Patents

Literature

76results about How to "Composite fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficient white-light organic electroluminescence device

ActiveCN103187537AFlexible control of luminous intensityGuaranteed luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerHole transport layer

The invention relates to a high-efficient white-light organic electroluminescence device which comprises a substrate, an anode layer, a luminous unit layer and a cathode layer; the luminous unit layer comprises a hole injection layer which is formed on the anode layer, a hole transport layer is formed on the hole injection layer, the cathode layer is formed on an electron transport layer, a plurality of luminous layers are arranged between the hole transport layer and the electron transport layer, each luminous layer comprises a fluorescence luminous layer and a phosphorescence luminous layer, and a barrier layer consisting of an electron transport material and a hole transport material of the same parent nucleus is arranged between the fluorescence luminous layer and the phosphorescence luminous layer; and a main body material of the phosphorescence luminous layer which is adjacent to the barrier layer comprises an electron transport material and a hoe transport material of the same parent nucleus. The luminous device can effectively allocate the electron transport efficiency and the hole transport efficiency and has the advantage of high luminous efficiency.

Owner:GUAN YEOLIGHT TECH CO LTD +1

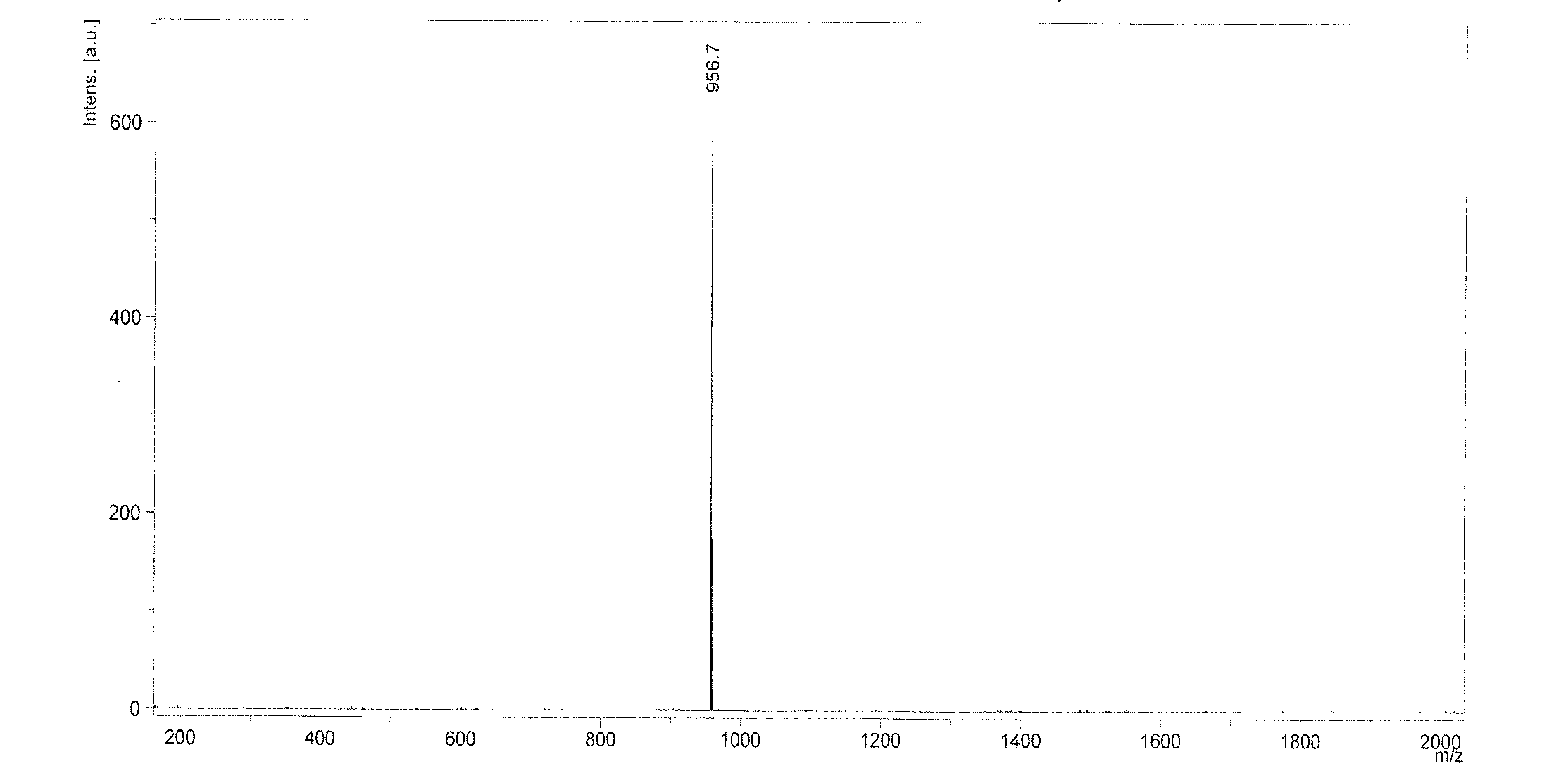

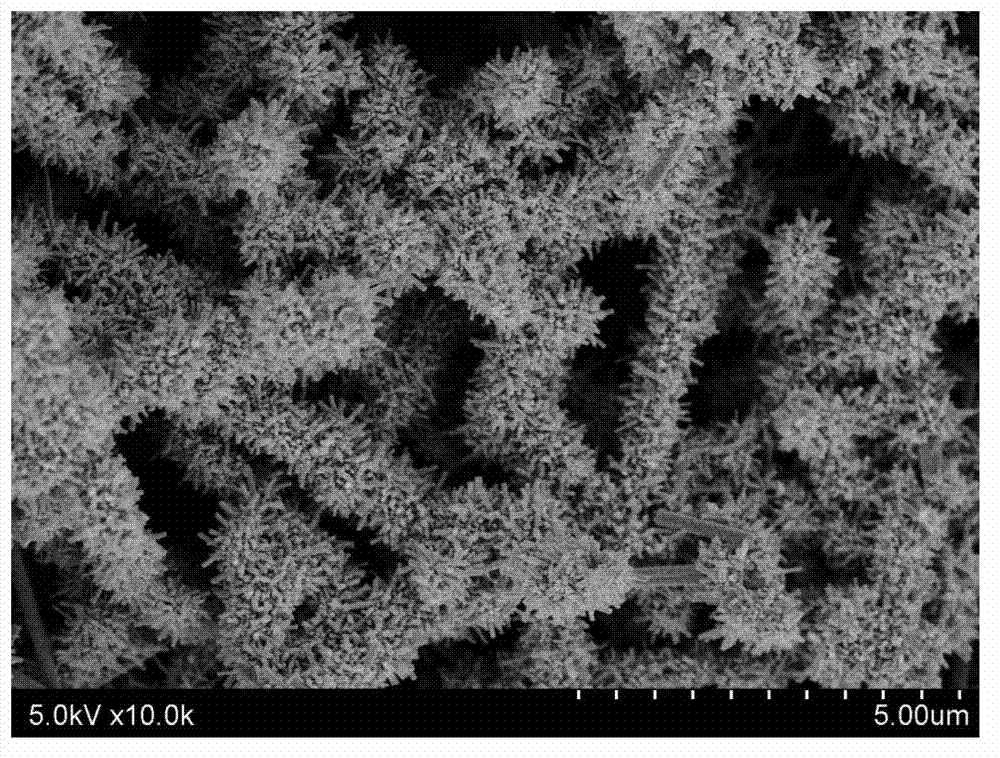

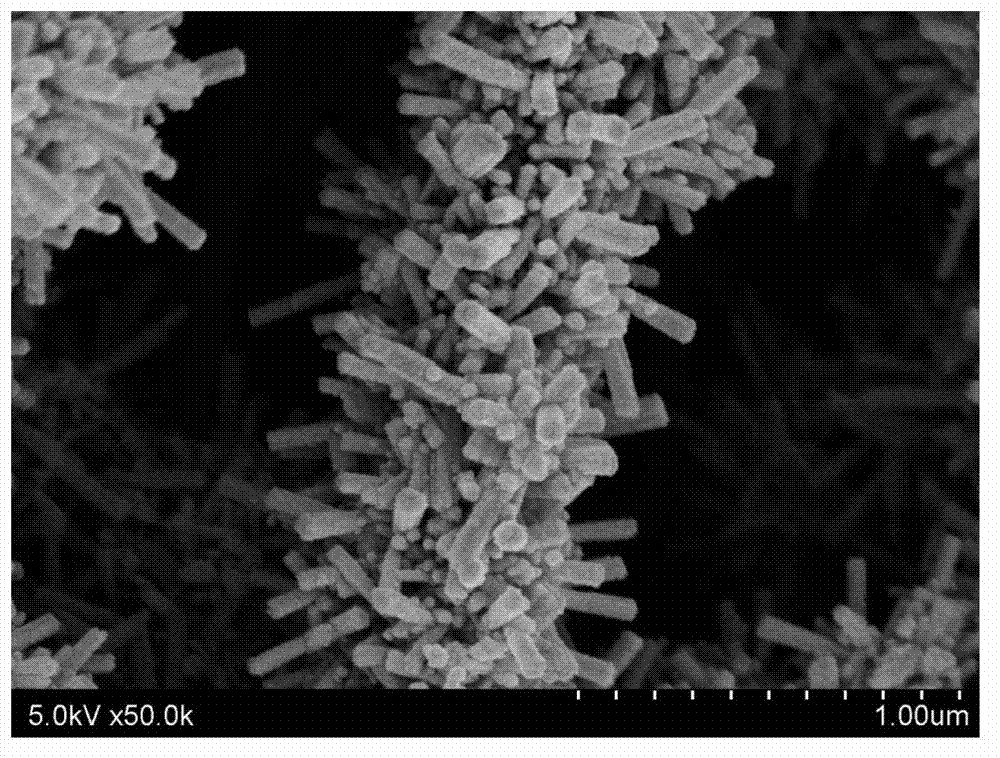

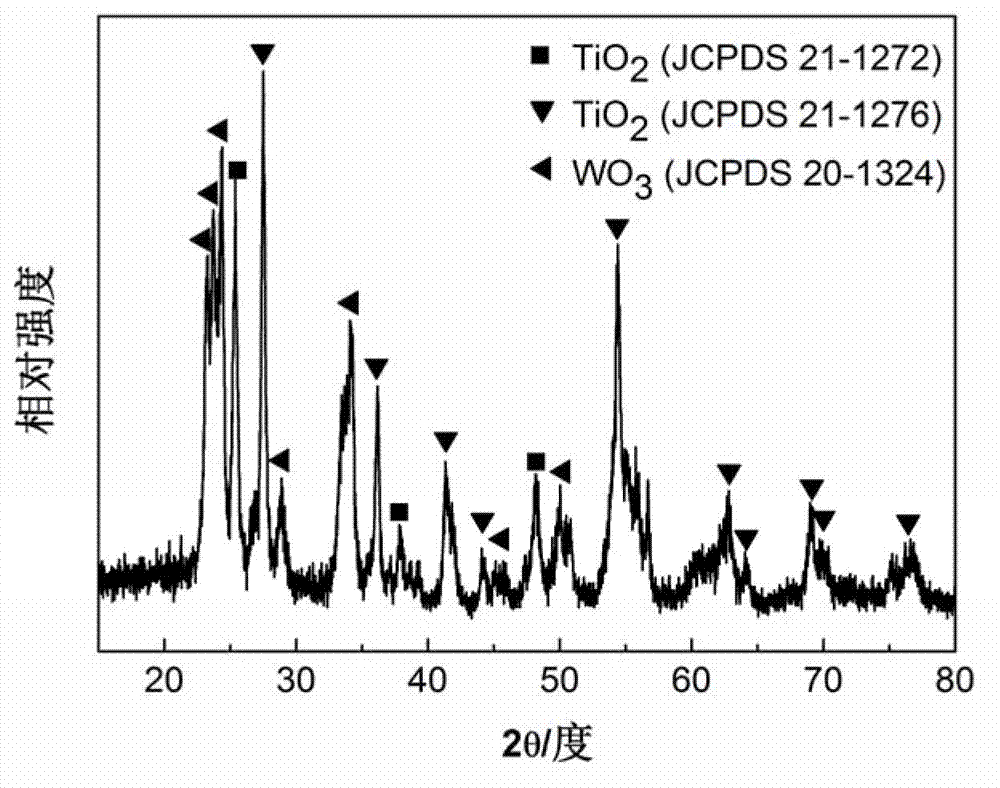

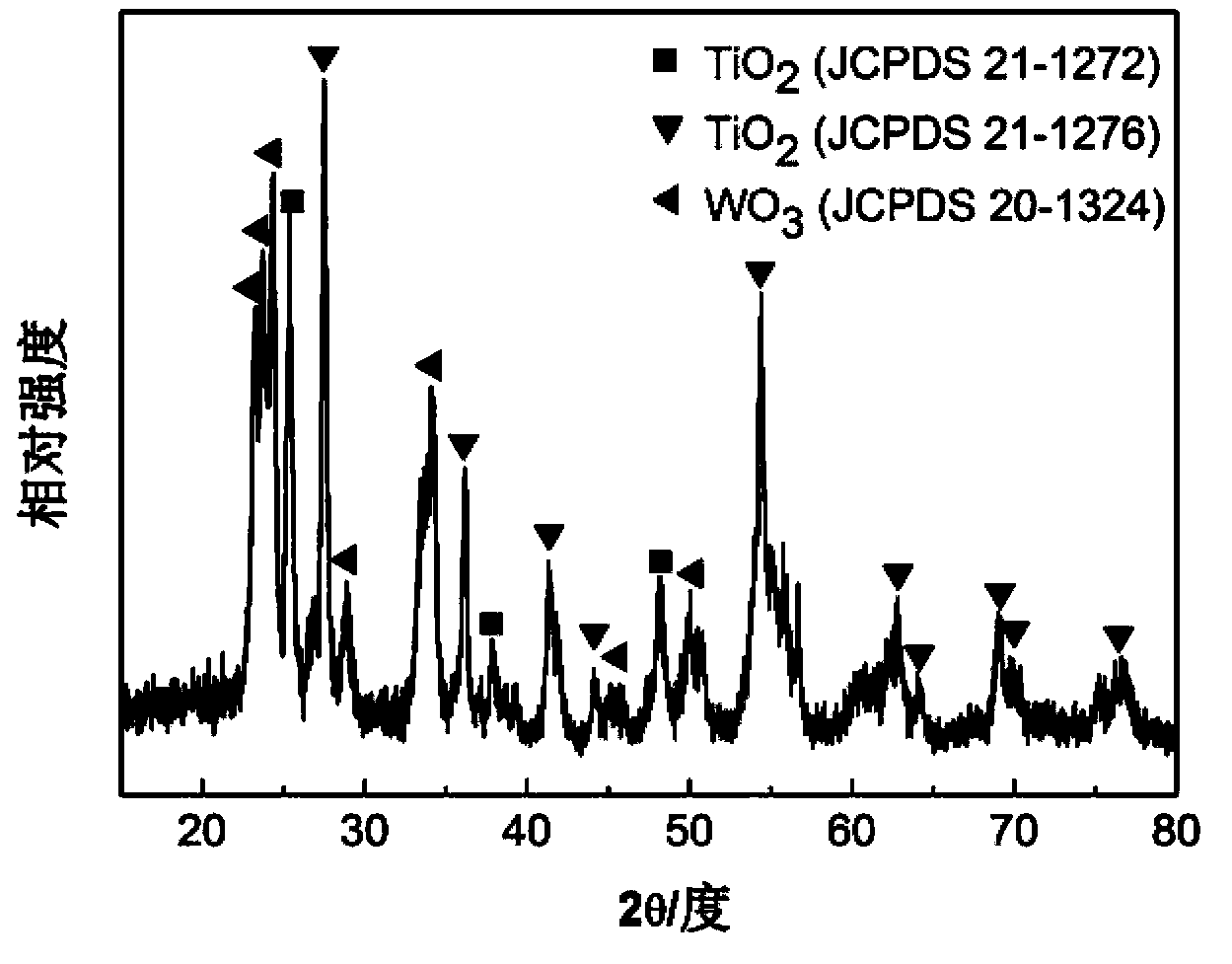

Preparation method of nano fiber containing TiO2/WO3 heterojunction

InactiveCN102926030ASimple methodComposite uniformInorganic material artificial filamentsFilament/thread formingSolventChemistry

The invention relates to a preparation method of a nano fiber containing TiO2 / WO3 heterojunction. The preparation method comprises the following steps of (1) adding soluble titanium salt into a mixed solvent of PVP (Poly Vinyl Pyrrolidone), absolute ethyl alcohol and acetic acid, and obtaining inorganic TiO2 nano fiber by adopting an electrostatic spinning and calcining method; and sequentially adding H2O2 and H2O in tungstic acid powder, and obtaining colorless and transparent WO3 sol; (2) preparing TiO2 nano fiber containing WO3 seed crystal by adding the TiO2 nano fiber into the WO3 sol; and (3) adding the WO3 sol, HMT (Hexamethylenetetramine) and water into the TiO2 nano fiber containing the WO3 seed crystal, and keeping warm for 6-12 hours under 120-180 DEG C; and drying a product which is obtained after hydrothermal in low temperature after centrifuging and water washing, and thus obtaining the nano fiber containing the TiO2 / WO3 heterojunction can be obtained. The preparation method disclosed by the invention is simple and practical, the composition of the TiO2 and the WO3 is more uniform and fuller, a large amount of contact interfaces can be formed, and the catalyzing ability can be increased.

