3DP technology realizing hierarchical compositing of multi-materials through single nozzle and application thereof

A multi-material, single-nozzle technology, applied in the field of 3D printing and biomedical material molding, achieves the effects of low cost, sufficient mixing, good equipment compatibility and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

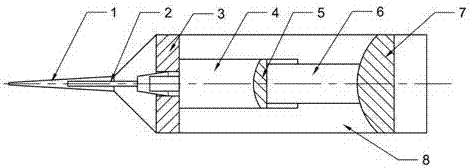

Embodiment 1

[0029] Choose a primary barrel with an inner diameter of ϕ25mm and a secondary barrel with an inner diameter of ϕ10mm to assemble the nozzle device. The diameters of the inner and outer material printing nozzles are 200μm and 400μm respectively, and the distance between the inner and outer nozzle ports is 8mm. According to the diagram figure 1 to assemble. Among them, the uniformly modulated bio-binder and nano-hydroxyapatite material are loaded in the secondary barrel (inside), and the uniformly modulated bio-binder and nano-tricalcium phosphate material are loaded in the primary barrel (outside). Hierarchical composite printing of dual-phase materials. The porous bone-like scaffold product is printed, and the printed scaffold is sintered at a high temperature of 1100°C to obtain a bone tissue engineering scaffold with multiple biological functions. The hydroxyapatite material in the core of the composite scaffold has higher mechanical strength and good biocompatibility; the...

Embodiment 2

[0031] Choose a primary barrel with an inner diameter of ϕ25mm and a secondary barrel with an inner diameter of ϕ10mm to assemble the nozzle device. The diameters of the inner and outer material printing nozzles are 200μm and 400μm respectively, and the distance between the inner and outer nozzle ports is 8mm. According to the diagram figure 1 to assemble. Among them, the uniformly modulated and uniform bio-binder and nano-Al are loaded in the secondary barrel (inside) 3 o 2 For powder materials, the first-stage barrel (outside) is loaded with uniformly modulated bio-binder and nano-tricalcium phosphate materials for hierarchical composite printing of dual-phase materials. The porous bone-like scaffold product is printed, and the printed scaffold is sintered at a high temperature of 1100°C to obtain a bone tissue engineering scaffold with multiple biological functional benefits. Composite scaffold core nano-Al 3 o 2The powder has excellent mechanical strength and biologica...

Embodiment 3

[0033] Using nano-zirconia powder with a particle diameter of 50-80nm and nano-biphasic calcium phosphate powder as raw materials, the raw material preparation and printing nozzle assembly process are the same as in Example 1, except that the printing materials loaded in the inner and outer barrels are different. , that is, a uniformly modulated bio-binder and nano-zirconia powder are loaded in the secondary barrel (inside), and a uniformly modulated bio-binder and nano-biphasic calcium phosphate powder are loaded in the primary barrel (outside). , the bone tissue engineering scaffolds prepared by printing have both good mechanical properties and osteogenic inductivity, and can be applied to the repair of defective bone tissue in bearing parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com