Magnetic polyamide, preparation method thereof and magnetic fibers obtained by using magnetic polyamide

A technology of polyamide fibers and polyamides, applied in the field of preparation of magnetic polyamides and magnetic polyamide fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

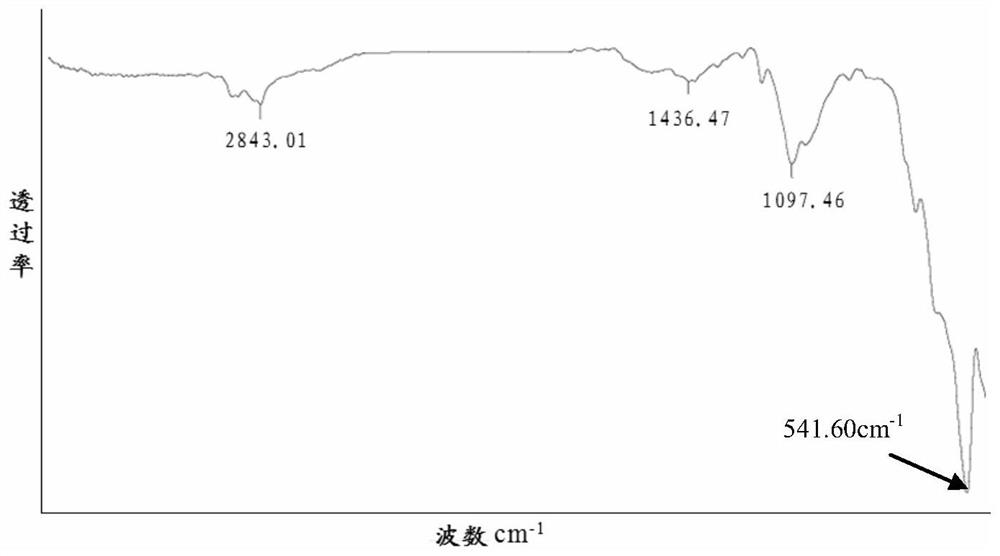

[0040] According to a preferred embodiment of the present invention, the magnetic particles are flaky magnetic particles, preferably composed of ferric oxide, ferric oxide, ferrous oxide, or a mixture thereof.

[0041] In a further preferred embodiment, the flaky magnetic particles are obtained as follows:

[0042] Step a, adding a monovalent metal salt into an alcoholic solvent to form a solution 1;

[0043] Step b, adding iron salt and surfactant into alcohol solvent to form solution 2;

[0044] Step c, adding solution one to solution two and stirring, and then reacting under a protective atmosphere to obtain the flaky magnetic particles.

[0045] In a further preferred embodiment, the magnetic particles are organically modified magnetic particles, preferably organically modified with a coupling agent, and then subjected to post-treatments such as separation and washing, preferably the coupling agent is selected from silane One or more of coupling agents, titanate coupling...

Embodiment 1

[0107] Embodiment 1 Preparation of flaky magnetic particles

[0108] The whole reaction was carried out under nitrogen atmosphere:

[0109] Dissolve 14.4g of sodium acetate in 80mL of ethylene glycol at 50°C to form solution 1;

[0110] Dissolve 5.4g of ferric chloride hexahydrate and 4g of PEG-800 in 70mL of ethylene glycol at 50°C to form solution 2;

[0111] Add solution 1 to solution 2 under stirring and stir for 5 minutes, then stir and react at 180° C. for 52 hours, collect the product, perform centrifugation, wash with deionized water and alcohol three times, and obtain the flaky magnetic particles.

