Moulding equipment and method for reinforced thermoplastic cellular composite sheet material by continuous glass fiber pre-dip polypropylene sheet material

A technology of reinforced thermoplastic and continuous glass fiber, which is applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve the problems of high manufacturing cost, low production efficiency, and low degree of automation of the production line, so as to improve mechanical properties, The effect of low manufacturing cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

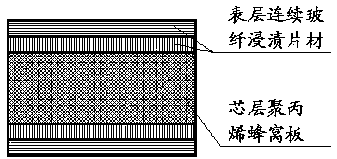

[0027] The upper surface layer and the lower surface layer of the continuous glass fiber prepreg sheet reinforced thermoplastic honeycomb composite sheet are composed of a continuous glass fiber unidirectional preimpregnated polypropylene sheet, the thickness of the sheet is 0.3mm, and the core layer is polypropylene honeycomb sheet. The thickness of the honeycomb panel is 12mm.

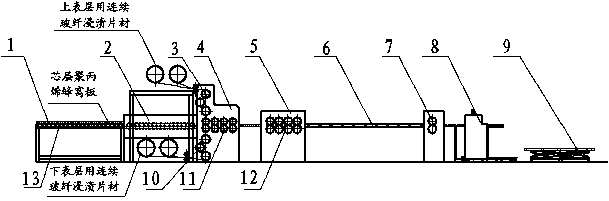

[0028] The molding equipment for continuous glass fiber prepreg sheets reinforced thermoplastic honeycomb composite panels includes, in turn, the conveying track for conveying the core layer (1), the infrared radiation preheating device (2) for preheating the core layer, conveying the surface layer, Unwinding system for preheating and tensioning (3), heating and compounding unit for heating, pressurizing and compounding the preheated surface layer and core layer (4), cooling unit for cooling and shaping the compounded sheet (5), A cooling bracket (6) for further cooling the formed composite sheet, a ...

Embodiment 2

[0039] The upper surface and the lower surface of the continuous glass fiber prepreg sheet reinforced thermoplastic honeycomb composite sheet are composed of two continuous glass fiber unidirectional preimpregnated polypropylene sheets, the thickness of the single sheet is 0.3mm, and the They are staggered at 0° / 90°, the core layer is polypropylene honeycomb panel, and the thickness of the honeycomb panel is 12mm.

[0040] The molding equipment of the continuous glass fiber prepreg sheet reinforced thermoplastic honeycomb composite board is the same as that in Example 1.

[0041] The production method of this composite plate is as follows:

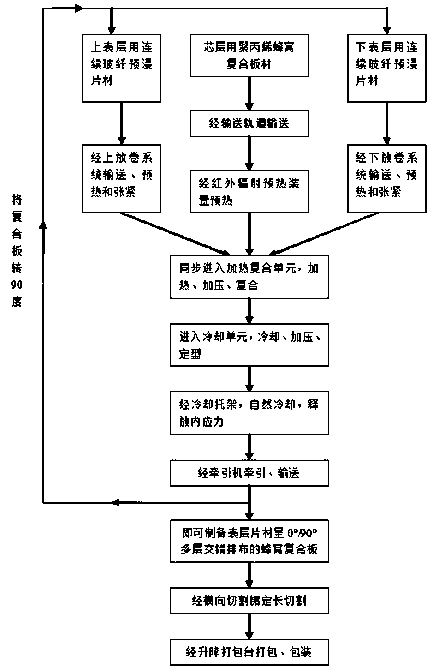

[0042] (1) The core polypropylene honeycomb panel placed on the conveying track (1) is guided into the infrared radiation preheating device (1) for preheating. The preheating temperature is 200°C and the preheating time is 1min;

[0043] (2) The upper and lower surfaces placed on the upper and lower unwinding system (3) are pre-impregnate...

Embodiment 3

[0051] The upper surface and the lower surface of the continuous glass fiber prepreg sheet reinforced thermoplastic honeycomb composite sheet are composed of three continuous glass fiber unidirectional preimpregnated polypropylene sheets. The thickness of each sheet is 0.3mm. 0° / 90° / 0° staggered arrangement, the core layer is polypropylene honeycomb panel, the thickness of the honeycomb panel is 12mm.

[0052] The molding equipment for continuous glass fiber prepreg sheets reinforced thermoplastic honeycomb composite panels includes, in turn, the conveying track for conveying the core layer (1), the infrared radiation preheating device (2) for preheating the core layer, conveying the surface layer, Unwinding system for preheating and tensioning (3), heating and compounding unit for heating, pressurizing and compounding the preheated surface layer and core layer (4), cooling unit for cooling and shaping the compounded sheet (5), A cooling bracket (6) for further cooling the for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com