Owner:DONGHUA UNIV

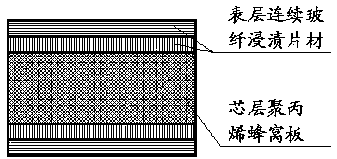

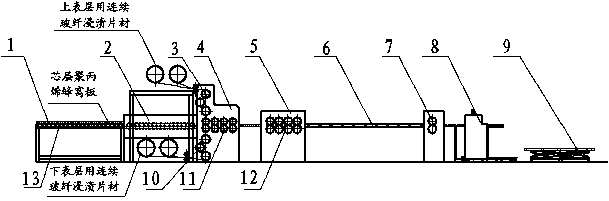

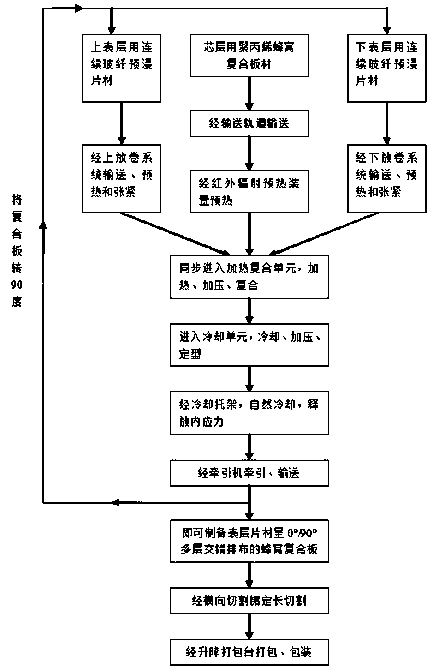

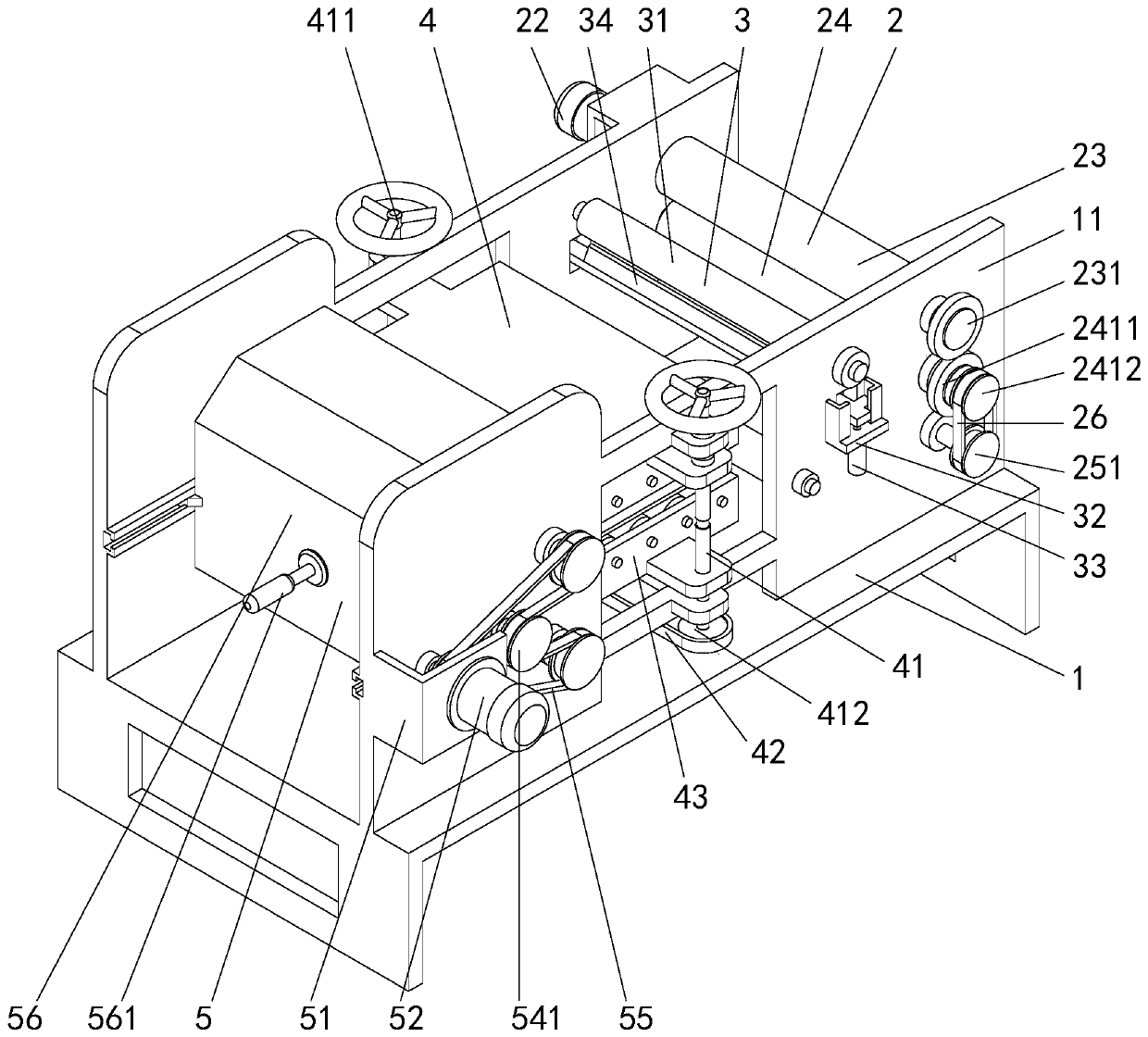

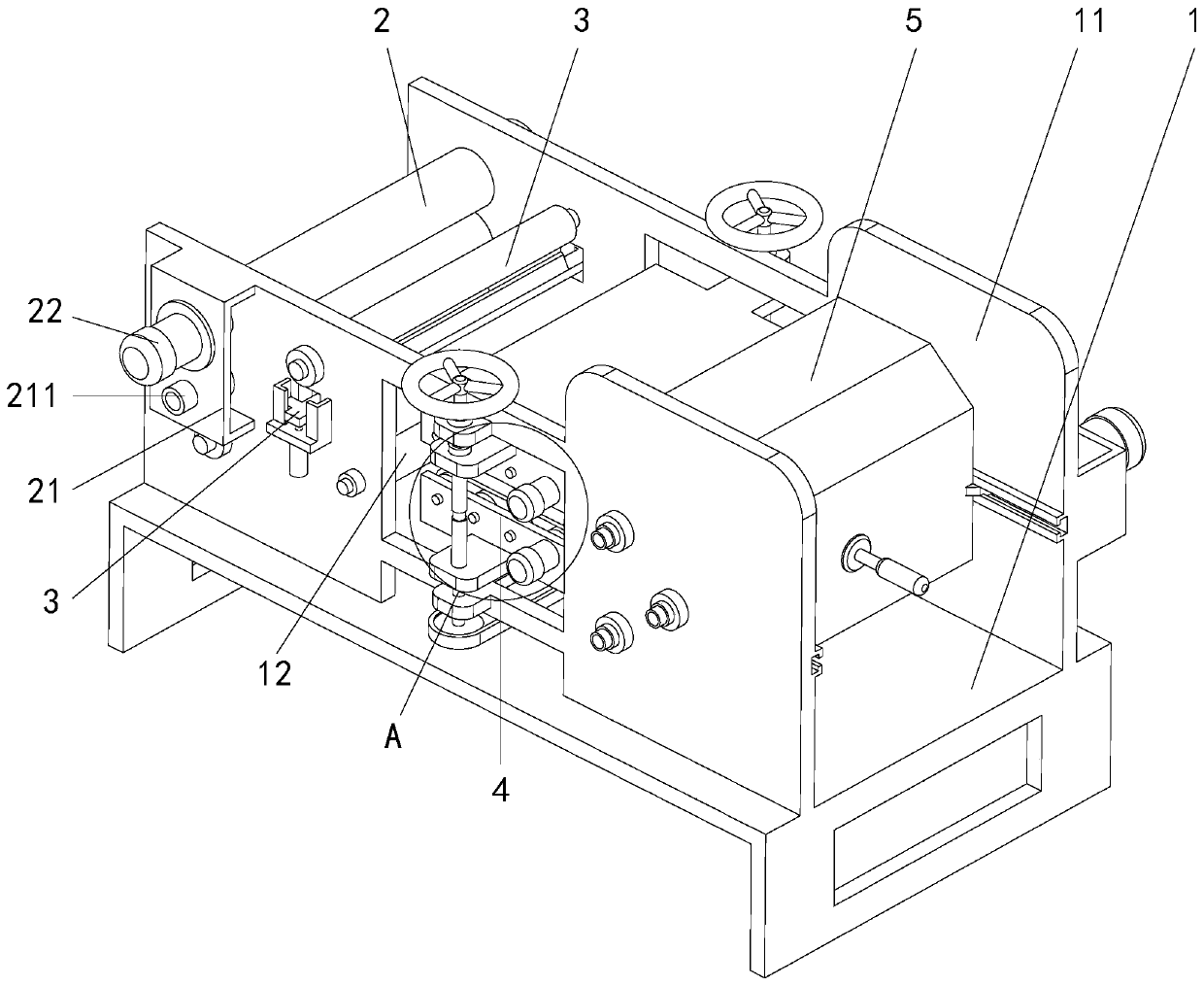

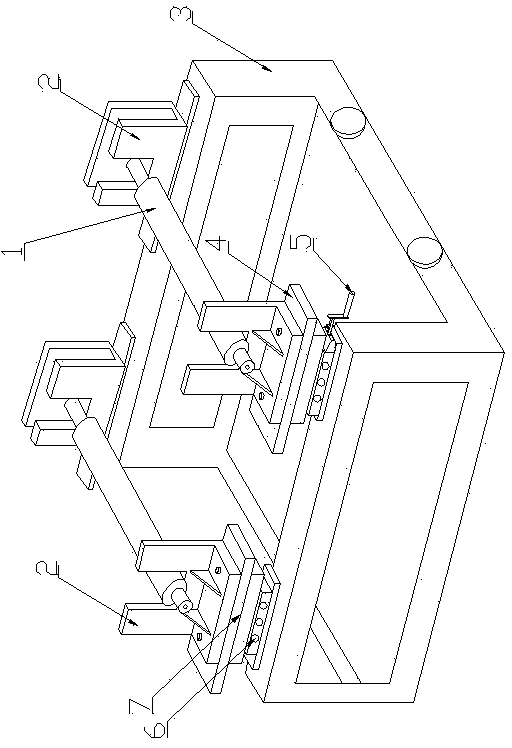

Moulding equipment and method for reinforced thermoplastic cellular composite sheet material by continuous glass fiber pre-dip polypropylene sheet material

InactiveCN104228295AOvercoming defects of poor surface qualityImprove mechanical propertiesLamination ancillary operationsLaminationThermoplasticGlass fiber

The invention relates to a moulding equipment and a method for a reinforced thermoplastic cellular composite sheet material by continuous glass fiber pre-dip polypropylene sheet material. The composite sheet material comprises a polypropylene honeycomb panel core layer and a continuous glass fiber pre-dip polypropylene sheet material surface layer, The moulding equipment of the composite sheet material comprises a conveying track for conveying the core layer, an infrared radiation preheating device for preheating the core layer, an unreeling system used for conveying, preheating and tensioning the surface, a heating composite unit for heating and pressurizing the preheated surface layer and the core layer, a cooling unit used for cooling and fixing the composited sheet material, a cooling carriage for cooling the moulded composite sheet material, a tractor for conveying power, a transverse sawing machine and an elevating packing bench. The core layer polypropylene honeycomb panel is guided into the infrared radiation preheating device for being preheated, the upper surface layer and the lower surface layer are preheated by the continuous glass fiber pre-dip polypropylene sheet material through rollers with a S-shaped arrangement, then synchronously enters into the heating composite unit for respectively realizing the transverse and longitudinal fusion composite, and pass through the cooling unit and the cooling carriage for cooling and fixing. The method has the advantages of low manufacture cost of the production equipment, high manufacture efficiency, high automation degree and low maintenance cost.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of chitosan modification barium ferrite filling multi-walled carbon nanotube/poly 3-methylthiophene composite wave-absorbing material

ActiveCN102627834AMagneticCluster reductionPigment treatment with macromolecular organic compoundsMicrowaveCarbon nanotube

The invention provides a preparation method of a chitosan modification barium ferrite filling multi-walled carbon nanotube / poly 3-methylthiophene composite wave-absorbing material. The method utilizes a carbon nanotube as a raw material, after the carbon nanotube is filled with barium ferrite, chitosan is coated on the carbon nanotube for modification, and then the carbon nanotube is composited with poly 3-methylthiophene to obtain the novel wave-absorbing material integrating magnetic loss, electrical loss and carbon nanotube wave absorption. Requirements for being thin, light, wide and strong of the wave-absorbing material are met. Therefore, the composite wave-absorbing material has wide application prospect in aspects of microwave absorption, electromagnetic radiation resistance and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

High water absorbing and retaining composite containing sericite and method for preparing the same

The water absorbing and maintaining composite material consists of water soluble unsaturated ethylene monomer, sericite in the amount of 2-300 wt% of the ethylene monomer, and water soluble free radical polymerization initiator in the amount of 0.001-1 wt% of the ethylene monomer. The preparation process includes adding sericite into 5-50 % concentration water soluble unsaturated ethylene monomer solution with water soluble free radical polymerization initiator or water soluble free radical polymerization initiator and crosslinking agent, dispersing, heating to 20-90 deg,c for polymerization of 1-10 hr, drying of the polymerized product at 40-150 deg.c and crushing mechanically to obtain grain product. The water absorbing and maintaining composite material has low cost, high absorption to calcium and magnesium ion aqua and high salt tolerance, and is suitable for use in agriculture and forestry.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

High water absorbing and retaining composite containing illite clay mineral and method for preparing the same

The water absorbing and maintaining composite material consists of water soluble unsaturated ethylene monomer, illite-clay mineral in the amount of 2-300 wt% of the ethylene monomer, and water soluble free radical polymerization initiator in the amount of 0.001-1 wt% of the ethylene monomer. The preparation process includes adding illite-clay mineral into 5-50 % concentration water soluble unsaturated ethylene monomer solution with water soluble free radical polymerization initiator or water soluble free radical polymerization initiator and crosslinking agent, dispersing, heating to 20-90 deg,c for polymerization of 1-10 hr, drying of the polymerized product at 40-150 deg.c and crushing mechanically to obtain grain product. The water absorbing and maintaining composite material has low cost, high absorption to calcium and magnesium ion aqua and high salt tolerance, and is suitable for use in agriculture and forestry.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

