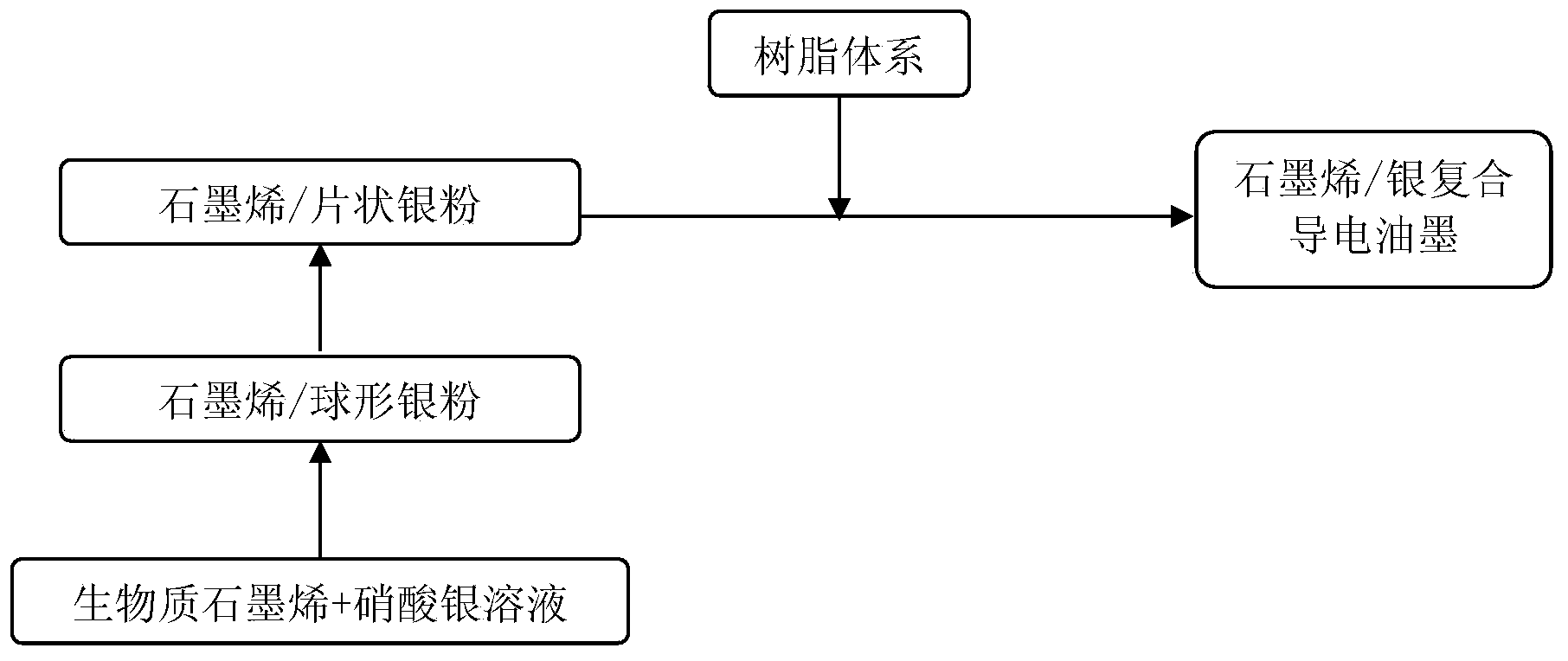

Preparation method of graphene/silver composite conductive printing ink

A composite conductive and graphene technology, used in inks, household appliances, applications, etc., can solve the problems of limited product application fields and high cost of silver conductive ink, achieve low cost, meet the resistivity, and reduce the effect of silver content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) 6g of PVP was dissolved in 1L of deionized water under stirring, then 100 grams of silver nitrate powder was added to the reaction medium, and then 10 grams of biomass graphene with a sheet size of 2 μm was added for use. Dissolve 20 grams of ascorbic acid in 1 L of absolute ethanol at room temperature and set aside. Place the three-neck flask in an oil bath, then put the reaction medium system containing graphene / silver nitrate into the flask, install an electric booster stirrer, a thermometer and a constant pressure dropping funnel. Heat the oil bath to 353K, then keep the temperature constant, drop the ethanol solution of ascorbic acid from the constant pressure dropping funnel under stirring, and finish the reaction after 6 hours. Pour the system out of the flask, and separate the solid and liquid in a high-speed centrifuge to obtain solid graphene / spherical silver powder particles, and the particle size of the spherical silver powder is 0.8 μm;

[0026] (2) Gr...

Embodiment 2

[0030] (1) Dissolve 60g of PVP in 10L of deionized water under stirring, then add 2000 grams of silver nitrate powder into the reaction medium, and then add 100 grams of biomass graphene with a sheet size of 5 μm for use. Dissolve 500 grams of ascorbic acid in 10 L of absolute ethanol at room temperature and set aside. Place the three-neck flask in an oil bath, then put the reaction medium system containing graphene / silver nitrate into the flask, install an electric booster stirrer, a thermometer and a constant pressure dropping funnel. Heat the oil bath to 353K, then keep the temperature constant, drop the ethanol solution of ascorbic acid from the constant pressure dropping funnel under stirring, and finish the reaction after 6 hours. Pour the system out of the flask, and separate the solid and liquid in a high-speed centrifuge to obtain solid graphene / spherical silver powder particles, and the particle size of the spherical silver powder is 1.5 μm;

[0031] (2) Graphene / sp...

Embodiment 3

[0035] (1) Dissolve 15g of PVP in 5L of deionized water under stirring, then add 500 grams of silver nitrate powder into the reaction medium, and then add 50 grams of biomass graphene with a sheet size of 5 μm for use. Dissolve 100 grams of ascorbic acid in 5 L of absolute ethanol at room temperature and set aside. Place the three-neck flask in an oil bath, then put the reaction medium system containing graphene / silver nitrate into the flask, install an electric booster stirrer, a thermometer and a constant pressure dropping funnel. Heat the oil bath to 353K, then keep the temperature constant, drop the ethanol solution of ascorbic acid from the constant pressure dropping funnel under stirring, and finish the reaction after 6 hours. Pour the system out of the flask, and separate the solid and liquid in a high-speed centrifuge to obtain solid graphene / spherical silver powder particles, and the particle size of the spherical silver powder is 2 μm;

[0036] (2) Graphene / spherica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com