Structured catalyst for preparing 1,3-propanediol by hydrogenation of glycerol water solution, and preparation method of 1,3-propanediol

A glycerin aqueous solution and catalyst technology, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the problem of non-arbitrary structure, easy wear of catalyst, change of residence time, etc. problems, to achieve large market value and industrial application prospects, no catalyst wear, low pressure drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

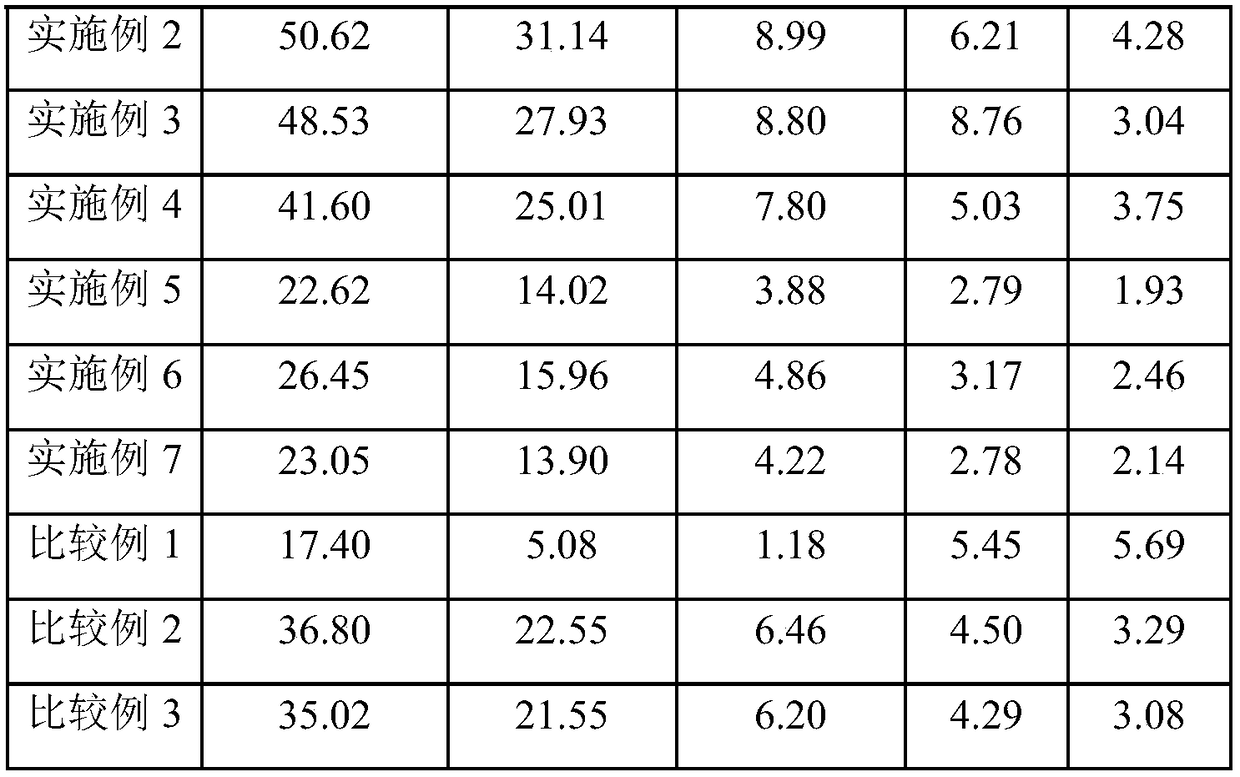

Examples

Embodiment 1

[0032] The catalyst used is Pt / Mo / W-structured ceramics, and the mass percentage of metal is Pt:Mo:W=2:1:10. The catalyst preparation steps include: 1) impregnating spinel ceramics with the required amount of ammonium metatungstate aqueous solution, keeping at 90°C for 20 hours, drying at 110°C, and roasting at 700°C for 3 hours to obtain a tungsten-structured ceramic composite oxide Carrier; 2) Use required amount of chloroplatinic acid and molybdenum nitrate in the carrier solution, impregnate for 9 hours, dry at 110°C, and roast at 400°C for 3 hours to obtain catalyst A.

Embodiment 2

[0034] The catalyst used is Pt / Co / W-structured ceramics, and the metal mass percentage is Pt:Co:W=2:0.5:10. The preparation steps were the same as in Example 1 to obtain catalyst B.

Embodiment 3

[0036] The catalyst used is Pt / Cr / W-structured ceramics, and the mass percentage of metal is Pt:Cr:W=2:1:15. The preparation steps were the same as in Example 1 to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com