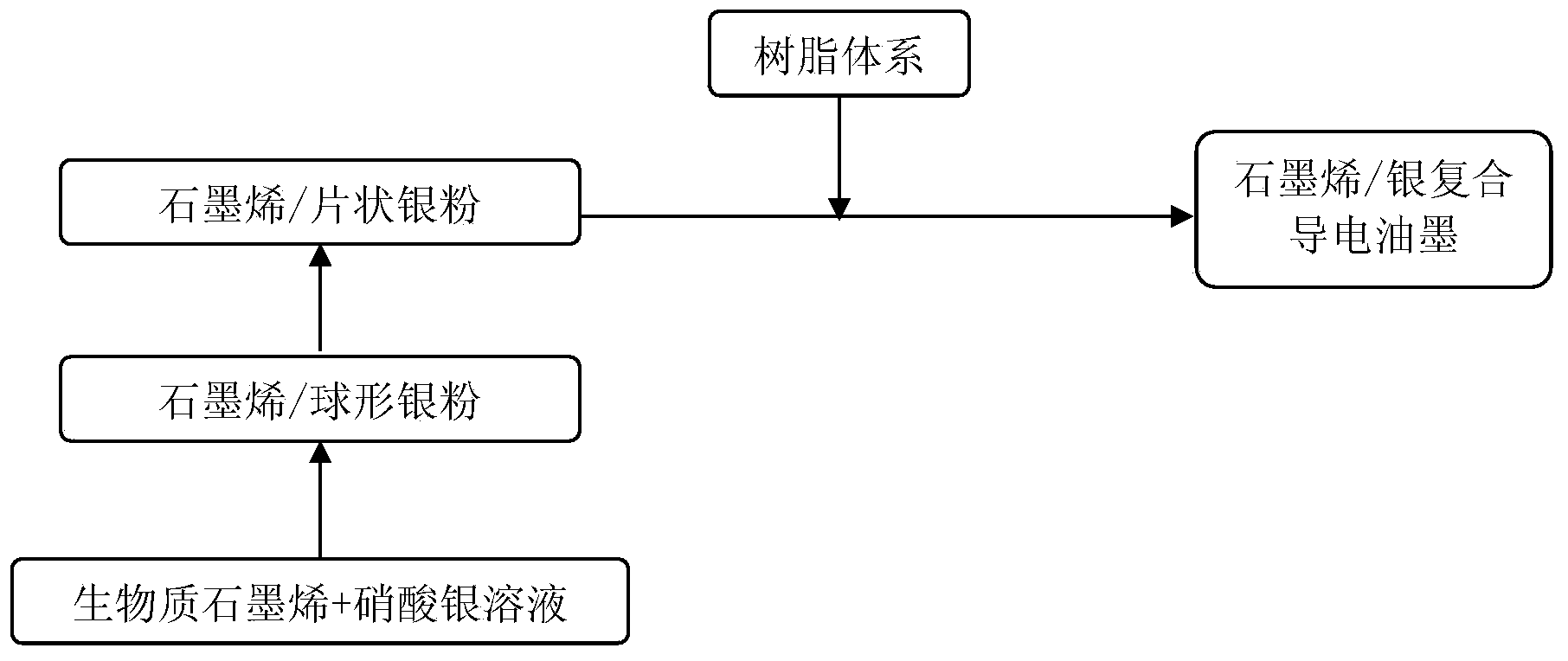

Preparation method of graphene/silver composite conductive printing ink

The invention discloses a preparation method of graphene / silver composite conductive printing ink. The method comprises the following steps: adding biomass graphene into a spherical silver powder reducing system to form graphene / spherical silver composite powder, performing mechanical ball milling to form graphene / sheet-like silver composite powder, and mixing the graphene / sheet-like silver composite powder and a resin system to form the graphene / silver composite conductive printing ink. According to the preparation method, the requirements of low resistivity, high fineness, large adhesion power and high hardness of an electronic circuit can be met while the silver content is reduced, and the graphene / silver composite conductive printing ink is expected to be widely applied to different electronic information products such as a touch screen, an RFID (radio frequency identification device), a flexible circuit and a supercapacitor.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

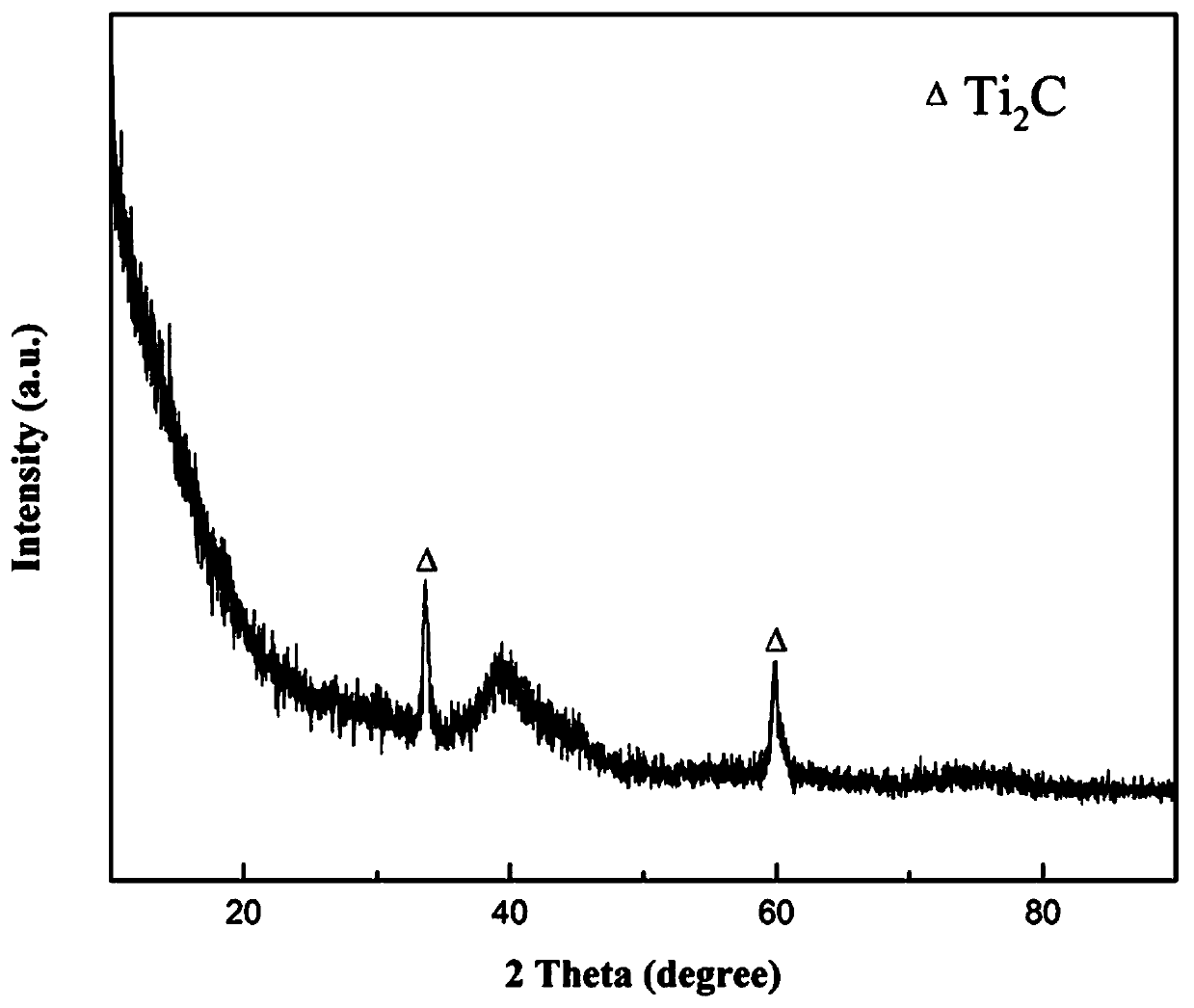

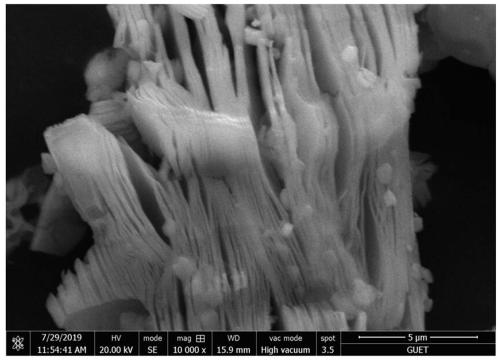

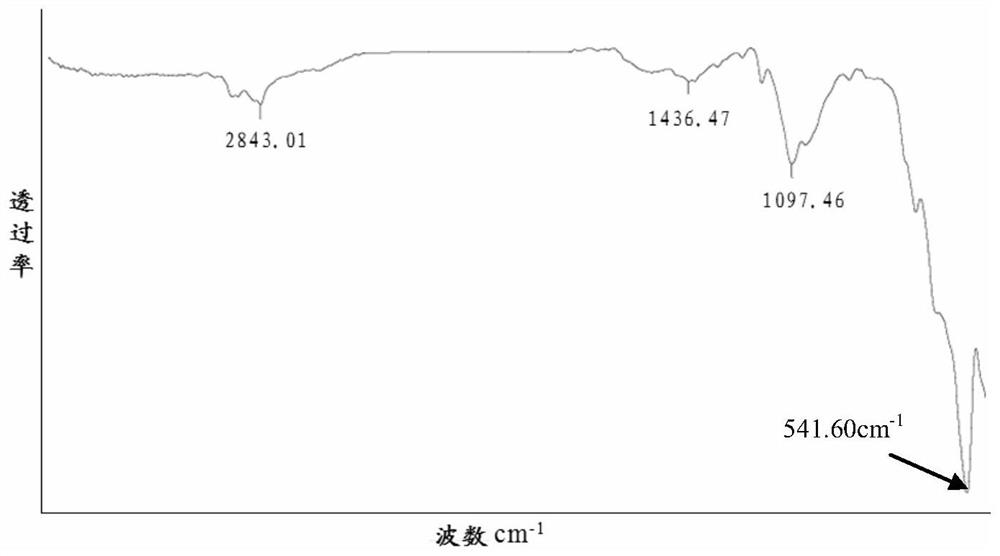

Two-dimensional titanium carbide-doped sodium aluminum hydride hydrogen storage material and preparation method thereof

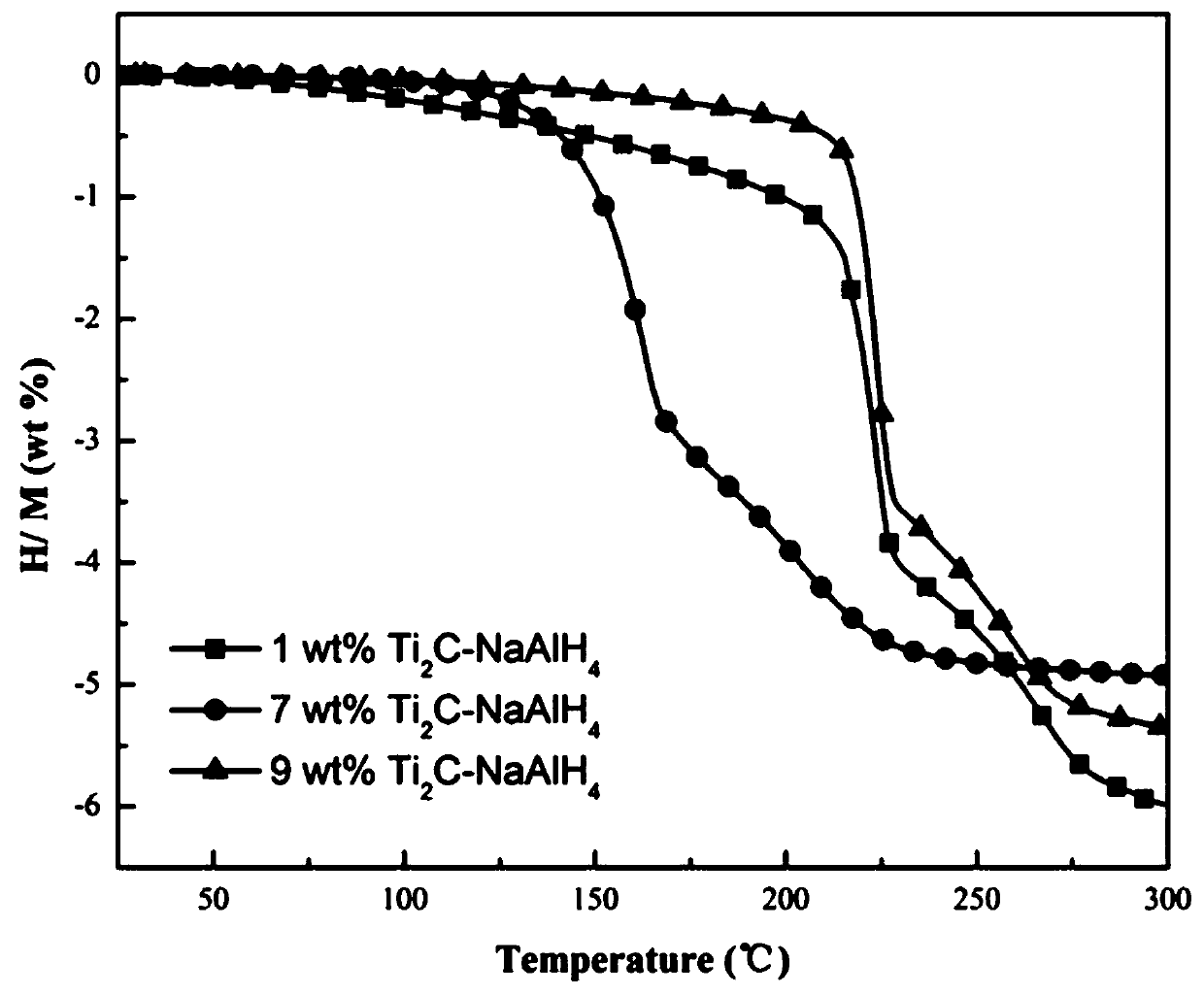

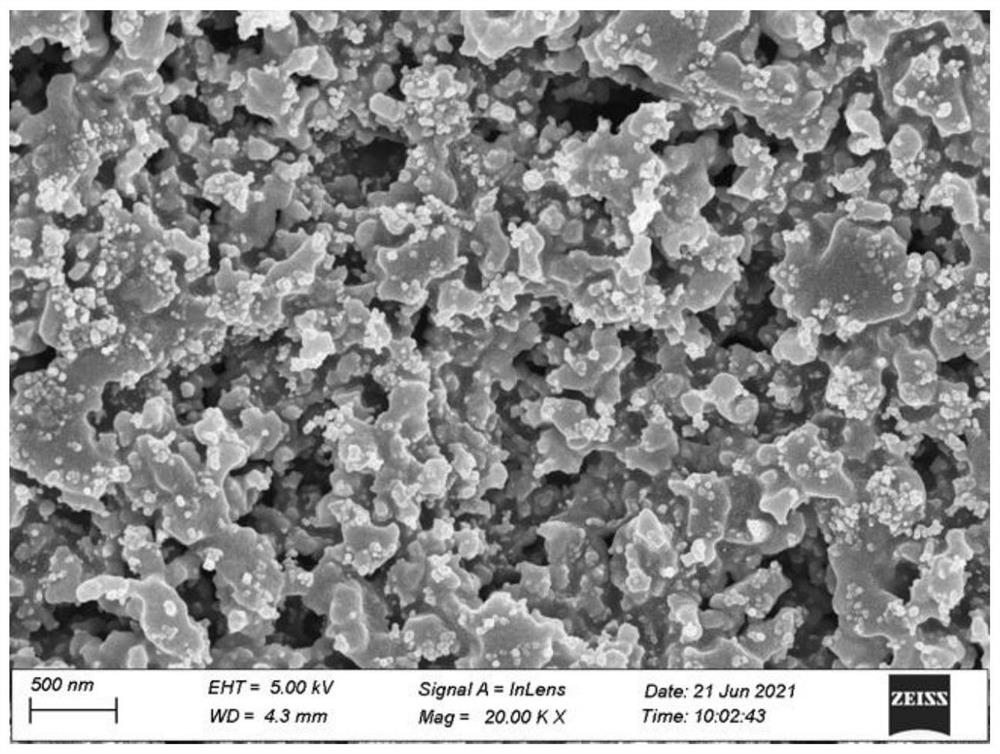

ActiveCN110436408AImprove hydrogen storage performanceHigh hydrogen storage capacityHydrogenMultiple metal hydridesSodium aluminium hydrideTitanium carbide

