Preparation method of novel carbon silicon composite material

A composite material and carbon-silicon technology, which is applied in the field of preparation of new carbon-silicon composite materials, can solve problems such as low capacity and unfavorable high-capacity lithium-ion batteries, and achieve the effects of wide sources, sustainable development, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

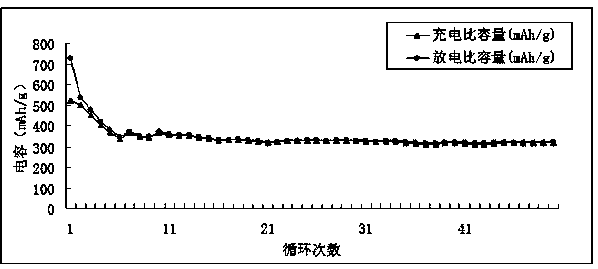

Embodiment 1

[0028] A method for preparing a novel carbon-silicon composite material, comprising the steps of:

[0029] S1. Pretreatment: first wash the betel nut shells with deionized water and cut them into pieces, put them in 1mol / L sodium hydroxide solution, soak in a water bath at 80°C for 10 hours, then put them in 1mol / L dilute Boil in hydrochloric acid solution until the betel nut shell is completely swollen, then wash the betel nut shell and then vacuum dry it for later use at a temperature of 55°C;

[0030] S2. Preparation of betel nut shell powder: put the treated betel nut shell into a tubular resistance furnace, carbonize for 1-2 hours under the protection of nitrogen, the carbonization temperature is 850-1000°C, and the heating rate is 1-10°C / min; The carbonized betel nut shells are put into a mortar and repeatedly ground into betel nut shell powder;

[0031] S3. Preparation of carbon-silicon composite material: mix betel nut shell powder, nano-silicon powder, artificial gra...

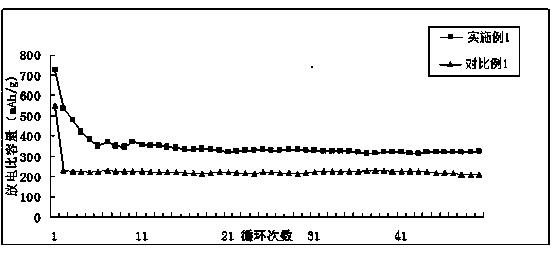

Embodiment 2

[0033] Except that betel nut shell powder, nano-silicon powder, artificial graphite powder and alcohol are mixed in a mass ratio of 2:4:1:0.8 in step S3, the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com