Production method of cotton-like environment-friendly hyperelastic plant complex fiber

A composite fiber and production method technology, applied in the processing of textile materials, yarn, textiles and papermaking, etc., can solve the problems of not meeting market requirements, weak imitation cotton effect, difficult fiber compounding, etc., and achieve dyeing stability guarantee , excellent elasticity, uniform fiber appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

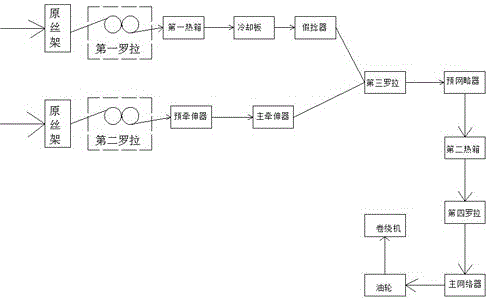

[0027] Such as figure 1 Show the specific embodiment of the production method of a kind of cotton-like environment-friendly superelastic plant composite fiber of the present invention: comprise the following steps:

[0028] a) Place the imitation cotton fiber on the raw silk frame, and the cotton imitation fiber enters the first hot box through the first roller for drafting, the temperature of the first hot box is 180°C, and the draft ratio of the cotton imitation fiber is 1.530, After drafting, enter the cooling plate for cooling, and then carry out false twisting through the false twister, and the false twist of the false twister is 90 °;

[0029] b) Place the plant fiber on the precursor frame, and the plant fiber enters the pre-drafter and the main drafter through the second roller for drafting, so that the drafting ratio of the plant fiber is 1.12;

[0030] c) Composite the false-twisted cotton-like fiber and the drawn plant fiber through the third roller;

[0031] d) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com