The invention discloses a two-dimensional titanium carbide-doped sodium aluminum hydride hydrogen storage material. The hydrogen storage material is prepared by mixing and ball milling of sodium aluminum hydride and two-dimensional titanium carbide (Ti2C); and the two-dimensional titanium carbide (Ti2C) has a two-dimensional sheet stacking structure. The preparation method comprises the followingsteps: 1) preparation of two-dimensional Ti2C; and 2) preparation of the two-dimensional titanium carbide-doped sodium aluminum hydride hydrogen storage material. When the material is applied to the hydrogen storage field and the doping amount of a catalyst is 1 wt%, the hydrogen evolution temperature of the system drops to 45 DEG C, and the hydrogen evolution amount reaches 6.0 wt%; and when thedoping amount of the catalyst is 9 wt%, the hydrogen evolution temperature of the system drops to 92 DEG C and the hydrogen evolution amount reaches 5.4 wt%. The preparation method has the following advantages: 1, the hydrogen evolution performance of sodium aluminum hydride is effectively improved, the doped sodium aluminum hydride material has a high hydrogen storage capacity and a high hydrogenevolution rate under mild conditions, the initial hydrogen evolution temperature drops to 45 DEG C, and the hydrogen evolution amount reaches 6.0 wt%; 2, Ti2C used as a catalyst is matched with the sodium aluminum hydride hydrogen storage material; and 3, the preparation method has the characteristics of low cost, simple preparation process, controllable reaction and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

High water absorbing and retaining composite containing rectorite clay mineral and method for preparing the same

The water absorbing and maintaining composite material consists of water soluble unsaturated ethylene monomer, rectorite-clay mineral in the amount of 2-300 wt% of the ethylene monomer, and water soluble free radical polymerization initiator in the amount of 0.001-1 wt% of the ethylene monomer. The preparation process includes adding rectorite-clay mineral into 5-50 % concentration water soluble unsaturated ethylene monomer solution with water soluble free radical polymerization initiator or water soluble free radical polymerization initiator and crosslinking agent, dispersing, heating to 20-90 deg,c for polymerization of 1-10 hr, drying of the polymerized product at 40-150 deg.c and crushing mechanically to obtain grain product. The water absorbing and maintaining composite material has low cost, high absorption to calcium and magnesium ion aqua and high salt tolerance, and is suitable for use in agriculture and forestry.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

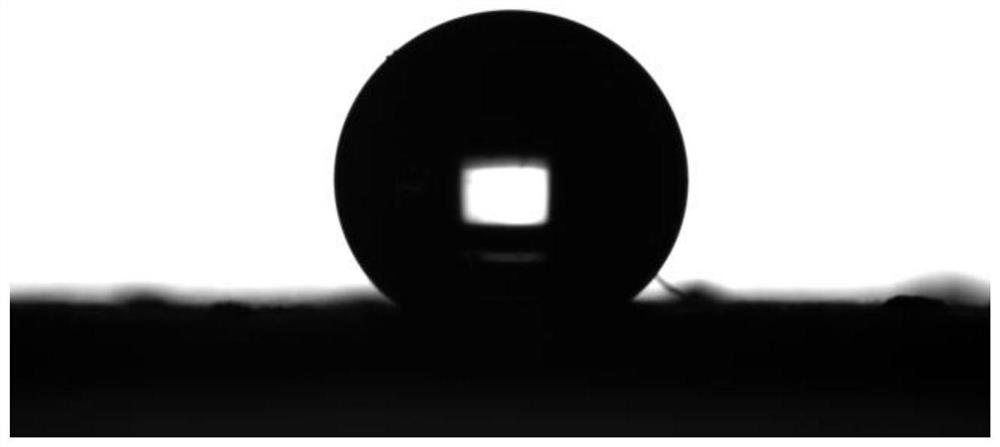

Biochar-titanium nitride super-hydrophobic photo-thermal coating material and preparation method thereof

ActiveCN113861841AHigh photothermal conversion efficiencyHigh mechanical strengthCoatings with pigmentsWater-repelling agents additionActive agentSilanes

The invention discloses a preparation method of a biochar-titanium nitride super-hydrophobic photo-thermal coating material, wherein the preparation method comprises the following steps: S1, adding biochar and titanium nitride into an organic solvent A, and stirring to obtain a biochar-titanium nitride mixture; S2, mixing the biochar-titanium nitride mixture with a surfactant, stirring, and drying to obtain surface modified powder; and S3, adding the surface-modified powder into an organic solvent B, stirring, adding a silane coupling agent, carrying out a cross-linking reaction, and continuously stirring to obtain the biochar-titanium nitride super-hydrophobic photo-thermal coating material. The preparation method has the advantages of simple and easily available raw materials in the preparation process, simple operation process, short preparation period, mild reaction conditions, high feasibility, no need of large-scale instruments and equipment, low capital investment, realization of large-scale industrial production and processing, and quite wide application prospects.

Owner:YANGTZE DELTA REGION INST OF UNIV OF ELECTRONICS SCI & TECH OF CHINE HUZHOU

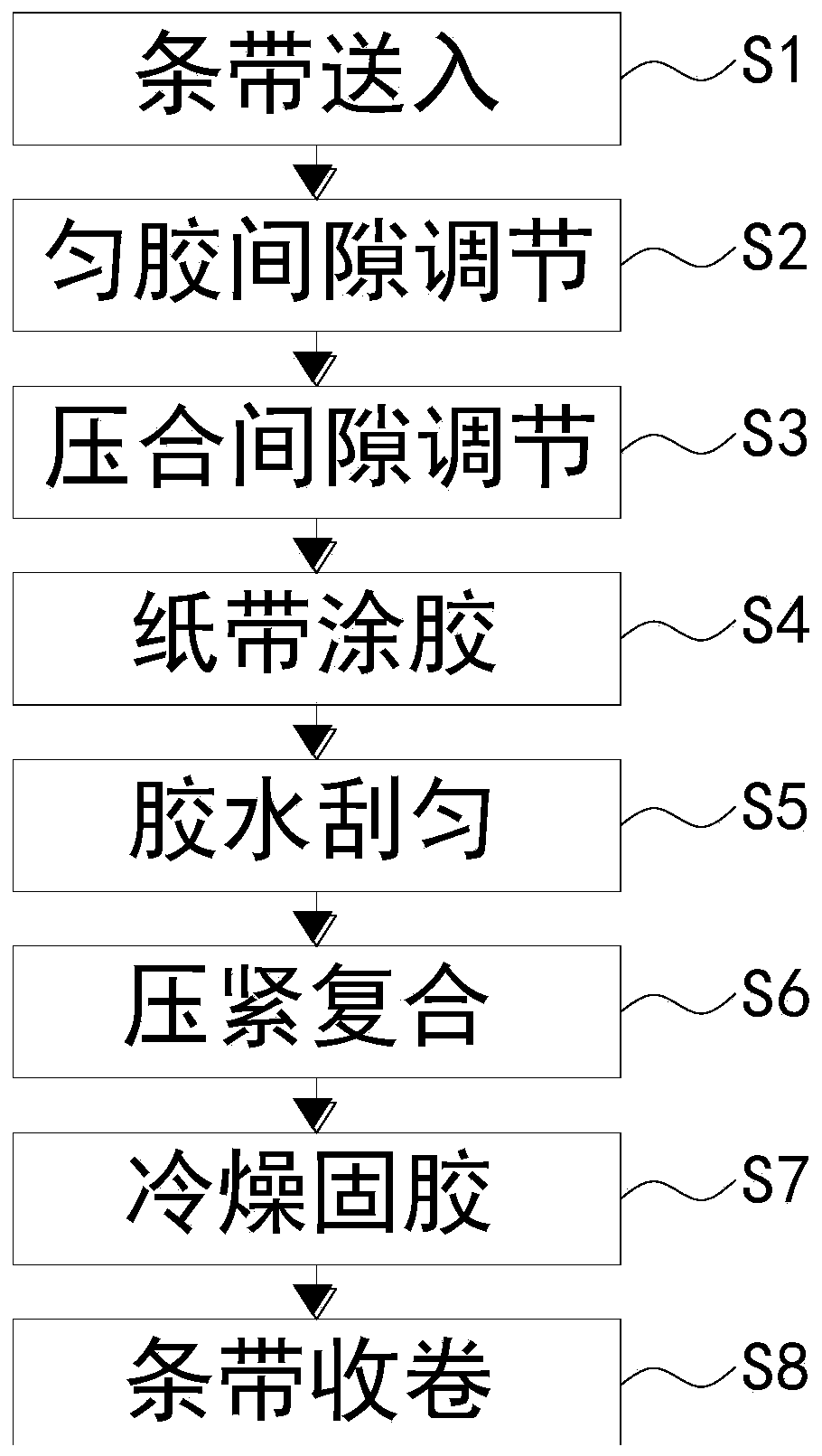

Production and manufacturing method of renewable environment-friendly paper-plastic composite bag

The invention relates to a production and manufacturing method of a renewable environment-friendly paper-plastic composite bag, and further particularly relates to a production and manufacturing device of the renewable environment-friendly paper-plastic composite bag. The production and manufacturing device specifically comprises a device seat, a gluing feeding mechanism, a glue uniformizing mechanism, a compressing composite mechanism and a cold-drying glue setting mechanism; two side vertical plates are parallelly arranged on the device seat; and the gluing feeding mechanism, the glue uniformizing mechanism, the compressing composite mechanism and the cold-drying glue setting mechanism are sequentially arranged between the two side vertical plates. Through the device involved in the method provided by the invention, a paper tape and a thin film tape can be quickly compressed to be composited, compositing is full and reliable, and the compositing quality is higher; and a cold-drying process is increased, thus direct winding after compositing is completed is facilitated, and the finished product quality of raw materials of the paper-plastic composite bag is guaranteed.

Owner:尤晨曦

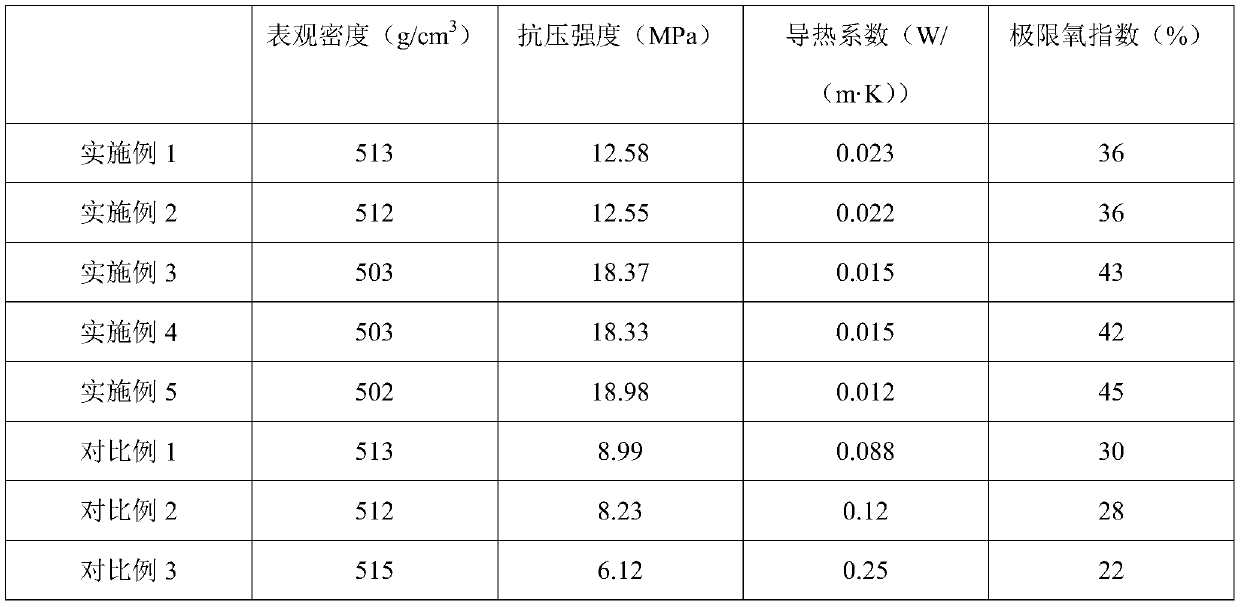

Energy-saving self-thermal insulation concrete and production process

The invention discloses an energy-saving thermal insulation concrete and a production process. According to the production process, cement, pulverized fuel ash, mineral powder, polypropylene fiber, sand, light aggregate, an admixture, water and the like are taken as raw materials to cooperate synergistically. The energy-saving thermal insulation concrete has high compressive strength, does not easily crack, has good fireproof performance and a good thermal insulation function, saves the energy and is environmentally friendly. The adopted polypropylene fiber can be a regenerated modified material, a waste polypropylene material is modified by using polyamide resin, the toughness of the polypropylene fiber is further improved after the modification treatment, thereby improving the compressive strength and other indexes of a concrete product.

Owner:台州普立德建筑科技有限公司

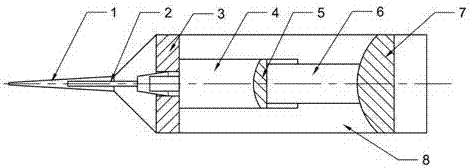

3DP technology realizing hierarchical compositing of multi-materials through single nozzle and application thereof

PendingCN106956432AEasy to implementLow costTissue regenerationDomestic articlesMulti materialComposite effect

The invention relates to a three-dimensional printing technology, and particularly relates to a 3DP technology realizing hierarchical compositing of multi-materials by using a single nozzle and an application thereof. According to the 3DP technology by using the single nozzle, on the basis of not changing an original three-dimensional printing technology equipment platform and on the premise of not changing an original movement mode and a control software of the printing equipment, the effect that different printing materials are continuously mixed, extruded and printed can be accurately realized through a first-stage printing material cylinder and a second-stage printing material cylinder which are designed to be arranged and a second-stage linkage piston device of a printing nozzle. According to the multi-material compositing printing nozzle, various printing materials can be fully composited, different materials are mixed sufficiently, and the composite effect is good; and the printing structure is a hierarchical wrapping and continuous compositing structure, and the 3DP technology has good equipment compatibility and feasibility, and has a wide application prospect in the field of biomedicine.

