Preparation method of bismuth quantum dot material growing in mesoporous silica nanoparticles

A mesoporous silica and nanoparticle technology, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve the problems of inability to prepare nanoparticles, complicated preparation process, inability to achieve protection, etc., and achieve low cost and operation. Simple and effective in improving light-to-heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

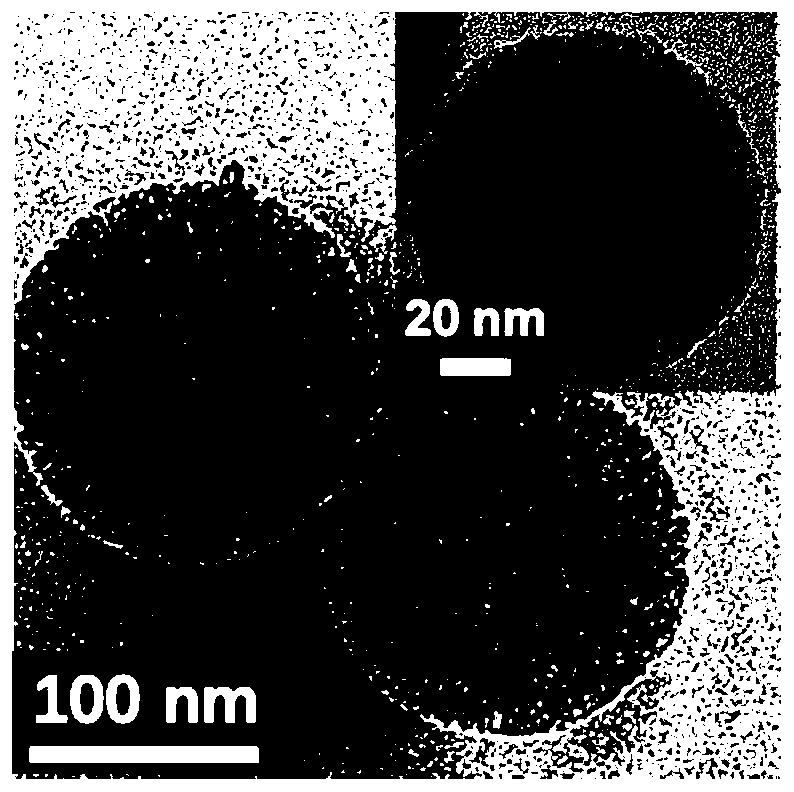

[0028] Bismuth quantum dots (Bi@SiO) grown on mesoporous silica nanoparticles provided by the present invention 2 ) preparation method of the material, the mesoporous silica nanoparticles with controllable pore size and particle size are prepared by organic template method, which specifically includes the following steps:

[0029] (1) Weigh 200 mg of cetyltrimethylammonium bromide and dissolve it in 10 ml of deionized water, and magnetically stir until dissolved to obtain the first solution.

[0030] (2) Add 20 ml of ethyl acetate, 5 ml of methanol and 3 ml of ammonia water in sequence to 95 ml of deionized water to obtain a second solution.

[0031] (3) Add the first solution dropwise to the second solution under stirring to obtain the third solution.

[0032] (4) In the stirring state, 0.5 ml tetraethyl orthosilicate was added dropwise to the third ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| quantum dot | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com