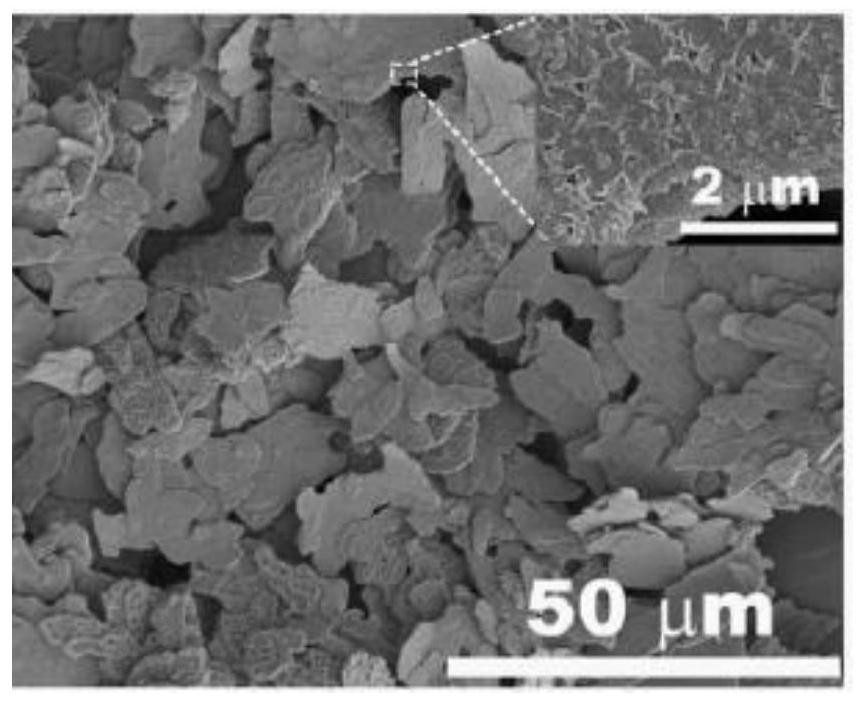

[0112] The flaky magnetic particle that embodiment 1 obtains carries out scanning electron microscope detection, and the result is as follows figure 1 shown, from figure 1 It can be seen from the figure that the obtained magnetic particles are in the shape of flakes, and the upper right illustration is a partially enlarged view, and it can be seen that the thickness o...

Embodiment 2

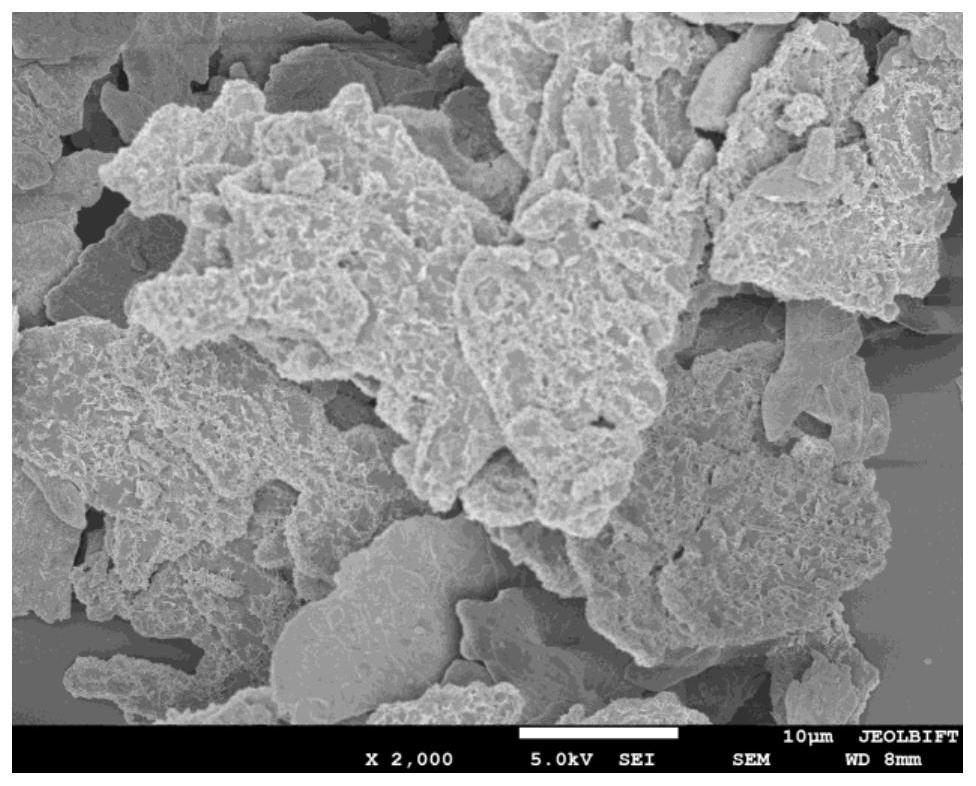

[0113] Example 2 Organically Modified Flaky Magnetic Particles

[0114] Put 100 g of the flaky magnetic particles prepared in Example 1 into an ethanol solution containing 0.8 g of γ-methacryloxypropyltrimethoxysilane, react at 60° C. for 3 hours, and then separate and wash with ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com