Owner:成都百年贝雅医疗科技有限公司

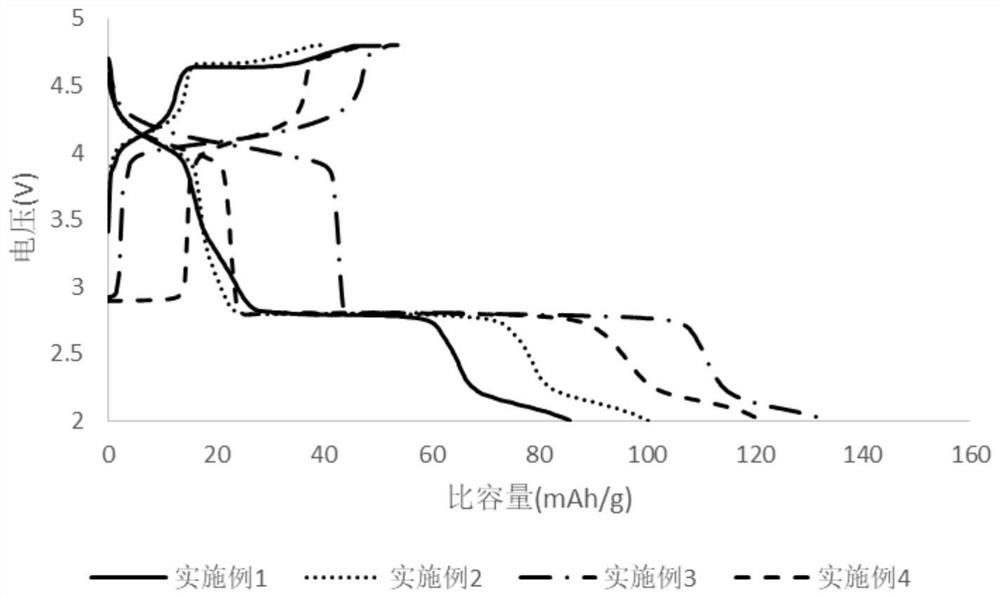

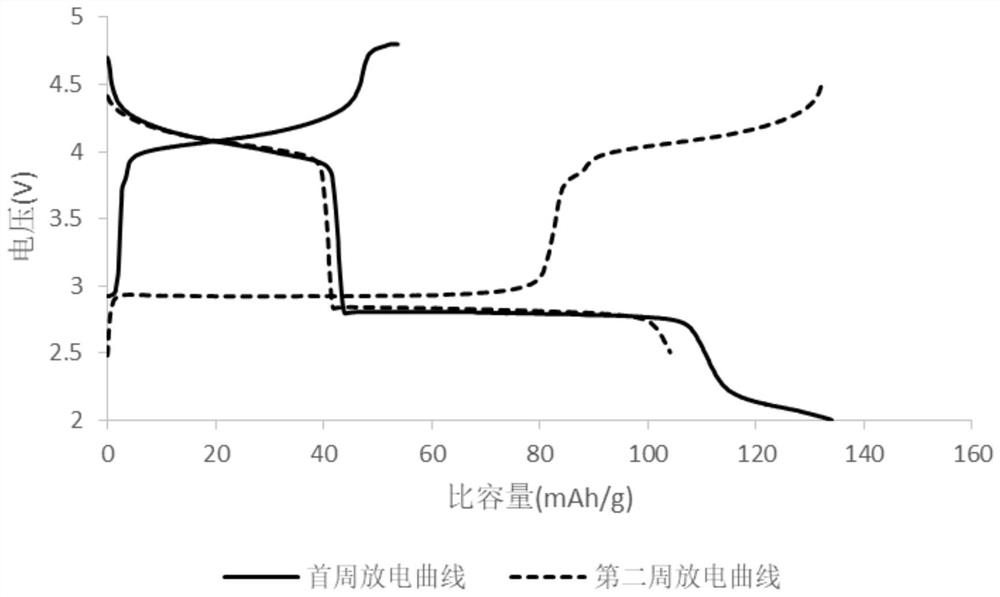

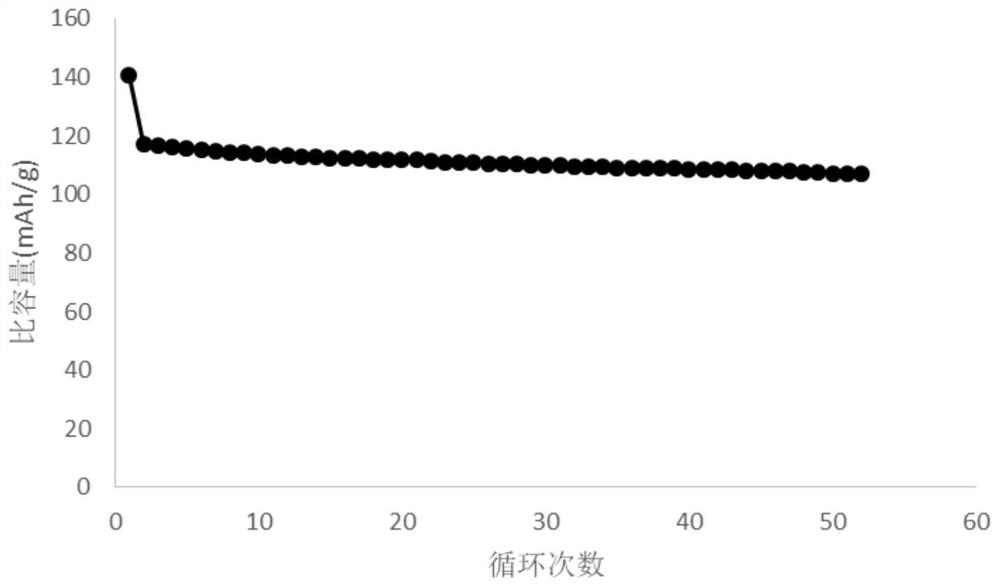

Iron-manganese-based positive electrode material, and preparation method and application thereof

ActiveCN113285051AOxidation state controlReduce contentElectrode thermal treatmentPositive electrodesElectrolytic agentElectrical battery

The invention provides an iron-manganese-based positive electrode material, and a preparation method and an application thereof. The preparation method comprises the steps that S1, an inorganic compound of lithium and a FexMny (OH) 2 precursor are subjected to oxidation sintering, an intermediate product is obtained, x is larger than 0 and smaller than 1.0, y is larger than 0 and smaller than 1.0, x + y = 1, and the ratio of the molar weight of Li in the inorganic compound of lithium to the total molar weight of Fe and Mn in the FexMny (OH) 2 precursor ranges from 0.1: 1 to 0.5: 1; and S2, second sintering is performed on the intermediate product in a nitrogen or first inert gas atmosphere condition to obtain the iron-manganese-based positive electrode material. The iron-manganese-based positive electrode material obtained by the preparation method disclosed by the invention is relatively low in lithium element content and relatively stable in structure so that the original structure of the iron-manganese-based positive electrode material is not influenced in the embedding and separating processes of lithium ions between a positive electrode and an electrolyte, and the cycling stability of the lithium ion battery is further ensured.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

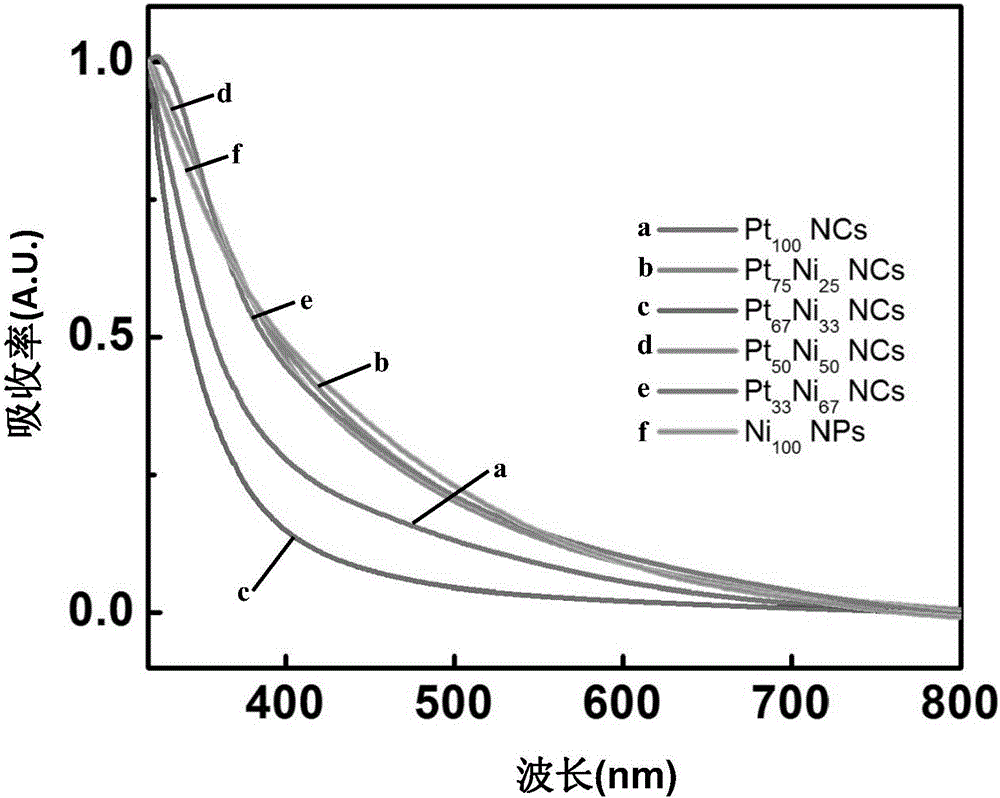

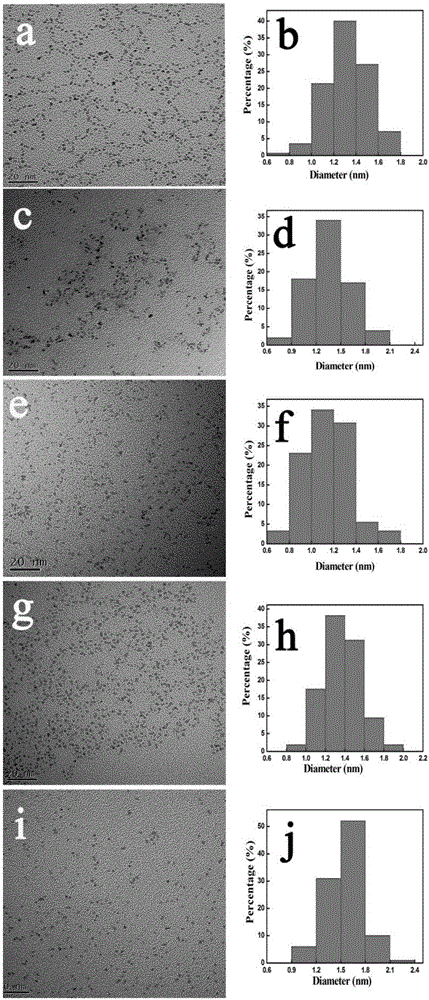

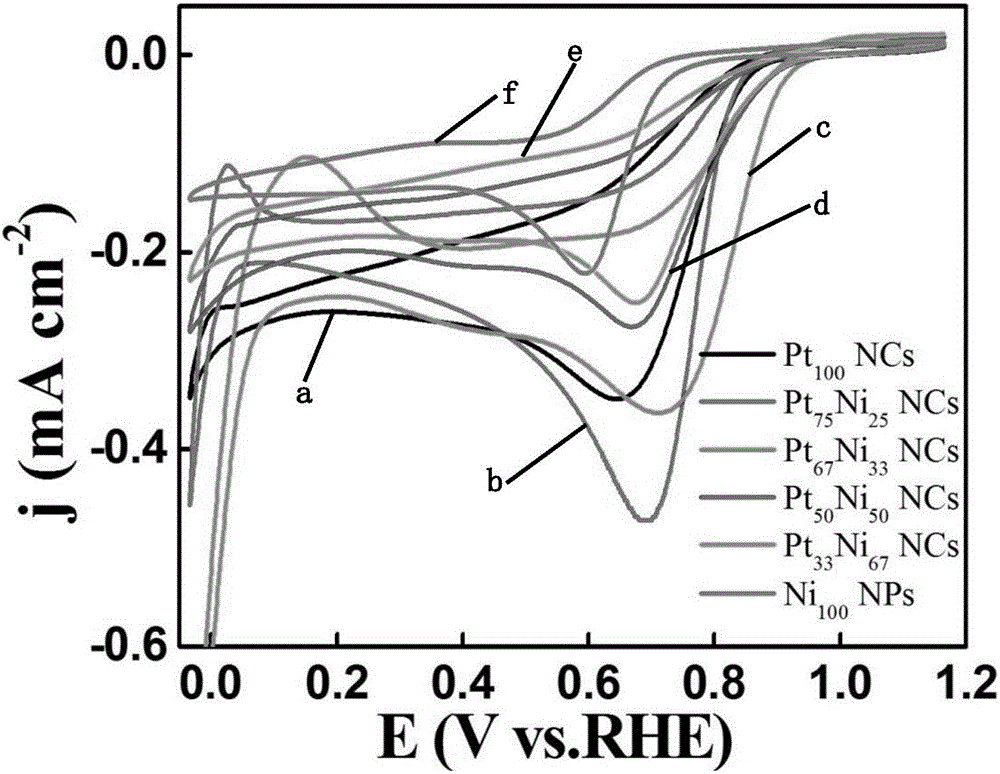

Preparation method for platinum-nickel alloy nanoclusters and fuel cell using the same

The invention discloses a preparation method for platinum-nickel alloy nanoclusters and a fuel cell using the same. The method comprises the steps of preparing nickel chloride hexahydrate and chloroplatinic acid with the molar ratio of platinum to nickel to be 0.2-5:1; preparing polyvinylpyrrolidone with the total molar ratio of polyvinylpyrrolidone to platinum and nickel to be 1:20-30; adding the prepared polyvinylpyrrolidone and the prepared nickel chloride hexahydrate into a heating device, and adding a solvent, wherein the mass ratio of the solvent to the polyvinylpyrrolidone is 100-200:1; heating to 75-90 DEG C, stirring while heating for 20-40 minutes; cooling the temperature of the heating device to be 0-5 DEG C, adding the prepared chloroplatinic acid into the heating device, adding the sodium hydroxide solution into the heating device to adjust the pH value to be 9-11, heating to 185-105 DEG C, stirring while heating for 1-5 hours, condensing and refluxing to obtain platinum-nickel alloy nanoclusters.

Owner:SOUTH CHINA NORMAL UNIVERSITY

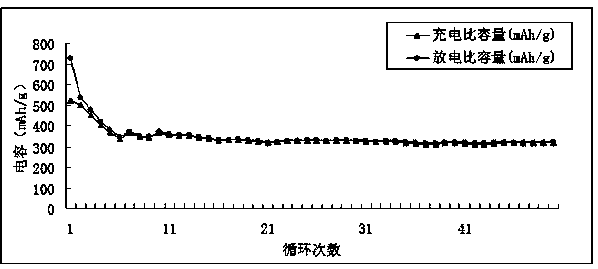

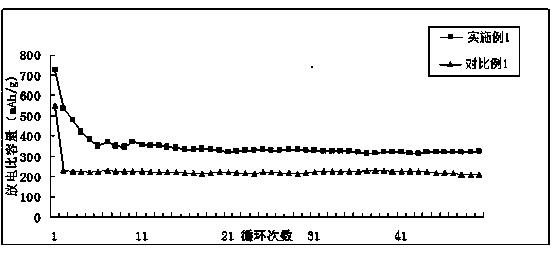

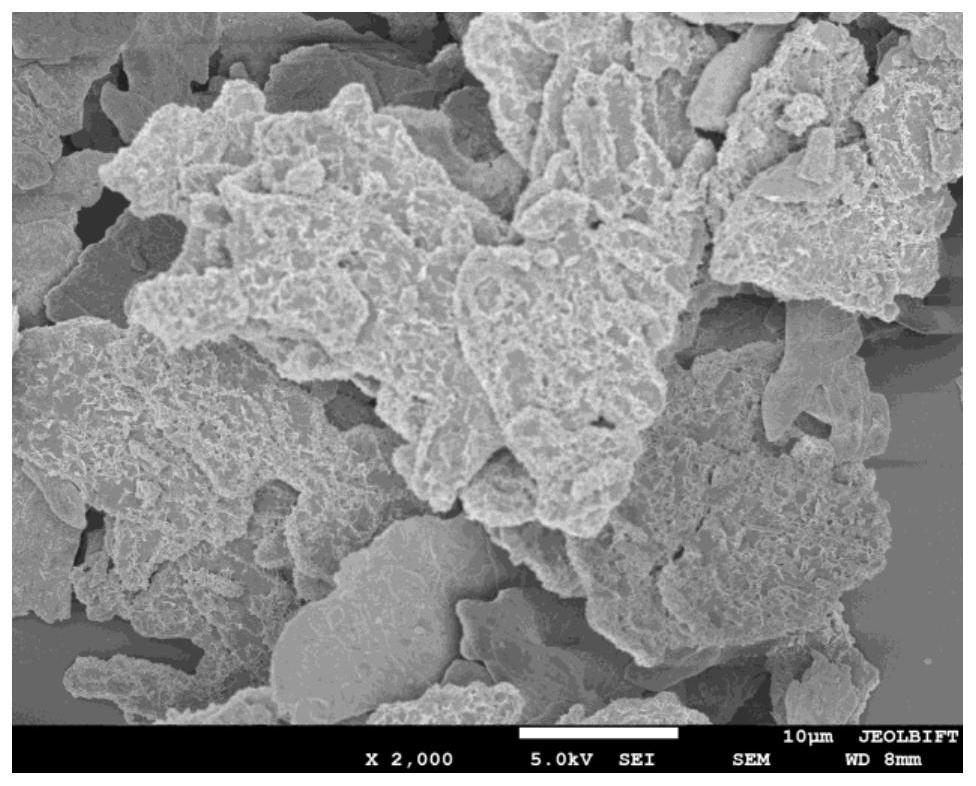

Preparation method of novel carbon silicon composite material

ActiveCN103928662APromote sustainable developmentSave raw materialsCell electrodesSecondary cellsNano siliconGraphite

The invention discloses a preparation method of a novel carbon silicon composite material. The preparation method comprises the following steps: adopting areca nut shells as a carbon source; after carrying out acid and alkali treatment on the areca nut shells, carbonizing into areca nut shell powder, then mixing the areca nut shell powder, nano silicon powder, artificial graphite powder and ethanol at a mass ratio of 1-2: 2-4: 0.5-1.0: 0.2-0.8; slowly adding into a ball mill, mechanically ball-milling for 18-22 hours, and then screening to obtain the carbon silicon composite material. The preparation method disclosed by the invention has the advantages that the cost is low, the preparation is simple, and a lithium battery prepared by utilizing the preparation method has a large capacity.

