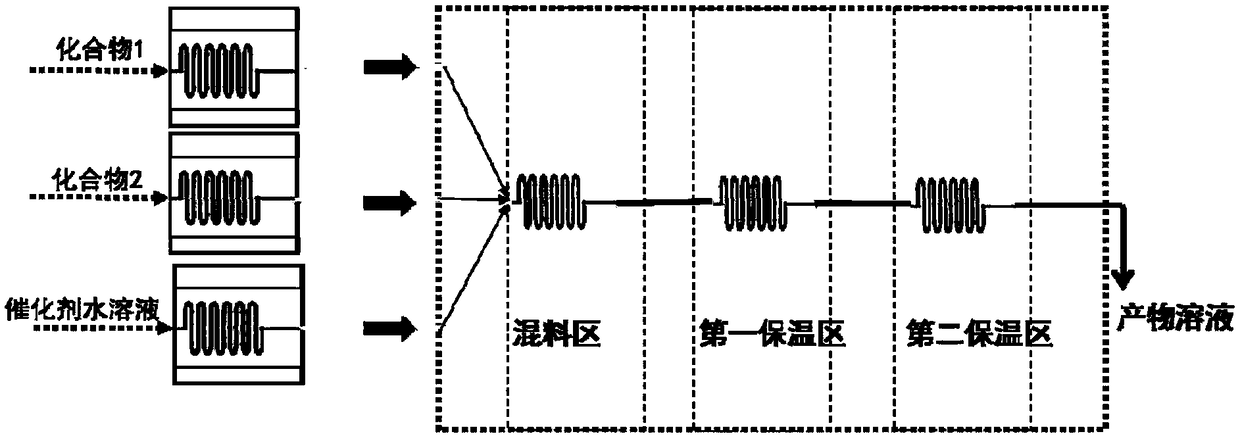

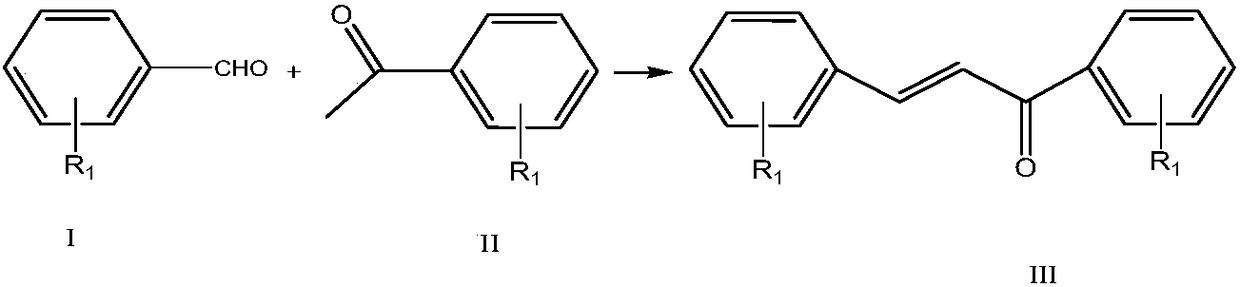

Method of utilizing micro channel reactor to prepare fluorine containing chalcone derivatives

InactiveCN108299174AImprove safety and operabilityImprove mass transfer efficiencyOrganic compound preparationCarbonyl compound preparationChalcone derivativeSolvent

The invention discloses a method of utilizing a micro channel reactor to prepare fluorine containing chalcone derivatives. The method comprises following steps: individually dissolving a compound represented by a formula I and a compound represented by a formula II into a solvent to prepare solutions; introducing the solutions and a catalyst water solution into a micro channel reactor, mixing, heating the mixture to a temperature of 20-50 DEG C, maintaining the temperature for 10 to 40 seconds, then heating the temperature to 50-180 DEG C, carrying out condensation reactions for 15 to 70 seconds, and acidifying the reaction product to obtain fluorine containing chalcone derivatives. The method obviously improves the reaction efficiency, largely shortens the reaction time, avoids the temperature runaway phenomenon of kettle reactions, reduces the generation of byproducts, and improves the safety. The production process is convenient to control. The production cost is reduced. The shortages such as large labor strength, long production period, low product quality, large amount of wastes, and the like, are overcome.

Owner:SHANGHAI CHEM REAGENT RES INST

Ultrasonic leaching-extracting separation method for yttrium-rich rare earth mine

InactiveCN101012512AIncrease speedImprove efficiencyProcess efficiency improvementRare-earth elementSulfate

The invention discloses an ultrasonic leaching-extracting separating method of enriched rare earth ore, which is characterized by the following: leaching enriched yttrium rare earth ore, leached liquid and extract in the same container; extracting group by group; separating; obtaining yttrium hydrochlorate or enriched sulfate material as residual phase and non-yttrium rare earth element hydrochlorate or enriched sulfate material as extracting phase.

Owner:YANGZHOU UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com