Preparing method of transition metal sulfide/carbonized polyacrylonitrile composite material

A carbonized polyacrylonitrile and transition metal technology, which is applied to hybrid capacitor electrodes, electrical components, battery electrodes, etc., can solve the problems of inability to ensure the combination of transition metal sulfides and carbon materials, and many steps, and achieve mass production. , low price, easy to promote and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

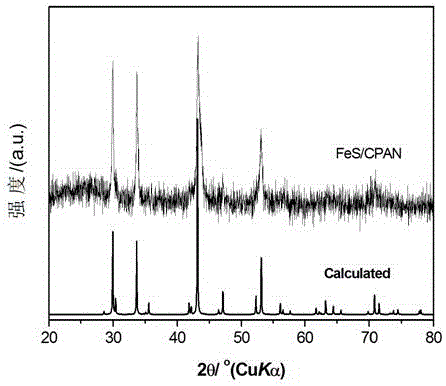

Embodiment 1

[0039] Weigh a Fe / S mixture with a total mass of 500 mg (the molar ratio of Fe and S is 1:1).

[0040] Weigh 240 mg of PAN and grind it into a finer powder.

[0041] Add the weighed Fe / S mixture into the ground PAN powder, grind again until the mixture is uniform, and vacuum seal the tube after tableting with a tablet machine. Put the sealed tube sample into a muffle furnace, slowly heat to 600-1000°C and react for 24-72 hours. After the reaction, the quartz tube was opened to take out the product, and ground to obtain the solid-phase reaction product FeS / CPAN.

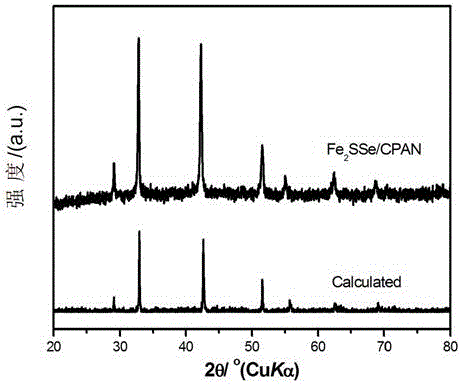

Embodiment 2

[0043] A mixture of Fe, Se and S with a total mass of 500 mg (the molar ratio of Fe, Se and S is 2:1:1) was placed in an agate mortar, and 240 mg of PAN after grinding was weighed, mixed and Grind evenly, then use a tablet press to compress into tablets, and then vacuum seal in a quartz tube. Put the sealed quartz tube into the muffle furnace, heat slowly to 600-1000°C and react for 24-72 hours. After the reaction, open the quartz tube to take out the product, grind it, and obtain the solid phase reaction product Fe 2 SSe / CPAN.

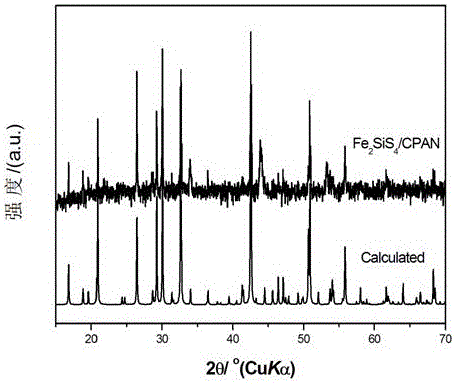

Embodiment 3

[0045] Weigh the Fe / Si / S mixture with a total mass of 500 mg (the molar ratio of Fe, Si, and S is 2:1:4).

[0046] Weigh 240 mg of PAN and grind it into a finer powder.

[0047]Add the weighed Fe / Si / S mixture into the ground PAN powder, grind it until it is evenly mixed, vacuum seal it into a quartz tube after tableting and transfer it to a muffle furnace, heat slowly to 600-1000°C and react for 24 ~72 hours. After the reaction, open the quartz tube to take out the product, grind it well, and obtain the solid phase reaction product Fe 2 SiS 4 XRD of / CPAN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com