Owner:GUANGDONG HAOMEI ALUMINUM

High water absorbing and retaining composite containing rectorite clay mineral and method for preparing the same

The water absorbing and maintaining composite material consists of water soluble unsaturated ethylene monomer, rectorite-clay mineral in the amount of 2-300 wt% of the ethylene monomer, and water soluble free radical polymerization initiator in the amount of 0.001-1 wt% of the ethylene monomer. The preparation process includes adding rectorite-clay mineral into 5-50 % concentration water soluble unsaturated ethylene monomer solution with water soluble free radical polymerization initiator or water soluble free radical polymerization initiator and crosslinking agent, dispersing, heating to 20-90 deg,c for polymerization of 1-10 hr, drying of the polymerized product at 40-150 deg.c and crushing mechanically to obtain grain product. The water absorbing and maintaining composite material has low cost, high absorption to calcium and magnesium ion aqua and high salt tolerance, and is suitable for use in agriculture and forestry.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Ppy @ ZIF-67 composite material and preparation method and application thereof

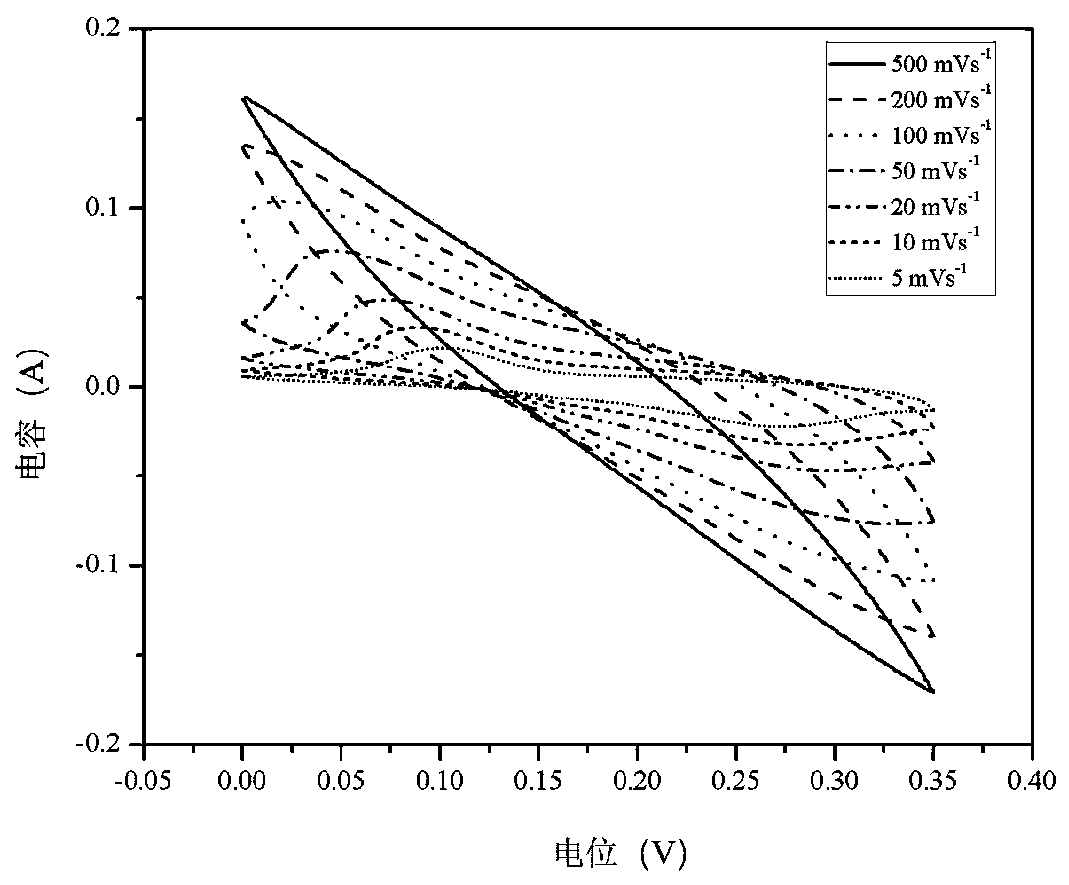

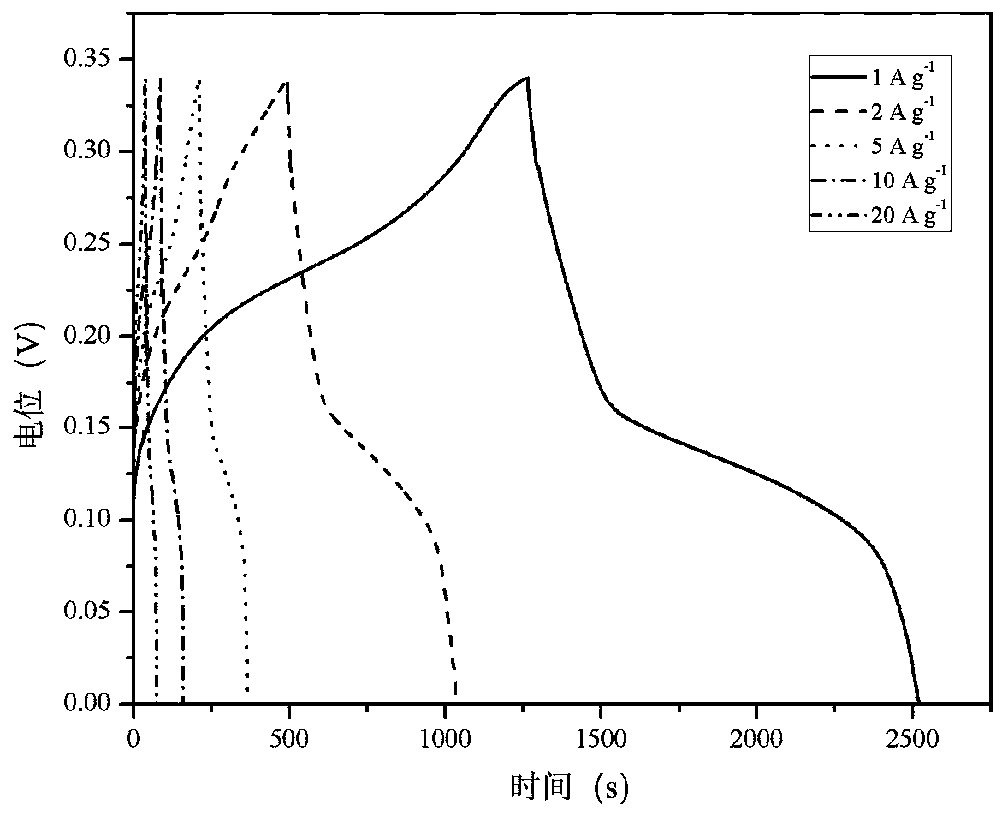

InactiveCN110634685AComposite fullyImprove electrochemical conductivityHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePotassium persulfate

The invention discloses a ppy @ ZIF-67 composite material and preparation method and application thereof. The preparation comprises the steps: (1) mixing and stirring cobalt nitrate hexahydrate, potassium persulfate and deionized aqueous solution so as to obtain a solution A; (2) mixing and stirring pyrrole monomer, sodium dodecyl sulfate, dimethylimidazole and deionized aqueous solution so as toobtain a solution B; 3) pouring the solution A into the solution B, heating, mixing and stirring, washing with deionized water and ethanol and drying so as to obtain the black powder ppy @ ZIF-67 composite material. The ppy @ ZIF-67 composite material is prepared into an electrode sheet to be applied supercapacitors and shows the specific capacitance of being up to 3600F / g and good magnification characteristics so as to be a quite potential supercapacitor material.

