Biochar-titanium nitride super-hydrophobic photo-thermal coating material and preparation method thereof

A coating material, titanium nitride technology, applied in the field of biochar-titanium nitride superhydrophobic photothermal coating materials and its preparation, can solve the problems of manufacturing process obstacles, expensive material costs, complex synthesis methods, etc., and achieve improved Mechanical strength and stability, less capital investment, enhanced photon absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

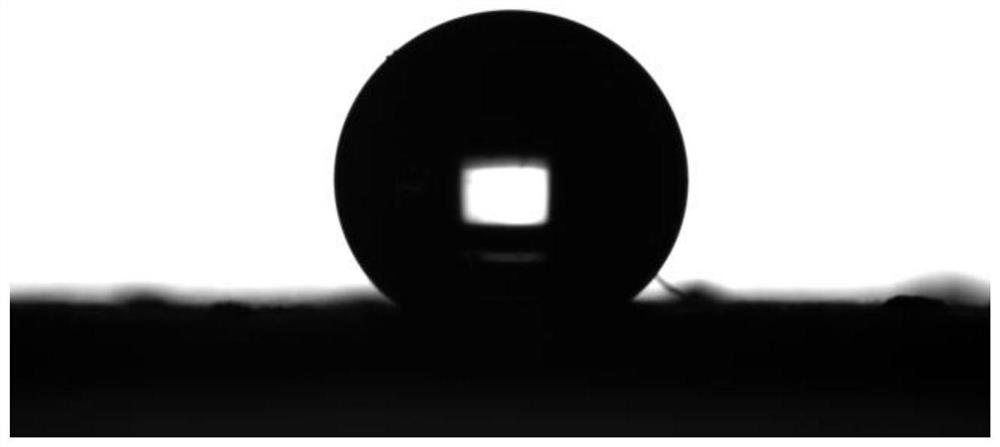

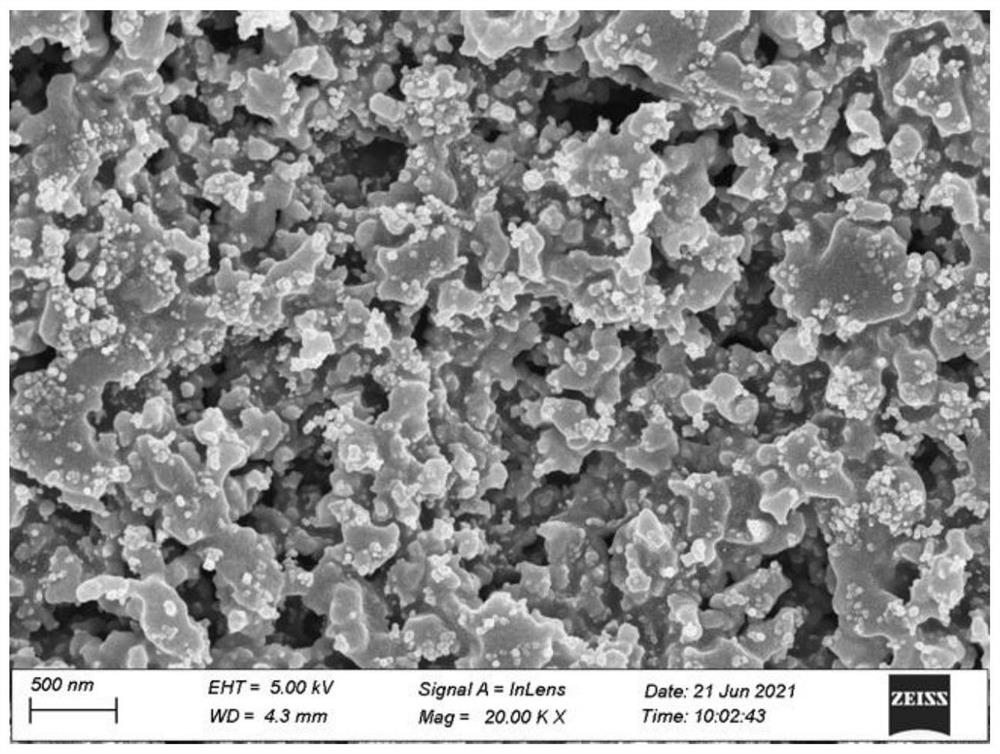

[0044] In order to obtain a photothermal coating with superhydrophobicity and good photothermal conversion efficiency, excellent mechanical strength and stability, the present invention provides a preparation of the biochar-titanium nitride superhydrophobic photothermal coating material method, including the following steps:

[0045] S1, adding biochar and titanium nitride to the organic solvent A, stirring to obtain a biochar-titanium nitride mixture;

[0046] S2. Mix the biochar-titanium nitride mixture with a surfactant, stir, and dry to obtain a surface-modified powder;

[0047] S3. Add the surface-modified powder into the organic solvent B for stirring, then add a silane coupling agent for cross-linking reaction, and continue stirring to obtain a biochar-titanium nitride superhydrophobic photothermal coating material.

[0048] The preparation method of the present invention has simple and easy-to-obtain raw materials, simple operation process, short preparation cycle, mi...

Embodiment 1

[0064] The preparation method of the superhydrophobic photothermal coating material of the biochar-titanium nitride of the present embodiment comprises the following steps:

[0065] Add 0.5g of biochar and 0.1g of titanium nitride to 12mL of absolute ethanol (based on the volume of absolute ethanol, the mass volume ratio of the total mass of biochar and titanium nitride is 50mg / mL), and stir to obtain biochar -Titanium nitride mixture; subsequently, add POTS (based on the volume of POTS, the mass volume ratio of biochar-titanium nitride mixture is 3g / mL), stir at room temperature for 3 hours, and dry to obtain surface modification The powder after the surface modification; the powder after the surface modification was added into ethyl acetate and stirred (in terms of the volume of ethyl acetate, the mass volume ratio of the powder after adding the surface modification was 100 mg / mL), and then PDMS ( The mass ratio of the surface-modified powder and PDMS is 2:1), and stirring f...

Embodiment 2

[0071] Add 0.5g of biochar and 0.5g of titanium nitride to 30mL of absolute ethanol (based on the volume of absolute ethanol, the mass volume ratio of the total mass of biochar and titanium nitride is 33.3mg / mL), and stir to obtain bio carbon-titanium nitride mixture; then, add POTS (based on the volume of POTS, the mass volume ratio of biochar-titanium nitride mixture is 1g / mL), stir at room temperature for 3 hours, and then dry it to obtain surface modification. The powder after the surface modification; the powder after the surface modification is added in ethyl acetate and stirred (according to the volume of ethyl acetate, the mass volume ratio of the powder after adding the surface modification is 50mg / mL), then add PDMS (The mass ratio of the surface-modified powder and PDMS is 5:1), and stirred for 30 minutes to obtain a biochar-titanium nitride superhydrophobic photothermal coating material.

[0072] The superhydrophobic photothermal coating material composite stock so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com