Owner:EAST CHINA NORMAL UNIV

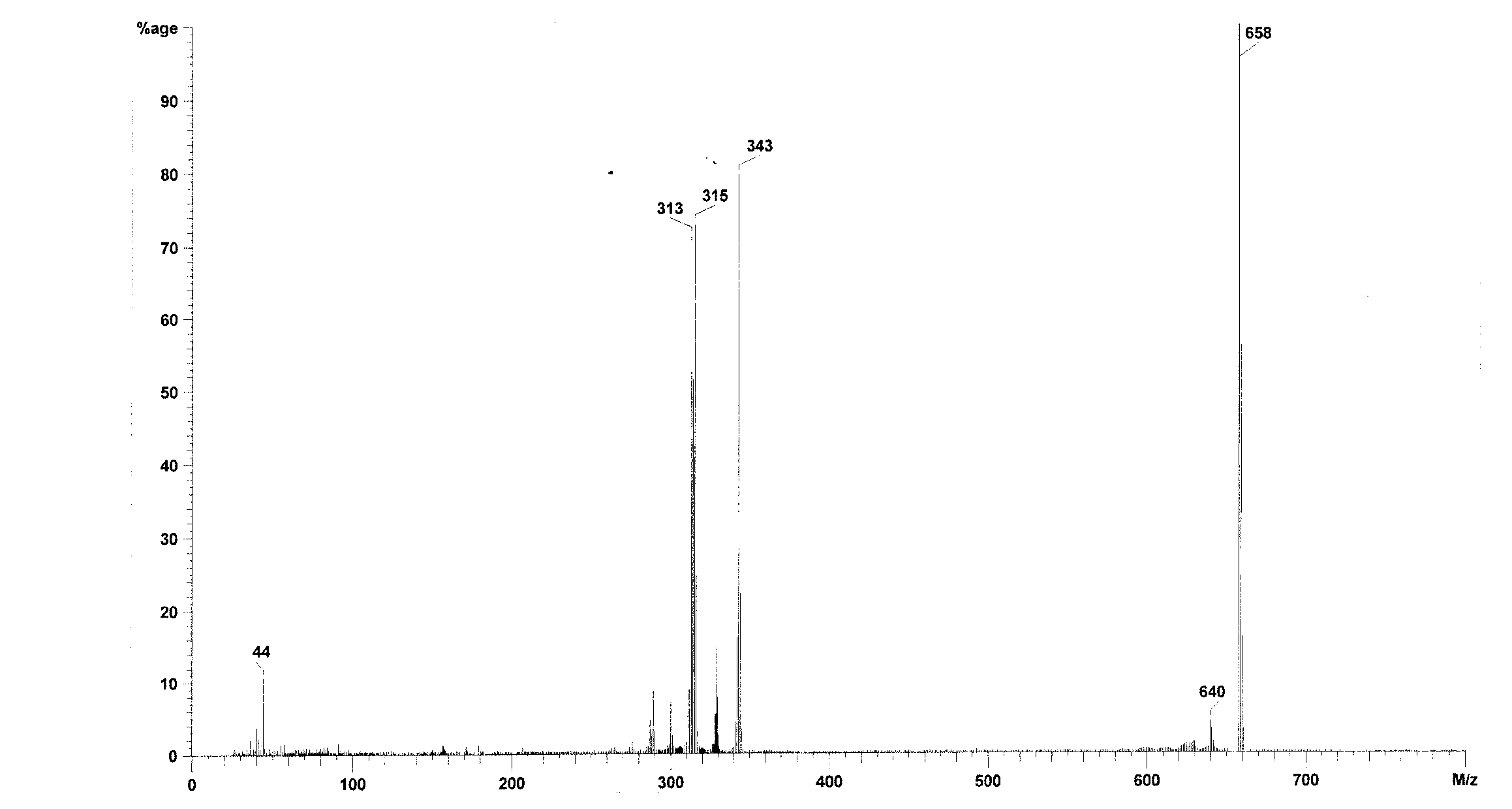

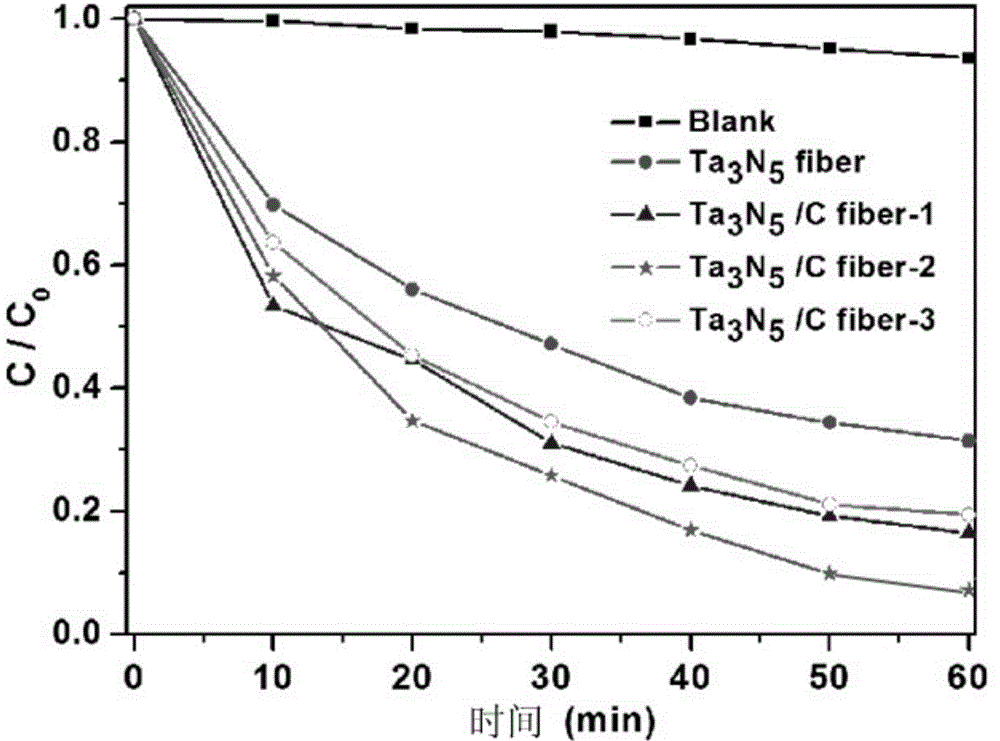

Ta3N5/C composite fiber photocatalyst and preparation method thereof

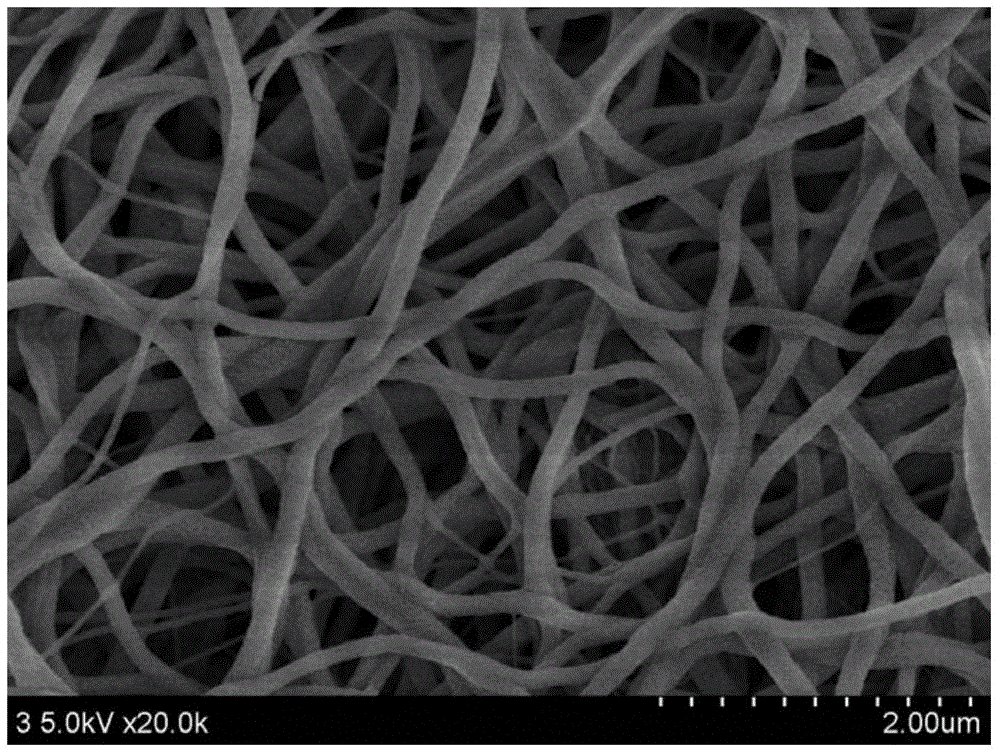

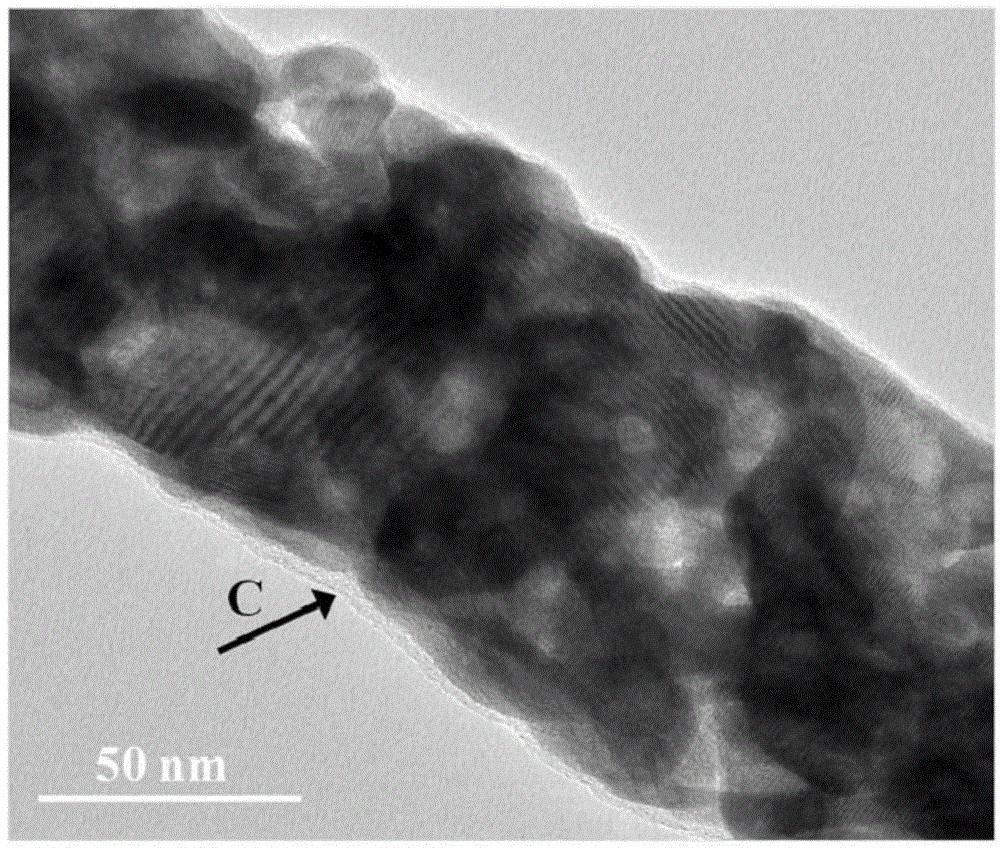

ActiveCN104888833AImprove photocatalytic activity and stabilityComposite uniformCatalyst activation/preparationElectrospinningFiber

The invention belongs to the field of metal-containing catalyst preparation, and specifically relates to a Ta3N5 / C composite fiber photocatalyst and a preparation method thereof. The method adopts an electrostatic spinning method to be combined with a hydrothermal method and calcination to prepare the Ta3N5 / C composite fiber photocatalyst. According to the prepared Ta3N5 / C composite fiber photocatalyst, a Ta3N5 nano fiber is evenly coated with a C membrane, a good heterojunction is formed, recombination of photo-generated electrons and holes is effectively restrained, and the Ta3N5 photocatalytic activity and stability performance are improved; besides, the Ta3N5 / C composite fiber photocatalyst has the characteristic of being easy to recycle, is a good photocatalytic material, and has important application values in environment, energy sources and other fields; and the preparation method is simple, equipment and other costs are relatively low, test conditions are controllable, and mass production preparation is facilitated.

Owner:浙江百汇建设工程管理有限公司

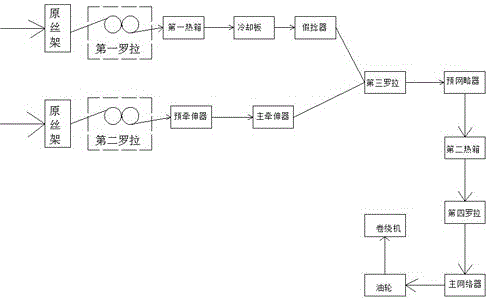

Production method of cotton-like environment-friendly hyperelastic plant complex fiber

PendingCN106757620AStrong sense of cottonUniform fiber appearanceYarnLiquid/gas/vapor textile treatmentLaundryYarn

The invention relates to a production method of cotton-like environment-friendly hyperelastic plant complex fiber. The method comprises the steps that cotton-like fiber enters a first heating box to be subjected to drafting through a first roller, then the cotton-like fiber enters a cooling plate to be subjected to cooling after drafting, and then the cotton-like fiber enters a false twister to be subjected to false twisting; plant fiber is placed on a protofilament support, and then the plant fiber enters a pre-drafting instrument and a main drafting instrument through a second roller to be subjected to drafting; the cotton-like fiber after false twisting and the plant fiber after drafting are compounded through a third roller; the compounded cotton-like fiber and the plant fiber are indrawn into a pre-interlacer to be subjected to preliminary increase of net points, after being set, the compounded cotton-like fiber and the plant fiber are indrawn into a fourth roller to be subjected to re-interlacing, and are then subjected to increase of net points again, and finally a coiler is utilized to conduct winding. According to the production method of the cotton-like environment-friendly hyperelastic plant complex fiber, the compounding performance is good, the feel of cotton is strong, the two kinds of fibers are fully compounded, the appearance of the fibers is uniform, the dyeing stability is guaranteed, and the cloth fabric effect is similar to cotton yarn fabric; meanwhile, the cotton-like environment-friendly hyperelastic plant complex fiber has the function of the plant fiber which is laundry resistant, and is excellent in elasticity.

Owner:NANTONG YONGSHENG FIBER NEW MATERIAL

Preparation method of nano fiber containing TiO2/WO3 heterojunction

InactiveCN102926030BComposite uniformComposite fullyInorganic material artificial filamentsFilament/thread formingFiberHeterojunction

The invention relates to a preparation method of a nano fiber containing TiO2 / WO3 heterojunction. The preparation method comprises the following steps of (1) adding soluble titanium salt into a mixed solvent of PVP (Poly Vinyl Pyrrolidone), absolute ethyl alcohol and acetic acid, and obtaining inorganic TiO2 nano fiber by adopting an electrostatic spinning and calcining method; and sequentially adding H2O2 and H2O in tungstic acid powder, and obtaining colorless and transparent WO3 sol; (2) preparing TiO2 nano fiber containing WO3 seed crystal by adding the TiO2 nano fiber into the WO3 sol; and (3) adding the WO3 sol, HMT (Hexamethylenetetramine) and water into the TiO2 nano fiber containing the WO3 seed crystal, and keeping warm for 6-12 hours under 120-180 DEG C; and drying a product which is obtained after hydrothermal in low temperature after centrifuging and water washing, and thus obtaining the nano fiber containing the TiO2 / WO3 heterojunction can be obtained. The preparation method disclosed by the invention is simple and practical, the composition of the TiO2 and the WO3 is more uniform and fuller, a large amount of contact interfaces can be formed, and the catalyzing ability can be increased.

Owner:DONGHUA UNIV

High water absorption and water retention composite materials containing sodium calcium aluminium silicate glue and method for preparing same

The invention relates to a high water-absorbing water-loss reducer formulation and its process for preparing, in which the water-absorbing water-retaining composite containing soda-aluminosilicate colloid is characterized in that it consists of soda-aluminosilicate colloid, water-soluble vinyl unsaturated monomer and water-soluble free radical polymerization initiator, in which the additive mass of the soda-aluminosilicate colloid is 2-200 % of the water-soluble vinyl unsaturated monomer and the additive mass of the water-soluble free radical polymerization initiator is 0.001-1 % of the water-soluble vinyl unsaturated monomer. The process for preparing includes: decentralizedly processing the soda-aluminosilicate colloid dissolved with water-soluble free radical polymerization initiator or water-soluble vinyl unsaturated monomer dissolved with water-soluble free radical polymerization initiator and coupling agent with 20-90 % of weight concentration at 30-90 DEG C and heating them for 1-10 hours, slicing the produced gel, drying, comminuting and screening to obtain the product at 40-150. The invention is of low preparation cost, higher input scaling factor and better salt resistance, so is suitable for agrisilviculture.

Owner:GUOJIA NEW MATERIAL HUBEI ENVIRONMENTAL PROT GEL IND PARK CO LTD

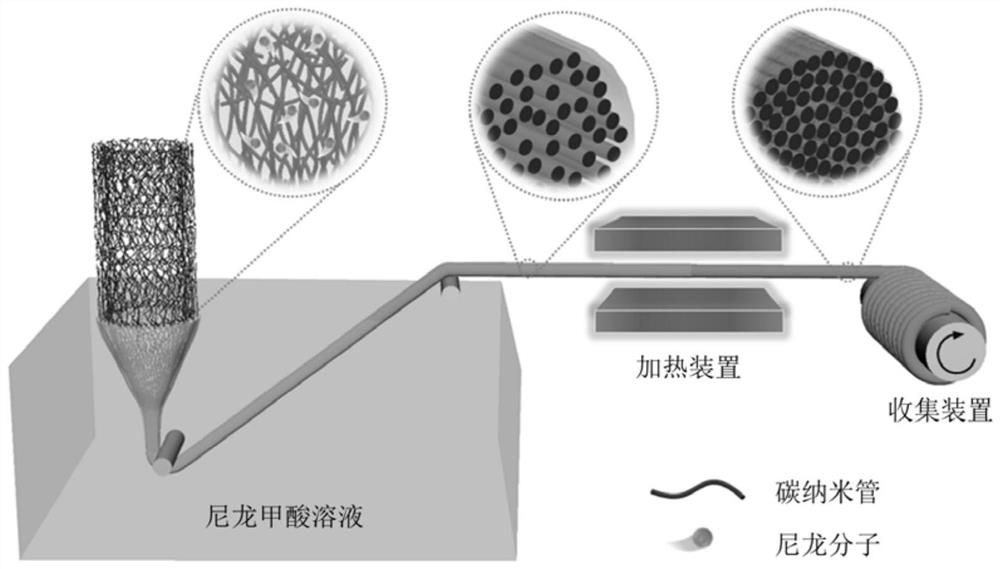

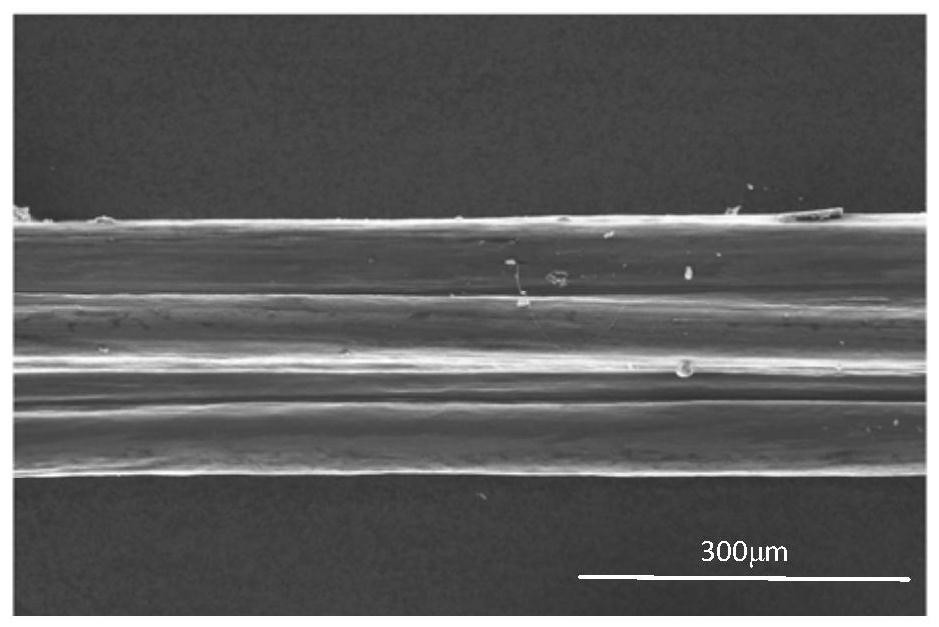

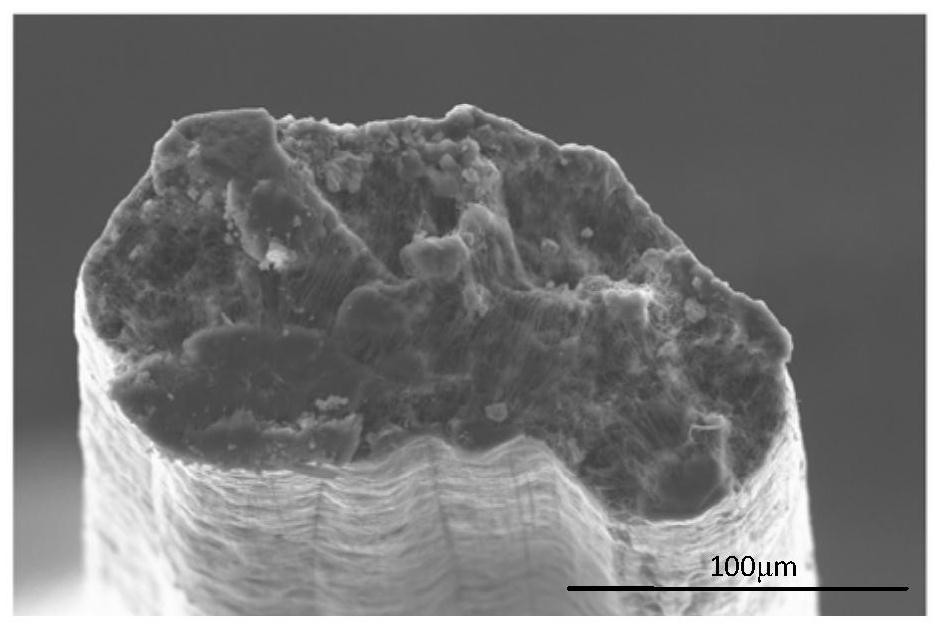

Oriented carbon nanotube reinforced nylon composite material and preparation method and application thereof

PendingCN112251830AComposite fullyImprove mechanical propertiesAdditive manufacturing apparatusMonocomponent copolyamides artificial filamentFluid phaseMechanical properties of carbon nanotubes

The invention discloses an oriented carbon nanotube reinforced nylon composite material and a preparation method and application thereof. The preparation method comprises the following steps: enablingan unshrunk carbon nanotube aggregate to directly enter a liquid phase system, and enabling nylon macromolecules contained in the liquid phase system to be in full contact and fully compounded with carbon nanotubes forming the carbon nanotube aggregate, thus forming a complex of the carbon nanotube aggregate and nylon; enabling the complex of the carbon nanotube aggregate and the nylon to shrink,enabling the carbon nanotubes in the complex to be oriented, then carrying out curing treatment, and collecting to obtain the oriented carbon nanotube reinforced nylon composite material. The preparation process is simple and controllable, the requirement of large-scale production is met, and the obtained product is excellent in mechanical property and can be used as a 3D printing material.

Owner:中国科学院苏州纳米技术与纳米仿生研究所南昌研究院

Offset regulation device for coiled material production

The invention relates to waterproof coiler production equipment, in particular to an offset regulation device for coiled material production. The offset regulation device is composed of a rolling shaft, a rolling shaft support and a support. An offset regulation device body is arranged on one side of the rolling shaft and is composed of a platform, a handle and a gear. According to the offset regulation device for coiled material production, the offset regulation device body is added on one side of the rolling shaft and offset of the rolling shaft can be effectively avoided so that complete combination between non-woven fabrics and pitch or between screen cloth grids and the pitch can be guaranteed and quality of produced products can be guaranteed.

Owner:JIANGSU CANLON BUILDING MATERIALS

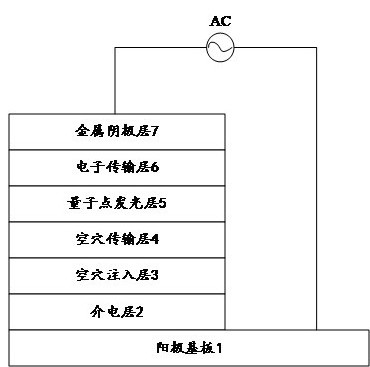

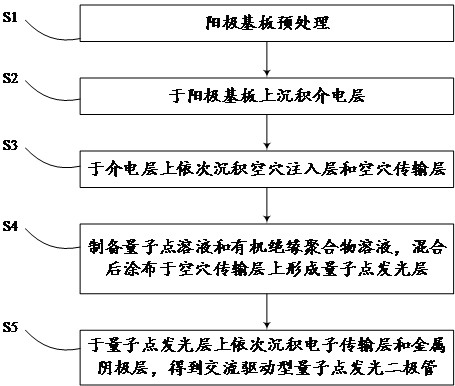

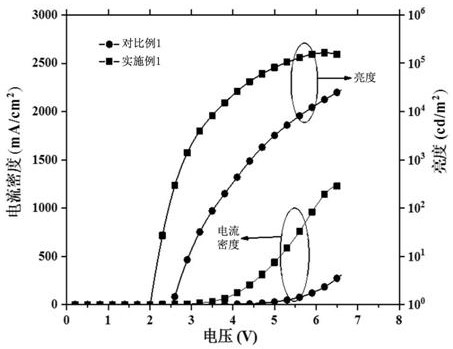

Alternating-current driving type quantum dot light-emitting diode and preparation method thereof

ActiveCN112186117AIncreased luminosityIncreased transmission densitySolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerPolymer solution

The invention discloses an alternating-current driving type quantum dot light emitting diode and a preparation method thereof. The alternating-current driving type quantum dot light emitting diode comprises an anode substrate, a dielectric layer, a hole injection layer, a hole transport layer, a quantum dot light emitting layer, an electron transport layer and a metal cathode layer which are sequentially arranged in a stacked mode; the quantum dot light-emitting layer is a blended film prepared from a quantum dot solution and an organic insulating polymer solution. By introducing the dielectric layer, carriers from electrodes are effectively blocked and stored, and charges injected into the device are regulated and controlled along with frequency conversion of alternating voltage, so thatthe device can normally work under the driving of the alternating voltage without adding an alternating current-direct current conversion device; by introducing the organic insulating polymer into thequantum dot light-emitting layer, defects on the surfaces of quantum dots are passivated, so that the carrier transport density is remarkably improved, electrons and holes are compounded more sufficiently, and the light-emitting performance of the light-emitting diode is remarkably improved.

Owner:JIANGHAN UNIVERSITY

Preparation method of chitosan modified barium ferrite filling multi-walled carbon nanotube/poly 3-methylthiophene composite wave-absorbing material

ActiveCN102627834BMagneticCluster reductionPigment treatment with macromolecular organic compoundsMicrowaveCarbon nanotube

The invention provides a preparation method of a chitosan modification barium ferrite filling multi-walled carbon nanotube / poly 3-methylthiophene composite wave-absorbing material. The method utilizes a carbon nanotube as a raw material, after the carbon nanotube is filled with barium ferrite, chitosan is coated on the carbon nanotube for modification, and then the carbon nanotube is composited with poly 3-methylthiophene to obtain the novel wave-absorbing material integrating magnetic loss, electrical loss and carbon nanotube wave absorption. Requirements for being thin, light, wide and strong of the wave-absorbing material are met. Therefore, the composite wave-absorbing material has wide application prospect in aspects of microwave absorption, electromagnetic radiation resistance and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

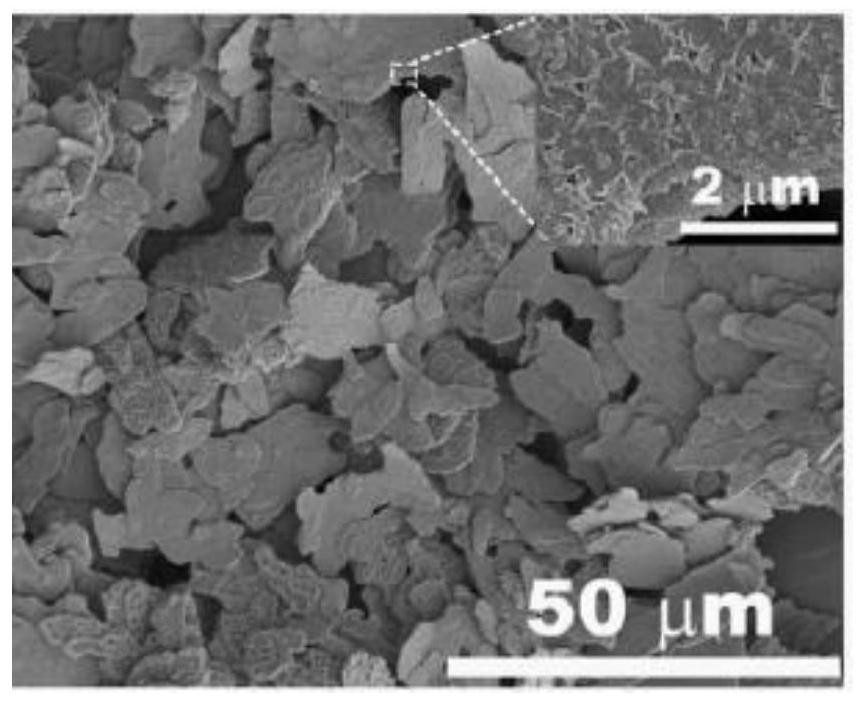

Environment-friendly carbon-silicon composite material

InactiveCN104201329APromote sustainable developmentComposite fullyCell electrodesSecondary cellsCarbon monofluorideChemical industry

The invention discloses an environment-friendly carbon-silicon composite material. The environment-friendly carbon-silicon composite material comprises the following substances in parts by weight: 55-64 parts of betelnut shell powder, 35-42 parts of nano-silicon powder, 10-12 parts of isobutyl methacrylate, 5-9 parts of nano-calcium sulfate, 11-14 parts of organic montmorillonite, 13-20 parts of stearic acid, 3-7 parts of polycarbodiimide, 5-9 parts of liquid paraffin, 10-14 parts of N-N'-diphenyl-p-phenylenediamine, 3.5-6.4 parts of aluminum acetylacetonate and 10-14 parts of carbon monofluoride. The environment-friendly carbon-silicon composite material has the beneficial effects that raw materials are low in cost, are wide in sources and meet the requirements of green chemical industry; a carbon material is composited with silicon by virtue of a mechanical ball-milling method, so that the preparation process is simple, and the materials are adequately composited together; the initial charge-discharge capacity of the carbon-silicon composite material disclosed by the invention is greatly increased, and the carbon-silicon composite material has good cycling stability.

Owner:QINGDAO HUA CHENG TIAN MACHINERY MFG

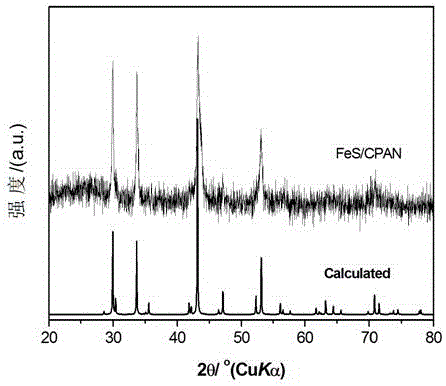

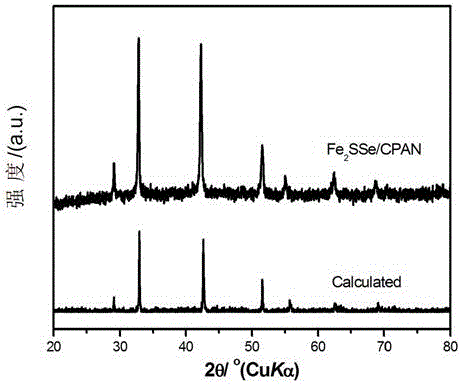

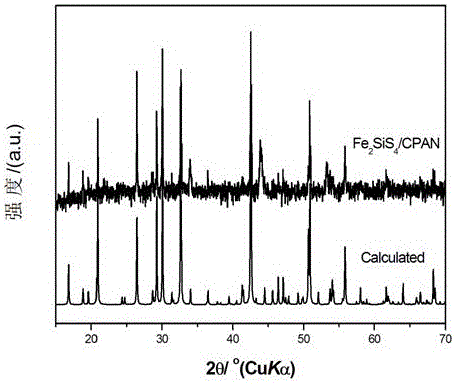

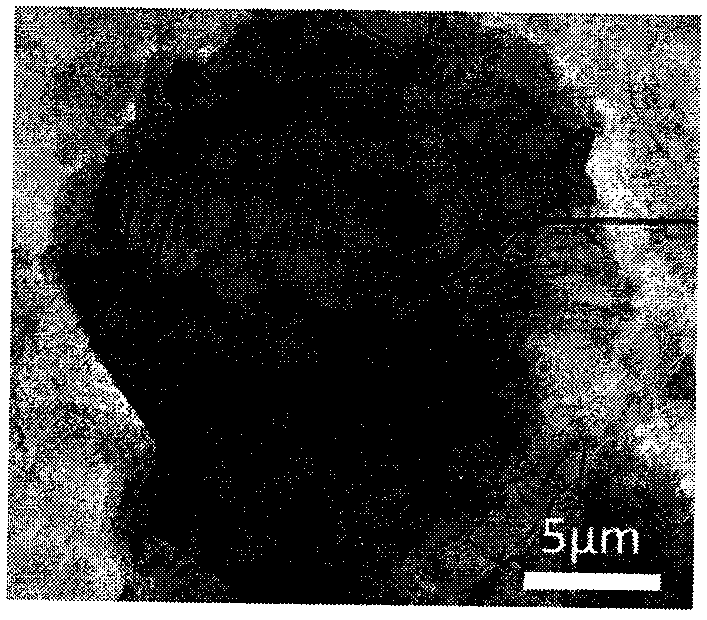

Preparing method of transition metal sulfide/carbonized polyacrylonitrile composite material

InactiveCN106229481AEasy to prepareEasy to operateHybrid capacitor electrodesCell electrodesMaterials preparationHigh volume manufacturing

The invention relates to a preparing method of a transition metal sulfide / carbonized polyacrylonitrile composite material, and belongs to the technical field of material preparation. The preparing method includes the steps that transition metal, sulfur and polyacrylonitrile are mixed and pressed into sheets, and the sheet-like mixture is sealed in the quartz tube in vacuum and reacts for 24-72 h at the environment temperature of 600-1000 DEG C to obtain the transition metal sulfide / carbonized polyacrylonitrile composite material. The carbon material can be obtained while transition metal sulfide is synthesized, which is beneficial for tightly combining the transition metal sulfide and the carbon material, and the related performance in the application field is improved. In addition, the preparing method is simple, easy to operate and suitable for large-batch production, and the requirement for equipment is closer to industrial application needs.

Owner:YANGZHOU UNIV

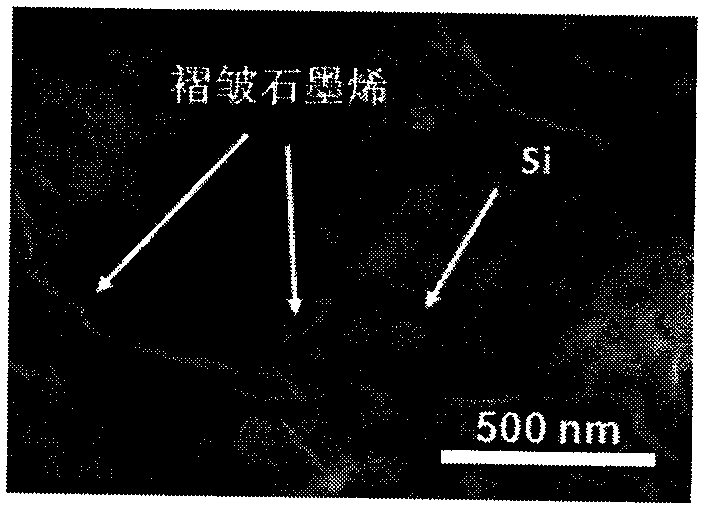

Preparation method of silicon/folded graphene electrode material

InactiveCN109326785ABuffer volume expansionComposite fullyNegative electrodesLi-accumulatorsComposite filmFiltration

The invention provides a preparation method of a silicon / folded graphene electrode material. Silicon-aluminum alloy particles are added into an graphene oxide solution and dispersed evenly through ultrasound, and suction filtration is conducted to form a composite thin film; the thin film is added into a diluted hydrochloric acid solution to react while being not completely dried; the thin film istaken out and naturally air-dried, and then heated so as to remove the residual solvent; graphene oxide is reduced by using a hydroiodic acid solution and washed with ethyl alcohol, and the silicon / folded graphene electrode material is obtained. Folded graphene in the method can be applied to enhance the charging property and the electricity storage property of a lithium battery, and can preventlithium from forming branched crystals. In addition, hydrochloric acid reacts with aluminum to generate gas, so that the interior of the graphene oxide thin film can generate a mass of folds; the reacted aluminum can also generate gaps to cause an effect similar to a hollow core-shell structure; high-elastic folded graphene can be compressed, and can effectively buffer volume expansion of silicon.

Owner:YANCHENG TEACHERS UNIV

Magnetic polyamide, preparation method thereof and magnetic fibers obtained by using magnetic polyamide

PendingCN112011176AComposite fullyWell mixedArtifical filament manufactureMonocomponent polyamides artificial filamentPolymer scienceIn situ polymerization

The invention discloses magnetic polyamide, a preparation method thereof and magnetic fibers obtained by using the magnetic polyamide. The preparation method comprises the following steps: firstly obtaining flaky magnetic particles, then carrying out organic modification on the flaky magnetic particles to obtain organic modified flaky magnetic particles, and then carrying out melt blending on theorganic modified flaky magnetic particles and polyamide or carrying out in-situ polymerization on the organic modified flaky magnetic particles and a polyamide monomer to obtain the magnetic polyamide; meanwhile, carrying out melt spinning on the magnetic polyamide to obtain the magnetic fibers. The magnetic polyamide and the magnetic fibers obtained according to the method have very excellent electromagnetic shielding property and mechanical property.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com